Cutting Oil Viscosity . The viscosity of neat cutting oil is chosen to suit the machining application. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. Oil viscosity is the internal friction within an oil that resists its flow. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. To simplify, the oil’s viscosity. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. Some operations need a very light oil, others a heavier viscosity. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently.

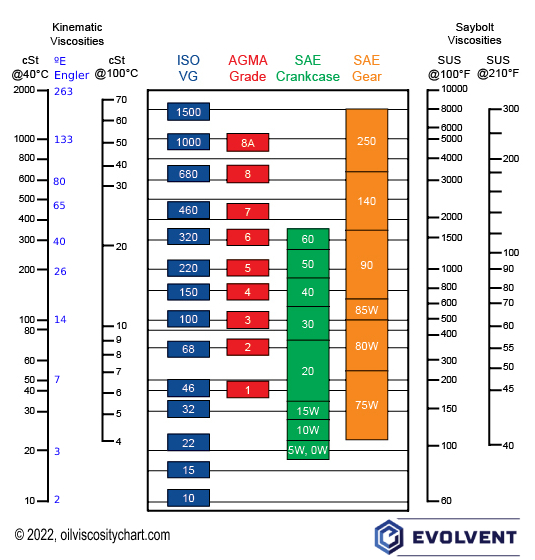

from www.oilviscositychart.com

Oil viscosity is the internal friction within an oil that resists its flow. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. Some operations need a very light oil, others a heavier viscosity. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. To simplify, the oil’s viscosity. The viscosity of neat cutting oil is chosen to suit the machining application.

Oil Viscosity Chart Compare, Choose, and Substitute Industrial Oil based on Viscosity

Cutting Oil Viscosity It measures the oil’s resistance to flow and is one of the most important factors in lubricants. To simplify, the oil’s viscosity. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. The viscosity of neat cutting oil is chosen to suit the machining application. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. Some operations need a very light oil, others a heavier viscosity. Oil viscosity is the internal friction within an oil that resists its flow. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment.

From precisionlubrication.com

Oil Viscosity A Practical Guide Cutting Oil Viscosity Oil viscosity is the internal friction within an oil that resists its flow. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. The viscosity of neat cutting oil is chosen to suit the machining application. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid. Cutting Oil Viscosity.

From www.researchgate.net

Effect of oil viscosity. Download Scientific Diagram Cutting Oil Viscosity Some operations need a very light oil, others a heavier viscosity. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. The viscosity of neat cutting oil is chosen to suit the machining application. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. Oil viscosity is the. Cutting Oil Viscosity.

From cnfilter8.en.made-in-china.com

China Cutting Oil Kinematic with ASTM D445 Viscosity Bath (VST2000) China Oil Cutting Oil Viscosity Oil viscosity is the internal friction within an oil that resists its flow. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. The viscosity of neat cutting oil is chosen to suit the. Cutting Oil Viscosity.

From ar.inspiredpencil.com

Viscosity Of Motor Oil Cutting Oil Viscosity The viscosity of neat cutting oil is chosen to suit the machining application. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. Oil viscosity is the internal friction within an oil that resists its. Cutting Oil Viscosity.

From www.pinterest.com

What is Oil Viscosity? Comparative Oil Viscosity Chart Viscosity, Oils, Hydraulic fluid Cutting Oil Viscosity Oil viscosity is the internal friction within an oil that resists its flow. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. Regularly analyze the condition of cutting oils. Cutting Oil Viscosity.

From www.redlinetools.com

Light Viscosity Cutting Oil 55 Gallon Drum Cutting Oil Viscosity To simplify, the oil’s viscosity. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. The viscosity of neat cutting oil is chosen to suit the machining application. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. Some operations need a very light oil, others a heavier. Cutting Oil Viscosity.

From www.researchgate.net

Oil viscosity of heavy fuel oils. Download Scientific Diagram Cutting Oil Viscosity It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Oil viscosity is the internal friction within an oil that resists its flow. Some operations need a very light oil, others a heavier viscosity. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. The viscosity of. Cutting Oil Viscosity.

From mavink.com

Viscosity Chart For Oil Cutting Oil Viscosity To simplify, the oil’s viscosity. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. The viscosity of neat cutting oil is chosen to suit the machining application. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. It measures the. Cutting Oil Viscosity.

From news.kixxoil.com

Engine Oil Viscosity Explained Kixx Newsroom Cutting Oil Viscosity Oil viscosity is the internal friction within an oil that resists its flow. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. To simplify, the oil’s viscosity. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. Cutting oils have different viscosities, base oils and. Cutting Oil Viscosity.

From www.researchgate.net

Viscosity of various vegetable oils at various temperatures Download Scientific Diagram Cutting Oil Viscosity The viscosity of neat cutting oil is chosen to suit the machining application. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. To simplify, the oil’s viscosity. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. It measures the oil’s resistance to flow and. Cutting Oil Viscosity.

From www.tribonet.org

Oil Viscosity Index and Viscosity Temperature Relation About Tribology Cutting Oil Viscosity It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Some operations need a very light oil, others a heavier viscosity. To simplify, the oil’s viscosity. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. The cutting oil’s main function will be cooling, especially with a. Cutting Oil Viscosity.

From aboutengineoils.com

Oil Viscosity Chart Guide to Selecting the Right Oil Cutting Oil Viscosity The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment.. Cutting Oil Viscosity.

From ktihydraulicsinc.com

Oil Viscosity vs Temperature (deg F) KTI Hydraulics, Inc. Cutting Oil Viscosity Some operations need a very light oil, others a heavier viscosity. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. To simplify, the oil’s viscosity. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. The. Cutting Oil Viscosity.

From www.youtube.com

Determination of Viscosity and Viscosity Index of oil YouTube Cutting Oil Viscosity Some operations need a very light oil, others a heavier viscosity. Oil viscosity is the internal friction within an oil that resists its flow. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid. Cutting Oil Viscosity.

From aboutengineoils.com

Oil Viscosity Chart Guide to Selecting the Right Oil Cutting Oil Viscosity It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. Some operations need a very light oil, others a heavier viscosity. To simplify, the oil’s viscosity. The cutting oil’s main function will be cooling, especially with a. Cutting Oil Viscosity.

From www.youtube.com

Oil Viscosity Explained YouTube Cutting Oil Viscosity Some operations need a very light oil, others a heavier viscosity. The viscosity of neat cutting oil is chosen to suit the machining application. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. It measures the oil’s resistance to flow and is one of the. Cutting Oil Viscosity.

From www.oilviscositychart.com

Oil Viscosity Chart Compare, Choose, and Substitute Industrial Oil based on Viscosity Cutting Oil Viscosity Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Viscosity is the measure of the oil’s resistance. Cutting Oil Viscosity.

From fusion-chemical.com

Everything You Need to Know About Cutting Fluids Cutting Oil Viscosity Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. Some operations need a very light oil, others a heavier viscosity. Oil viscosity is the internal friction within an oil that resists its flow. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner,. Cutting Oil Viscosity.

From www.lubetechshop.co.uk

ExcelCut 433 Low Viscosity Extreme Pressure Neat Cutting Oil Ideal for Gear Cutting Deep Hole Cutting Oil Viscosity Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. To simplify, the oil’s viscosity. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid. Cutting Oil Viscosity.

From www.researchgate.net

Water cut vs. viscosity curve for mixtures of BZ194 oil and produced... Download Scientific Cutting Oil Viscosity Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. To simplify, the oil’s viscosity. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. The viscosity of neat. Cutting Oil Viscosity.

From www.dieselarmy.com

Oil Viscosity A Discussion With The Professionals At AMSOIL Cutting Oil Viscosity To simplify, the oil’s viscosity. The viscosity of neat cutting oil is chosen to suit the machining application. Some operations need a very light oil, others a heavier viscosity. Oil viscosity is the internal friction within an oil that resists its flow. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Viscosity. Cutting Oil Viscosity.

From www.researchgate.net

Viscosity vs temperature of base cutting fluids Download Scientific Diagram Cutting Oil Viscosity Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. The viscosity of neat cutting oil is chosen to suit the machining application. It measures the oil’s resistance to flow and. Cutting Oil Viscosity.

From www.hotshotsecret.com

What is Oil Viscosity? Low vs High Viscosity Cutting Oil Viscosity Oil viscosity is the internal friction within an oil that resists its flow. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. Some operations need a very light oil, others a heavier viscosity. The viscosity of neat cutting oil is chosen to suit the machining application. Viscosity is the measure of the oil’s. Cutting Oil Viscosity.

From www.csidesigns.com

Viscosity Chart Free Resource Cutting Oil Viscosity The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. Oil viscosity is the internal friction within an oil that resists its flow. Some operations need a very light oil, others a heavier viscosity. It measures the oil’s resistance to flow and is one of the. Cutting Oil Viscosity.

From www.sexizpix.com

What Is Oil Viscosity Comparative Oil Viscosity Chart Viscosity Sexiz Pix Cutting Oil Viscosity Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. Some operations need a very light oil, others a heavier viscosity. The viscosity of neat cutting oil is chosen to suit the machining application. To simplify, the oil’s viscosity. It measures the oil’s resistance to flow and is one of the. Cutting Oil Viscosity.

From www.researchgate.net

shows the plot of the oil viscosity whose calculated values are well... Download Scientific Cutting Oil Viscosity Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. The viscosity of neat cutting oil is chosen to suit the machining application. To simplify, the oil’s viscosity. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. Oil viscosity is. Cutting Oil Viscosity.

From www.best-synthetic-oil.com.au

Amsoil Australia Blog Understanding Oil Viscosity Cutting Oil Viscosity To simplify, the oil’s viscosity. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more. Cutting Oil Viscosity.

From sciencenotes.org

Viscosity Definition and Examples Cutting Oil Viscosity Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Some operations need. Cutting Oil Viscosity.

From www.sundevilauto.com

Engine Oil Viscosity Rating Sun Devil Auto Cutting Oil Viscosity The viscosity of neat cutting oil is chosen to suit the machining application. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Some operations need a very light oil, others a heavier viscosity. Viscosity is the. Cutting Oil Viscosity.

From ricksfreeautorepairadvice.com

Understanding Motor Oil Specifications — Ricks Free Auto Repair Advice Ricks Free Auto Repair Cutting Oil Viscosity Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. The viscosity of neat cutting oil is chosen to suit the machining application. Oil viscosity is the internal friction within an oil that resists its flow. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination. Cutting Oil Viscosity.

From wiki.anton-paar.com

Viscosity of Engine Oil viscosity table and viscosity chart Anton Paar Wiki Cutting Oil Viscosity Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. To simplify, the oil’s viscosity. Some operations need a very light oil, others a heavier viscosity. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. The. Cutting Oil Viscosity.

From news.kixxoil.com

Engine Oil Viscosity Explained Kixx Newsroom Cutting Oil Viscosity The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since the thinner, diluted fluid carries heat away more efficiently. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. Some operations need. Cutting Oil Viscosity.

From bceweb.org

Sae 30 Oil Viscosity Chart A Visual Reference of Charts Chart Master Cutting Oil Viscosity Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. Some operations need a very light oil, others a heavier viscosity. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. The cutting oil’s main function will be cooling, especially with a synthetic cutting fluid, since. Cutting Oil Viscosity.

From oilviscositychart.com

How to Choose An Oil Oil Viscosity Chart Cutting Oil Viscosity Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. To simplify, the oil’s viscosity. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Cutting oils have different viscosities, base oils and additives depending on the processes and which metals. Oil viscosity is the internal friction within. Cutting Oil Viscosity.

From mungfali.com

Viscosity Comparison Chart Cutting Oil Viscosity The viscosity of neat cutting oil is chosen to suit the machining application. Regularly analyze the condition of cutting oils through methods such as viscosity testing, ph level checks, and contamination assessment. To simplify, the oil’s viscosity. It measures the oil’s resistance to flow and is one of the most important factors in lubricants. Viscosity is the measure of the. Cutting Oil Viscosity.