Clamping Unit Meaning . In this post, you'll learn what an injection molding. A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. An injection molding machine relies heavily on its clamping unit to ensure quality and precision. The clamping unit’s primary function is to hold the mold halves together during the injection process. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. What is injection molding clamping unit? Once the plastic is injected.

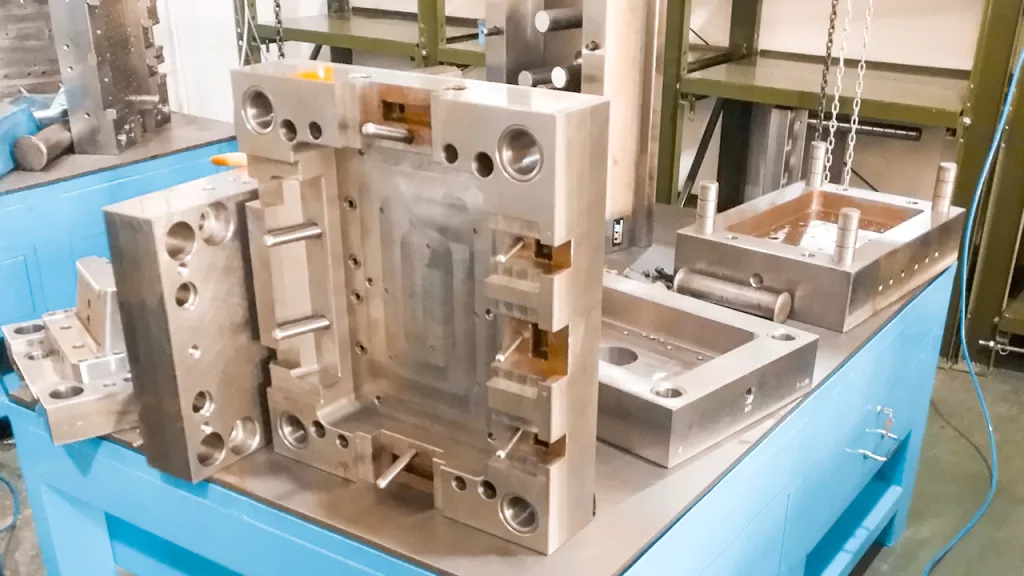

from prototool.com

In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. Once the plastic is injected. An injection molding machine relies heavily on its clamping unit to ensure quality and precision. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. The clamping unit’s primary function is to hold the mold halves together during the injection process. A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. What is injection molding clamping unit? A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. In this post, you'll learn what an injection molding.

Understanding the Clamping Unit in an Injection Molding Machine

Clamping Unit Meaning The clamping unit’s primary function is to hold the mold halves together during the injection process. A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. What is injection molding clamping unit? An injection molding machine relies heavily on its clamping unit to ensure quality and precision. The clamping unit’s primary function is to hold the mold halves together during the injection process. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. In this post, you'll learn what an injection molding. A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. Once the plastic is injected.

From www.youtube.com

Clamping System in Injection Moulding Machine, Toggle clamping Clamping Unit Meaning A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. In this post, you'll learn what an injection molding. Once the plastic is injected. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. A clamping unit. Clamping Unit Meaning.

From inchbyinch.de

INCH Technical English clamping devices Clamping Unit Meaning A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. Once the plastic is injected. What is injection molding clamping unit? An injection molding machine relies heavily on its clamping unit to ensure quality and precision. A clamping unit for an imm is used to keep the. Clamping Unit Meaning.

From www.thorlabs.com

Controlling the Holding Force of a Clamping Fork via Screw Position Clamping Unit Meaning Once the plastic is injected. A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. The clamping unit’s primary function is to hold the mold halves. Clamping Unit Meaning.

From polymeracademy.com

CLAMPING SYSTEM OF INJECTION MOULDING Clamping Unit Meaning Once the plastic is injected. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. What is injection molding clamping unit? A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. In this post, you'll learn what. Clamping Unit Meaning.

From biwfixture.com

CLAMP UNIT BIW FIXTURE DESIGN Clamping Unit Meaning An injection molding machine relies heavily on its clamping unit to ensure quality and precision. In this post, you'll learn what an injection molding. A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. The clamping units are used to keep the mold shut against the forces. Clamping Unit Meaning.

From www.directindustry.com

Modular zeropoint clamping unit SPN series ZIMMER GROUP steel Clamping Unit Meaning In this post, you'll learn what an injection molding. An injection molding machine relies heavily on its clamping unit to ensure quality and precision. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. The clamping unit’s primary function is to hold the mold halves together during the injection process.. Clamping Unit Meaning.

From www.iqsdirectory.com

Plastic Injection Molding What Is It? How Does It Work? Clamping Unit Meaning An injection molding machine relies heavily on its clamping unit to ensure quality and precision. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. The clamping unit’s primary function is to hold the mold halves together during the injection process. In injection molding, precise clamping force ensures the. Clamping Unit Meaning.

From www.totallockout.com

Universal Valve Base Clamping Unit Total Lockout Clamping Unit Meaning In this post, you'll learn what an injection molding. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. An injection molding machine relies heavily on its clamping unit to ensure quality and precision. The clamping unit’s primary function is to hold the mold halves together during the injection process.. Clamping Unit Meaning.

From www.iqsdirectory.com

Thermoplastic Molding Process, Types, Materials, and Applications Clamping Unit Meaning In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. A clamping unit is a crucial component of an injection molding machine that securely holds the mold. Clamping Unit Meaning.

From www.magneticplaten.com

Injection Molding Clamping Unit HVR MAG Clamping Unit Meaning A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. Once the plastic is injected. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. An injection molding machine relies heavily on its clamping unit to ensure. Clamping Unit Meaning.

From www.directindustry.com

Manual clamping unit HK series Bosch Rexroth Linear Motion Clamping Unit Meaning What is injection molding clamping unit? In this post, you'll learn what an injection molding. Once the plastic is injected. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. The clamping unit’s primary function is to hold the mold halves together during the injection process. A clamping unit. Clamping Unit Meaning.

From www.directindustry.com

Manual clamping unit Engineering Data hydraulic / modular / multiple Clamping Unit Meaning A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. The clamping unit’s primary function is to hold the mold halves together during the injection process. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. An. Clamping Unit Meaning.

From www.haenchen-hydraulic.com

Maintenance manual Disassembly and assembly clamping units RatioClamp® Clamping Unit Meaning A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. The clamping unit’s primary function is to hold the mold halves together during the injection process. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the.. Clamping Unit Meaning.

From thefluidpowercatalogue.com

Clamping Unit The Fluid Power Catalogue Clamping Unit Meaning A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. An injection molding machine relies heavily on its clamping unit to ensure quality and precision. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. The clamping. Clamping Unit Meaning.

From www.youtube.com

Shaft Clamping Units YouTube Clamping Unit Meaning A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. The clamping units are used to keep the mold shut against the forces developed when injection pressure. Clamping Unit Meaning.

From ind-sup.co.uk

Clamping Unit Industrial Supply Specialists Clamping Unit Meaning Once the plastic is injected. What is injection molding clamping unit? In this post, you'll learn what an injection molding. A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. The clamping units are used to keep the mold shut against the forces developed when injection pressure. Clamping Unit Meaning.

From www.youtube.com

Shaft Clamping Units "Trueround" YouTube Clamping Unit Meaning Once the plastic is injected. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. An injection molding machine relies heavily on its clamping unit to ensure quality and precision. In this post, you'll learn what an injection molding. A clamping unit for an imm is used to keep the. Clamping Unit Meaning.

From www.smwautoblok.com

Zero Point Clamping System Archives SMW Autoblok SV Clamping Unit Meaning A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. The clamping unit’s primary function is to hold the mold halves together during the injection process. In this post, you'll learn what an injection molding. An injection molding machine relies heavily on its clamping unit to ensure. Clamping Unit Meaning.

From www.fixtureworks.com

OD Holding Clamps Standard Clamping Unit (CP120) Fixtureworks Clamping Unit Meaning In this post, you'll learn what an injection molding. What is injection molding clamping unit? The clamping unit’s primary function is to hold the mold halves together during the injection process. Once the plastic is injected. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. An injection molding. Clamping Unit Meaning.

From www.imcgrupo.com

Clamping force in injection molding IMC Grupo Clamping Unit Meaning In this post, you'll learn what an injection molding. A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. What is injection molding clamping unit? The clamping unit’s primary function is to hold the mold halves together during the injection process. The clamping units are used to. Clamping Unit Meaning.

From www.aliexpress.com

Linear Guide Clamping Clamping Units for Medium Heavy Load Linear Clamping Unit Meaning An injection molding machine relies heavily on its clamping unit to ensure quality and precision. A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. A. Clamping Unit Meaning.

From www.magneticplaten.com

Injection Molding Clamping Unit HVR MAG Clamping Unit Meaning An injection molding machine relies heavily on its clamping unit to ensure quality and precision. The clamping unit’s primary function is to hold the mold halves together during the injection process. Once the plastic is injected. A clamping unit for an imm is used to keep the mold shut against the forces developed when injection pressure pushes plastic into. In. Clamping Unit Meaning.

From www.zoro.co.uk

Coromant Capto Manual clamping unit for Doosan machines Zoro UK Clamping Unit Meaning The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. Once the plastic is injected. What is injection molding clamping unit? The clamping unit’s primary function is to hold the mold halves together during the injection process. In this post, you'll learn what an injection molding. A clamping unit. Clamping Unit Meaning.

From prototool.com

Understanding the Clamping Unit in an Injection Molding Machine Clamping Unit Meaning In this post, you'll learn what an injection molding. An injection molding machine relies heavily on its clamping unit to ensure quality and precision. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. Once the plastic is injected. In injection molding, precise clamping force ensures the mold stays. Clamping Unit Meaning.

From www.mscdirect.com

Sandvik Coromant Lathe Modular Clamping Units; Clamping Unit Type Clamping Unit Meaning In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. The clamping unit’s primary function is to hold the mold halves together during the injection process. In this post, you'll learn what an injection molding. A clamping unit for an imm is used to keep the mold shut against the. Clamping Unit Meaning.

From www.smwautoblok.com

Zero Point Clamping System Archives SMW Autoblok SV Clamping Unit Meaning Once the plastic is injected. The clamping unit’s primary function is to hold the mold halves together during the injection process. In this post, you'll learn what an injection molding. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. An injection molding machine relies heavily on its clamping. Clamping Unit Meaning.

From emactra.com

LType Clamping Unit Emactra Machine Industries India is a leading Clamping Unit Meaning The clamping unit’s primary function is to hold the mold halves together during the injection process. An injection molding machine relies heavily on its clamping unit to ensure quality and precision. The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. What is injection molding clamping unit? In this. Clamping Unit Meaning.

From www.mechanicaleducation.com

Clamping Devices Rules And Types Of Clamping Devices Mechanical Clamping Unit Meaning An injection molding machine relies heavily on its clamping unit to ensure quality and precision. The clamping unit’s primary function is to hold the mold halves together during the injection process. What is injection molding clamping unit? A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process.. Clamping Unit Meaning.

From www.myplasticmold.com

injection molding machine components and its function Clamping Unit Meaning Once the plastic is injected. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. What is injection molding clamping unit? In this post, you'll learn what. Clamping Unit Meaning.

From www.youtube.com

Working principle MX series big injection molding machine's clamp unit Clamping Unit Meaning In this post, you'll learn what an injection molding. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. What is injection molding clamping unit? The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. A clamping unit for. Clamping Unit Meaning.

From skill-lync.com

Week 6 Clamp Unit & PinClamp Unit Design Challenge SkillLync Clamping Unit Meaning In this post, you'll learn what an injection molding. What is injection molding clamping unit? A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. An injection molding machine relies heavily on its clamping unit to ensure quality and precision. Once the plastic is injected. In injection. Clamping Unit Meaning.

From www.scribd.com

Clamp Unit PDF Applied And Interdisciplinary Physics Mechanical Clamping Unit Meaning The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. A clamping unit is a crucial component of an injection molding machine that securely holds the mold in place during the injection process. What is injection molding clamping unit? A clamping unit for an imm is used to keep. Clamping Unit Meaning.

From www.youtube.com

Clamping mechanism 7 Toggle Clamp 4 YouTube Clamping Unit Meaning The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. In this post, you'll learn what an injection molding. What is injection molding clamping unit? A clamping unit for. Clamping Unit Meaning.

From www.slideshare.net

Clamping and Clamping Devices Clamping Unit Meaning The clamping unit’s primary function is to hold the mold halves together during the injection process. In this post, you'll learn what an injection molding. In injection molding, precise clamping force ensures the mold stays closed during the process, preventing defects like flash or damage. An injection molding machine relies heavily on its clamping unit to ensure quality and precision.. Clamping Unit Meaning.

From www.myplasticmold.com

Injection Molding Machine Components And Its Function Clamping Unit Meaning The clamping units are used to keep the mold shut against the forces developed when injection pressure pushes plastic into the. Once the plastic is injected. In this post, you'll learn what an injection molding. An injection molding machine relies heavily on its clamping unit to ensure quality and precision. A clamping unit for an imm is used to keep. Clamping Unit Meaning.