Carbon Paper Electrical Conductivity . Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel.

from www.mdpi.com

At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is.

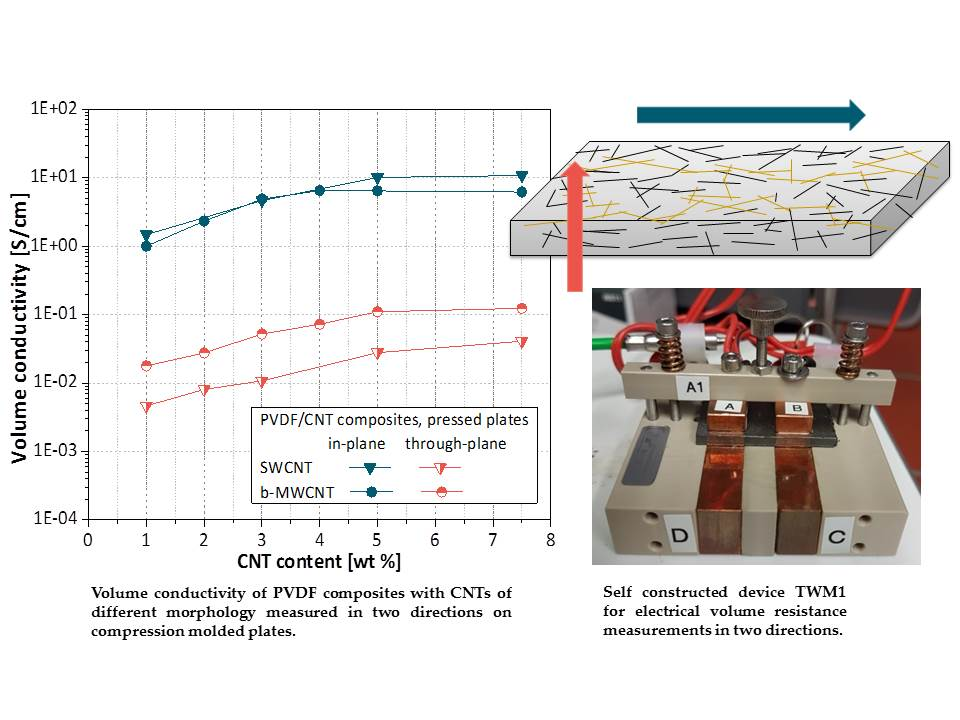

Polymers Free FullText Direction Dependent Electrical Conductivity

Carbon Paper Electrical Conductivity At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is.

From nalaishengwu.en.made-in-china.com

High Purity Natural Good Electrical Conductivity Flexible Graphite Carbon Paper Electrical Conductivity At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability. Carbon Paper Electrical Conductivity.

From www.carbongraphiteplate.com

Heat Spreader 12um Carbon Graphite Paper High Electric Conductivity Carbon Paper Electrical Conductivity Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. Once. Carbon Paper Electrical Conductivity.

From www.researchgate.net

Tests of electrical conductivity of a) naked carbon paper and) with the Carbon Paper Electrical Conductivity Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. The resultant carbon paper. Carbon Paper Electrical Conductivity.

From www.semanticscholar.org

Table 1 from The role of the electric conductivity of carbons in the Carbon Paper Electrical Conductivity Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form. Carbon Paper Electrical Conductivity.

From www.mdpi.com

Applied Sciences Free FullText Review on the Electrical Resistance Carbon Paper Electrical Conductivity It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. At the same time,. Carbon Paper Electrical Conductivity.

From www.academia.edu

(PDF) Electrical conductivity of thermal carbon blacks Christian Roy Carbon Paper Electrical Conductivity Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. It is. Carbon Paper Electrical Conductivity.

From www.carbonfiber-composites.com

4mm Electrical Conductivity Carbon Fiber Plate High Strength Carbon Sheet Carbon Paper Electrical Conductivity Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. At the same time, the. Carbon Paper Electrical Conductivity.

From www.semanticscholar.org

[PDF] AN ELECTRICAL CONDUCTIVITY TRANSLATOR FOR CARBONS Semantic Scholar Carbon Paper Electrical Conductivity It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. Once boron. Carbon Paper Electrical Conductivity.

From www.carbonfiber-composites.com

4mm Electrical Conductivity Carbon Fiber Plate High Strength Carbon Sheet Carbon Paper Electrical Conductivity It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Once boron is added,. Carbon Paper Electrical Conductivity.

From www.researchgate.net

DC electrical conductivity of carbonbased at different Carbon Paper Electrical Conductivity Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely.. Carbon Paper Electrical Conductivity.

From frt-graphite.en.made-in-china.com

Good Electrical Conductivity Flexible Graphite Carbon Paper in Roll Carbon Paper Electrical Conductivity At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical. Carbon Paper Electrical Conductivity.

From www.researchgate.net

Effect of milling time on electrical conductivity of activated carbon Carbon Paper Electrical Conductivity At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a. Carbon Paper Electrical Conductivity.

From hmroyal.com

Carbon Black Achieves the Highest Electrical Conductivity Carbon Paper Electrical Conductivity At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is. Carbon Paper Electrical Conductivity.

From www.researchgate.net

(PDF) Electrical conductivity of conductive carbon blacks Influence of Carbon Paper Electrical Conductivity The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. Currently, there are many materials used for. Carbon Paper Electrical Conductivity.

From www.frontiersin.org

Frontiers AllCarbon Conductors for Electronic and Electrical Wiring Carbon Paper Electrical Conductivity The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Currently, there are many. Carbon Paper Electrical Conductivity.

From www.researchgate.net

Temperature dependence of the conductivity of carbon fibers. Download Carbon Paper Electrical Conductivity The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. Once boron is added, there is. Carbon Paper Electrical Conductivity.

From www.semanticscholar.org

Figure 1 from Effect of carbonization temperature on electrical Carbon Paper Electrical Conductivity Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. Carbon papers. Carbon Paper Electrical Conductivity.

From www.researchgate.net

(PDF) Electrical conductivity of conductive carbon blacks Influence of Carbon Paper Electrical Conductivity Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Currently,. Carbon Paper Electrical Conductivity.

From www.carbonfiber-composites.com

4mm Electrical Conductivity Carbon Fiber Plate High Strength Carbon Sheet Carbon Paper Electrical Conductivity Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. The resultant carbon paper has. Carbon Paper Electrical Conductivity.

From unirun2022.en.made-in-china.com

High Electric Conductivity Pyrolytic Carbon Graphite Heat Spreader Carbon Paper Electrical Conductivity It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Currently, there are many. Carbon Paper Electrical Conductivity.

From unirun2022.en.made-in-china.com

Expanded Pyrolytic Paper High Conductivity Purity Carbon Industrial Carbon Paper Electrical Conductivity It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Carbon papers (cps). Carbon Paper Electrical Conductivity.

From www.carbongraphiteplate.com

Flexible 32um Carbon Graphite Paper Electrical Conductive Carbon Paper Electrical Conductivity The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high.. Carbon Paper Electrical Conductivity.

From www.mdpi.com

Polymers Free FullText Direction Dependent Electrical Conductivity Carbon Paper Electrical Conductivity Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. It. Carbon Paper Electrical Conductivity.

From www.researchgate.net

Electrical conductivity of a PANbased carbon fiber versus temperature Carbon Paper Electrical Conductivity At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Once. Carbon Paper Electrical Conductivity.

From www.researchgate.net

(PDF) Electrical conductivity of thermal carbon blacks Influence of Carbon Paper Electrical Conductivity Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. At. Carbon Paper Electrical Conductivity.

From www.mdpi.com

Polymers Free FullText Direction Dependent Electrical Conductivity Carbon Paper Electrical Conductivity Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. Carbon papers. Carbon Paper Electrical Conductivity.

From pubs.acs.org

Carbon Fibers with High Electrical Conductivity Laser Irradiation of Carbon Paper Electrical Conductivity Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. The resultant carbon. Carbon Paper Electrical Conductivity.

From www.scribd.com

NSTSE Class 8 Solved Paper 2010 PDF Electrical Resistivity And Carbon Paper Electrical Conductivity Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form. Carbon Paper Electrical Conductivity.

From www.researchgate.net

Variation of resistivity (a) and electrical conductivity (b) of carbon Carbon Paper Electrical Conductivity Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. The resultant carbon paper has. Carbon Paper Electrical Conductivity.

From unirun2022.en.made-in-china.com

High Purity Expanded Paper High Conductivity Purity Carbon Industrial Carbon Paper Electrical Conductivity Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. At the. Carbon Paper Electrical Conductivity.

From www.alibaba.com

Carbon Paper Roll Thermal High Conductivity Electrically Carbon Carbon Paper Electrical Conductivity It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. Carbon papers (cps) formed from carbon fibers. Carbon Paper Electrical Conductivity.

From www.alibaba.com

Carbon Paper Roll Thermal High Conductivity Electrically Carbon Carbon Paper Electrical Conductivity Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. Currently, there are many materials used for gdl, mainly including carbon paper [19], carbon cloth [20], nonwoven fabric [21] or metal. It is found that incorporation of mwcnts reveals an increase in electrical conductivity and flexural modulus. Once boron is. Carbon Paper Electrical Conductivity.

From www.researchgate.net

Electrical conductivity of carbon fiber mats as a function of Carbon Paper Electrical Conductivity Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. Currently, there are. Carbon Paper Electrical Conductivity.

From www.researchgate.net

Electric conductivity vs . pressure for some of the prepared carbon Carbon Paper Electrical Conductivity Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. At the same time, the phenolic resin bonds the carbon fibers into a stable uniform porous structure, which together form a channel. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. Carbon. Carbon Paper Electrical Conductivity.

From www.carbonfiber-composites.com

4mm Electrical Conductivity Carbon Fiber Plate High Strength Carbon Sheet Carbon Paper Electrical Conductivity Once boron is added, there is an immediate and remarkable rise of electrical conductivity, and this enhancement is closely. The resultant carbon paper has porosity gradient distribution parallel to the flow direction and improvement of permeability is. Carbon papers (cps) formed from carbon fibers (cfs) have several unique properties, such as a high electrical conductivity, a high. It is found. Carbon Paper Electrical Conductivity.