Spray Drying Atomization . A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. The steps of the spray drying process involve: The process of spray drying is illustrated in figure 1. Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium.

from www.mdpi.com

Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. The process of spray drying is illustrated in figure 1. Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. The steps of the spray drying process involve: A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator.

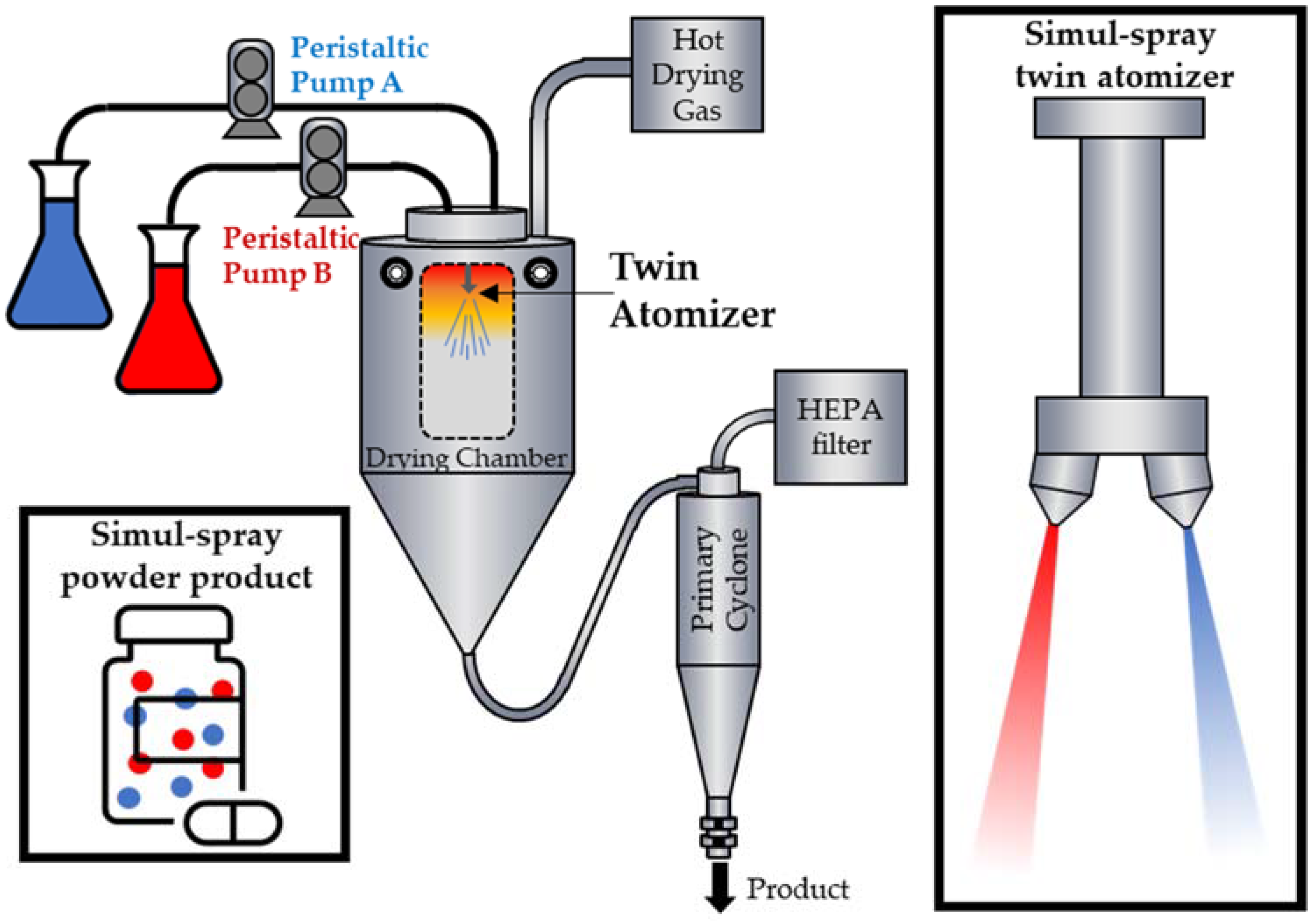

Pharmaceutics Free FullText Simultaneous Spray Drying for

Spray Drying Atomization Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. The process of spray drying is illustrated in figure 1. The steps of the spray drying process involve: Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator.

From www.researchgate.net

Picture of spraydrying device used in this experiment (Niro Atomizer Spray Drying Atomization Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. The steps of the spray drying process involve: The process of. Spray Drying Atomization.

From www.machineryoffers.com

KODI Highspeed Electric Atomizer Centrifugal Spray Dryer Atomizer Spray Drying Atomization Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying is a transformation of feed from a fluid state into a dried particulate form. Spray Drying Atomization.

From www.shachiengineering.com

Crystallization & atomiser spray dryer Shachi engineering Spray Drying Atomization Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning. Spray Drying Atomization.

From mavink.com

Spray Dryer Process Spray Drying Atomization The steps of the spray drying process involve: The process of spray drying is illustrated in figure 1. A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying. Spray Drying Atomization.

From www.researchgate.net

Schematic of spray dryer. 1nitrogen supply, 2pumps, 3atomizer and Spray Drying Atomization The process of spray drying is illustrated in figure 1. The steps of the spray drying process involve: A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al.,. Spray Drying Atomization.

From me-trading.de

Used Niro Atomizer Spray Dryer up to 650 kg/h M&E Trading Spray Drying Atomization The steps of the spray drying process involve: Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. A spray dryer consists of. Spray Drying Atomization.

From www.researchgate.net

(PDF) Spray drying A crystallization technique A review Spray Drying Atomization The process of spray drying is illustrated in figure 1. The steps of the spray drying process involve: Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying. Spray Drying Atomization.

From www.spray-dryingmachine.com

Ss304 Corn Starch Centrifugal Atomizer Spray Dryer Industrial Spray Drying Atomization Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. The steps of the spray drying process involve: The process of spray drying is illustrated in figure 1. A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for. Spray Drying Atomization.

From www.researchgate.net

Schematic of spray dryer with atomizer (left), cyclone (middle) and fan Spray Drying Atomization Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. The process of spray drying is illustrated in figure 1. A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying. Spray Drying Atomization.

From www.allfordrugs.com

Spray Drying All About Drugs Spray Drying Atomization Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying is the process of creating useful powders from a. Spray Drying Atomization.

From www.spraydrysys.com

Spray Dryer Atomization, Spray Drying. Spray Drying Atomization A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. Spray drying involves the atomization of a liquid into hot air. Spray Drying Atomization.

From www.youtube.com

Rotary atomizer for Spray Dryer YouTube Spray Drying Atomization A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. The steps of the spray drying process involve: Spray drying is. Spray Drying Atomization.

From www.spray-dryingmachine.com

SUS304 milk powder Centrifugal Atomizer Spray Dryer with steam heating Spray Drying Atomization The steps of the spray drying process involve: Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. The process of spray drying. Spray Drying Atomization.

From spraydrying.blogspot.com

spray drying ROTARY DISK ATOMIZERS Spray Drying Atomization Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. Spray drying is the process of creating useful powders from a liquid slurry. Spray Drying Atomization.

From www.indiamart.com

Steel Coated Rotary Atomizer Spray Dryers, Automation Grade Automatic Spray Drying Atomization The steps of the spray drying process involve: The process of spray drying is illustrated in figure 1. Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed. Spray Drying Atomization.

From www.researchgate.net

A schematic diagram of the Büchi Nano Spray Dryer B90 and its Spray Drying Atomization Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. The process of spray drying is illustrated in figure 1. Spray drying. Spray Drying Atomization.

From dedert.com

Spray Drying Dryer Types, Advantages and Applications Spray Drying Atomization Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. The process of spray drying is illustrated in figure 1. Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. Spray. Spray Drying Atomization.

From www.industrial-dryer.com

Secadora JiangSu Xiandao Spray Drying Atomization Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying is a transformation of feed from a fluid state into a dried. Spray Drying Atomization.

From www.shpilotech.com

Principle and application of lab spray dryer different kinds lab Spray Drying Atomization The steps of the spray drying process involve: Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying is a transformation of. Spray Drying Atomization.

From www.pharmaceuticalmachineryequipment.com

750mm H2O Rotary Atomizer 670L Spray Drying Equipment Spray Drying Atomization Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. The steps of the spray drying process involve: A spray dryer consists of. Spray Drying Atomization.

From www.researchgate.net

Typical spray dryer atomizer designs Download Scientific Diagram Spray Drying Atomization Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying is the process of converting a solution, suspension or emulsion into dried. Spray Drying Atomization.

From www.industrial-dryers.com

Pressure Atomizer Spray Drying Machine JiangSu Xiandao Spray Drying Atomization Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. The process of spray drying is illustrated in figure 1. A spray dryer. Spray Drying Atomization.

From www.pharmaceuticalmachineryequipment.com

Atomizer Centrifugal Spray Pharmaceutical Dryers Liquid Sprying Drying Spray Drying Atomization Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. The process of spray drying is illustrated in figure 1. The steps of the. Spray Drying Atomization.

From www.doingmachine.com

LPG Industrial Centrifugal Atomizer Spray Dryer Buy industrial spray Spray Drying Atomization A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying is a transformation of feed from a fluid state into a dried. Spray Drying Atomization.

From powder-equipment.en.made-in-china.com

Herb and Plant Extract Centrifugal Atomization Spray Drying Dryer Spray Drying Atomization A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying is a transformation of feed from a fluid state into a dried. Spray Drying Atomization.

From www.researchgate.net

Schematic diagram of the atomization and sprayfreezedrying process Spray Drying Atomization Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. The process of spray drying is illustrated in figure 1. Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. Spray drying is a. Spray Drying Atomization.

From drug-dev.com

SPRAYDRIED DISPERSIONS Efficient ScaleUp Strategy for SprayDried Spray Drying Atomization Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. The steps of the spray drying process involve: A spray dryer. Spray Drying Atomization.

From techniprocessgroup.com

Spray Dryer Atomization Systems Techni Process Group Spray Drying Atomization Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. The steps of the spray drying process involve: A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying involves the atomization of. Spray Drying Atomization.

From www.fasska.com

Process Spray Drying Atomization The process of spray drying is illustrated in figure 1. Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. The steps of the. Spray Drying Atomization.

From www.scientistlive.com

Spray drying with a three channel nozzle Scientist Live Spray Drying Atomization Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying involves the atomization of a liquid into hot air chamber to. Spray Drying Atomization.

From ar.inspiredpencil.com

Water Rotary Atomizers Spray Drying Atomization A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. The process of spray drying is illustrated in figure 1. Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying is the. Spray Drying Atomization.

From www.mdpi.com

Pharmaceutics Free FullText Simultaneous Spray Drying for Spray Drying Atomization Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. The steps of the spray drying process involve: A spray dryer. Spray Drying Atomization.

From www.researchgate.net

A typical opencycle spray dryer showing the key stages of atomization Spray Drying Atomization Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying is the process of converting a solution, suspension or emulsion into dried powder in a single step by passing an. A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and. Spray Drying Atomization.

From powder-equipment.en.made-in-china.com

Lithium Anode Phosphate Graphene Centrifugal Atomization Spray Drying Spray Drying Atomization Spray drying involves the atomization of a liquid into hot air chamber to remove water (henning et al., 2006) and often includes preliminary heat. Spray drying is a transformation of feed from a fluid state into a dried particulate form by spraying the feed into a hot drying medium. The process of spray drying is illustrated in figure 1. The. Spray Drying Atomization.

From www.researchgate.net

Detailed illustration of a spray drying process. (1) Atomization, (2 Spray Drying Atomization A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. Spray drying is the process of creating useful powders from a liquid slurry for a vast variety of industry including food, flavors,. Spray drying involves the atomization of a liquid into hot air chamber to remove. Spray Drying Atomization.