Casting Defects In Green Sand Moulding . By the end of the module, you will be able to identify one shrinkage defect, one gas. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. You will find the cause behind each. Here we introduce 5 major types of sand casting defects commonly see in metalworking. Terms such as slag defect and cold shut are part of the defect process. This module describes the causes of common green sand defects. Yes, you’ll decrease your sand related casting defects. Foundry personnel can be quick to label a defect cause based on a cursory examination. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a greenish hue and earning its name. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot.

from thors.com

Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. Here we introduce 5 major types of sand casting defects commonly see in metalworking. This module describes the causes of common green sand defects. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. You will find the cause behind each. Terms such as slag defect and cold shut are part of the defect process. Foundry personnel can be quick to label a defect cause based on a cursory examination. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. By the end of the module, you will be able to identify one shrinkage defect, one gas.

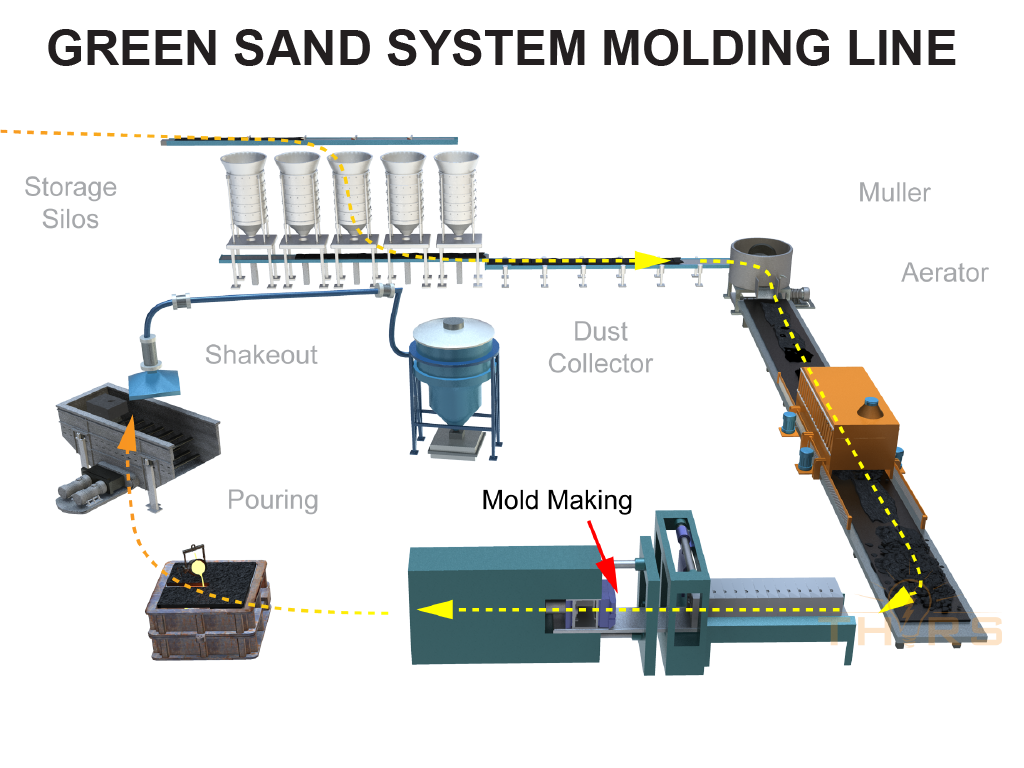

What Equipment and Systems Are Used in a Green Sand Foundry?

Casting Defects In Green Sand Moulding By the end of the module, you will be able to identify one shrinkage defect, one gas. This module describes the causes of common green sand defects. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a greenish hue and earning its name. You will find the cause behind each. Here we introduce 5 major types of sand casting defects commonly see in metalworking. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. Foundry personnel can be quick to label a defect cause based on a cursory examination. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. Terms such as slag defect and cold shut are part of the defect process. By the end of the module, you will be able to identify one shrinkage defect, one gas. Yes, you’ll decrease your sand related casting defects. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations.

From www.andersonglobal.com

Sand Casting Patterns Anderson Global Casting Defects In Green Sand Moulding You will find the cause behind each. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. By the end of the module, you will be able to identify one shrinkage defect, one gas. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns,. Casting Defects In Green Sand Moulding.

From www.scribd.com

Control of Green Sand Moulding Casting Technology PDF Casting Defects In Green Sand Moulding Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a greenish hue and earning its name. Yes, you’ll decrease your sand related casting defects. Terms such as slag defect and cold. Casting Defects In Green Sand Moulding.

From www.pentzcastsolutions.com

Automated Green Sand Molding Green Sand Casting Molds Casting Defects In Green Sand Moulding Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. Here we introduce 5 major types of sand casting defects commonly see in metalworking. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a greenish hue and earning its name. By the. Casting Defects In Green Sand Moulding.

From monroeengineering.com

The 6Step Process of Sand Casting Molding OneMonroe Casting Defects In Green Sand Moulding Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. It involves the creation. Casting Defects In Green Sand Moulding.

From www.disagroup.com

Matchplate moulding for green sand casting explained Casting Defects In Green Sand Moulding However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. This module describes the causes of common green sand defects. Terms such as slag defect and cold shut are part of the defect process. Yes, you’ll decrease your sand related casting defects. Green sand moulding is a traditional and widely. Casting Defects In Green Sand Moulding.

From www.zhycasting.com

Control measures of sand sticking on the surface of cylinder block castings ZHY Casting Casting Defects In Green Sand Moulding Foundry personnel can be quick to label a defect cause based on a cursory examination. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. You will find the cause behind each. Yes, you’ll decrease your sand related casting defects. It involves the creation of moulds using a mixture of silica sand,. Casting Defects In Green Sand Moulding.

From marinerspointpro.com

Green Sand Moulding Complete Process & Methods Marinerspoint Pro Casting Defects In Green Sand Moulding Here we introduce 5 major types of sand casting defects commonly see in metalworking. You will find the cause behind each. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. Foundry personnel can be quick to label a defect cause based on a cursory examination. Green sand moulding is. Casting Defects In Green Sand Moulding.

From justinfozone.blogspot.com

Sand Casting Defects Informational Encyclopedia Casting Defects In Green Sand Moulding By the end of the module, you will be able to identify one shrinkage defect, one gas. Terms such as slag defect and cold shut are part of the defect process. You will find the cause behind each. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. Foundry personnel can. Casting Defects In Green Sand Moulding.

From jp.pinterest.com

Different Types of Casting Defects Their Causes and Remedies It cast, Machining metal Casting Defects In Green Sand Moulding Terms such as slag defect and cold shut are part of the defect process. Foundry personnel can be quick to label a defect cause based on a cursory examination. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. By the end of the module, you will be able to identify. Casting Defects In Green Sand Moulding.

From www.youtube.com

Green Sand Systems Defects App Demo YouTube Casting Defects In Green Sand Moulding By the end of the module, you will be able to identify one shrinkage defect, one gas. Yes, you’ll decrease your sand related casting defects. This module describes the causes of common green sand defects. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. Here we introduce 5 major. Casting Defects In Green Sand Moulding.

From www.zhycasting.com

Scab defect of grey cast iron engine block by green sand casting ZHY Casting Casting Defects In Green Sand Moulding You will find the cause behind each. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. This module describes the causes of common green sand defects. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. It involves the creation. Casting Defects In Green Sand Moulding.

From www.zhycasting.com

Analysis of casting sand mold defects ZHY Casting Casting Defects In Green Sand Moulding By the end of the module, you will be able to identify one shrinkage defect, one gas. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. Foundry personnel can be quick to label a defect cause based on a cursory examination. It involves the creation of moulds using a mixture. Casting Defects In Green Sand Moulding.

From vietnamcastiron.com

Green sand casting How to apply on foundry casting parts processes Casting Defects In Green Sand Moulding Yes, you’ll decrease your sand related casting defects. You will find the cause behind each. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a greenish hue and earning its name. Foundry personnel can be quick to label a defect cause based on a cursory examination. Here we introduce 5. Casting Defects In Green Sand Moulding.

From learnmech.com

Green sand moulding Steps , Advantages and Disadvantages Casting Defects In Green Sand Moulding Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. By the end of the module, you will be able to identify one shrinkage defect, one gas. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. Here we introduce 5 major types. Casting Defects In Green Sand Moulding.

From www.youtube.com

Bench Moulding, Floor Moulding, Pit Moulding, Green Sand, Dry Sand, Loam Sand Moulding Process Casting Defects In Green Sand Moulding Yes, you’ll decrease your sand related casting defects. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. This module describes the causes of common green sand defects. By the end of the. Casting Defects In Green Sand Moulding.

From www.scribd.com

Casting Defects Sand Mold, Metal Casting PDF Casting (Metalworking) Foundry Casting Defects In Green Sand Moulding However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. You will find the cause behind each. Yes, you’ll decrease your sand related casting defects. By the end of the module, you. Casting Defects In Green Sand Moulding.

From www.mdpi.com

Metals Free FullText Casting Defects in SandMold Cast Irons—An Illustrated Review with Casting Defects In Green Sand Moulding This module describes the causes of common green sand defects. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. Here we introduce 5 major types of sand casting defects commonly see in metalworking. Yes, you’ll decrease your sand related casting defects. Green sand moulding is a traditional and widely used foundry. Casting Defects In Green Sand Moulding.

From learnmech.com

Green sand moulding Steps , Advantages and Disadvantages Casting Defects In Green Sand Moulding However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. Here we introduce 5 major types of sand casting defects commonly see in metalworking. You will find the cause behind each. Terms such as slag defect and cold shut are part of the defect process. By the end of the. Casting Defects In Green Sand Moulding.

From www.solutionsfonderie.com

Test and control green sand properties in realtime Solutions Fonderie Casting Defects In Green Sand Moulding Terms such as slag defect and cold shut are part of the defect process. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a greenish hue and earning its name. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. Green. Casting Defects In Green Sand Moulding.

From www.iqsdirectory.com

Sand Casting Construction, Types, Applications, and Advantages Casting Defects In Green Sand Moulding Foundry personnel can be quick to label a defect cause based on a cursory examination. You will find the cause behind each. Yes, you’ll decrease your sand related casting defects. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. It involves the creation of moulds using a mixture of silica sand,. Casting Defects In Green Sand Moulding.

From www.zen-young.com

Six Common Causes of Defects in Wet Casting (Part 1) Casting Defects In Green Sand Moulding Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a greenish hue and earning its name. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green. Casting Defects In Green Sand Moulding.

From www.researchgate.net

(PDF) Casting Defects in SandMold Cast Irons—An Illustrated Review with Emphasis on Spheroidal Casting Defects In Green Sand Moulding You will find the cause behind each. This module describes the causes of common green sand defects. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. It involves the creation of moulds. Casting Defects In Green Sand Moulding.

From www.mechanicalbooster.com

What is Casting Defects Types, Causes and Remedies? Mechanical Booster Casting Defects In Green Sand Moulding However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. You will find the cause behind each. By the end of the module, you will be able to identify one shrinkage defect, one gas. This module describes the causes of common green sand defects. Green sand moulding is a traditional. Casting Defects In Green Sand Moulding.

From www.steel-foundry.com

Description, Reasons and Remedies of Common Sand Casting Defects Investment Casting Company Casting Defects In Green Sand Moulding You will find the cause behind each. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. Terms such as slag defect and cold shut are part of the defect process. Here we introduce 5 major types of sand casting defects commonly see in metalworking. This module describes the causes of. Casting Defects In Green Sand Moulding.

From www.youtube.com

Making a green sand mold Casting 2 YouTube Casting Defects In Green Sand Moulding It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a greenish hue and earning its name. Foundry personnel can be quick to label a defect cause based on a cursory examination. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot.. Casting Defects In Green Sand Moulding.

From tacitceiyrs.blogspot.com

Sand Casting Process tacitceiyrs Casting Defects In Green Sand Moulding Foundry personnel can be quick to label a defect cause based on a cursory examination. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. By the end of the module, you will be able to identify one shrinkage defect, one gas. Yes, you’ll decrease your sand related casting defects. You will. Casting Defects In Green Sand Moulding.

From thors.com

Green Sand Defect Analysis Course Casting Defects In Green Sand Moulding Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a greenish hue and earning its name. You will find the cause behind each. Foundry personnel can be quick to label a defect. Casting Defects In Green Sand Moulding.

From thors.com

What Equipment and Systems Are Used in a Green Sand Foundry? Casting Defects In Green Sand Moulding Yes, you’ll decrease your sand related casting defects. This module describes the causes of common green sand defects. Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. Foundry personnel can be quick to label a defect cause based on a cursory examination. However, without a sand cooler , you’ll have. Casting Defects In Green Sand Moulding.

From www.mechgrace.com

Study Green Sand Moulding Green Sand Casting Application Mechgrace Casting Defects In Green Sand Moulding Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. Here we introduce 5 major types of sand casting defects commonly see in metalworking. Foundry personnel can be quick to label a defect cause based on a cursory examination. However, without a sand cooler , you’ll have a hard time controlling. Casting Defects In Green Sand Moulding.

From www.improprecision.com

Green Sand vs. Resin Sand Casting Impro Casting Defects In Green Sand Moulding Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. You will find the cause behind each. Terms such as slag defect and cold shut are part of the defect process. Here we introduce 5 major types of sand casting defects commonly see in metalworking. It involves the creation of moulds. Casting Defects In Green Sand Moulding.

From www.amazon.com

EFFECTS OF MOULDING SAND IN SAND MOULD CASTING AND IT’S DEFECT FINDING Casting Defects In Green Sand Moulding This module describes the causes of common green sand defects. You will find the cause behind each. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. Here we introduce 5 major. Casting Defects In Green Sand Moulding.

From www.zhycasting.com

Analysis of common problems in sand casting ZHY Casting Casting Defects In Green Sand Moulding Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. Foundry personnel can be quick to label a defect cause based on a cursory examination. Yes, you’ll decrease your sand related. Casting Defects In Green Sand Moulding.

From www.academia.edu

(PDF) It is time to play name that green sand casting defect Gustavo Bretz Academia.edu Casting Defects In Green Sand Moulding Learn about probable causes and suggested remedies of various casting defects such as blow holes, shrinkage, porosity, misruns, hot. You will find the cause behind each. By the end of the module, you will be able to identify one shrinkage defect, one gas. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties. Casting Defects In Green Sand Moulding.

From vietnamcastiron.com

5 types of Sand casting defects and how to prevent to improve cast quality Casting Defects In Green Sand Moulding Foundry personnel can be quick to label a defect cause based on a cursory examination. However, without a sand cooler , you’ll have a hard time controlling and stabilizing green sand properties ( believe our. This module describes the causes of common green sand defects. Green sand moulding is a traditional and widely used foundry process that forms the backbone. Casting Defects In Green Sand Moulding.

From www.bd-machinery.com

Introducing Green Sand Casting 2023 Casting Defects In Green Sand Moulding It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a greenish hue and earning its name. Chokkalingam and nazirudeen [17] demonstrated a systematic procedure to identify and analyze a significant casting defect, mold crush,. Green sand moulding is a traditional and widely used foundry process that forms the backbone of. Casting Defects In Green Sand Moulding.