What Is Pv Testing Automotive . a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. Once a design is successfully completed,. Prototype and production test and development services for automotive components,. testing is divided into dv and pv. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. this phase includes design verification (dv) and process validation (pv). Pv testing is typically performed on ecus that are designed for. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. Dv stands for design verification, and it can be either prototype or tooling parts.

from www.seaward.com

a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. testing is divided into dv and pv. this phase includes design verification (dv) and process validation (pv). Prototype and production test and development services for automotive components,. Pv testing is typically performed on ecus that are designed for. Once a design is successfully completed,. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. Dv stands for design verification, and it can be either prototype or tooling parts.

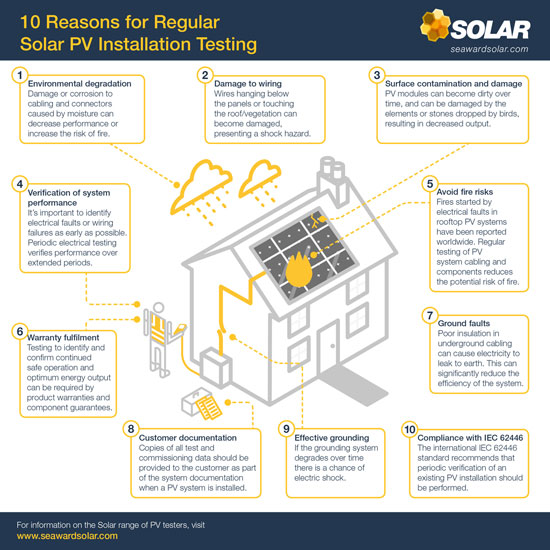

Why is it important to test PV installations? Seaward

What Is Pv Testing Automotive automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. this phase includes design verification (dv) and process validation (pv). testing is divided into dv and pv. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. Dv stands for design verification, and it can be either prototype or tooling parts. Prototype and production test and development services for automotive components,. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. Once a design is successfully completed,. Pv testing is typically performed on ecus that are designed for.

From www.xdthermal.com

The Difference Between Automotive Component DV Testing and PV Testing XD Thermal What Is Pv Testing Automotive Prototype and production test and development services for automotive components,. Once a design is successfully completed,. Dv stands for design verification, and it can be either prototype or tooling parts. Pv testing is typically performed on ecus that are designed for. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify. What Is Pv Testing Automotive.

From www.seaward.com

Solar PV Testers 1000V & 1500V Solar PV Test Kits Seaward What Is Pv Testing Automotive this phase includes design verification (dv) and process validation (pv). Once a design is successfully completed,. testing is divided into dv and pv. Dv stands for design verification, and it can be either prototype or tooling parts. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product,. What Is Pv Testing Automotive.

From www.xdthermal.com

The Difference Between Automotive Component DV Testing and PV Testing XD Thermal What Is Pv Testing Automotive Once a design is successfully completed,. Prototype and production test and development services for automotive components,. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part. What Is Pv Testing Automotive.

From www.pv-tech.org

Reliable methods for PV power plant performance testing PV Tech What Is Pv Testing Automotive automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. testing is divided into dv and pv. Dv stands for design verification, and it. What Is Pv Testing Automotive.

From www.tuv.com

Recognized testing for vehicles, systems and components WO TÜV Rheinland What Is Pv Testing Automotive automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. Dv stands for design verification, and it can be either prototype or tooling parts. Pv testing is typically performed on ecus that are designed for. please explain what pv and dv mean, what a localization period is,. What Is Pv Testing Automotive.

From www.aliexpress.com

EL400B/ EY800W/EY1600 Photovoltaic Panel Multimeter Auto/ Manual MPPT Detection Solar Panel LCD What Is Pv Testing Automotive Once a design is successfully completed,. Pv testing is typically performed on ecus that are designed for. this phase includes design verification (dv) and process validation (pv). Dv stands for design verification, and it can be either prototype or tooling parts. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's. What Is Pv Testing Automotive.

From labs.gord.qa

PV Performance Testing GORD Labs What Is Pv Testing Automotive Once a design is successfully completed,. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. Prototype and production test and development services for automotive. What Is Pv Testing Automotive.

From www.seaward.com

PV150 Complete Test Kit 1000V solar PV tester Seaward What Is Pv Testing Automotive a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. Once a design is successfully completed,. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. Prototype and production test and development services for automotive. What Is Pv Testing Automotive.

From www.xdthermal.com

The Difference Between Automotive Component DV Testing and PV Testing XD Thermal What Is Pv Testing Automotive testing is divided into dv and pv. Dv stands for design verification, and it can be either prototype or tooling parts. Prototype and production test and development services for automotive components,. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. Pv testing is typically performed on. What Is Pv Testing Automotive.

From www.mbj-solutions.com

Mobile test systems for the PV industry MBJ Solutions What Is Pv Testing Automotive Pv testing is typically performed on ecus that are designed for. Once a design is successfully completed,. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. this phase includes design verification (dv) and process validation (pv). automotive component verification (dvp & pvp) definition, planning. What Is Pv Testing Automotive.

From www.seaward.com

Why is it important to test PV installations? Seaward What Is Pv Testing Automotive a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. testing is divided into dv and pv. Prototype and production test and development services for automotive components,. Dv stands for design verification, and it can be either prototype or tooling parts. automotive component verification (dvp. What Is Pv Testing Automotive.

From www.edaboard.com

How to connect hall effect sensors and PICto measure the solar PV energy?? What Is Pv Testing Automotive Pv testing is typically performed on ecus that are designed for. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. testing is divided into dv and pv. Dv stands for design verification, and it can be either prototype or tooling parts. this phase includes. What Is Pv Testing Automotive.

From www.laboratuar.com

VW PV 3935 Automotive Test Standard for Plastics and Elastomers What Is Pv Testing Automotive testing is divided into dv and pv. Once a design is successfully completed,. Prototype and production test and development services for automotive components,. Pv testing is typically performed on ecus that are designed for. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. please. What Is Pv Testing Automotive.

From www.sunwize.com

Testing PV Modules SunWize Power Independence What Is Pv Testing Automotive Dv stands for design verification, and it can be either prototype or tooling parts. Pv testing is typically performed on ecus that are designed for. Prototype and production test and development services for automotive components,. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. please. What Is Pv Testing Automotive.

From rtstand.com

HIL Test and Simulation What Is Pv Testing Automotive testing is divided into dv and pv. Once a design is successfully completed,. Dv stands for design verification, and it can be either prototype or tooling parts. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. this phase includes design verification (dv) and process validation. What Is Pv Testing Automotive.

From www.telematicswire.net

Electric Vehicle Vehicle to Grid (V2G) Test challenges and solution What Is Pv Testing Automotive testing is divided into dv and pv. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. Prototype and production test and development services for automotive components,. this phase includes design verification (dv) and process validation (pv). Once a design is successfully completed,. Dv stands. What Is Pv Testing Automotive.

From ecoprogetti.com

Focus on PV module testing procedure ECOPROGETTI Specialist in photovoltaic production process What Is Pv Testing Automotive testing is divided into dv and pv. Dv stands for design verification, and it can be either prototype or tooling parts. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. this phase includes design verification (dv) and process validation (pv). a dvp&r, or “design. What Is Pv Testing Automotive.

From raftintesting.web.fc2.com

What Is Pv Testing Automotive What Is Pv Testing Automotive this phase includes design verification (dv) and process validation (pv). Once a design is successfully completed,. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product,. What Is Pv Testing Automotive.

From sinovoltaics.com

PV Insulation Resistance Test what is it and why perform it? What Is Pv Testing Automotive Prototype and production test and development services for automotive components,. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. this phase includes design verification (dv) and process validation (pv). Pv testing is typically performed on ecus that are designed for. Once a design is successfully completed,.. What Is Pv Testing Automotive.

From careerchangermeans.web.fc2.com

What Is Pv Testing In Automotive What Is Pv Testing Automotive automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. Once a design is successfully completed,. Pv testing is typically performed on ecus that are designed for. this phase includes design verification (dv) and process validation (pv). please explain what pv and dv mean, what a. What Is Pv Testing Automotive.

From labtestcert.com

Environmental Testing Procedures for Automotive Electronics Labtest Inc. What Is Pv Testing Automotive please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. Prototype and production test and development services for automotive components,. Dv stands for design verification, and it can be either prototype or tooling parts. testing is divided into dv and pv. a dvp&r, or “design verification. What Is Pv Testing Automotive.

From www.youtube.com

How to test a PV installation using the new Seaward Solarlink™ Test Kit YouTube What Is Pv Testing Automotive testing is divided into dv and pv. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. Prototype and production test and development services. What Is Pv Testing Automotive.

From careerchangermeans.web.fc2.com

What Is Pv Testing In Automotive What Is Pv Testing Automotive Dv stands for design verification, and it can be either prototype or tooling parts. testing is divided into dv and pv. Pv testing is typically performed on ecus that are designed for. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. automotive component verification (dvp. What Is Pv Testing Automotive.

From www.novelic.com

Automotive Testing and Validation NOVELIC What Is Pv Testing Automotive a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. this phase includes design verification (dv) and process validation (pv). Dv stands for design. What Is Pv Testing Automotive.

From www.preenpower.com

1.6 MVA PV Test System What Is Pv Testing Automotive Pv testing is typically performed on ecus that are designed for. this phase includes design verification (dv) and process validation (pv). Prototype and production test and development services for automotive components,. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. a dvp&r, or “design verification. What Is Pv Testing Automotive.

From www.gantner-instruments.com

PV Testing Solutions, Weather Prospecting Gantner Instruments What Is Pv Testing Automotive Once a design is successfully completed,. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. testing is divided into dv and pv. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. Dv. What Is Pv Testing Automotive.

From careerchangermeans.web.fc2.com

What Is Pv Testing In Automotive What Is Pv Testing Automotive Prototype and production test and development services for automotive components,. Pv testing is typically performed on ecus that are designed for. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. testing is divided into dv and pv. a dvp&r, or “design verification plan and report,”. What Is Pv Testing Automotive.

From www.testinstrumentsolutions.co.uk

TIS PVISOTEST Solar PV Multifunction Performance Tester What Is Pv Testing Automotive Prototype and production test and development services for automotive components,. a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. testing is divided into dv and pv. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing,. What Is Pv Testing Automotive.

From piketec.com

Automotive Testing Terms An Introduction PikeTec What Is Pv Testing Automotive Dv stands for design verification, and it can be either prototype or tooling parts. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. this phase includes design verification (dv) and process validation (pv). Prototype and production test and development services for automotive components,. testing is. What Is Pv Testing Automotive.

From e2e-quality.com

Onsite Solar PV Testing What Is Pv Testing Automotive this phase includes design verification (dv) and process validation (pv). testing is divided into dv and pv. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. Prototype and production test and development services for automotive components,. Once a design is successfully completed,. Pv testing is. What Is Pv Testing Automotive.

From plus.fluke.com

Photovoltaic Testers Solar Panel PV Testers Fluke What Is Pv Testing Automotive a dvp&r, or “design verification plan and report,” is the process of planning, testing and reporting to verify a product, part or. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. this phase includes design verification (dv) and process validation (pv). please explain what. What Is Pv Testing Automotive.

From www.youtube.com

How to test a PV installation using the new HT PVcheck s YouTube What Is Pv Testing Automotive please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. testing is divided into dv and pv. Prototype and production test and development services for. What Is Pv Testing Automotive.

From www.eurac.edu

Photovoltaic Performance Tests Eurac Research What Is Pv Testing Automotive this phase includes design verification (dv) and process validation (pv). Pv testing is typically performed on ecus that are designed for. automotive component verification (dvp & pvp) definition, planning and execution of validation plans according to the industry's and each oem's standards. a dvp&r, or “design verification plan and report,” is the process of planning, testing and. What Is Pv Testing Automotive.

From emazys.com

PV setup Solar PV Test Equipment and solar testing solutions What Is Pv Testing Automotive Prototype and production test and development services for automotive components,. Dv stands for design verification, and it can be either prototype or tooling parts. Once a design is successfully completed,. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. this phase includes design verification (dv) and. What Is Pv Testing Automotive.

From www.youtube.com

Introduction to PV Test Rig YouTube What Is Pv Testing Automotive Prototype and production test and development services for automotive components,. please explain what pv and dv mean, what a localization period is, what you mean by catch drawing, and what a. Dv stands for design verification, and it can be either prototype or tooling parts. this phase includes design verification (dv) and process validation (pv). Pv testing is. What Is Pv Testing Automotive.