Gage Block Deburring Stone . Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. The flatness, parallelism and surface finish necessary to. All mitutoyo gage blocks meet or exceed all known specifications. If a block does not wring together with other blocks, it may be the result of nicks. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. I can get a 15,000. The solution for wringing problems. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. If a block does not wring together with other blocks, it may be the result of nicks or other damage. Are these the same as ceramic water stones? Blocks may be checked for burrs with a gage block stone before wringing. Recommendations for a deburring stone that i can use on the gauge blocks? A gage block stone with serrated grooves is recommended.

from www.dnc-testing.com

Are these the same as ceramic water stones? A gage block stone with serrated grooves is recommended. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. The solution for wringing problems. Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. If a block does not wring together with other blocks, it may be the result of nicks or other damage. Recommendations for a deburring stone that i can use on the gauge blocks? The flatness, parallelism and surface finish necessary to. All mitutoyo gage blocks meet or exceed all known specifications.

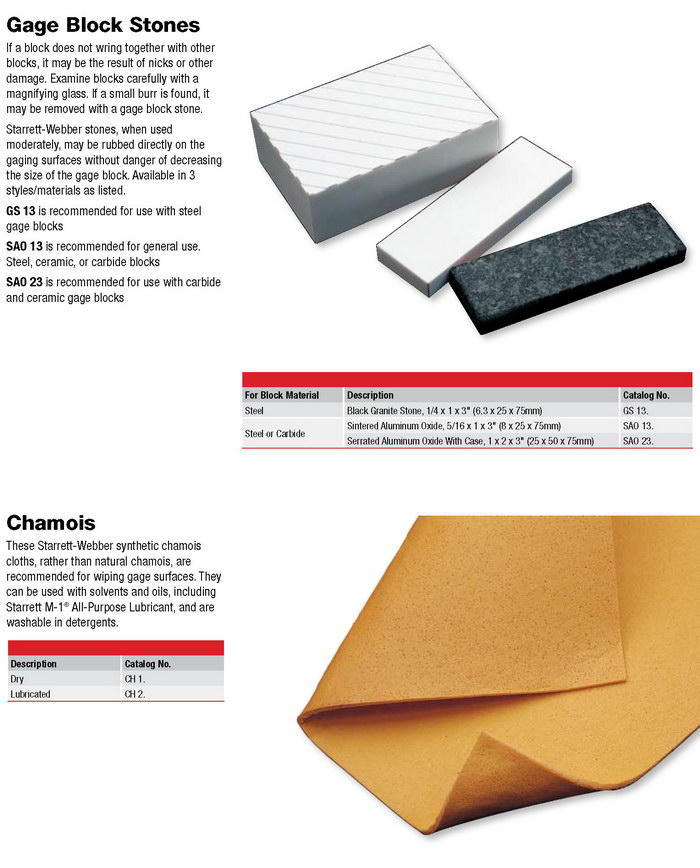

PT. Danachrist Teknindo Gage Block Stones

Gage Block Deburring Stone The flatness, parallelism and surface finish necessary to. The solution for wringing problems. I can get a 15,000. The flatness, parallelism and surface finish necessary to. All mitutoyo gage blocks meet or exceed all known specifications. If a block does not wring together with other blocks, it may be the result of nicks or other damage. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. A gage block stone with serrated grooves is recommended. Recommendations for a deburring stone that i can use on the gauge blocks? Are these the same as ceramic water stones? Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. If a block does not wring together with other blocks, it may be the result of nicks. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. Blocks may be checked for burrs with a gage block stone before wringing.

From www.amazon.ca

4Pcs Diamond Hand Polishing Pads, 60 120 200 400 Grit Diamond Sanding Gage Block Deburring Stone The solution for wringing problems. The flatness, parallelism and surface finish necessary to. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. A gage block stone with serrated grooves is recommended. If a block does not wring together with other blocks, it may be the result of nicks. If a block does. Gage Block Deburring Stone.

From www.etundra.com

Globe MCA17 Deburring Stone eTundra Gage Block Deburring Stone Recommendations for a deburring stone that i can use on the gauge blocks? All mitutoyo gage blocks meet or exceed all known specifications. Blocks may be checked for burrs with a gage block stone before wringing. A gage block stone with serrated grooves is recommended. If a block does not wring together with other blocks, it may be the result. Gage Block Deburring Stone.

From www.shorttrackspecialist.com

DMT D4 diamond deburring stone Specialist in Short Track Skating Gage Block Deburring Stone The flatness, parallelism and surface finish necessary to. Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. A gage block stone with serrated grooves is recommended. The solution for wringing problems. Recommendations for a deburring stone that i can use on the gauge blocks? I can get. Gage Block Deburring Stone.

From www.liveauctionworld.com

Fowler .1001 to 4" Precision Gage Blocks, Grade +/.000050" Gage Block Deburring Stone I can get a 15,000. The flatness, parallelism and surface finish necessary to. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. All mitutoyo gage blocks meet or exceed all known specifications. Are these the same as ceramic water stones? If a block does not wring together with other blocks, it may. Gage Block Deburring Stone.

From www.worthpoint.com

DoAll Gage Block Deburring Stone 4545312805 Gage Block Deburring Stone All mitutoyo gage blocks meet or exceed all known specifications. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. The flatness, parallelism and surface finish necessary to. Blocks may be checked for burrs with a gage block stone before wringing. A gage block stone is included for burr removal as well as. Gage Block Deburring Stone.

From www.walmart.com

Diamond Hand Pad Polishing Edging Deburring Sanding Block for Stone Gage Block Deburring Stone The solution for wringing problems. Blocks may be checked for burrs with a gage block stone before wringing. If a block does not wring together with other blocks, it may be the result of nicks or other damage. Recommendations for a deburring stone that i can use on the gauge blocks? A gage block stone with serrated grooves is recommended.. Gage Block Deburring Stone.

From www.skiequipmentuk.co.uk

Holmenkol Ski Edge Gummi StoneDeburring Block Anything Technical Gage Block Deburring Stone All mitutoyo gage blocks meet or exceed all known specifications. Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. I can get a 15,000. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. Blocks may be checked for burrs. Gage Block Deburring Stone.

From www.worthpoint.com

DoAll Gage Block Deburring Stone 4545312805 Gage Block Deburring Stone If a block does not wring together with other blocks, it may be the result of nicks or other damage. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. Recommendations for a deburring stone that i can use on the gauge blocks? If a block does not wring together. Gage Block Deburring Stone.

From sparxhockey.eu

Deburring Block Set Sparx EU Gage Block Deburring Stone A gage block stone with serrated grooves is recommended. Recommendations for a deburring stone that i can use on the gauge blocks? If a block does not wring together with other blocks, it may be the result of nicks or other damage. If a block does not wring together with other blocks, it may be the result of nicks. Blocks. Gage Block Deburring Stone.

From www.practicalmachinist.com

Cleaning gage blocks. Page 2 Gage Block Deburring Stone Are these the same as ceramic water stones? The solution for wringing problems. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. If a block does not wring together with other blocks, it may be the result of nicks or other damage. Blocks may be checked for burrs with a gage block. Gage Block Deburring Stone.

From www.worthpoint.com

DOALL Black Granite Deburring Stone For Gauge Blocks 2" x 3.5" Dressing Gage Block Deburring Stone Blocks may be checked for burrs with a gage block stone before wringing. Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. A gage block stone with serrated grooves is recommended. A gage block stone is included for burr removal as well as a 2 optical flat. Gage Block Deburring Stone.

From www.worthpoint.com

DoAll Gage Block Deburring Stone 4545312805 Gage Block Deburring Stone If a block does not wring together with other blocks, it may be the result of nicks. Blocks may be checked for burrs with a gage block stone before wringing. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. A gage block stone with serrated grooves is recommended. Are. Gage Block Deburring Stone.

From www.dnc-testing.com

PT. Danachrist Teknindo Gage Block Stones Gage Block Deburring Stone A gage block stone with serrated grooves is recommended. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. All mitutoyo gage blocks meet or exceed all known specifications. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. If a block does. Gage Block Deburring Stone.

From www.worthpoint.com

DoAll Gage Block Deburring Stone 4545312805 Gage Block Deburring Stone Blocks may be checked for burrs with a gage block stone before wringing. The solution for wringing problems. If a block does not wring together with other blocks, it may be the result of nicks. I can get a 15,000. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness.. Gage Block Deburring Stone.

From www.penntoolco.com

Precise 8 Piece Long Gage Block Set (GRADE 1) 303530 Penn Tool Co Gage Block Deburring Stone Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. All mitutoyo gage blocks meet or exceed all known specifications. The solution for wringing problems. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. Recommendations for a. Gage Block Deburring Stone.

From www.worthpoint.com

DoAll Gage Block Deburring Stone 4545312805 Gage Block Deburring Stone Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. A gage block stone with serrated grooves is recommended. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. A gage block stone is included for burr removal as well as. Gage Block Deburring Stone.

From www.practicalmachinist.com

Lapping Stone for Deburring Table Gage Block Deburring Stone If a block does not wring together with other blocks, it may be the result of nicks. Recommendations for a deburring stone that i can use on the gauge blocks? I can get a 15,000. If a block does not wring together with other blocks, it may be the result of nicks or other damage. A gage block stone with. Gage Block Deburring Stone.

From www.worthpoint.com

DOALL Black Granite Deburring Stone For Gauge Blocks 2" x 3.5" Dressing Gage Block Deburring Stone Recommendations for a deburring stone that i can use on the gauge blocks? Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. All mitutoyo gage blocks meet or exceed all known specifications. If a block does not wring together with other blocks, it may be the result. Gage Block Deburring Stone.

From www.ebay.com

Brown & Sharpe 77 Piece Rectangular Squaring Gage Block Set (100 Gage Block Deburring Stone I can get a 15,000. Blocks may be checked for burrs with a gage block stone before wringing. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or.. Gage Block Deburring Stone.

From www.knivesandtools.com

Skerper Arkansas Deburring Stone NASP01, Hard Black Arkansas Gage Block Deburring Stone Are these the same as ceramic water stones? The flatness, parallelism and surface finish necessary to. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. Recommendations for a deburring stone that i can use on the gauge blocks? If a block does not wring together with other blocks, it. Gage Block Deburring Stone.

From www.cottandco.com

Gage Block Set, 88 Blocks, Grade 1 Gage Block Deburring Stone All mitutoyo gage blocks meet or exceed all known specifications. Blocks may be checked for burrs with a gage block stone before wringing. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. A gage block stone with serrated grooves is recommended. The flatness, parallelism and surface finish necessary to. Are these the. Gage Block Deburring Stone.

From www.youtube.com

[Automated deburring] XEBEC Stone Flexible Shaft Disc Type YouTube Gage Block Deburring Stone Blocks may be checked for burrs with a gage block stone before wringing. Are these the same as ceramic water stones? A gage block stone with serrated grooves is recommended. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. Deburring the measuring faces of steel gage blocks by lightly swiping them along. Gage Block Deburring Stone.

From bullseyecalibration.com

Starrett ber (Inches) Gage Block Set 80 Pcs. Square Steel Set Gage Block Deburring Stone A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. The flatness, parallelism and surface finish necessary to. If a block does not wring together with other blocks, it may be the result of nicks. Blocks may be checked for burrs with a gage block stone before wringing. Deburring the measuring faces of. Gage Block Deburring Stone.

From www.amazon.in

Electroplated Sanding Block, 4Pcs Hand Polishing Pad Deburring Trimming Gage Block Deburring Stone All mitutoyo gage blocks meet or exceed all known specifications. A gage block stone with serrated grooves is recommended. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. Deburring the measuring faces. Gage Block Deburring Stone.

From www.practicalmachinist.com

Cleaning gage blocks. Gage Block Deburring Stone The flatness, parallelism and surface finish necessary to. A gage block stone with serrated grooves is recommended. Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. All mitutoyo gage blocks. Gage Block Deburring Stone.

From www.judgetool.com

Individual Gage Blocks Gage Blocks Judge Tool & Gage Gage Block Deburring Stone A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. A gage block stone with serrated grooves is recommended. The solution for wringing problems. All mitutoyo gage blocks meet or exceed all known specifications. Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat,. Gage Block Deburring Stone.

From www.walmart.com

Diamond Hand Pad Polishing Edging Deburring Sanding Block for Stone Gage Block Deburring Stone The solution for wringing problems. If a block does not wring together with other blocks, it may be the result of nicks or other damage. Recommendations for a deburring stone that i can use on the gauge blocks? Are these the same as ceramic water stones? If a block does not wring together with other blocks, it may be the. Gage Block Deburring Stone.

From www.urneeds.co.uk

Sirman Deburring Stone Ref 19300201 urneeds.co.uk Gage Block Deburring Stone The solution for wringing problems. A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. The flatness, parallelism and surface finish necessary to. Are these the same as ceramic water stones? Blocks may be checked for burrs with a gage block stone before wringing. If a block does not wring. Gage Block Deburring Stone.

From www.allpointsfps.com

GLOBE M092 Deburring Stone Gage Block Deburring Stone A gage block stone with serrated grooves is recommended. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. The flatness, parallelism and surface finish necessary to. Blocks may be checked for burrs with a gage block stone before wringing. If a block does not wring together with other blocks, it may be. Gage Block Deburring Stone.

From ielects.com.au

011 3343 050 Deburring Stone 12mm Hole J2000/ J3000/ J4000/ J5000 Gage Block Deburring Stone The flatness, parallelism and surface finish necessary to. A gage block stone with serrated grooves is recommended. Blocks may be checked for burrs with a gage block stone before wringing. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a protective. A gage block stone is included for burr removal as well as a. Gage Block Deburring Stone.

From www.microqualitycorp.com

Steel Grade B Individual Rectangular Gage Block Rectangular Micro Gage Block Deburring Stone The flatness, parallelism and surface finish necessary to. The solution for wringing problems. Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. Are these the same as ceramic water stones? I can get a 15,000. A chamois cloth and two ounce bottle of starrett m1 oil are. Gage Block Deburring Stone.

From www.grainger.com

GLOBE Deburring Stone C10, C12, G10, 19XL23M092 Grainger Gage Block Deburring Stone A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. All mitutoyo gage blocks meet or exceed all known specifications. I can get a 15,000. The solution for wringing problems. A gage block stone with serrated grooves is recommended. A chamois cloth and two ounce bottle of starrett m1 oil. Gage Block Deburring Stone.

From www.webstaurantstore.com

Berkel 0140082900409 Deburring Stone Gage Block Deburring Stone Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. Blocks may be checked for burrs with a gage block stone before wringing. I can get a 15,000. All mitutoyo gage blocks meet or exceed all known specifications. If a block does not wring together with other blocks,. Gage Block Deburring Stone.

From www.slideserve.com

PPT Gage Blocks PowerPoint Presentation, free download ID574331 Gage Block Deburring Stone Deburring the measuring faces of steel gage blocks by lightly swiping them along the face of a clean, flat, serrated, arkansas, or. The flatness, parallelism and surface finish necessary to. A gage block stone with serrated grooves is recommended. The solution for wringing problems. A chamois cloth and two ounce bottle of starrett m1 oil are included to apply a. Gage Block Deburring Stone.

From www.worthpoint.com

DoAll Gage Block Deburring Stone 4545312805 Gage Block Deburring Stone A gage block stone is included for burr removal as well as a 2 optical flat for checking block flatness. Are these the same as ceramic water stones? Recommendations for a deburring stone that i can use on the gauge blocks? The solution for wringing problems. A gage block stone with serrated grooves is recommended. All mitutoyo gage blocks meet. Gage Block Deburring Stone.