Wave Solder Circuit Board . Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. This includes solder fluxing, preheating, solder waves, and cooling. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. Manual soldering involves soldering circuit boards by hand. In this process, the boards are passed over a wave of molten solder. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. Learn how to prevent wave soldering. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. The solder wave can also be formed by injecting nitrogen gas into the solder pool.

from eevibes.com

The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. This includes solder fluxing, preheating, solder waves, and cooling. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. The solder wave can also be formed by injecting nitrogen gas into the solder pool. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. Manual soldering involves soldering circuit boards by hand. Learn how to prevent wave soldering. In this process, the boards are passed over a wave of molten solder.

What are the Soldering Processes of Printed Circuit Board (PCB)? EEVibes

Wave Solder Circuit Board Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. Manual soldering involves soldering circuit boards by hand. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. The solder wave can also be formed by injecting nitrogen gas into the solder pool. This includes solder fluxing, preheating, solder waves, and cooling. In this process, the boards are passed over a wave of molten solder. Learn how to prevent wave soldering.

From blog.epectec.com

PCB Wave Soldering And Minimum Pitch Distance Wave Solder Circuit Board Learn how to prevent wave soldering. The solder wave can also be formed by injecting nitrogen gas into the solder pool. In this process, the boards are passed over a wave of molten solder. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. This includes solder. Wave Solder Circuit Board.

From langkesz.en.made-in-china.com

Wave Soldering Printed Circuit Boards PCB Assembly China Wave Wave Solder Circuit Board The solder wave can also be formed by injecting nitrogen gas into the solder pool. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. In this process, the boards are passed over a wave of molten solder. Manual soldering involves soldering circuit boards by hand. Wave soldering is a (mostly) automated process where fabricators pass. Wave Solder Circuit Board.

From www.sono-tek.com

Wave Solder Fluxing SonoTek Wave Solder Circuit Board Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. In this process, the boards are passed over a wave of molten solder. Learn. Wave Solder Circuit Board.

From www.makartechnologies.com

The Wave Soldering Process 5 Key Steps Makar Technologies Wave Solder Circuit Board Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. Manual soldering involves soldering circuit boards by hand. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. In this process, the boards are passed over a wave of molten solder. Learn how. Wave Solder Circuit Board.

From eevibes.com

What are the Soldering Processes of Printed Circuit Board (PCB)? EEVibes Wave Solder Circuit Board The solder wave can also be formed by injecting nitrogen gas into the solder pool. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. Learn how to prevent wave soldering. Manual soldering involves soldering circuit boards by hand. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a. Wave Solder Circuit Board.

From fyotrcles.blob.core.windows.net

Solder Circuit Board Name at Peter Arnold blog Wave Solder Circuit Board The solder wave can also be formed by injecting nitrogen gas into the solder pool. Manual soldering involves soldering circuit boards by hand. In this process, the boards are passed over a wave of molten solder. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. Wave soldering is a (mostly) automated process where fabricators. Wave Solder Circuit Board.

From www.pcbunlimited.com

E400 LEADFREE WAVE SOLDER Wave Solder Machines Wave Soldering Wave Solder Circuit Board Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. Learn how to prevent wave soldering. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. This includes solder fluxing, preheating, solder waves, and. Wave Solder Circuit Board.

From www.wellpcb.com

PCB WeldingMethods and Techniques on How to Reduce the Problems Wave Solder Circuit Board Learn how to prevent wave soldering. This includes solder fluxing, preheating, solder waves, and cooling. Manual soldering involves soldering circuit boards by hand. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable. Wave Solder Circuit Board.

From www.protoexpress.com

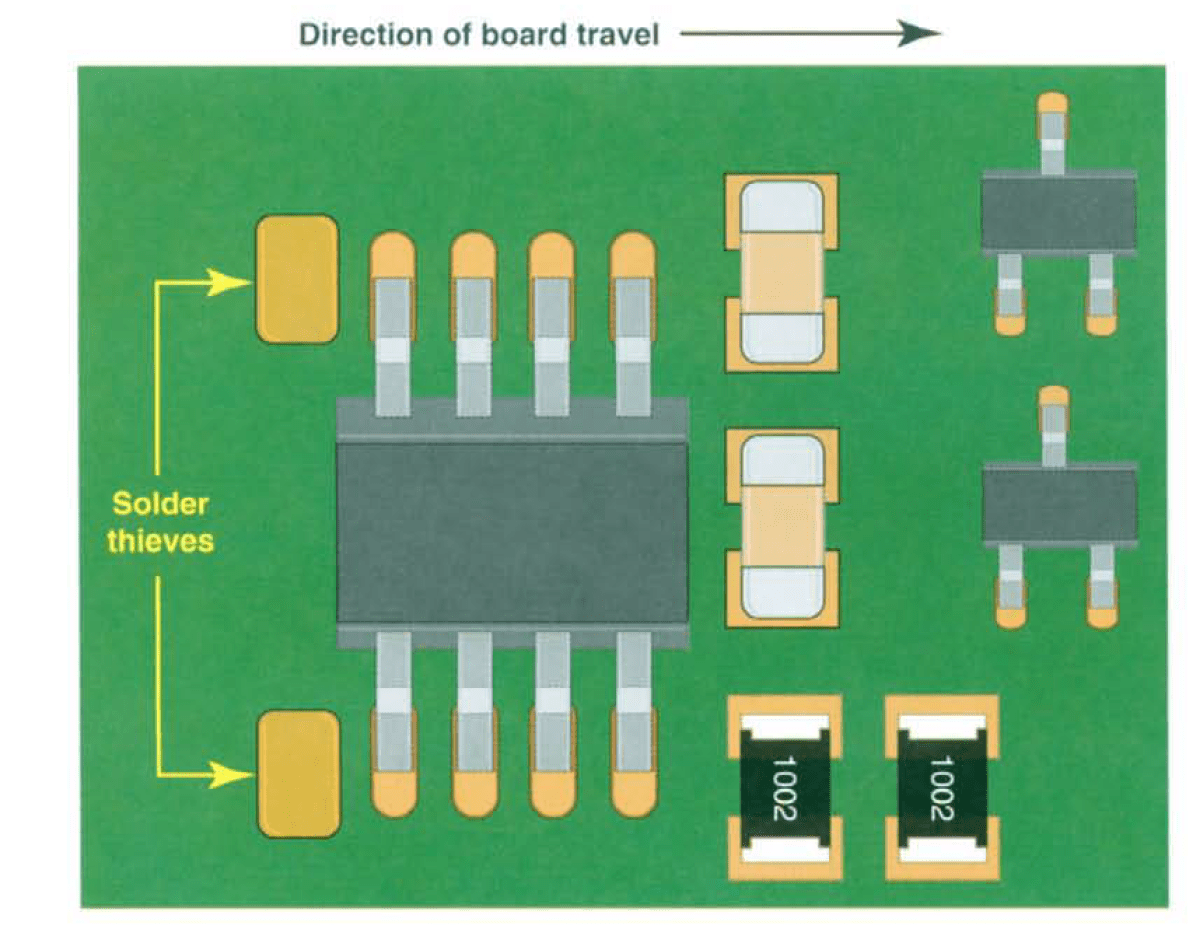

Wave Soldering Design Considerations Sierra Circuit Wave Solder Circuit Board Manual soldering involves soldering circuit boards by hand. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. Learn how to prevent wave soldering. In this process, the boards are passed over a wave of molten solder. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core. Wave Solder Circuit Board.

From nick-lee.en.made-in-china.com

China SMT Wave Soldering Process Printed Circuit Board PWB Assembly Wave Solder Circuit Board The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. In this process, the boards are passed over a wave of molten solder. Manual soldering involves soldering circuit boards by hand. The solder wave can also be formed by injecting nitrogen gas into the solder pool. Wave soldering is a (mostly) automated process where fabricators. Wave Solder Circuit Board.

From mb-mfg.com

Wave Solder Pallets MB Manufacturing Wave Solder Circuit Board Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. This includes solder fluxing, preheating, solder waves, and cooling. Manual soldering involves soldering circuit boards by hand. The wave soldering process allows manufacturers. Wave Solder Circuit Board.

From jhdpcb.com

Wave And Reflow Soldering In PCB Soldering Process Guide Jhdpcb Wave Solder Circuit Board Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. This includes solder fluxing, preheating, solder waves, and cooling. In this process, the boards are passed over a wave of molten solder. Manual soldering involves soldering circuit boards by hand. The solder wave can also be formed. Wave Solder Circuit Board.

From www.altekelectronics.com

LeadFree Wave Solder LeadFree Soldering LeadFree Solder Wave Solder Circuit Board Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. The solder wave can also be formed by injecting nitrogen gas into the solder pool. Learn how to prevent wave soldering. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. This includes. Wave Solder Circuit Board.

From eevibes.com

What are the Soldering Processes of Printed Circuit Board (PCB)? EEVibes Wave Solder Circuit Board This includes solder fluxing, preheating, solder waves, and cooling. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit. Wave Solder Circuit Board.

From www.raypcb.com

Printed circuit board soldering process and soldering method Printed Wave Solder Circuit Board Manual soldering involves soldering circuit boards by hand. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. Learn how to prevent wave soldering. This includes solder fluxing, preheating, solder waves, and cooling. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. In this process, the boards are passed over. Wave Solder Circuit Board.

From suntronicinc.com

MustKnow Things About PCB Soldering Process Suntronic Inc. Wave Solder Circuit Board The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. This includes solder fluxing, preheating, solder waves, and cooling. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains. Wave Solder Circuit Board.

From exoorqsyk.blob.core.windows.net

Circuit Board With Solder at Tommy Moser blog Wave Solder Circuit Board In this process, the boards are passed over a wave of molten solder. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. The solder wave can also be formed by injecting nitrogen gas into the solder pool. Despite the electronics industry’s shift towards smt (surface mount. Wave Solder Circuit Board.

From www.scribd.com

Wave Soldering PDF Printed Circuit Board Soldering Wave Solder Circuit Board In this process, the boards are passed over a wave of molten solder. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. Learn how to prevent wave soldering. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. This includes solder. Wave Solder Circuit Board.

From www.youtube.com

How to Solder on PCB properly Soldering Techniques for Beginners Wave Solder Circuit Board Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital.. Wave Solder Circuit Board.

From www.pcbboardservice.com

TACONIC Quick Turn PCB Multilayer Printed Circuit Board Wave Soldering Wave Solder Circuit Board Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. Learn how to prevent wave soldering. Wave soldering. Wave Solder Circuit Board.

From www.wavesolderpallet.com

Adjustable Wave Solder pallet Wave Solder Circuit Board Learn how to prevent wave soldering. In this process, the boards are passed over a wave of molten solder. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. Wave soldering is a (mostly) automated process where fabricators pass multiple printed. Wave Solder Circuit Board.

From eevibes.com

What are the Soldering Processes of Printed Circuit Board (PCB)? EEVibes Wave Solder Circuit Board Learn how to prevent wave soldering. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. The solder wave can also be formed by injecting nitrogen gas into the solder pool. Manual soldering involves soldering circuit boards by hand. In this process, the boards are passed over. Wave Solder Circuit Board.

From www.protoexpress.com

Making Sense of Wave Soldering Sierra Circuits Wave Solder Circuit Board Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical.. Wave Solder Circuit Board.

From www.researchgate.net

(PDF) Lead Free Wave Soldering Process Optimization for Simple to Wave Solder Circuit Board This includes solder fluxing, preheating, solder waves, and cooling. Manual soldering involves soldering circuit boards by hand. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. In this process, the boards are passed over a wave of molten solder. The solder wave can also be formed. Wave Solder Circuit Board.

From www.wisegeek.com

How Do I Choose the Best Circuit Board Solder? (with pictures) Wave Solder Circuit Board This includes solder fluxing, preheating, solder waves, and cooling. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. Manual soldering involves soldering circuit boards by hand. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. The solder wave can also. Wave Solder Circuit Board.

From joibjtmin.blob.core.windows.net

Soldering Electronic Components On A Circuit Board at Sarah McCullough blog Wave Solder Circuit Board Manual soldering involves soldering circuit boards by hand. The solder wave can also be formed by injecting nitrogen gas into the solder pool. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. This includes solder fluxing, preheating, solder waves, and cooling. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards. Wave Solder Circuit Board.

From fyotrcles.blob.core.windows.net

Solder Circuit Board Name at Peter Arnold blog Wave Solder Circuit Board Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. Learn how to prevent wave soldering. Manual soldering involves soldering circuit boards by hand. The solder wave can also be formed by injecting nitrogen gas into the solder pool. This includes solder fluxing, preheating, solder waves, and. Wave Solder Circuit Board.

From www.newark.com

WES207 Weller Soldering, Circuit Board, For Use With Weller WESD51 Wave Solder Circuit Board The solder wave can also be formed by injecting nitrogen gas into the solder pool. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. In this process, the boards are passed over a wave of molten solder. The wave soldering process allows manufacturers to quickly and. Wave Solder Circuit Board.

From www.build-electronic-circuits.com

3 NeedToKnow Soldering Techniques + Guerrilla Soldering Wave Solder Circuit Board The solder wave can also be formed by injecting nitrogen gas into the solder pool. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. Learn how to prevent wave soldering. This includes solder fluxing, preheating, solder waves, and cooling. Despite the electronics industry’s shift towards smt. Wave Solder Circuit Board.

From www.newark.com

WES207 Weller Soldering, Circuit Board, For Use With Weller WESD51 Wave Solder Circuit Board Manual soldering involves soldering circuit boards by hand. Learn how to prevent wave soldering. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. The solder wave can also be formed by injecting nitrogen gas into the solder pool. The wave soldering process allows manufacturers to quickly. Wave Solder Circuit Board.

From www.cleverir.com

Controlling printed circuit board preheat during wave solder Wave Solder Circuit Board Manual soldering involves soldering circuit boards by hand. Learn how to prevent wave soldering. In this process, the boards are passed over a wave of molten solder. This includes solder fluxing, preheating, solder waves, and cooling. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. Despite the electronics industry’s shift towards smt (surface mount. Wave Solder Circuit Board.

From www.alibaba.com

Wave Solder Pallet Materials For Printed Circuit Boards Buy Wave Wave Solder Circuit Board In this process, the boards are passed over a wave of molten solder. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. Manual soldering involves soldering circuit boards by hand. Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down. Wave Solder Circuit Board.

From www.storyblocks.com

Selective Wave Soldering Process During Stock Footage SBV329358007 Wave Solder Circuit Board Wave soldering is a basic operation in the fabrication of printed circuit boards that lays down a core foundation for producing dependable electrical. The solder wave can also be formed by injecting nitrogen gas into the solder pool. Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten. Wave Solder Circuit Board.

From useevn.com

Wave Soldering Term and Process Wave Soldering • USE Electronics Wave Solder Circuit Board Wave soldering is a (mostly) automated process where fabricators pass multiple printed circuit boards through a bath or stream of hot molten solder. In this process, the boards are passed over a wave of molten solder. Learn how to prevent wave soldering. The wave soldering process allows manufacturers to quickly and reliably solder large printed circuit boards. The solder wave. Wave Solder Circuit Board.

From www.wavesolderpallet.com

Adjustable Wave Solder pallet Wave Solder Circuit Board Learn how to prevent wave soldering. In this process, the boards are passed over a wave of molten solder. Despite the electronics industry’s shift towards smt (surface mount technology), wave soldering remains vital. The solder wave can also be formed by injecting nitrogen gas into the solder pool. The wave soldering process allows manufacturers to quickly and reliably solder large. Wave Solder Circuit Board.