Cutting Grooves In Metal . This article delves into the distinctive characteristics of. It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. External grooving, internal grooving, straight turning grooving, face grooving, and. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Whether you are slot or. It is commonly used for surface finishing and shaping hard materials. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. Cut off, slot, and groove milling. This article explores five types of grooving:

from www.ferguson.com

Whether you are slot or. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. This article delves into the distinctive characteristics of. It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. Cut off, slot, and groove milling. It is commonly used for surface finishing and shaping hard materials. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. External grooving, internal grooving, straight turning grooving, face grooving, and. This article explores five types of grooving:

Pipe Fabrication Services Cutting, Threading & Grooving

Cutting Grooves In Metal This article explores five types of grooving: Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. Whether you are slot or. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. This article delves into the distinctive characteristics of. External grooving, internal grooving, straight turning grooving, face grooving, and. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. This article explores five types of grooving: Cut off, slot, and groove milling. It is commonly used for surface finishing and shaping hard materials.

From www.youtube.com

G1221 Walter Cut grooving boring bar Internal grooving with cool Cutting Grooves In Metal This article explores five types of grooving: It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. Cut off, slot, and groove milling. External grooving, internal grooving, straight turning grooving, face. Cutting Grooves In Metal.

From www.goldballmachine.com

CNC V Grooving machine,CNC V cutting machine, V cutting machinewuxi Cutting Grooves In Metal It is commonly used for surface finishing and shaping hard materials. This article explores five types of grooving: Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Cut off, slot, and groove. Cutting Grooves In Metal.

From pacesupply.com

Pace Supply CG1100 Cut Grooving Tool, 2 to 12 in Pipe Cutting Grooves In Metal External grooving, internal grooving, straight turning grooving, face grooving, and. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. This article explores five types of grooving: Whether you are slot or. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. It. Cutting Grooves In Metal.

From www.youtube.com

How to Cut Grooves and Dados YouTube Cutting Grooves In Metal Cut off, slot, and groove milling. This article delves into the distinctive characteristics of. It is commonly used for surface finishing and shaping hard materials. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. This article explores five types of grooving: It involves cutting grooves along the bend line,. Cutting Grooves In Metal.

From www.dreamstime.com

Turning Operation on Cnc Machine in Metalworking Industry. Cutting Tool Cutting Grooves In Metal Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. It is commonly used for surface finishing and shaping hard materials. This article explores five types of grooving: It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. This article delves into the distinctive. Cutting Grooves In Metal.

From dxozgxtzg.blob.core.windows.net

How To Cut Metal On A Table Saw at Larry Topping blog Cutting Grooves In Metal Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. Whether you are slot or. This article explores five types of grooving: In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. It involves cutting grooves along the bend line,. Cutting Grooves In Metal.

From www.cnchydraulicpressbrake.com

CNC VGrooving Machine for Aluminum plate industry , sheet metal Cutting Grooves In Metal It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. It is commonly used for surface finishing and shaping hard materials. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. This article delves into the distinctive characteristics of. Grooving, a. Cutting Grooves In Metal.

From www.youtube.com

Cutting Grooves On A Manual Lathe YouTube Cutting Grooves In Metal Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. External grooving, internal grooving, straight turning grooving, face grooving, and. This article delves into the distinctive characteristics of. Cut off, slot, and groove milling.. Cutting Grooves In Metal.

From www.wikihow.com

3 Simple Ways to Cut Grooves in Wood wikiHow Cutting Grooves In Metal It is commonly used for surface finishing and shaping hard materials. External grooving, internal grooving, straight turning grooving, face grooving, and. Whether you are slot or. Cut off, slot, and groove milling. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. This article delves into the distinctive characteristics of.. Cutting Grooves In Metal.

From fyovtteck.blob.core.windows.net

Metal Lathe Thread Cutting Tool at David Chaffin blog Cutting Grooves In Metal Whether you are slot or. External grooving, internal grooving, straight turning grooving, face grooving, and. Cut off, slot, and groove milling. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific. Cutting Grooves In Metal.

From www.aliexpress.com

Mzg Zq1616l4 Zq2020l4 Width Grooving Cnc Lathe Machining Cutting Cutting Grooves In Metal External grooving, internal grooving, straight turning grooving, face grooving, and. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. This article delves into the distinctive characteristics of. Whether you. Cutting Grooves In Metal.

From www.youtube.com

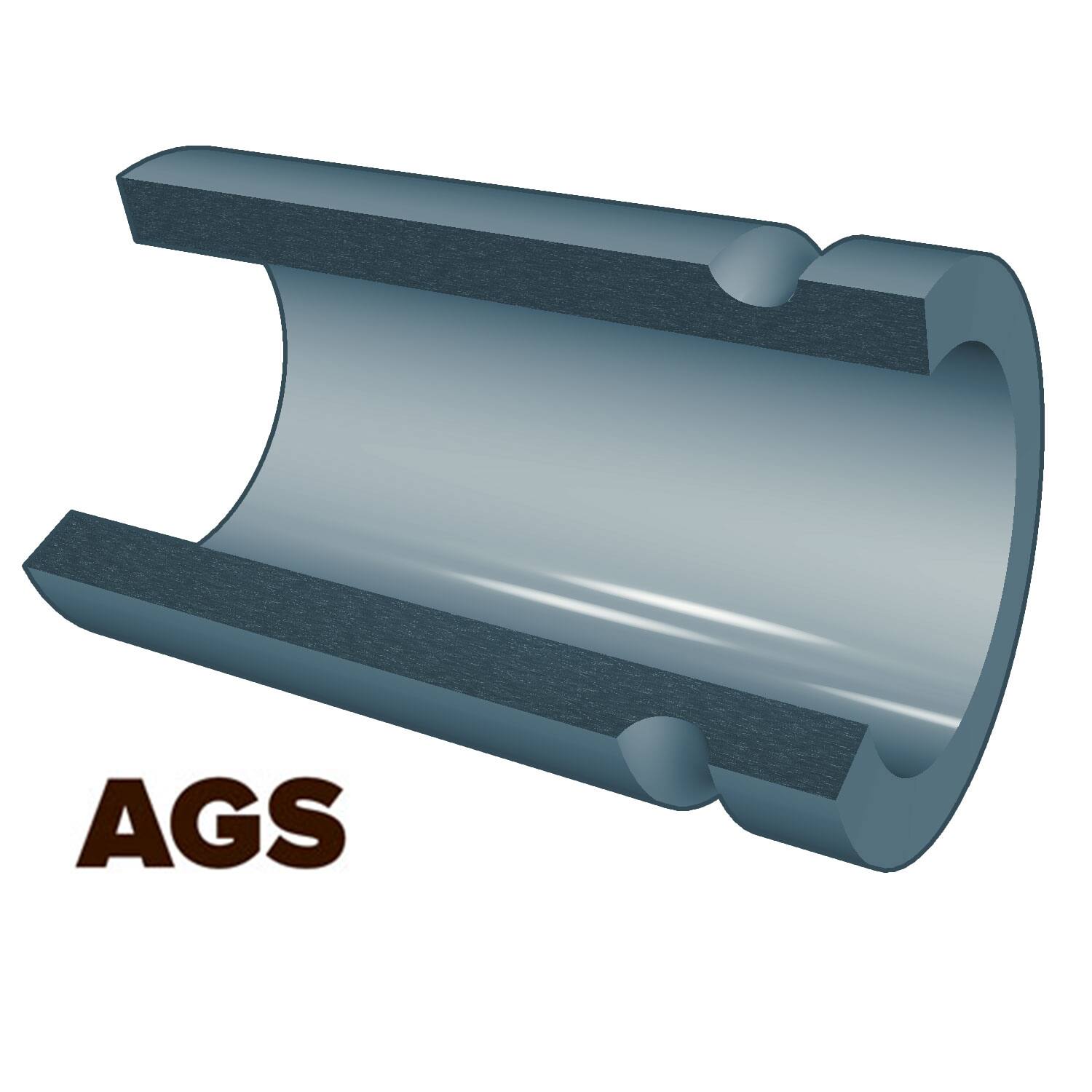

cutting grease grooves in bushings x y z cnc, machining internal oil Cutting Grooves In Metal Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. Cut off, slot, and groove milling. External grooving, internal grooving, straight turning grooving, face grooving, and. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Grooving allows for more. Cutting Grooves In Metal.

From www.youtube.com

Cutting Grease Grooves on cnc lathe. YouTube Cutting Grooves In Metal This article explores five types of grooving: External grooving, internal grooving, straight turning grooving, face grooving, and. This article delves into the distinctive characteristics of. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. It is commonly used for surface finishing and shaping hard materials. Whether you are slot or. It involves. Cutting Grooves In Metal.

From sawsummary.com

How To Use A Router To Cut A Groove Saw Summary Cutting Grooves In Metal External grooving, internal grooving, straight turning grooving, face grooving, and. It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. This article explores five types of grooving: Cut off, slot, and groove milling. This. Cutting Grooves In Metal.

From www.aliexpress.com

Buy MZG ZQ1616R 3 ZQ2020R 3 Width Grooving CNC Lathe Cutting Grooves In Metal Whether you are slot or. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. External grooving, internal grooving, straight turning grooving, face grooving, and. It is commonly used for surface finishing and. Cutting Grooves In Metal.

From www.made-in-china.com

China Stainless Steel CNC V Cutting Machine, V Cut Machine, V Grooving Cutting Grooves In Metal Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. This article delves into the distinctive characteristics of. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Cut off, slot, and groove milling. This article explores five types of. Cutting Grooves In Metal.

From www.aliexpress.com

MZG CGWSR1616W02 CNC Lathe Machining External Cutting Toolholder Groove Cutting Grooves In Metal Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. Cut off, slot, and groove milling. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. This article delves into the distinctive characteristics of. External grooving, internal grooving, straight turning grooving, face grooving,. Cutting Grooves In Metal.

From www.youtube.com

GROOVEX Groove Milling YouTube Cutting Grooves In Metal External grooving, internal grooving, straight turning grooving, face grooving, and. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. It involves cutting grooves along the bend line, which allows for small outside. Cutting Grooves In Metal.

From www.ferguson.com

Pipe Fabrication Services Cutting, Threading & Grooving Cutting Grooves In Metal Whether you are slot or. This article explores five types of grooving: This article delves into the distinctive characteristics of. External grooving, internal grooving, straight turning grooving, face grooving, and. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Grooving allows for more precise control over the bending process,. Cutting Grooves In Metal.

From www.thefabricator.com

Precision sheet metal bending and the V groove Part II Cutting Grooves In Metal This article delves into the distinctive characteristics of. Whether you are slot or. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. External grooving, internal grooving, straight turning grooving, face grooving, and. Cut off, slot, and groove milling. Grooving allows for more precise control over the bending process, especially. Cutting Grooves In Metal.

From www.aliexpress.com

MZG ZQ 16 20 25 MM Grooving Width 2mm CNC Lathe Machining Cutting Cutting Grooves In Metal It is commonly used for surface finishing and shaping hard materials. It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. This article delves into the distinctive characteristics of. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. This article. Cutting Grooves In Metal.

From www.youtube.com

HOW TO GROOVE CUT ON LATHE MACHINE YouTube Cutting Grooves In Metal Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Whether you are slot or. This article delves into the distinctive characteristics of. It is commonly used for surface finishing and shaping hard. Cutting Grooves In Metal.

From www.youtube.com

Cutting Grooves on a lathe by HSS tool YouTube Cutting Grooves In Metal Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. External grooving, internal grooving, straight turning grooving, face grooving, and. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. It involves cutting grooves along the bend line, which allows for small outside. Cutting Grooves In Metal.

From toolsforworkingwood.com

How to Cut a Groove in a Frame By Hand and Without a Plow Plane Cutting Grooves In Metal Whether you are slot or. It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. This article delves into the distinctive characteristics of. External grooving, internal grooving, straight turning grooving, face grooving, and. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. In. Cutting Grooves In Metal.

From toolsforworkingwood.com

How to Cut a Groove in a Frame By Hand and Without a Plow Plane Cutting Grooves In Metal It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. External grooving, internal grooving, straight turning grooving, face grooving, and. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Grooving allows for more precise control over the bending process, especially. Cutting Grooves In Metal.

From www.youtube.com

Cut perfect grooves with this DIY tool! YouTube Cutting Grooves In Metal This article explores five types of grooving: It is commonly used for surface finishing and shaping hard materials. Cut off, slot, and groove milling. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. External grooving, internal grooving, straight turning grooving, face grooving, and. Grooving allows for more precise control. Cutting Grooves In Metal.

From www.pinterest.ca

Pin on Резцы Cutting Grooves In Metal Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. It is commonly used for surface finishing and shaping hard materials. Cut off, slot, and groove milling. This article explores five types of grooving: It involves cutting grooves along the bend line, which allows for small outside bend radii and. Cutting Grooves In Metal.

From www.youtube.com

SNG Internal grooving tools for small diameter with high performance Cutting Grooves In Metal Whether you are slot or. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. External grooving, internal grooving, straight turning grooving, face grooving, and. It is commonly used for surface finishing and. Cutting Grooves In Metal.

From www.reddit.com

The flame cut texture. 2” solid steel round bar split lengthwise with Cutting Grooves In Metal In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Cut off, slot, and groove milling. Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. Whether you are slot or. This article delves into the distinctive characteristics of. It involves cutting grooves. Cutting Grooves In Metal.

From engineersblog.net

What is the design criteria of Groove Joints? Explain in details step Cutting Grooves In Metal It is commonly used for surface finishing and shaping hard materials. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Cut off, slot, and groove milling. External grooving, internal grooving, straight turning grooving, face grooving, and. It involves cutting grooves along the bend line, which allows for small outside. Cutting Grooves In Metal.

From www.youtube.com

Groove MIlling YouTube Cutting Grooves In Metal It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. It is commonly used for surface finishing and shaping hard materials. Grooving allows for more precise control over the bending process,. Cutting Grooves In Metal.

From www.dreamstime.com

Professional Construction Power Tool for Cutting Grooves in Concrete Cutting Grooves In Metal Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. This article explores five types of grooving: Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. Cut off, slot, and groove milling. It is commonly used for surface finishing and shaping hard. Cutting Grooves In Metal.

From fyoeiheie.blob.core.windows.net

What Does A Grooving Mean at Donald Wheatley blog Cutting Grooves In Metal This article explores five types of grooving: Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. Cut off, slot, and groove milling. Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. This article delves into the distinctive characteristics of. It involves. Cutting Grooves In Metal.

From www.youtube.com

machining oil grooves YouTube Cutting Grooves In Metal It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. Whether you are slot or. Cut off, slot, and groove milling. This article explores five types of grooving: Grooving, a fundamental cnc lathe operation, involves the precision crafting of grooves to meet exact specifications, enhancing component functionality and. Grooving allows for. Cutting Grooves In Metal.

From gionppkxz.blob.core.windows.net

How To Cut A V Groove For Mat Board at Lon Pumphrey blog Cutting Grooves In Metal External grooving, internal grooving, straight turning grooving, face grooving, and. This article explores five types of grooving: Grooving allows for more precise control over the bending process, especially for complex geometries and tight tolerances. In contrast, grooving is a cutting operation used to create slots or grooves in a workpiece, usually with specific grooving. Whether you are slot or. Cut. Cutting Grooves In Metal.