In What Condition Is Brazing Preferred To Soft Soldering . The main difference between these two metal joining techniques is the temperature at which they are conducted. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. Brazing/soldering is a method of joining without melting the base materials. This method is broadly divided. Brazing involves heating the filler metal to temperatures above. Nor can they, as a rule, produce joints that offer resistance to temperatures above 200°f (93°c). Soldering and brazing can be used to join metals that are difficult to weld together, such as copper, brass, aluminum, and stainless steel. Brazed joints have a zonal structure. Let’s take a look at these two processes, and see how they compare. Instead, it uses a filler material (brazing paste or soft filler material i.e. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined.

from www.cruxweld.com

In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. Brazing involves heating the filler metal to temperatures above. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Nor can they, as a rule, produce joints that offer resistance to temperatures above 200°f (93°c). The main difference between these two metal joining techniques is the temperature at which they are conducted. Brazed joints have a zonal structure. Let’s take a look at these two processes, and see how they compare. This method is broadly divided. Soldering and brazing can be used to join metals that are difficult to weld together, such as copper, brass, aluminum, and stainless steel.

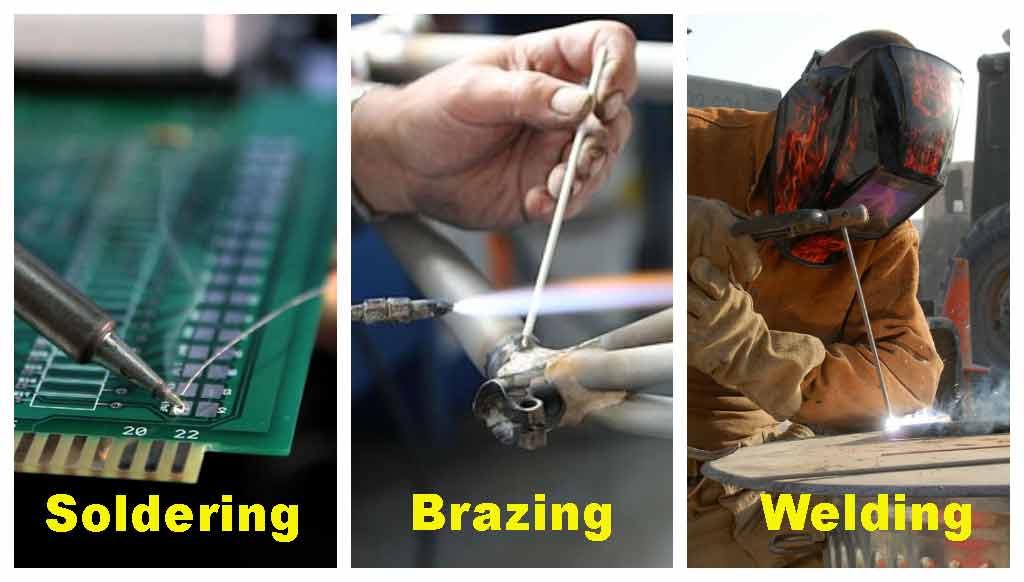

The Difference between Soldering and Brazing with Welding [The

In What Condition Is Brazing Preferred To Soft Soldering Nor can they, as a rule, produce joints that offer resistance to temperatures above 200°f (93°c). Brazing involves heating the filler metal to temperatures above. Brazing/soldering is a method of joining without melting the base materials. Nor can they, as a rule, produce joints that offer resistance to temperatures above 200°f (93°c). Instead, it uses a filler material (brazing paste or soft filler material i.e. Brazed joints have a zonal structure. The main difference between these two metal joining techniques is the temperature at which they are conducted. In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. This method is broadly divided. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. Let’s take a look at these two processes, and see how they compare. Soldering and brazing can be used to join metals that are difficult to weld together, such as copper, brass, aluminum, and stainless steel.

From www.amazon.com

DONGLIANG Welding rods 50pcs Aluminum Welding Electrodes In What Condition Is Brazing Preferred To Soft Soldering Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. The main difference between these two metal joining techniques is the temperature at which they are conducted. Soldering and brazing can be used to join metals that are difficult to weld together, such as. In What Condition Is Brazing Preferred To Soft Soldering.

From forum.heatinghelp.com

soldering vs brazing of ac unit — Heating Help The Wall In What Condition Is Brazing Preferred To Soft Soldering Soldering and brazing can be used to join metals that are difficult to weld together, such as copper, brass, aluminum, and stainless steel. Brazing involves heating the filler metal to temperatures above. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Let’s take a look at these two processes, and see how. In What Condition Is Brazing Preferred To Soft Soldering.

From mechathon.com

Soldering vs Brazing; Its Process, Advantages, Disadvantages In What Condition Is Brazing Preferred To Soft Soldering Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. This method is broadly divided. The main difference between these two metal joining techniques is the temperature at which they are conducted. In brazing and soldering, soldering is the joining method that uses filler. In What Condition Is Brazing Preferred To Soft Soldering.

From www.youtube.com

SOLDERING ,BRAZING AND BRAZE WELDING YouTube In What Condition Is Brazing Preferred To Soft Soldering Brazing involves heating the filler metal to temperatures above. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. This method is broadly divided. Instead, it uses a filler material (brazing paste or soft filler material i.e. Let’s take a look at these two. In What Condition Is Brazing Preferred To Soft Soldering.

From www.youtube.com

Welding, brazing and soldering differences. Braze vs. Weld. Beginner In What Condition Is Brazing Preferred To Soft Soldering Brazing involves heating the filler metal to temperatures above. Nor can they, as a rule, produce joints that offer resistance to temperatures above 200°f (93°c). Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Brazed joints have a zonal structure. Instead, it uses a filler material (brazing paste or soft filler material. In What Condition Is Brazing Preferred To Soft Soldering.

From hxekyhvsa.blob.core.windows.net

Brazing Definition Chemistry at Todd Hernandez blog In What Condition Is Brazing Preferred To Soft Soldering Soldering and brazing can be used to join metals that are difficult to weld together, such as copper, brass, aluminum, and stainless steel. This method is broadly divided. Brazed joints have a zonal structure. In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. Brazing/soldering is a method of joining without melting. In What Condition Is Brazing Preferred To Soft Soldering.

From www.expondo.ie

Brazing and soft soldering practical examples expondo.co.uk In What Condition Is Brazing Preferred To Soft Soldering Brazed joints have a zonal structure. Nor can they, as a rule, produce joints that offer resistance to temperatures above 200°f (93°c). Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Instead, it uses a filler material (brazing paste or soft filler material i.e. In brazing and soldering, soldering is the joining. In What Condition Is Brazing Preferred To Soft Soldering.

From www.youtube.com

An Awesome Alternative To Brazing HVAC Lines. Staybrite 8 Soft Solder In What Condition Is Brazing Preferred To Soft Soldering Brazed joints have a zonal structure. Let’s take a look at these two processes, and see how they compare. Soldering and brazing can be used to join metals that are difficult to weld together, such as copper, brass, aluminum, and stainless steel. Brazing involves heating the filler metal to temperatures above. Brazing/soldering is a method of joining without melting the. In What Condition Is Brazing Preferred To Soft Soldering.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The In What Condition Is Brazing Preferred To Soft Soldering The main difference between these two metal joining techniques is the temperature at which they are conducted. Nor can they, as a rule, produce joints that offer resistance to temperatures above 200°f (93°c). Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Let’s take a look at these two processes, and see. In What Condition Is Brazing Preferred To Soft Soldering.

From www.contractormag.com

Common Brazing Mistakes and How to Avoid Them Contractor In What Condition Is Brazing Preferred To Soft Soldering Brazing/soldering is a method of joining without melting the base materials. Brazing involves heating the filler metal to temperatures above. Let’s take a look at these two processes, and see how they compare. Brazed joints have a zonal structure. Instead, it uses a filler material (brazing paste or soft filler material i.e. Brazing and soldering are in essence very similar. In What Condition Is Brazing Preferred To Soft Soldering.

From www.theengineerspost.com

Difference Between Brazing and Soldering [Guide with PDF] In What Condition Is Brazing Preferred To Soft Soldering Brazing involves heating the filler metal to temperatures above. Brazing/soldering is a method of joining without melting the base materials. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. Soldering and brazing can be used to join metals that are difficult to weld. In What Condition Is Brazing Preferred To Soft Soldering.

From exouthzlp.blob.core.windows.net

Copper Brazing Wire at Salvador Lane blog In What Condition Is Brazing Preferred To Soft Soldering Brazed joints have a zonal structure. Instead, it uses a filler material (brazing paste or soft filler material i.e. Brazing/soldering is a method of joining without melting the base materials. This method is broadly divided. The main difference between these two metal joining techniques is the temperature at which they are conducted. Let’s take a look at these two processes,. In What Condition Is Brazing Preferred To Soft Soldering.

From www.youtube.com

Weld Braze Solder How to Join Metals? What is Welding Brazing In What Condition Is Brazing Preferred To Soft Soldering Brazed joints have a zonal structure. Brazing/soldering is a method of joining without melting the base materials. Instead, it uses a filler material (brazing paste or soft filler material i.e. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Nor can they, as a rule, produce joints that offer resistance to temperatures. In What Condition Is Brazing Preferred To Soft Soldering.

From www.youtube.com

Brazing v.s. Soft Solder YouTube In What Condition Is Brazing Preferred To Soft Soldering Soldering and brazing can be used to join metals that are difficult to weld together, such as copper, brass, aluminum, and stainless steel. The main difference between these two metal joining techniques is the temperature at which they are conducted. In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. Brazing involves. In What Condition Is Brazing Preferred To Soft Soldering.

From pediaa.com

Difference Between Soldering and Brazing In What Condition Is Brazing Preferred To Soft Soldering Instead, it uses a filler material (brazing paste or soft filler material i.e. In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. This method is broadly divided. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Brazed joints have a zonal structure. Soldering. In What Condition Is Brazing Preferred To Soft Soldering.

From www.iowalum.com

What is Soldering? Three types of soldering methods In What Condition Is Brazing Preferred To Soft Soldering Brazing/soldering is a method of joining without melting the base materials. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. Instead, it uses a filler material (brazing paste or soft filler material i.e. In brazing and soldering, soldering is the joining method that. In What Condition Is Brazing Preferred To Soft Soldering.

From www.youtube.com

Differences between Soldering and Brazing. YouTube In What Condition Is Brazing Preferred To Soft Soldering Soldering and brazing can be used to join metals that are difficult to weld together, such as copper, brass, aluminum, and stainless steel. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. Instead, it uses a filler material (brazing paste or soft filler. In What Condition Is Brazing Preferred To Soft Soldering.

From weldbits.com

Brazing VS Soldering VS Welding What’s The Difference? In What Condition Is Brazing Preferred To Soft Soldering Instead, it uses a filler material (brazing paste or soft filler material i.e. The main difference between these two metal joining techniques is the temperature at which they are conducted. Brazed joints have a zonal structure. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Brazing/soldering is a method of joining without. In What Condition Is Brazing Preferred To Soft Soldering.

From www.slideserve.com

PPT Soldering, Brazing and Braze Welding PowerPoint Presentation In What Condition Is Brazing Preferred To Soft Soldering This method is broadly divided. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. The main difference between these two metal joining techniques is the temperature at which they are conducted. In brazing and soldering, soldering is the joining method that uses filler. In What Condition Is Brazing Preferred To Soft Soldering.

From www.weldingtipsandtricks.com

Silver Brazing In What Condition Is Brazing Preferred To Soft Soldering Nor can they, as a rule, produce joints that offer resistance to temperatures above 200°f (93°c). Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. Instead, it uses a filler material (brazing paste or. In What Condition Is Brazing Preferred To Soft Soldering.

From www.youtube.com

What´s the Difference between Soldering and Welding? Soldering vs In What Condition Is Brazing Preferred To Soft Soldering Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. Brazing involves heating the filler metal to temperatures above. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Brazed joints have a zonal structure. This method. In What Condition Is Brazing Preferred To Soft Soldering.

From www.theengineerspost.com

Difference Between Brazing and Soldering [Guide with PDF] In What Condition Is Brazing Preferred To Soft Soldering Nor can they, as a rule, produce joints that offer resistance to temperatures above 200°f (93°c). Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Brazed joints have a zonal structure. This method is broadly divided. Let’s take a look at these two processes, and see how they compare. Instead, it uses. In What Condition Is Brazing Preferred To Soft Soldering.

From engineeringlearner.com

Types of Brazing Definition, Principle, Applications, Advantages In What Condition Is Brazing Preferred To Soft Soldering Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Soldering and brazing can be used to join metals that are difficult to weld together, such as. In What Condition Is Brazing Preferred To Soft Soldering.

From exogxeodb.blob.core.windows.net

Welding Soldering And Brazing Workers Salary at Debbie Bilyeu blog In What Condition Is Brazing Preferred To Soft Soldering Nor can they, as a rule, produce joints that offer resistance to temperatures above 200°f (93°c). Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. Brazing involves heating the filler metal to temperatures above. This method is broadly divided. Soldering is a joining. In What Condition Is Brazing Preferred To Soft Soldering.

From www.fullagartech.com

What are the different methods of brazing? TWI In What Condition Is Brazing Preferred To Soft Soldering Brazing/soldering is a method of joining without melting the base materials. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Brazing involves heating the filler metal to temperatures above. Brazed joints have a zonal structure. In brazing and soldering, soldering is the joining method that uses filler materials with a low melting. In What Condition Is Brazing Preferred To Soft Soldering.

From giokqsgey.blob.core.windows.net

Solder La Definition at Ora Mendez blog In What Condition Is Brazing Preferred To Soft Soldering Brazed joints have a zonal structure. In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. Brazing/soldering is a method of joining without melting the base materials. Let’s take a look at these two processes, and see how they compare. Instead, it uses a filler material (brazing paste or soft filler material. In What Condition Is Brazing Preferred To Soft Soldering.

From www.bbc.co.uk

Joining methods Metals Eduqas GCSE Design and Technology Revision In What Condition Is Brazing Preferred To Soft Soldering In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. The main difference between these two metal joining techniques is the temperature at which they are conducted. This method is broadly divided. Instead, it uses a filler material (brazing paste or soft filler material i.e. Brazing and soldering are in essence very. In What Condition Is Brazing Preferred To Soft Soldering.

From blog.thepipingmart.com

Brazing vs Soldering Copper What's the Difference In What Condition Is Brazing Preferred To Soft Soldering Brazed joints have a zonal structure. In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. This method is broadly divided. Soldering and brazing can be. In What Condition Is Brazing Preferred To Soft Soldering.

From blog.thepipingmart.com

Brazing vs Silver Soldering What's the Difference In What Condition Is Brazing Preferred To Soft Soldering Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Brazing involves heating the filler metal to temperatures above. Let’s take a look at these two processes, and see how they compare. Instead, it uses a filler material (brazing paste or soft filler material i.e. Brazing and soldering are in essence very similar. In What Condition Is Brazing Preferred To Soft Soldering.

From shopee.com.my

Aluminium Flux Welding Soldering Brazing Flux Powder for Low In What Condition Is Brazing Preferred To Soft Soldering Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. Brazing involves heating the filler metal to temperatures above. The main difference between these two metal joining. In What Condition Is Brazing Preferred To Soft Soldering.

From www.amgmetalmecanica.com

Soldadura Brazing ¿Qué es? AMG MetalMecánica In What Condition Is Brazing Preferred To Soft Soldering Let’s take a look at these two processes, and see how they compare. In brazing and soldering, soldering is the joining method that uses filler materials with a low melting point. Brazing/soldering is a method of joining without melting the base materials. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is. In What Condition Is Brazing Preferred To Soft Soldering.

From www.pinterest.com

7 Main differences between brazing and soldering (Simplified) Brazing In What Condition Is Brazing Preferred To Soft Soldering Brazed joints have a zonal structure. Let’s take a look at these two processes, and see how they compare. Brazing/soldering is a method of joining without melting the base materials. Brazing and soldering are in essence very similar in that a filler metal (the braze or solder) is melted between the two components to be joined. Soldering and brazing can. In What Condition Is Brazing Preferred To Soft Soldering.

From www.youtube.com

Ditch Brazing. Learn To Use Staybrite 8 Soft Solder For HVAC Copper In What Condition Is Brazing Preferred To Soft Soldering Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Brazed joints have a zonal structure. Brazing/soldering is a method of joining without melting the base materials. Let’s take a look at these two processes, and see how they compare. Brazing involves heating the filler metal to temperatures above. This method is broadly. In What Condition Is Brazing Preferred To Soft Soldering.

From cnzengo.en.made-in-china.com

Warehouse Welding Soft Solder Paste Brazing Flux for Welding Work In What Condition Is Brazing Preferred To Soft Soldering This method is broadly divided. Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Soldering and brazing can be used to join metals that are difficult to weld together, such as copper, brass, aluminum, and stainless steel. The main difference between these two metal joining techniques is the temperature at which they. In What Condition Is Brazing Preferred To Soft Soldering.

From www.mingledorffs.com

Soldering, Brazing, and Welding Mingledorff's In What Condition Is Brazing Preferred To Soft Soldering Soldering is a joining process in which the filler metal melts completely below 450c (840f), whereas brazing. Brazing/soldering is a method of joining without melting the base materials. Let’s take a look at these two processes, and see how they compare. Instead, it uses a filler material (brazing paste or soft filler material i.e. In brazing and soldering, soldering is. In What Condition Is Brazing Preferred To Soft Soldering.