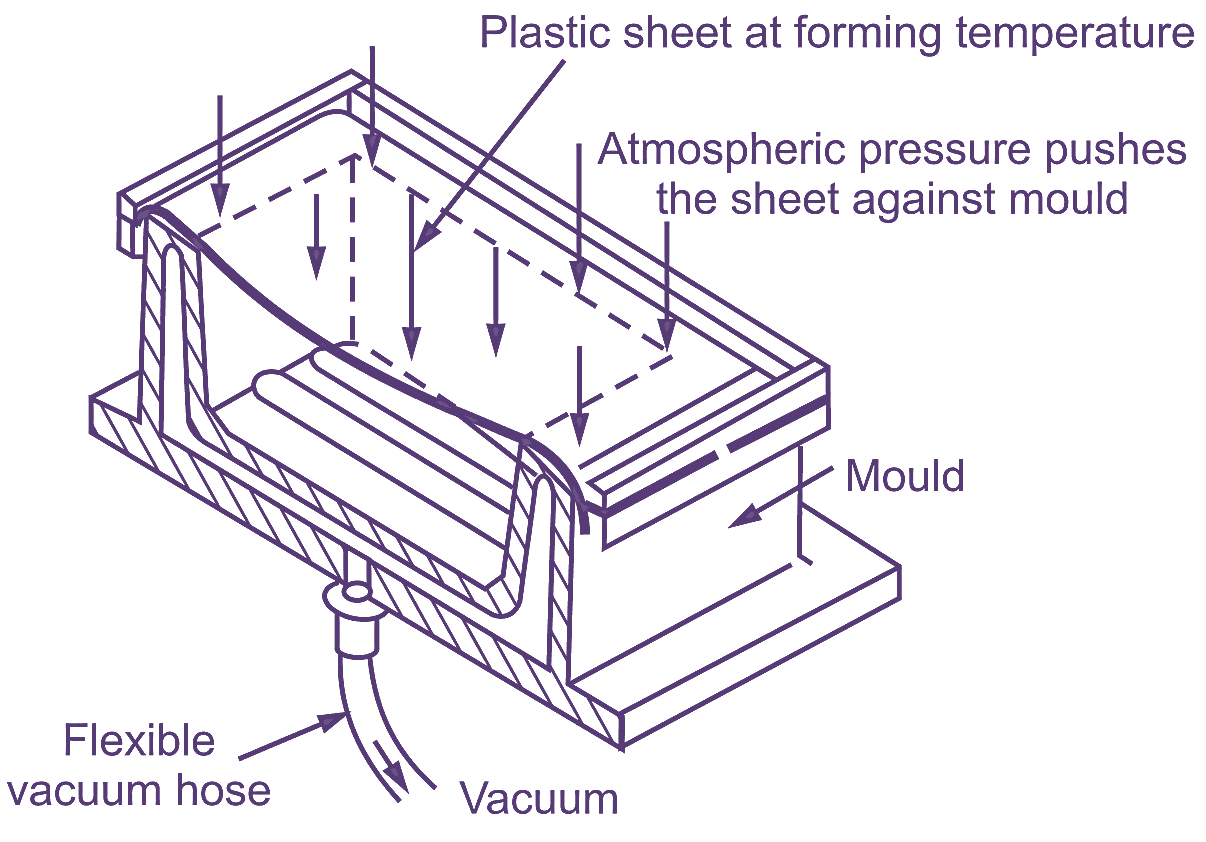

Short Run Vacuum Forming . Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. With pressure forming, compressed air pushes the plastic down. with vacuum forming, a vacuum pump sucks the plastic into the mould. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. considering vacuum forming for your project? the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling.

from electricalworkbook.com

Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. with vacuum forming, a vacuum pump sucks the plastic into the mould. considering vacuum forming for your project? Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. With pressure forming, compressed air pushes the plastic down. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified.

What is Vacuum Forming? Process, Applications, Products & Advantages

Short Run Vacuum Forming Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. considering vacuum forming for your project? With pressure forming, compressed air pushes the plastic down. the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. with vacuum forming, a vacuum pump sucks the plastic into the mould. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding.

From cekkidwp.blob.core.windows.net

How To Avoid bing In Vacuum Forming at Kevin Hahn blog Short Run Vacuum Forming With pressure forming, compressed air pushes the plastic down. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. Vacuum forming is quicker and more affordable,. Short Run Vacuum Forming.

From www.youtube.com

How To Vacuum Form in 3 Easy Steps YouTube Short Run Vacuum Forming considering vacuum forming for your project? with vacuum forming, a vacuum pump sucks the plastic into the mould. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming. Short Run Vacuum Forming.

From theprodesigngroup.com

6 Simple Steps to Vacuum Forming The Pro Design Group Gardena, CA Short Run Vacuum Forming considering vacuum forming for your project? With pressure forming, compressed air pushes the plastic down. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. the vacuum forming process. Short Run Vacuum Forming.

From foammolders.com

Vacuum Forming The Processes Foam Molders Uses To Create HighQuality Short Run Vacuum Forming Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. considering vacuum forming for your project? the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. With pressure forming, compressed air pushes the plastic down. with vacuum forming, a. Short Run Vacuum Forming.

From www.volpinprops.com

Protoform Vacuum Forming Machine Volpin Props Short Run Vacuum Forming Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. with vacuum forming, a vacuum pump sucks the plastic into the mould. vacuum forming of plastics can be an. Short Run Vacuum Forming.

From www.youtube.com

Vacuum Forming Step By Step Guide YouTube Short Run Vacuum Forming the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. with vacuum forming, a vacuum pump sucks the plastic into the mould. With pressure forming, compressed air pushes the plastic down. considering vacuum forming for your project? vacuum forming of plastics can be an extremely. Short Run Vacuum Forming.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research Short Run Vacuum Forming vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. Vacuum forming is quicker and more affordable, but pressure forming. Short Run Vacuum Forming.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research Short Run Vacuum Forming Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. With pressure forming, compressed air pushes the plastic down. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries. Short Run Vacuum Forming.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited Short Run Vacuum Forming with vacuum forming, a vacuum pump sucks the plastic into the mould. considering vacuum forming for your project? the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. With pressure forming, compressed air pushes the plastic down. vacuum forming of plastics can be an extremely. Short Run Vacuum Forming.

From www.plas-tech.co.uk

Vac Forming The Advantages of Vacuum Forming Short Run Vacuum Forming vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. considering vacuum forming for your project? Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. with vacuum. Short Run Vacuum Forming.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited Short Run Vacuum Forming Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. considering vacuum forming for your project? With pressure forming, compressed air pushes the plastic. Short Run Vacuum Forming.

From www.awardplastics.co.nz

Vacuum Forming Short Run Vacuum Forming Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers,. Short Run Vacuum Forming.

From www.techsoft.co.uk

Vacuum Forming TechSoft Short Run Vacuum Forming considering vacuum forming for your project? the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. With pressure forming,. Short Run Vacuum Forming.

From www.youtube.com

Vacuum Forming Process Working Applications ENGINEERING STUDY Short Run Vacuum Forming Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. With pressure forming, compressed air pushes the plastic down. considering vacuum forming for your project? vacuum forming of plastics. Short Run Vacuum Forming.

From www.youtube.com

Vacuum forming 01 main process YouTube Short Run Vacuum Forming the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. with vacuum forming, a vacuum pump sucks the plastic into the mould. Vacuum forming is. Short Run Vacuum Forming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Short Run Vacuum Forming vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. considering vacuum forming for your project? the vacuum forming process works by heating. Short Run Vacuum Forming.

From www.alibaba.com

Custom Rapid Prototype Vacuum Casting Pu Like Plastic Abs Prototyping Short Run Vacuum Forming Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. With pressure forming, compressed air pushes the plastic down. the vacuum forming process works. Short Run Vacuum Forming.

From www.youtube.com

Formech 508FS (with new PLC) Floor Standing Vacuum Forming Machine Short Run Vacuum Forming the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. With pressure forming, compressed air pushes the plastic down. vacuum forming of plastics can be an extremely cost effective way. Short Run Vacuum Forming.

From www.alibaba.com

Custom Rapid Prototype Vacuum Casting Pu Like Plastic Abs Prototyping Short Run Vacuum Forming vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. with vacuum forming, a vacuum pump sucks the plastic into the mould. considering. Short Run Vacuum Forming.

From 3-dtechnicalservices.com

Vacuum Forming Services 3D Technical Services Short Run Vacuum Forming considering vacuum forming for your project? with vacuum forming, a vacuum pump sucks the plastic into the mould. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. With pressure forming, compressed air pushes the plastic down. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of. Short Run Vacuum Forming.

From www.ccmiplastics.com

CCMI Plastics Custom Plastics Thermoforming and Vacuum Forming Short Run Vacuum Forming the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. with vacuum forming, a vacuum pump sucks the plastic into the mould. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short. Short Run Vacuum Forming.

From spottingit.com

The advantages of vacuum forming Spotting IT Short Run Vacuum Forming Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. With pressure forming, compressed air pushes the plastic down. vacuum forming of plastics can be an extremely cost effective way. Short Run Vacuum Forming.

From www.instructables.com

Vacuum Forming Rig 12 Steps (with Pictures) Instructables Short Run Vacuum Forming With pressure forming, compressed air pushes the plastic down. with vacuum forming, a vacuum pump sucks the plastic into the mould. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers,. Short Run Vacuum Forming.

From www.plas-tech.co.uk

How Does Vac Forming Work? Vacuum Forming Yorkshire Short Run Vacuum Forming vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. with vacuum forming, a vacuum pump sucks the plastic. Short Run Vacuum Forming.

From www.youtube.com

Formech explores how vacuum forming is innovating design at Pratt Short Run Vacuum Forming with vacuum forming, a vacuum pump sucks the plastic into the mould. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. Typically, it. Short Run Vacuum Forming.

From 3-dtechnicalservices.com

Vacuum Forming Services 3D Technical Services Short Run Vacuum Forming vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. considering vacuum forming for your project? Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. With pressure forming,. Short Run Vacuum Forming.

From phase-2.org

What are the benefits of vacuum forming? Move to a new phase Short Run Vacuum Forming vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. considering vacuum forming for your project? With pressure forming,. Short Run Vacuum Forming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Short Run Vacuum Forming Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. With pressure forming, compressed air pushes the plastic down. the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. considering vacuum forming for your project?. Short Run Vacuum Forming.

From jiahaoplastic.en.made-in-china.com

Custom Rapid Prototype Vacuum Casting Plastic ABS Prototyping Short Run Short Run Vacuum Forming vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. With pressure forming, compressed air pushes the plastic down. considering vacuum forming for your project? the vacuum forming process works by heating a plastic sheet, forming it into a shaped. Short Run Vacuum Forming.

From plasticmouldingsnorthern.co.uk

How To Vacuum Form Plastic Mouldings Northern Short Run Vacuum Forming Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. considering vacuum forming for your project? With pressure forming, compressed air pushes the plastic down. vacuum forming of plastics. Short Run Vacuum Forming.

From www.brayplastics.co.uk

What is Vacuum Forming? Bray Plastics Short Run Vacuum Forming with vacuum forming, a vacuum pump sucks the plastic into the mould. With pressure forming, compressed air pushes the plastic down. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum,. Short Run Vacuum Forming.

From centerlinemodels.com

Vacuum Forming Center Line Model and Prototype Builders Short Run Vacuum Forming Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. the vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. With pressure forming, compressed air pushes the plastic down. vacuum forming of plastics can be. Short Run Vacuum Forming.

From www.rocheindustry.com

Handbook The Ultimate Guide To Vacuum Forming 2024 Updated Short Run Vacuum Forming vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. considering vacuum forming for your project? with vacuum forming, a vacuum pump sucks. Short Run Vacuum Forming.

From www.hotrod.com

How to build a vacuum forming mold to make your own plastic parts Short Run Vacuum Forming with vacuum forming, a vacuum pump sucks the plastic into the mould. Typically, it finds its extensive use across pharmaceutical and automotive manufacturing industries because of its high efficiency and economical cost over molding. With pressure forming, compressed air pushes the plastic down. considering vacuum forming for your project? the vacuum forming process works by heating a. Short Run Vacuum Forming.

From formlabs.com

Introduction to Vacuum Forming Short Run Vacuum Forming with vacuum forming, a vacuum pump sucks the plastic into the mould. Vacuum forming is quicker and more affordable, but pressure forming can produce a higher level of detail. vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. the. Short Run Vacuum Forming.