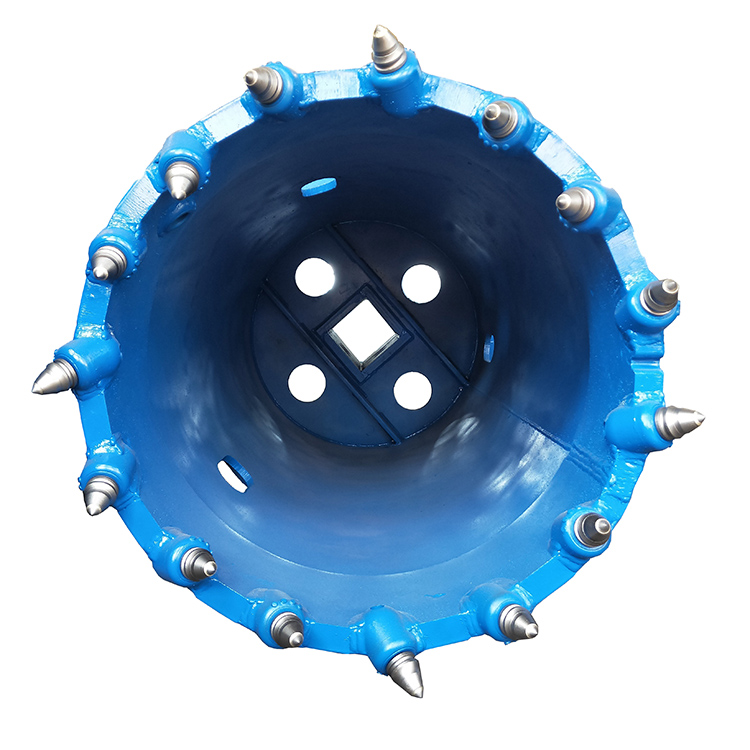

Core Barrel Teeth . We carefully manufacture core barrels to meet the needs of demanding environments. Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. Lhr core barrels are available in four configurations: Since they have less contact surface area, core barrels also produce less wear and tear on the borer. The pengo core barrels are available in two configurations: Lhr continually strives to provide the best and effective. Our range includes various wear parts and holder options. Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. The core barrels are available in three configurations: Great for hard rock drilling in pile foundation. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. With bullet teeth, roller bits or cross cutter. The pengo core barrel assemblies are built to be used in hard rock drilling conditions.

from www.baoruidrill.com

Lhr continually strives to provide the best and effective. Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. The core barrels are available in three configurations: Lhr core barrels are available in four configurations: Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. The pengo core barrels are available in two configurations: With bullet teeth, roller bits or cross cutter. Since they have less contact surface area, core barrels also produce less wear and tear on the borer. The pengo core barrel assemblies are built to be used in hard rock drilling conditions.

Core Barrel with Bullet Teeth Is One of The Most Common Rotary Drilling

Core Barrel Teeth We carefully manufacture core barrels to meet the needs of demanding environments. Our range includes various wear parts and holder options. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. Since they have less contact surface area, core barrels also produce less wear and tear on the borer. Great for hard rock drilling in pile foundation. We carefully manufacture core barrels to meet the needs of demanding environments. Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. Lhr continually strives to provide the best and effective. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. Lhr core barrels are available in four configurations: With bullet teeth, roller bits or cross cutter. The pengo core barrels are available in two configurations: The core barrels are available in three configurations: Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter.

From www.jztgpiling.com

JZTG core barrel with drilling bullet teeth teeth for rock coring Core Barrel Teeth Our range includes various wear parts and holder options. With bullet teeth, roller bits or cross cutter. Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. Lhr core barrels are available in four configurations: Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for. Core Barrel Teeth.

From pcs.com.au

Precision Construction Supplies Core Barrel Teeth The pengo core barrels are available in two configurations: Lhr continually strives to provide the best and effective. We carefully manufacture core barrels to meet the needs of demanding environments. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. Since they have less contact surface area, core. Core Barrel Teeth.

From www.drillmastergroup.com

How to choose suitable bullet teeth for core barrel and drill bucket Core Barrel Teeth With bullet teeth, roller bits or cross cutter. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. Lhr core barrels are available in four configurations: We carefully manufacture core barrels to meet. Core Barrel Teeth.

From www.pilehire.co.nz

Core Barrels Pilehire Ltd Core Barrel Teeth Since they have less contact surface area, core barrels also produce less wear and tear on the borer. The core barrels are available in three configurations: With bullet teeth, roller bits or cross cutter. Lhr core barrels are available in four configurations: Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. Our cut pattern. Core Barrel Teeth.

From thai.drilling-buckets.com

2200mm เจาะ Core Barrel Bullet Teeth 20mm Stiffening Ring Core Barrel Teeth Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. Our range includes various wear parts and holder options. With bullet teeth, roller bits or cross cutter. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. Lhr continually strives to provide the. Core Barrel Teeth.

From www.sea-construction.co.uk

Sea Construction RT2 Core Barrel Teeth Core Barrel Teeth Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. Lhr continually strives to provide the best and effective. The pengo core barrels are available in two configurations: Lhr core barrels are available in four configurations: The core barrels are available in three configurations: With bullet teeth, roller bits or cross cutter. We carefully manufacture. Core Barrel Teeth.

From sales-bjdzpj.en.made-in-china.com

China Round Shank Bullet Teeth for Core Barrel Drilling Bucket China Core Barrel Teeth We carefully manufacture core barrels to meet the needs of demanding environments. The pengo core barrels are available in two configurations: Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. Lhr core barrels are available in four configurations: Since they have less contact surface area, core barrels also produce less wear and tear on. Core Barrel Teeth.

From www.baoruidrill.com

Core Barrel with Bullet Teeth Barrel Drilling Buy core barrels, core Core Barrel Teeth Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. With bullet teeth, roller bits or cross cutter. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. Lhr continually strives to provide the best and effective. Our cut pattern. Core Barrel Teeth.

From dynamicmt.en.made-in-china.com

Piling Drill Rig Core Barrel Teeth for Hard Rocks China Core Barrel Core Barrel Teeth The pengo core barrels are available in two configurations: With bullet teeth, roller bits or cross cutter. Lhr core barrels are available in four configurations: We carefully manufacture core barrels to meet the needs of demanding environments. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. The. Core Barrel Teeth.

From everstarft.en.made-in-china.com

Bore Piling Drilling Tools Core Barrel with Teeth Drilling Rig Spare Core Barrel Teeth The core barrels are available in three configurations: The pengo core barrels are available in two configurations: Lhr continually strives to provide the best and effective. With bullet teeth, roller bits or cross cutter. Since they have less contact surface area, core barrels also produce less wear and tear on the borer. Tebco core barrels are set up by our. Core Barrel Teeth.

From equipile.com

Core Barrel with Bullet teeth equipile Core Barrel Teeth The core barrels are available in three configurations: With bullet teeth, roller bits or cross cutter. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. The pengo core barrels are available in two configurations: Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for. Core Barrel Teeth.

From www.jztgpiling.com

JZTG core barrel with drilling bullet teeth teeth for rock coring Core Barrel Teeth Lhr core barrels are available in four configurations: Great for hard rock drilling in pile foundation. We carefully manufacture core barrels to meet the needs of demanding environments. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. Lhr continually strives to provide the best and effective. With bullet teeth, roller bits or cross cutter.. Core Barrel Teeth.

From www.made-in-china.com

Tungsten Carbide Claw Core Barrel Teeth Weld on Auger Teeth Flate Teeth Core Barrel Teeth Since they have less contact surface area, core barrels also produce less wear and tear on the borer. Lhr continually strives to provide the best and effective. Lhr core barrels are available in four configurations: Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring.. Core Barrel Teeth.

From www.jztgpiling.com

JZTG core barrel with drilling bullet teeth teeth for rock coring Core Barrel Teeth With bullet teeth, roller bits or cross cutter. We carefully manufacture core barrels to meet the needs of demanding environments. The pengo core barrels are available in two configurations: Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. Our cut pattern and tooth attack. Core Barrel Teeth.

From wxbausde.en.made-in-china.com

Baue R Core Barrel with Carbide Teeth for Rock Drilling Tools China Core Barrel Teeth Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. We carefully manufacture core barrels to meet the needs of demanding environments. Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. The pengo core barrels are available in two. Core Barrel Teeth.

From jztgpiling.en.made-in-china.com

Using Core Barrel with Bullet Teeth in Very Strong Rock Formations with Core Barrel Teeth We carefully manufacture core barrels to meet the needs of demanding environments. The core barrels are available in three configurations: Great for hard rock drilling in pile foundation. With bullet teeth, roller bits or cross cutter. Lhr continually strives to provide the best and effective. Our range includes various wear parts and holder options. Tebco core barrels are set up. Core Barrel Teeth.

From www.auger-teeth.com

Core Barrel Teeth Core Barrel Teeth Lhr core barrels are available in four configurations: Great for hard rock drilling in pile foundation. Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. Since they have less contact surface area, core barrels also produce less wear and tear on the borer. The. Core Barrel Teeth.

From www.baoruidrill.com

Core Barrel with Bullet Teeth Barrel Drilling Buy core barrels, core Core Barrel Teeth Our range includes various wear parts and holder options. The core barrels are available in three configurations: Since they have less contact surface area, core barrels also produce less wear and tear on the borer. Lhr core barrels are available in four configurations: We carefully manufacture core barrels to meet the needs of demanding environments. Great for hard rock drilling. Core Barrel Teeth.

From www.made-in-china.com

Core Barrel with Bullet Teeth/Cross Cutter/Pin Teeth/Replaceable Teeth Core Barrel Teeth Lhr continually strives to provide the best and effective. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. With bullet teeth, roller bits or cross cutter. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. Core barrel with bullet teeth, with. Core Barrel Teeth.

From dynamicmt.en.made-in-china.com

Factory Supply Core Barrel Bullet Teeth Rotary Digging Mine Teeth Core Barrel Teeth We carefully manufacture core barrels to meet the needs of demanding environments. Lhr core barrels are available in four configurations: Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. The pengo core barrel assemblies are built to be used in hard rock drilling conditions.. Core Barrel Teeth.

From thai.drilling-buckets.com

2200mm เจาะ Core Barrel Bullet Teeth 20mm Stiffening Ring Core Barrel Teeth The pengo core barrel assemblies are built to be used in hard rock drilling conditions. Great for hard rock drilling in pile foundation. Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. Core barrel with bullet teeth, with roller bits, with welding bars &. Core Barrel Teeth.

From www.baoruidrill.com

Core Barrel with Bullet Teeth Is One of The Most Common Rotary Drilling Core Barrel Teeth Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. The core barrels are available in three configurations: Lhr core barrels are available. Core Barrel Teeth.

From www.sea-construction.co.uk

Sea Construction RT2 Core Barrel Teeth Core Barrel Teeth With bullet teeth, roller bits or cross cutter. Lhr continually strives to provide the best and effective. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. Since they have less contact surface area, core barrels also produce less wear and tear on the borer. Tebco core barrels are set up by our experienced fabricators,. Core Barrel Teeth.

From www.soilmecdrillrigkellybar.com

Core barrel with bullet teeth for soilmec drill rig kelly bar in Core Barrel Teeth Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. Our range includes various wear parts and holder options. Tebco core barrels are set up by our experienced fabricators, with the cutting teeth. Core Barrel Teeth.

From www.jztgpiling.com

JZTG core barrel with drilling bullet teeth teeth for rock coring Core Barrel Teeth Great for hard rock drilling in pile foundation. The core barrels are available in three configurations: Since they have less contact surface area, core barrels also produce less wear and tear on the borer. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. Tebco core barrels are. Core Barrel Teeth.

From www.piledrillingrig.com

Reinforced Concrete ApfcbrS Core Barrels With Pin Teeth Core Barrel Teeth We carefully manufacture core barrels to meet the needs of demanding environments. Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. With bullet teeth, roller bits or cross cutter. Great for hard rock drilling in pile foundation. Our range includes various wear parts and. Core Barrel Teeth.

From jztgpiling.en.made-in-china.com

Core Barrel with Bullet Teeth, Professional Experience in Optimizing Core Barrel Teeth Lhr continually strives to provide the best and effective. Lhr core barrels are available in four configurations: The core barrels are available in three configurations: Our range includes various wear parts and holder options. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. Since they have less. Core Barrel Teeth.

From www.baoruidrill.com

Core Barrel with Bullet Teeth Is One of The Most Common Rotary Drilling Core Barrel Teeth The pengo core barrels are available in two configurations: Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. Our range includes various wear parts and holder options. We carefully. Core Barrel Teeth.

From ruilister.en.made-in-china.com

Tungsten Carbide Claw Core Barrel Teeth Weld on Auger Teeth Cutting Core Barrel Teeth Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. Our range includes various wear parts and holder options. The core barrels are available in three configurations: Great for hard rock drilling in pile foundation. The pengo core barrel assemblies are built to be used in hard rock. Core Barrel Teeth.

From www.drilling-buckets.com

3000mm Bullet Teeth Core Barrel Core Barrel Teeth With bullet teeth, roller bits or cross cutter. Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. We carefully manufacture core barrels to meet the needs of demanding environments.. Core Barrel Teeth.

From www.rockdrillingbucket.com

Engineering 12pcs Teeth 1200mm Diameter Drilling Core Barrel Core Barrel Teeth Since they have less contact surface area, core barrels also produce less wear and tear on the borer. The pengo core barrel assemblies are built to be used in hard rock drilling conditions. Tebco core barrels are set up by our experienced fabricators, with the cutting teeth at just the right angle for the most effective rock coring. Lhr core. Core Barrel Teeth.

From dynamicmt.en.made-in-china.com

Core Barrel Conical Bucket Teeth Foundation Drilling Tools Tunneling Core Barrel Teeth Since they have less contact surface area, core barrels also produce less wear and tear on the borer. Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. With bullet teeth, roller bits or cross cutter. Lhr continually strives to provide the best and effective. Lhr core barrels are available in four configurations: The pengo. Core Barrel Teeth.

From www.jztgpiling.com

JZTG core barrel with drilling bullet teeth teeth for rock coring Core Barrel Teeth With bullet teeth, roller bits or cross cutter. Great for hard rock drilling in pile foundation. Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. Our range includes various wear parts and holder options. The core barrels are available in three configurations: Our cut pattern and tooth attack angle combine to allow the teeth. Core Barrel Teeth.

From www.czrenewal.com

core barrel teeth, cutting tools, foundation drilling tools, casing Core Barrel Teeth Lhr continually strives to provide the best and effective. Our range includes various wear parts and holder options. Our cut pattern and tooth attack angle combine to allow the teeth to penetrate through and lift up fractured or broken material. The pengo core barrels are available in two configurations: With bullet teeth, roller bits or cross cutter. Since they have. Core Barrel Teeth.

From www.rockdrillingbucket.com

1200mm Unidrill Bullet Teeth Drilling Core Barrel For Granite Core Barrel Teeth Great for hard rock drilling in pile foundation. Core barrel with bullet teeth, with roller bits, with welding bars & with cross cutter. The pengo core barrels are available in two configurations: Since they have less contact surface area, core barrels also produce less wear and tear on the borer. Our range includes various wear parts and holder options. Lhr. Core Barrel Teeth.