Dip Coating Vs Spin Coating . this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. In today’s blog post, coating systems takes a look at several key differences. for the rheology of photoresist coating in microelectronics, spin coating works well. dip coating and spray coating are the two most common ways these coatings are applied, but in some. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost.

from www.findlight.net

dip coating and spray coating are the two most common ways these coatings are applied, but in some. for the rheology of photoresist coating in microelectronics, spin coating works well. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. In today’s blog post, coating systems takes a look at several key differences. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some.

AR Coating Techniques Thin Film Deposition Methods

Dip Coating Vs Spin Coating In today’s blog post, coating systems takes a look at several key differences. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. In today’s blog post, coating systems takes a look at several key differences. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. for the rheology of photoresist coating in microelectronics, spin coating works well. dip coating and spray coating are the two most common ways these coatings are applied, but in some.

From www.mdpi.com

Coatings Free FullText ThinFilm Coating Methods A Successful Dip Coating Vs Spin Coating this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. In today’s blog. Dip Coating Vs Spin Coating.

From www.precisiondipcoating.com

Dip Coating vs. Spin Coating Which Method Is Best for You? Dip Coating Vs Spin Coating dip coating and spray coating are the two most common ways these coatings are applied, but in some. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. In today’s blog post, coating systems takes a look at several key differences. for the rheology of photoresist coating in microelectronics, spin coating. Dip Coating Vs Spin Coating.

From coatingsystems.com

How Does DipSpin Coating Actually Work? Coating Systems Dip Coating Vs Spin Coating In today’s blog post, coating systems takes a look at several key differences. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. this guide aims to introduce general spin coating. Dip Coating Vs Spin Coating.

From stcdipspin.com

STC Dip Spin Dip Spin Coating Equipment Dip Coating Vs Spin Coating applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. In today’s blog post, coating systems takes a look at several key differences. the dip coating process can be. Dip Coating Vs Spin Coating.

From www.researchgate.net

SolGel Dip Coating Process. Download Scientific Diagram Dip Coating Vs Spin Coating for the rheology of photoresist coating in microelectronics, spin coating works well. In today’s blog post, coating systems takes a look at several key differences. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. dip coating and spray coating are the two most common ways these coatings are applied, but. Dip Coating Vs Spin Coating.

From www.youtube.com

Dip spin coating machine YouTube Dip Coating Vs Spin Coating for the rheology of photoresist coating in microelectronics, spin coating works well. In today’s blog post, coating systems takes a look at several key differences. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that. Dip Coating Vs Spin Coating.

From www.decc.com

Dip Spin vs Rack Spray Coating Process & Equipment The DECC Company Dip Coating Vs Spin Coating for the rheology of photoresist coating in microelectronics, spin coating works well. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. the dip coating process can be. Dip Coating Vs Spin Coating.

From www.researchgate.net

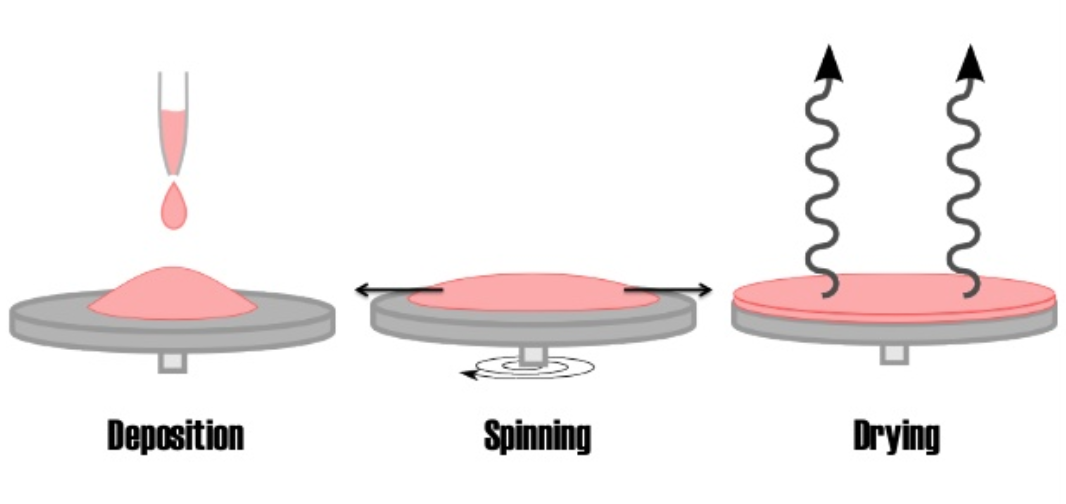

Schematic diagram of the solgel spin coating technique for thin film Dip Coating Vs Spin Coating In today’s blog post, coating systems takes a look at several key differences. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. dip coating and spray coating are. Dip Coating Vs Spin Coating.

From coatingsystems.com

DipSpin Coating LP at Coating Systems Dip Coating Vs Spin Coating for the rheology of photoresist coating in microelectronics, spin coating works well. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. dip coating and spray coating are the two most common ways these coatings are applied, but in some. In today’s blog post, coating systems takes a look at several. Dip Coating Vs Spin Coating.

From coatingsystems.com

DipSpin Coatings, Custom Coatings, Coating Systems, Inc. Dip Coating Vs Spin Coating this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. for the. Dip Coating Vs Spin Coating.

From minsun.com

DipSpin Coating Equipment MINSUN Technology Co., LTD. Dip Coating Vs Spin Coating the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. for the rheology of photoresist coating in microelectronics, spin coating works well. dip coating and spray coating are the two most common ways these coatings are applied, but in some. applying a dip/spin coating over thin zinc plate to encapsulate. Dip Coating Vs Spin Coating.

From www.slideserve.com

PPT Dip coating techniques PowerPoint Presentation, free download Dip Coating Vs Spin Coating applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. In today’s blog post, coating systems takes a look at several key differences. dip coating and spray coating are. Dip Coating Vs Spin Coating.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process Dip Coating Vs Spin Coating for the rheology of photoresist coating in microelectronics, spin coating works well. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. the dip coating process can be. Dip Coating Vs Spin Coating.

From www.researchgate.net

Solgel dip coating and spin coating processes of ZnO nanoparticles Dip Coating Vs Spin Coating for the rheology of photoresist coating in microelectronics, spin coating works well. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. dip coating and spray coating are the two. Dip Coating Vs Spin Coating.

From www.researchgate.net

Dipcoating steps (1) immersion and dwell time, (2) deposition and Dip Coating Vs Spin Coating dip coating and spray coating are the two most common ways these coatings are applied, but in some. In today’s blog post, coating systems takes a look at several key differences. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. for the rheology of photoresist coating. Dip Coating Vs Spin Coating.

From www.mdpi.com

Polymers Free FullText A Review of Electro Conductive Textiles Dip Coating Vs Spin Coating In today’s blog post, coating systems takes a look at several key differences. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. dip coating and spray coating are the two most common ways these coatings are applied, but in some. the dip coating process can be divided into. Dip Coating Vs Spin Coating.

From www.researchgate.net

Key stages of the spincoating process Download Scientific Diagram Dip Coating Vs Spin Coating for the rheology of photoresist coating in microelectronics, spin coating works well. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. In today’s blog post, coating systems takes a look at several key differences. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and. Dip Coating Vs Spin Coating.

From www.slideserve.com

PPT Dip coating techniques PowerPoint Presentation, free download Dip Coating Vs Spin Coating the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. for the rheology of photoresist coating in microelectronics, spin coating works well. dip coating and spray coating are the two most common ways these coatings are applied, but in some. In today’s blog post, coating systems takes a look at several. Dip Coating Vs Spin Coating.

From www.decc.com

Dip Spin vs Rack Spray Coating Process & Equipment The DECC Company Dip Coating Vs Spin Coating In today’s blog post, coating systems takes a look at several key differences. for the rheology of photoresist coating in microelectronics, spin coating works well. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an. Dip Coating Vs Spin Coating.

From www.researchgate.net

The dipcoating process and the considerable electrostatic Dip Coating Vs Spin Coating dip coating and spray coating are the two most common ways these coatings are applied, but in some. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. . Dip Coating Vs Spin Coating.

From www.findlight.net

AR Coating Techniques Thin Film Deposition Methods Dip Coating Vs Spin Coating the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. for the rheology of photoresist coating in microelectronics, spin coating works well. this guide aims to introduce general spin coating. Dip Coating Vs Spin Coating.

From www.researchgate.net

Schematic diagram a spray coating, b dipcoating, c tape casting—doctor Dip Coating Vs Spin Coating the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. In today’s blog post, coating systems takes a look at several key differences. for the rheology of photoresist coating in microelectronics,. Dip Coating Vs Spin Coating.

From pubs.acs.org

Influence of Spin Coating and Dip Coating with Gelatin/Hydroxyapatite Dip Coating Vs Spin Coating this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. for the rheology of photoresist coating in microelectronics, spin coating works well. dip coating and spray coating are the two most common ways these coatings are applied, but in some. applying a dip/spin coating over thin zinc plate. Dip Coating Vs Spin Coating.

From www.semanticscholar.org

Modeling and the main stages of spin coating process A review Dip Coating Vs Spin Coating this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. In today’s blog post, coating systems takes a look at several key differences. for the rheology of photoresist coating in microelectronics, spin coating works well. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an. Dip Coating Vs Spin Coating.

From www.researchgate.net

Scheme 3. Scheme of layer preparation using the spin coating (a) and Dip Coating Vs Spin Coating the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. dip coating and spray coating are the two most common ways these coatings are applied, but in some. In today’s blog post, coating systems takes a look at several key differences. for the rheology of photoresist coating in microelectronics, spin coating. Dip Coating Vs Spin Coating.

From www.researchgate.net

Schematic diagram of spin coating method step by step process a Dip Coating Vs Spin Coating applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. In today’s blog post, coating systems takes a look at several key differences. for the rheology of photoresist coating in microelectronics,. Dip Coating Vs Spin Coating.

From www.researchgate.net

2. (a) Dip coating process and (b) spin coating process. Source Dip Coating Vs Spin Coating for the rheology of photoresist coating in microelectronics, spin coating works well. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. the dip coating process can be. Dip Coating Vs Spin Coating.

From www.researchgate.net

Schematic of dip coating [124] Download Scientific Diagram Dip Coating Vs Spin Coating In today’s blog post, coating systems takes a look at several key differences. for the rheology of photoresist coating in microelectronics, spin coating works well. applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. the dip coating process can be divided into three important technical stages,. Dip Coating Vs Spin Coating.

From www.researchgate.net

Stages scheme of Spin Coating Download Scientific Diagram Dip Coating Vs Spin Coating dip coating and spray coating are the two most common ways these coatings are applied, but in some. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. applying a dip/spin coating. Dip Coating Vs Spin Coating.

From gamma.app

Exploring Spin and Dip Coating Dip Coating Vs Spin Coating the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. In today’s blog post, coating systems takes a look at several key differences. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. applying a dip/spin coating over thin zinc plate to encapsulate. Dip Coating Vs Spin Coating.

From www.researchgate.net

Schematic representation of (a) dip coating; (b) spin coating; and (c Dip Coating Vs Spin Coating In today’s blog post, coating systems takes a look at several key differences. dip coating and spray coating are the two most common ways these coatings are applied, but in some. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. this guide aims to introduce general spin coating concepts, cover. Dip Coating Vs Spin Coating.

From www.researchgate.net

Scheme 1. Schematic representation of the dipcoating of activated Dip Coating Vs Spin Coating applying a dip/spin coating over thin zinc plate to encapsulate the zinc is an answer that is effective and cost. In today’s blog post, coating systems takes a look at several key differences. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. for the rheology of photoresist coating in microelectronics,. Dip Coating Vs Spin Coating.

From www.researchgate.net

Schematic representation of the dipcoating method and the heat Dip Coating Vs Spin Coating dip coating and spray coating are the two most common ways these coatings are applied, but in some. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. for the rheology of photoresist coating in microelectronics, spin coating works well. applying a dip/spin coating over thin zinc plate. Dip Coating Vs Spin Coating.

From coatingsystems.com

DipSpin Coating Why Use DipSpin? Coating Systems Dip Coating Vs Spin Coating In today’s blog post, coating systems takes a look at several key differences. the dip coating process can be divided into three important technical stages, immersion, withdrawal and evaporation. for the rheology of photoresist coating in microelectronics, spin coating works well. dip coating and spray coating are the two most common ways these coatings are applied, but. Dip Coating Vs Spin Coating.

From www.researchgate.net

Schematic illustration of the solutionbased (dipcoating) process with Dip Coating Vs Spin Coating for the rheology of photoresist coating in microelectronics, spin coating works well. this guide aims to introduce general spin coating concepts, cover spin coating equations and theory, and describe some. dip coating and spray coating are the two most common ways these coatings are applied, but in some. applying a dip/spin coating over thin zinc plate. Dip Coating Vs Spin Coating.