What Is Dc Welding Used For . Direct current (“dc”) output is the preferred power source for most welding operations. We have analyzed dc versus ac power by looking at what they are pros and cons for each. Quicker deposition rates when welding thin sheet metals (dc negative) offers. Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. But, alternating current (“ac”) plays. The primary difference is polarity: Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Welding professionals often talk about the pros and cons of ac vs. Ac welders are not affected by the magnetic field thus eliminating arc blow, unlike the dc current. A smoother welding result than with ac. Which of these you choose will depend on. Ac welding penetrates deeper and can weld magnetic materials, the dc is smoother and easier to weld. Ac (alternating current) welding alternates rapidly between dc negative and dc positive, while dc (direct current) uses a straight polarity current to supply electricity to the electrode. More commonly used than ac welding, dc welding is considered to be superior in many regards. The dc welder requires a generator for conversion as power grids supply current in the ac phase.

from www.wiringdigital.com

Ac and dc welding carries different voltage for each welding machine. A smaller amount of spatter. Ac welders are not affected by the magnetic field thus eliminating arc blow, unlike the dc current. Direct current (“dc”) output is the preferred power source for most welding operations. Ac (alternating current) welding alternates rapidly between dc negative and dc positive, while dc (direct current) uses a straight polarity current to supply electricity to the electrode. Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. The primary difference is polarity: But, alternating current (“ac”) plays. Quicker deposition rates when welding thin sheet metals (dc negative) offers. Welding professionals often talk about the pros and cons of ac vs.

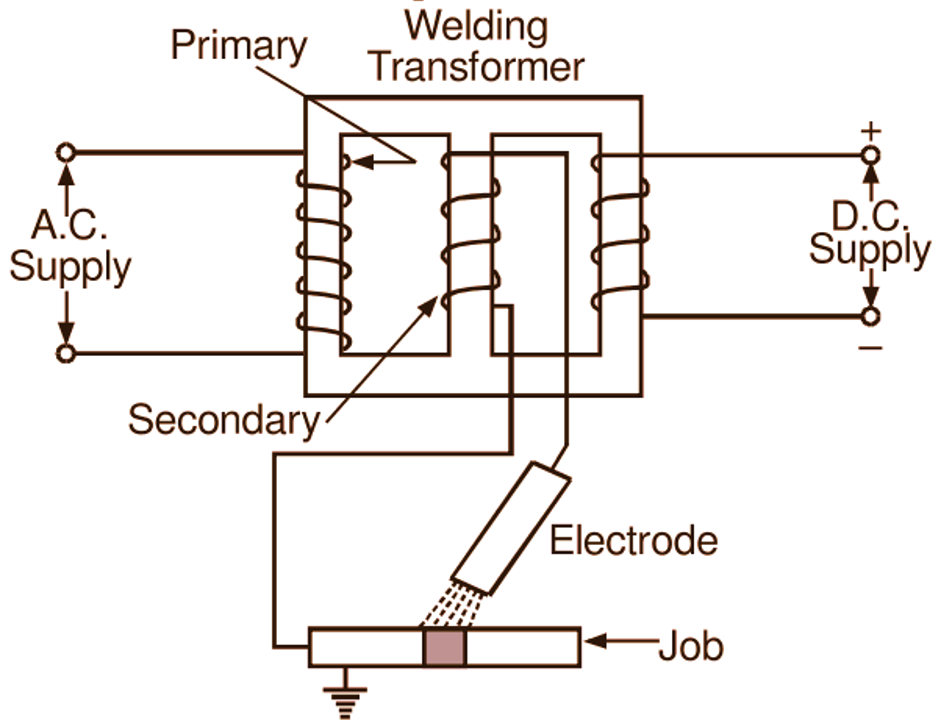

dc welding circuit diagram Wiring Digital and Schematic

What Is Dc Welding Used For Ac and dc welding carries different voltage for each welding machine. A smaller amount of spatter. Direct current (“dc”) output is the preferred power source for most welding operations. More commonly used than ac welding, dc welding is considered to be superior in many regards. Ac welding penetrates deeper and can weld magnetic materials, the dc is smoother and easier to weld. Ac welders are not affected by the magnetic field thus eliminating arc blow, unlike the dc current. But, alternating current (“ac”) plays. A smoother welding result than with ac. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. The dc welder requires a generator for conversion as power grids supply current in the ac phase. The primary difference is polarity: Ac and dc welding carries different voltage for each welding machine. Quicker deposition rates when welding thin sheet metals (dc negative) offers. Ac (alternating current) welding alternates rapidly between dc negative and dc positive, while dc (direct current) uses a straight polarity current to supply electricity to the electrode. Which of these you choose will depend on.

From weldingquery.com

Ac vs Dc Welding What Is the Difference? Welding Query What Is Dc Welding Used For But, alternating current (“ac”) plays. Which of these you choose will depend on. Ac welding penetrates deeper and can weld magnetic materials, the dc is smoother and easier to weld. Ac and dc welding carries different voltage for each welding machine. We have analyzed dc versus ac power by looking at what they are pros and cons for each. The. What Is Dc Welding Used For.

From weldingmastermind.com

11 Tips for TIG Welding Aluminum with DC Welding Mastermind What Is Dc Welding Used For Ac and dc welding carries different voltage for each welding machine. Direct current (“dc”) output is the preferred power source for most welding operations. But, alternating current (“ac”) plays. More commonly used than ac welding, dc welding is considered to be superior in many regards. The primary difference is polarity: Ac welding penetrates deeper and can weld magnetic materials, the. What Is Dc Welding Used For.

From www.acehardwareblog.com

What are the advantages of using DC TIG welding machine? What Is Dc Welding Used For But, alternating current (“ac”) plays. Ac (alternating current) welding alternates rapidly between dc negative and dc positive, while dc (direct current) uses a straight polarity current to supply electricity to the electrode. Direct current (“dc”) output is the preferred power source for most welding operations. Which of these you choose will depend on. We have analyzed dc versus ac power. What Is Dc Welding Used For.

From www.wcwelding.com

Arc Welding Rods Guide What Is Dc Welding Used For Ac welding penetrates deeper and can weld magnetic materials, the dc is smoother and easier to weld. Which of these you choose will depend on. Ac welders are not affected by the magnetic field thus eliminating arc blow, unlike the dc current. Ac and dc welding carries different voltage for each welding machine. More commonly used than ac welding, dc. What Is Dc Welding Used For.

From weldingquize.blogspot.com

POLARITY IN DC ARC WELDING WELD TECH EDUCATION What Is Dc Welding Used For Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Ac and dc welding carries different voltage for each welding machine. Ac welders are not affected by the magnetic field thus eliminating arc blow, unlike the dc current. The primary difference is polarity: A smaller amount. What Is Dc Welding Used For.

From weldinginsider.com

AC & DC Welding What are they and How is it Different Welding Insider What Is Dc Welding Used For Welding professionals often talk about the pros and cons of ac vs. A smaller amount of spatter. A smoother welding result than with ac. The dc welder requires a generator for conversion as power grids supply current in the ac phase. Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously.. What Is Dc Welding Used For.

From weldingtroop.com

AC vs. DC Welding (Pros & Cons + More) What Is Dc Welding Used For But, alternating current (“ac”) plays. Ac (alternating current) welding alternates rapidly between dc negative and dc positive, while dc (direct current) uses a straight polarity current to supply electricity to the electrode. A smaller amount of spatter. We have analyzed dc versus ac power by looking at what they are pros and cons for each. Ac welding penetrates deeper and. What Is Dc Welding Used For.

From www.walmart.com

Amico ARC140, 140 Amp Stick ARC Welder, Inverter DC Welding Soldering What Is Dc Welding Used For Ac and dc welding carries different voltage for each welding machine. The dc welder requires a generator for conversion as power grids supply current in the ac phase. Direct current (“dc”) output is the preferred power source for most welding operations. But, alternating current (“ac”) plays. Dc stands for direct current, meaning that the current is only flowing in one. What Is Dc Welding Used For.

From www.youtube.com

AC WELDING AND DC WELDING DIFFERENCE ANUNIVERSE 22 YouTube What Is Dc Welding Used For Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. A smoother welding result than with ac. We have analyzed dc versus ac power by looking at what they are pros and cons for each. Ac welding penetrates deeper and can weld magnetic materials, the dc is smoother and easier to. What Is Dc Welding Used For.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) What Is Dc Welding Used For Which of these you choose will depend on. A smoother welding result than with ac. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Ac (alternating current) welding alternates rapidly between dc negative and dc positive, while dc (direct current) uses a straight polarity current. What Is Dc Welding Used For.

From weldingclarity.com

AC vs DC Welding Which is the Best Fit for Your Needs? What Is Dc Welding Used For But, alternating current (“ac”) plays. Ac and dc welding carries different voltage for each welding machine. The dc welder requires a generator for conversion as power grids supply current in the ac phase. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. More commonly used. What Is Dc Welding Used For.

From www.youtube.com

Miller Multimatic 220 AC/DC Mig Welding Techniques YouTube What Is Dc Welding Used For Direct current (“dc”) output is the preferred power source for most welding operations. The primary difference is polarity: We have analyzed dc versus ac power by looking at what they are pros and cons for each. Welding professionals often talk about the pros and cons of ac vs. A smoother welding result than with ac. Which of these you choose. What Is Dc Welding Used For.

From www.dcwelding.co.nz

DC Welding Christchurch welder sales, service and hire Christchurch What Is Dc Welding Used For Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. The dc welder requires a generator for conversion as power grids supply current in the ac phase.. What Is Dc Welding Used For.

From www.spot-weldingmachine.com

Medium Frequency DC Welding Machine for Copper Plate Welding What Is Dc Welding Used For A smoother welding result than with ac. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Ac (alternating current) welding alternates rapidly between dc negative and dc positive, while dc (direct current) uses a straight polarity current to supply electricity to the electrode. But, alternating. What Is Dc Welding Used For.

From weldguru.com

AC vs. DC Welding Differences Compared (with Pros & Cons) What Is Dc Welding Used For The dc welder requires a generator for conversion as power grids supply current in the ac phase. A smoother welding result than with ac. Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. Ac welders are not affected by the magnetic field thus eliminating arc blow, unlike the dc current.. What Is Dc Welding Used For.

From www.perfectwelders.com

Welding for BeginnersWhat is the Difference Between AC Welding and DC What Is Dc Welding Used For The dc welder requires a generator for conversion as power grids supply current in the ac phase. The primary difference is polarity: Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. More commonly used than ac welding, dc welding is considered to be superior in. What Is Dc Welding Used For.

From houseandbeyond.org

AC vs. DC Welding Everything You Need to Know (Winter 2024) What Is Dc Welding Used For The primary difference is polarity: We have analyzed dc versus ac power by looking at what they are pros and cons for each. The dc welder requires a generator for conversion as power grids supply current in the ac phase. Ac and dc welding carries different voltage for each welding machine. More commonly used than ac welding, dc welding is. What Is Dc Welding Used For.

From weldingpros.net

AC vs DC Welding With TIG & Stick on Alternating Current What Is Dc Welding Used For Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Direct current (“dc”) output is the preferred power source for most welding operations. Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. The primary difference is. What Is Dc Welding Used For.

From sciencing.com

What Is the Difference Between AC & DC Welding? Sciencing What Is Dc Welding Used For Ac welding penetrates deeper and can weld magnetic materials, the dc is smoother and easier to weld. Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. The dc welder requires a generator for conversion as power grids supply current in the ac phase. Dc welding is generally preferred for most. What Is Dc Welding Used For.

From weldempire.com

AC vs DC Welding Applications & Main Differences What Is Dc Welding Used For But, alternating current (“ac”) plays. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Ac welders are not affected by the magnetic field thus eliminating arc blow, unlike the dc current. A smaller amount of spatter. We have analyzed dc versus ac power by looking. What Is Dc Welding Used For.

From weldinguru.com

What is the difference between AC and DC Welding (AC vs DC) Weldinguru What Is Dc Welding Used For But, alternating current (“ac”) plays. A smaller amount of spatter. Which of these you choose will depend on. The dc welder requires a generator for conversion as power grids supply current in the ac phase. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Dc. What Is Dc Welding Used For.

From weldinginsider.com

AC & DC Welding What are they and How is it Different Welding Insider What Is Dc Welding Used For Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. We have analyzed dc versus ac power by looking at what they are pros and cons for each. But, alternating current (“ac”) plays. The dc welder requires a generator for conversion as power grids supply current. What Is Dc Welding Used For.

From dcwelding.com

DC Welding & Fabrication Ltd. What Is Dc Welding Used For The primary difference is polarity: The dc welder requires a generator for conversion as power grids supply current in the ac phase. We have analyzed dc versus ac power by looking at what they are pros and cons for each. Ac and dc welding carries different voltage for each welding machine. A smoother welding result than with ac. Quicker deposition. What Is Dc Welding Used For.

From weldguru.com

AC vs. DC Welding Differences Compared (with Pros & Cons) What Is Dc Welding Used For Welding professionals often talk about the pros and cons of ac vs. Ac and dc welding carries different voltage for each welding machine. A smaller amount of spatter. Quicker deposition rates when welding thin sheet metals (dc negative) offers. A smoother welding result than with ac. Dc welding is generally preferred for most welding applications because it offers smoother and. What Is Dc Welding Used For.

From metronwelding.ie

Lincoln Electric Aspect 200 AC DC Tig Welder Metron Welding What Is Dc Welding Used For More commonly used than ac welding, dc welding is considered to be superior in many regards. Ac (alternating current) welding alternates rapidly between dc negative and dc positive, while dc (direct current) uses a straight polarity current to supply electricity to the electrode. Ac welding penetrates deeper and can weld magnetic materials, the dc is smoother and easier to weld.. What Is Dc Welding Used For.

From www.youtube.com

AC vs DC Welding with TIG Welding Machine for Aluminum, SS Welding [AC What Is Dc Welding Used For A smaller amount of spatter. Ac (alternating current) welding alternates rapidly between dc negative and dc positive, while dc (direct current) uses a straight polarity current to supply electricity to the electrode. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. But, alternating current (“ac”). What Is Dc Welding Used For.

From www.walmart.com

MMA200, 200 Amp Stick Arc DC Inverter Welder, 110/230V Dual Voltage What Is Dc Welding Used For The primary difference is polarity: Quicker deposition rates when welding thin sheet metals (dc negative) offers. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. Welding. What Is Dc Welding Used For.

From www.chinaweldingmachines.com

How to Judge The Output Polarity of the DC Welding Machine? What Is Dc Welding Used For The primary difference is polarity: Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. But, alternating current (“ac”) plays. A smoother welding result than with ac. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper.. What Is Dc Welding Used For.

From weldingquery.com

Ac vs Dc Welding What Is the Difference? Welding Query What Is Dc Welding Used For Quicker deposition rates when welding thin sheet metals (dc negative) offers. Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. Ac and dc welding carries different voltage for each welding machine. A smaller amount of spatter. The primary difference is polarity: The dc welder requires a generator for conversion as. What Is Dc Welding Used For.

From weldingquery.com

Ac vs Dc Welding What Is the Difference? Welding Query What Is Dc Welding Used For Ac welding penetrates deeper and can weld magnetic materials, the dc is smoother and easier to weld. Ac and dc welding carries different voltage for each welding machine. Which of these you choose will depend on. Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. Direct current (“dc”) output is. What Is Dc Welding Used For.

From www.spot-weldingmachine.com

Threephase Medium Frequency DC Welding Machine What Is Dc Welding Used For A smaller amount of spatter. A smoother welding result than with ac. Which of these you choose will depend on. Quicker deposition rates when welding thin sheet metals (dc negative) offers. Ac welders are not affected by the magnetic field thus eliminating arc blow, unlike the dc current. The primary difference is polarity: Dc welding is generally preferred for most. What Is Dc Welding Used For.

From welding-world-awards.com

AC vs DC Welding understanding the Difference Between AC and DC TIG What Is Dc Welding Used For Ac and dc welding carries different voltage for each welding machine. Welding professionals often talk about the pros and cons of ac vs. But, alternating current (“ac”) plays. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Which of these you choose will depend on.. What Is Dc Welding Used For.

From www.wiringdigital.com

dc welding circuit diagram Wiring Digital and Schematic What Is Dc Welding Used For But, alternating current (“ac”) plays. Ac (alternating current) welding alternates rapidly between dc negative and dc positive, while dc (direct current) uses a straight polarity current to supply electricity to the electrode. A smaller amount of spatter. Ac welding penetrates deeper and can weld magnetic materials, the dc is smoother and easier to weld. Direct current (“dc”) output is the. What Is Dc Welding Used For.

From www.weldingtribe.com

How to Hook up Stick Welding Leads Welding Tribe What Is Dc Welding Used For Which of these you choose will depend on. We have analyzed dc versus ac power by looking at what they are pros and cons for each. Quicker deposition rates when welding thin sheet metals (dc negative) offers. Ac welding penetrates deeper and can weld magnetic materials, the dc is smoother and easier to weld. Welding professionals often talk about the. What Is Dc Welding Used For.

From ronixtools.com

DC ARC welding machine 🧰 Ronix Tools What Is Dc Welding Used For Dc stands for direct current, meaning that the current is only flowing in one direction, and it flows continuously. A smaller amount of spatter. Dc welding is generally preferred for most welding applications because it offers smoother and more stable arcs, easier starts, fewer arc outages, and deeper. Ac welding penetrates deeper and can weld magnetic materials, the dc is. What Is Dc Welding Used For.