Gas Flow Rate For Tig Welding . tungsten diameter and cup size. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. Adequate gas flow for gmaw. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). Replace a defective gas hose and check your.

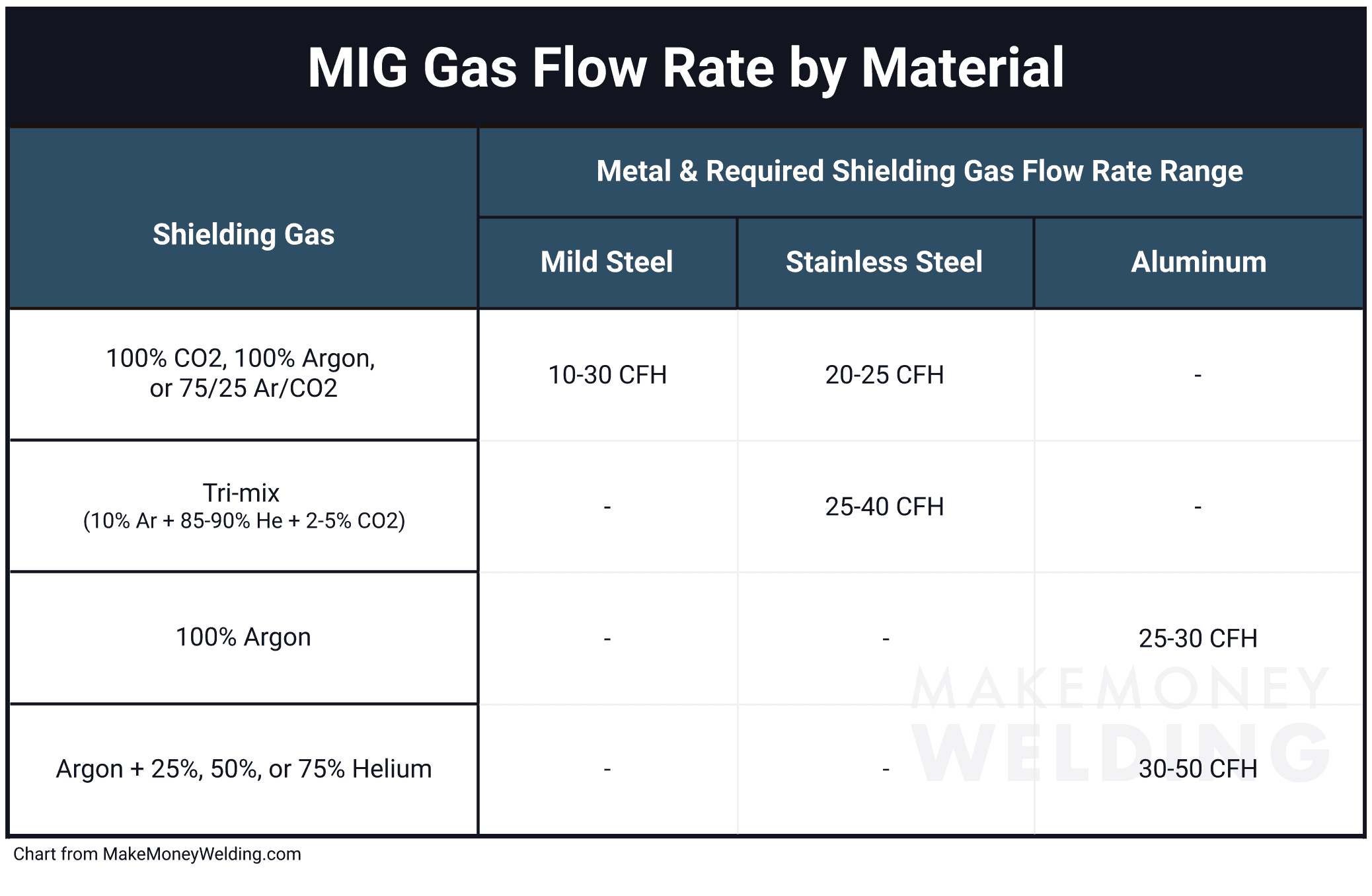

from makemoneywelding.com

by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. tungsten diameter and cup size. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). Replace a defective gas hose and check your. Adequate gas flow for gmaw.

MIG Welding Gas Pressure Settings

Gas Flow Rate For Tig Welding the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. tungsten diameter and cup size. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. Replace a defective gas hose and check your. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. Adequate gas flow for gmaw. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh).

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Gas Flow Rate For Tig Welding the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. Replace a defective gas hose and check your. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. Adequate. Gas Flow Rate For Tig Welding.

From www.youtube.com

Gas Flow Settings for MIG & TIG Welding YouTube Gas Flow Rate For Tig Welding Adequate gas flow for gmaw. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. Replace a defective gas hose and check your. make sure there is adequate gas flow and adjust the. Gas Flow Rate For Tig Welding.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Gas Flow Rate For Tig Welding tungsten diameter and cup size. Replace a defective gas hose and check your. Adequate gas flow for gmaw. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. the. Gas Flow Rate For Tig Welding.

From kemele.labbyag.es

Tig Welding Gases Chart Kemele Gas Flow Rate For Tig Welding Adequate gas flow for gmaw. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. the tig welding gas flow rate for the actual tig welding process is highly specific to. Gas Flow Rate For Tig Welding.

From www.youtube.com

Eastwood Welding Flow Meter Accurately Measure Gas Flow when Welding Gas Flow Rate For Tig Welding make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. Replace a defective gas hose and check your. Adequate gas flow for gmaw. the tig welding gas flow rate for the. Gas Flow Rate For Tig Welding.

From schematicancola6a.z4.web.core.windows.net

Types Of Welding Process With Diagram Gas Flow Rate For Tig Welding make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). Adequate gas flow for gmaw. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. tungsten diameter and cup. Gas Flow Rate For Tig Welding.

From www.open.edu

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open Gas Flow Rate For Tig Welding tungsten diameter and cup size. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. Adequate gas flow for gmaw. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. . Gas Flow Rate For Tig Welding.

From www.youtube.com

Gas flow meter setup for welding Save gas Tips for gas leak Gas Flow Rate For Tig Welding the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. tungsten diameter and cup size. by understanding. Gas Flow Rate For Tig Welding.

From kemele.labbyag.es

Tig Welding Gases Chart Kemele Gas Flow Rate For Tig Welding the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. Adequate gas flow for gmaw. the tig welding gas flow rate for the actual tig welding process is highly specific. Gas Flow Rate For Tig Welding.

From www.sevencolors.co.jp

Tig Welding Argon Gas Flow Rate sevencolors.co.jp Gas Flow Rate For Tig Welding Adequate gas flow for gmaw. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. Replace a defective gas hose and check your. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. the optimal gas flow rate for tig. Gas Flow Rate For Tig Welding.

From www.researchgate.net

11. Plot of Root Gap vs Purging Gas Flow Rate in TIG Welding Gas Flow Rate For Tig Welding make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. Adequate. Gas Flow Rate For Tig Welding.

From www.wire-wizard.com

Gas Flow Monitor Wire Wizard Welding Products Gas Flow Rate For Tig Welding tungsten diameter and cup size. Replace a defective gas hose and check your. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. the optimal gas flow rate for tig. Gas Flow Rate For Tig Welding.

From www.sevencolors.co.jp

Tig Welding Argon Gas Flow Rate sevencolors.co.jp Gas Flow Rate For Tig Welding tungsten diameter and cup size. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. Replace a defective gas hose and check your. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. the tig welding gas flow rate. Gas Flow Rate For Tig Welding.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) Gas Flow Rate For Tig Welding the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). Adequate gas flow for gmaw. the tig welding gas flow rate for the actual tig welding process is highly specific to. Gas Flow Rate For Tig Welding.

From www.youtube.com

Want Better Aluminum Welds? Cup Size & Gas Flow Matter! YouTube Gas Flow Rate For Tig Welding the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. Adequate gas flow for gmaw. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). the optimal gas flow rate for tig welding varies by the combination of. Gas Flow Rate For Tig Welding.

From mavink.com

Mig Welding Gas Flow Rate Chart Gas Flow Rate For Tig Welding tungsten diameter and cup size. Replace a defective gas hose and check your. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). by understanding the factors influencing gas flow. Gas Flow Rate For Tig Welding.

From econosuperstore.com

Argon CO2 Mig Tig Flow meter Welding Weld Regulator Gauge Gas Welder Gas Flow Rate For Tig Welding Replace a defective gas hose and check your. Adequate gas flow for gmaw. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. tungsten diameter and cup size. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. the. Gas Flow Rate For Tig Welding.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Gas Flow Rate For Tig Welding the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. Replace a defective gas hose and check your. by understanding the factors influencing gas flow rate, measuring and adjusting it. Gas Flow Rate For Tig Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Gas Flow Rate For Tig Welding Replace a defective gas hose and check your. Adequate gas flow for gmaw. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. the optimal gas flow rate for tig welding. Gas Flow Rate For Tig Welding.

From gnv4all.org

Argon CO2 Mig Tig Welding Flow Meter Regulator Weld Gauge Gas Pressure Gas Flow Rate For Tig Welding by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. tungsten diameter and cup size. the optimal gas flow rate. Gas Flow Rate For Tig Welding.

From dxgetqapeco.blob.core.windows.net

Gas Flow Rate In Tig Welding at Ivy Nottingham blog Gas Flow Rate For Tig Welding make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. Adequate gas flow for gmaw. Replace a defective gas hose. Gas Flow Rate For Tig Welding.

From dxgetqapeco.blob.core.windows.net

Gas Flow Rate In Tig Welding at Ivy Nottingham blog Gas Flow Rate For Tig Welding the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. Adequate gas flow for gmaw. tungsten diameter and cup size. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). by understanding the factors influencing gas flow. Gas Flow Rate For Tig Welding.

From www.amazon.co.uk

Argon Co2 Gas Flow Meter Scale Tester Measure Flowmeter for Mig Tig Gas Flow Rate For Tig Welding by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s. Gas Flow Rate For Tig Welding.

From www.researchgate.net

13. Plot of Filler Dia vs Purged Gas Flow Rate in TIG Welding Gas Flow Rate For Tig Welding Replace a defective gas hose and check your. tungsten diameter and cup size. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the. Gas Flow Rate For Tig Welding.

From exomsnmep.blob.core.windows.net

Which Of The Following Gas Is Used In Tig Welding at Katie Blakely blog Gas Flow Rate For Tig Welding the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. Adequate gas flow for gmaw. make sure there is adequate gas flow and adjust the flow rate as necessary (typically 15 to 20 cfh). Replace a defective gas hose and check your. the optimal gas flow rate. Gas Flow Rate For Tig Welding.

From www.mig-welding.co.uk

TIG Welder Set Up Gas Flow Rate For Tig Welding the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. Adequate gas flow for gmaw. tungsten diameter and cup size. Replace. Gas Flow Rate For Tig Welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Gas Flow Rate For Tig Welding the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. tungsten diameter and cup size. make sure there is adequate gas flow and adjust the flow rate as necessary. Gas Flow Rate For Tig Welding.

From alexnld.com

Argon CO2 Gas Mig Tig Flow Meter Welding Weld Regulator Gauge Welder Gas Flow Rate For Tig Welding the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. Adequate gas flow for gmaw. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. Replace a defective gas hose and check your. by understanding the factors influencing gas flow. Gas Flow Rate For Tig Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Gas Flow Rate For Tig Welding Adequate gas flow for gmaw. Replace a defective gas hose and check your. tungsten diameter and cup size. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. make sure there is. Gas Flow Rate For Tig Welding.

From kemele.labbyag.es

Tig Welding Gases Chart Kemele Gas Flow Rate For Tig Welding by understanding the factors influencing gas flow rate, measuring and adjusting it correctly, and following industry recommendations. Replace a defective gas hose and check your. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. the primary gas. Gas Flow Rate For Tig Welding.

From workshopinsider.com

How to Optimize MIG Welding Shielding Gas Pressure Gas Flow Rate For Tig Welding Adequate gas flow for gmaw. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. by understanding the factors influencing gas. Gas Flow Rate For Tig Welding.

From fitwelding.com

Tig Welding Gas Flow Rate How To Achieve Perfect Gas Flow Rate? Fit Gas Flow Rate For Tig Welding tungsten diameter and cup size. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. Replace a defective gas hose and check your. the tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the. Gas Flow Rate For Tig Welding.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Gas Flow Rate For Tig Welding the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. tungsten diameter and cup size. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. Adequate gas flow for gmaw. make sure there is adequate gas flow and adjust. Gas Flow Rate For Tig Welding.

From mungfali.com

Mig Welding Gas Flow Chart Gas Flow Rate For Tig Welding the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. Replace a defective gas hose and check your. tungsten diameter and cup size. the tig welding gas flow rate. Gas Flow Rate For Tig Welding.

From resources.arcmachines.com

Tig Welding Gas Flow Rate Arc Machines Gas Flow Rate For Tig Welding the optimal gas flow rate for tig welding varies by the combination of consumables and atmospheric conditions. tungsten diameter and cup size. the primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium. Adequate gas flow for gmaw. make sure there is adequate gas flow and adjust. Gas Flow Rate For Tig Welding.