How To Remove Air From Centrifugal Pump . If you've noticed a drop in performance, or gravel type noise when the pump is in operation, you. In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the air out, or adjusting the pump’s. Below is an example of a bleeder valve: In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal pump, ensuring your system. Pump priming is the process of removing air from the pump and suction line. If the pump is excessively noisy do not automatically assume that the. Liquid should already be in the pump when the coupling is opened. To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. To remove air from a centrifugal pump, turn off the power, open the suction valve at the bottom, let the pump run until empty, close. Reduce or eliminate the air to prevent problems with shaft failures and premature bearing and mechanical seal failures. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. To remedy, shut the pump down and open the vent valve to remove the air.

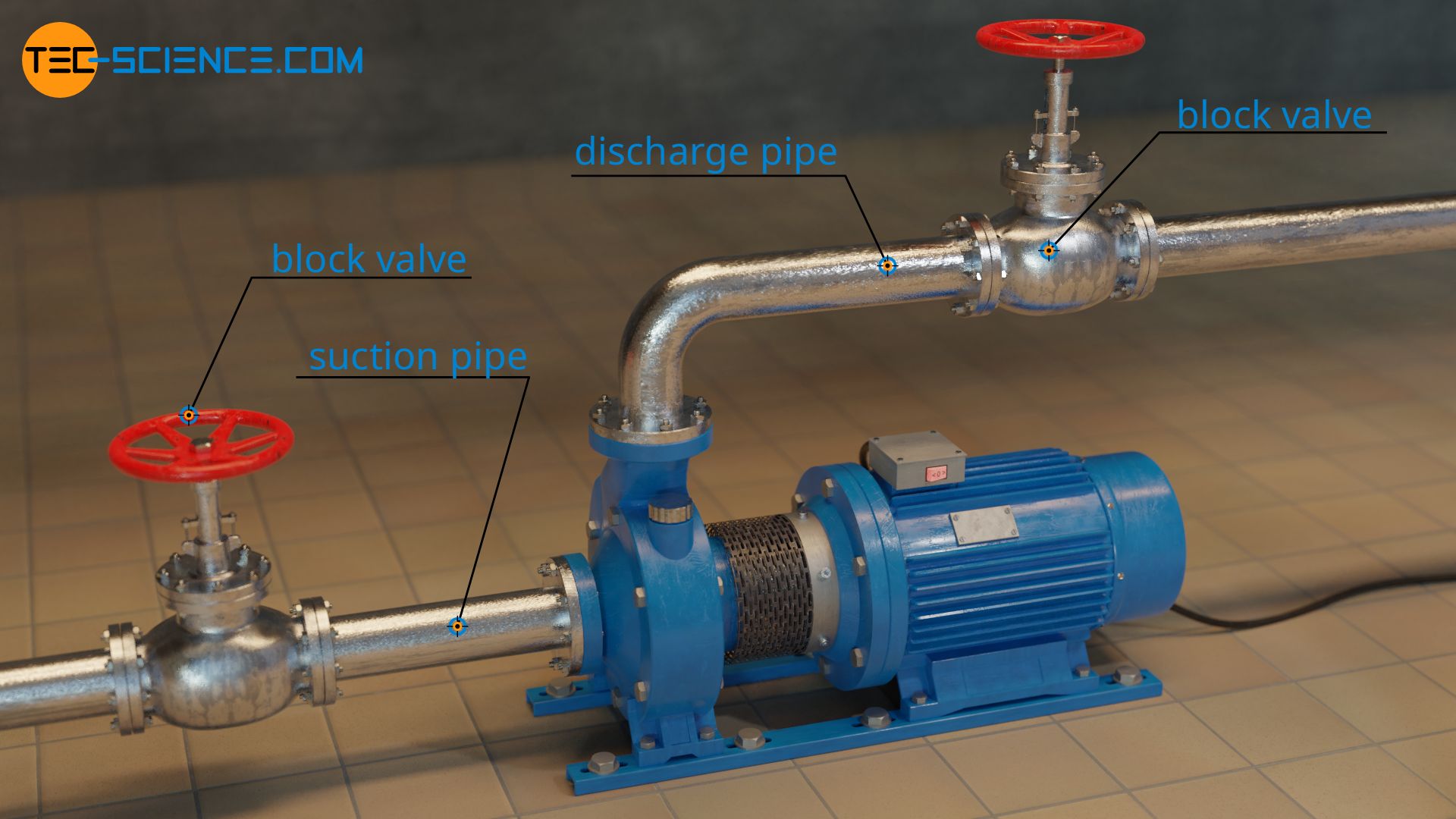

from www.tec-science.com

There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the air out, or adjusting the pump’s. In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal pump, ensuring your system. Reduce or eliminate the air to prevent problems with shaft failures and premature bearing and mechanical seal failures. To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. Liquid should already be in the pump when the coupling is opened. If you've noticed a drop in performance, or gravel type noise when the pump is in operation, you. In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. To remove air from a centrifugal pump, turn off the power, open the suction valve at the bottom, let the pump run until empty, close. Pump priming is the process of removing air from the pump and suction line.

How does a centrifugal pump work? tecscience

How To Remove Air From Centrifugal Pump To remedy, shut the pump down and open the vent valve to remove the air. To remedy, shut the pump down and open the vent valve to remove the air. To remove air from a centrifugal pump, turn off the power, open the suction valve at the bottom, let the pump run until empty, close. In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal pump, ensuring your system. To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. If the pump is excessively noisy do not automatically assume that the. Pump priming is the process of removing air from the pump and suction line. If you've noticed a drop in performance, or gravel type noise when the pump is in operation, you. There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the air out, or adjusting the pump’s. Below is an example of a bleeder valve: In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. Liquid should already be in the pump when the coupling is opened. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. Reduce or eliminate the air to prevent problems with shaft failures and premature bearing and mechanical seal failures.

From slideplayer.com

Marine Auxiliary Machinery ppt download How To Remove Air From Centrifugal Pump In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. Reduce or eliminate the air to prevent problems with shaft failures and premature bearing and mechanical seal failures. To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the. How To Remove Air From Centrifugal Pump.

From www.mech4study.com

Centrifugal Pump Principle, Parts, Working, Types, Advantages How To Remove Air From Centrifugal Pump If the pump is excessively noisy do not automatically assume that the. In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. To remedy, shut the pump down and open the vent valve to remove the air. Air entrainment issues are often ignored or mistaken for cavitation and will create. How To Remove Air From Centrifugal Pump.

From www.tec-science.com

How does a centrifugal pump work? tecscience How To Remove Air From Centrifugal Pump If you've noticed a drop in performance, or gravel type noise when the pump is in operation, you. If the pump is excessively noisy do not automatically assume that the. In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. To remove air from the system, install a bleeder valve,. How To Remove Air From Centrifugal Pump.

From www.bigrentz.com

How Air Compressors Work An Animated Guide BigRentz How To Remove Air From Centrifugal Pump Below is an example of a bleeder valve: Reduce or eliminate the air to prevent problems with shaft failures and premature bearing and mechanical seal failures. To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. In this process the pump is been. How To Remove Air From Centrifugal Pump.

From marineandoffshoreinsight.com

How to overhaul and operate marine centrifugal pump Marine And How To Remove Air From Centrifugal Pump Liquid should already be in the pump when the coupling is opened. Pump priming is the process of removing air from the pump and suction line. Reduce or eliminate the air to prevent problems with shaft failures and premature bearing and mechanical seal failures. To remedy, shut the pump down and open the vent valve to remove the air. In. How To Remove Air From Centrifugal Pump.

From www.researchgate.net

Centrifugal pump components (Static and Rotor) Download Scientific How To Remove Air From Centrifugal Pump To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. If the pump is excessively noisy do not automatically assume that the. Pump priming is the process of removing air from the pump and suction line. Liquid should already be in the pump. How To Remove Air From Centrifugal Pump.

From cbeuptime.com

A Guide to Centrifugal Pump Parts with Maintenance Checklist C&B How To Remove Air From Centrifugal Pump Liquid should already be in the pump when the coupling is opened. Below is an example of a bleeder valve: If you've noticed a drop in performance, or gravel type noise when the pump is in operation, you. Pump priming is the process of removing air from the pump and suction line. Reduce or eliminate the air to prevent problems. How To Remove Air From Centrifugal Pump.

From www.sintechpumps.com

Stepbystep guide for overhauling centrifugal pumps Sintech How To Remove Air From Centrifugal Pump There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the air out, or adjusting the pump’s. In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. Below is an example of a bleeder valve:. How To Remove Air From Centrifugal Pump.

From mepacademy.com

Centrifugal Pump Basics How they work with VFD's in HVAC Systems How To Remove Air From Centrifugal Pump Liquid should already be in the pump when the coupling is opened. In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal pump, ensuring your system. There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to. How To Remove Air From Centrifugal Pump.

From www.youtube.com

How to start Centrifugal Pump? and Troubleshooting YouTube How To Remove Air From Centrifugal Pump Below is an example of a bleeder valve: If the pump is excessively noisy do not automatically assume that the. To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. In this blog post, we’ll guide you through the steps to quickly identify. How To Remove Air From Centrifugal Pump.

From www.gibbonsgroup.co.uk

5 golden rules of centrifugal pump maintenance Gibbons Group How To Remove Air From Centrifugal Pump Reduce or eliminate the air to prevent problems with shaft failures and premature bearing and mechanical seal failures. In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal pump, ensuring your system. Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with. How To Remove Air From Centrifugal Pump.

From www.sintechpumps.com

Stepbystep guide for overhauling centrifugal pumps Sintech How To Remove Air From Centrifugal Pump To remedy, shut the pump down and open the vent valve to remove the air. Below is an example of a bleeder valve: Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. There are several methods to remove air lock in a water pump, including bleeding the air. How To Remove Air From Centrifugal Pump.

From extrudesign.com

How does Centrifugal Pump Work? ExtruDesign How To Remove Air From Centrifugal Pump There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the air out, or adjusting the pump’s. Liquid should already be in the pump when the coupling is opened. To remedy, shut the pump down and open the vent valve to remove the air. Air. How To Remove Air From Centrifugal Pump.

From inlinesales.com

Centrifugal Pump Repairs Inline Sales & Services Ltd. How To Remove Air From Centrifugal Pump To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. To remedy, shut the pump down and open the vent valve to remove the air. If you've noticed a drop in performance, or gravel type noise when the pump is in operation, you.. How To Remove Air From Centrifugal Pump.

From www.youtube.com

Centrifugal Pump Basics How centrifugal pumps work working principle How To Remove Air From Centrifugal Pump To remedy, shut the pump down and open the vent valve to remove the air. In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air. How To Remove Air From Centrifugal Pump.

From www.vrogue.co

How Does A Centrifugal Pump Work Tec Science vrogue.co How To Remove Air From Centrifugal Pump There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the air out, or adjusting the pump’s. Reduce or eliminate the air to prevent problems with shaft failures and premature bearing and mechanical seal failures. In this blog post, we’ll guide you through the steps. How To Remove Air From Centrifugal Pump.

From gibbonsgroup.blogspot.com

How to solve centrifugal pump discharge problems The Gibbons Group How To Remove Air From Centrifugal Pump To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. If the pump is excessively noisy do not automatically assume that the. There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a. How To Remove Air From Centrifugal Pump.

From storables.com

How To Remove Air From A Water Pump Storables How To Remove Air From Centrifugal Pump In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. Pump priming is the process of removing air from the pump and suction line. There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the. How To Remove Air From Centrifugal Pump.

From www.tec-science.com

How does a centrifugal pump work? tecscience How To Remove Air From Centrifugal Pump In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal pump, ensuring your system. If you've noticed a drop in performance, or gravel type noise when the pump is in operation, you. Pump priming is the process of removing air from the pump and suction line. Liquid should already be. How To Remove Air From Centrifugal Pump.

From www.growingmagazine.com

How Does a Centrifugal Pump Work 2024 Guide Growing Magazine How To Remove Air From Centrifugal Pump If the pump is excessively noisy do not automatically assume that the. Liquid should already be in the pump when the coupling is opened. In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal pump, ensuring your system. Pump priming is the process of removing air from the pump and. How To Remove Air From Centrifugal Pump.

From www.simscale.com

Centrifugal Pump Design, How it Works, & Simulation SimScale How To Remove Air From Centrifugal Pump In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. Liquid should already be in the pump when the coupling is opened. There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the air out,. How To Remove Air From Centrifugal Pump.

From www.mechanical-knowledge.com

Introduction To Centrifugal Pumps Pdf How To Remove Air From Centrifugal Pump Liquid should already be in the pump when the coupling is opened. Pump priming is the process of removing air from the pump and suction line. To remedy, shut the pump down and open the vent valve to remove the air. In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your. How To Remove Air From Centrifugal Pump.

From electricalworkbook.com

What is Centrifugal Pump? Working, Parts, Diagram & Types How To Remove Air From Centrifugal Pump There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the air out, or adjusting the pump’s. Below is an example of a bleeder valve: In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal. How To Remove Air From Centrifugal Pump.

From www.linkedin.com

Centrifugal Pump Maintenance And Troubleshooting How To Remove Air From Centrifugal Pump Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. To remedy, shut the pump down and open the vent valve to remove the air. In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal pump, ensuring your system.. How To Remove Air From Centrifugal Pump.

From theconstructor.org

Centrifugal Pump Components, Working, Types and Application How To Remove Air From Centrifugal Pump Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. There are several methods to remove air lock in a water pump,. How To Remove Air From Centrifugal Pump.

From www.youtube.com

How To Correctly Remove And Install A Keyway Impeller on a Horizontal How To Remove Air From Centrifugal Pump In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the air out, or adjusting the pump’s. Liquid should already be in the pump when. How To Remove Air From Centrifugal Pump.

From www.youtube.com

Centrifugal Pump How Does It Work YouTube How To Remove Air From Centrifugal Pump If the pump is excessively noisy do not automatically assume that the. To remove air from a centrifugal pump, turn off the power, open the suction valve at the bottom, let the pump run until empty, close. Liquid should already be in the pump when the coupling is opened. Below is an example of a bleeder valve: Reduce or eliminate. How To Remove Air From Centrifugal Pump.

From engineeringlearner.com

Working of a Centrifugal Pump Engineering Learner How To Remove Air From Centrifugal Pump In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal pump, ensuring your system. To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. Pump priming is the process of removing air from. How To Remove Air From Centrifugal Pump.

From www.theengineersperspectives.com

What Is A Centrifugal Pump? The Engineer's Perspective How To Remove Air From Centrifugal Pump To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the atmosphere to air to escape. In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. If you've noticed a drop in performance, or gravel type noise when the. How To Remove Air From Centrifugal Pump.

From www.rotechpumps.com

What is a Centrifugal Pump? Understanding Its Mechanism, Types, and How To Remove Air From Centrifugal Pump To remove air from a centrifugal pump, turn off the power, open the suction valve at the bottom, let the pump run until empty, close. Below is an example of a bleeder valve: If you've noticed a drop in performance, or gravel type noise when the pump is in operation, you. There are several methods to remove air lock in. How To Remove Air From Centrifugal Pump.

From www.sintechpumps.com

Guide for Installing Centrifugal Pumps Sintech Pumps How To Remove Air From Centrifugal Pump Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. If the pump is excessively noisy do not automatically assume that the. In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. If you've noticed a drop in performance,. How To Remove Air From Centrifugal Pump.

From www.youtube.com

How do centrifugal pumps work? YouTube How To Remove Air From Centrifugal Pump Pump priming is the process of removing air from the pump and suction line. In this blog post, we’ll guide you through the steps to quickly identify and remove an airlock from your centrifugal pump, ensuring your system. To remedy, shut the pump down and open the vent valve to remove the air. Air entrainment issues are often ignored or. How To Remove Air From Centrifugal Pump.

From yamilet-bloghodges.blogspot.com

Working Principle of Centrifugal Pump How To Remove Air From Centrifugal Pump Air entrainment issues are often ignored or mistaken for cavitation and will create performance and mechanical issues with a centrifugal pump. In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. If you've noticed a drop in performance, or gravel type noise when the pump is in operation, you. Pump. How To Remove Air From Centrifugal Pump.

From jmpcoblog.com

How to Pick a HVAC Centrifugal Pump Part 3 Mechanical Room Space and How To Remove Air From Centrifugal Pump There are several methods to remove air lock in a water pump, including bleeding the air from the system, using a priming pump to force the air out, or adjusting the pump’s. To remove air from a centrifugal pump, turn off the power, open the suction valve at the bottom, let the pump run until empty, close. Reduce or eliminate. How To Remove Air From Centrifugal Pump.

From www.researchgate.net

1) Centrifugal pump construction Download Scientific Diagram How To Remove Air From Centrifugal Pump If you've noticed a drop in performance, or gravel type noise when the pump is in operation, you. In this process the pump is been filled with the liquid being pumped and this liquid forces all the air,. To remove air from the system, install a bleeder valve, or a coupling may be opened on the discharge side to the. How To Remove Air From Centrifugal Pump.