Drill Hole Vias . Through hole vias, buried vias, and blind vias. Find out the considerations for aspect ratio, annular ring, signal integrity, and fabrication cost of vias. Where and how to use them. These are referred to as blind vias (from a surface layer to the next layer in) and buried vias (between two internal layers). Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). It is this parameter that is an important determinant of via reliability. When a via is placed in a pcb, the drill size and the depth into the pcb define a via's aspect ratio. There are three main types of pcb vias used: Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal layers. By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. The ability to reliably fabricate vias with different aspect ratios depends on several factors.

from www.protoexpress.com

When a via is placed in a pcb, the drill size and the depth into the pcb define a via's aspect ratio. Through hole vias, buried vias, and blind vias. These are referred to as blind vias (from a surface layer to the next layer in) and buried vias (between two internal layers). A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. It is this parameter that is an important determinant of via reliability. Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal layers. By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. Where and how to use them. The ability to reliably fabricate vias with different aspect ratios depends on several factors. There are three main types of pcb vias used:

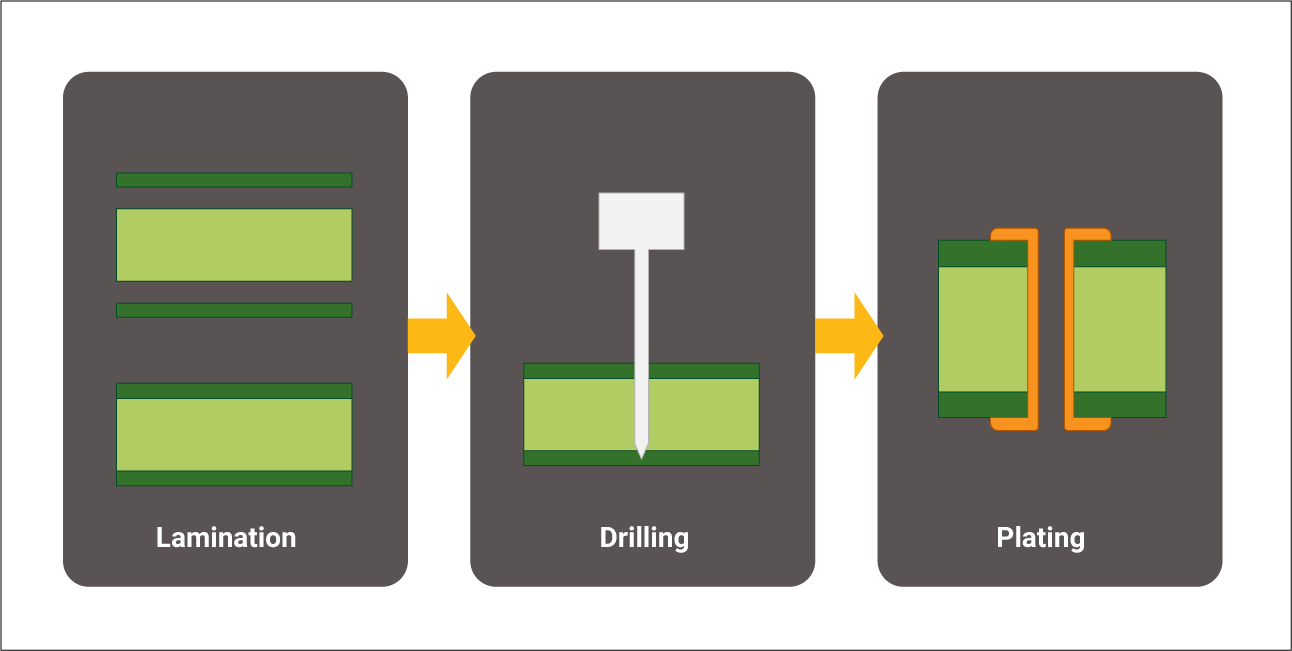

Drills and ThroughHole Plating Sierra Circuits

Drill Hole Vias Find out the considerations for aspect ratio, annular ring, signal integrity, and fabrication cost of vias. When a via is placed in a pcb, the drill size and the depth into the pcb define a via's aspect ratio. There are three main types of pcb vias used: Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal layers. Where and how to use them. It is this parameter that is an important determinant of via reliability. A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. Through hole vias, buried vias, and blind vias. Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). Find out the considerations for aspect ratio, annular ring, signal integrity, and fabrication cost of vias. By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. The ability to reliably fabricate vias with different aspect ratios depends on several factors. These are referred to as blind vias (from a surface layer to the next layer in) and buried vias (between two internal layers).

From www.abp.net.cn

The different types of PCB vias and their applications ABP Electronics Drill Hole Vias There are three main types of pcb vias used: Through hole vias, buried vias, and blind vias. The ability to reliably fabricate vias with different aspect ratios depends on several factors. Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). Find out the considerations for aspect ratio,. Drill Hole Vias.

From aapcb.com

Via Types Advanced Assembly Drill Hole Vias Through hole vias, buried vias, and blind vias. The ability to reliably fabricate vias with different aspect ratios depends on several factors. Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal layers. Learn the difference between blind and buried vias, two types of holes that connect different layers. Drill Hole Vias.

From www.atechpcb.com

The via types in PCB design and fabrication Drill Hole Vias Find out the considerations for aspect ratio, annular ring, signal integrity, and fabrication cost of vias. Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal layers. A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a. Drill Hole Vias.

From www.rushpcb.co.uk

Laser Drilled Microvias LaserDrilled Microvias Manufacturer Drill Hole Vias There are three main types of pcb vias used: Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). Through hole vias, buried vias, and blind vias. Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal. Drill Hole Vias.

From blog.mbedded.ninja

Pads, Vias And Holes mbedded.ninja Drill Hole Vias It is this parameter that is an important determinant of via reliability. Through hole vias, buried vias, and blind vias. A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. By drilling vias at certain points during the fabrication. Drill Hole Vias.

From www.circuitwork.tech

Reverse Engineering High Speed Circuit Board Drilling Drawing Drill Hole Vias There are three main types of pcb vias used: A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. When a via is placed in a pcb, the drill size and the depth into the pcb define a via's. Drill Hole Vias.

From camptechii.com

What's the difference between plated throughhole and via? Camptech II Circuits Inc. Drill Hole Vias The ability to reliably fabricate vias with different aspect ratios depends on several factors. Through hole vias, buried vias, and blind vias. These are referred to as blind vias (from a surface layer to the next layer in) and buried vias (between two internal layers). When a via is placed in a pcb, the drill size and the depth into. Drill Hole Vias.

From www.protoexpress.com

How Does Laser Drilling Work in PCBs? Sierra Circuits Drill Hole Vias Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. A via is a drilled and plated hole in a pcb that allows a signal. Drill Hole Vias.

From www.nextpcb.com

PCB Via An Ultimate Guide Drill Hole Vias Where and how to use them. It is this parameter that is an important determinant of via reliability. A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. Vias can be used to connect component leads to signal traces. Drill Hole Vias.

From lenoxlaser.com

What is Laser Drilling? Lenox Laser Micro Drilling and Machining Drill Hole Vias It is this parameter that is an important determinant of via reliability. A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. Vias can be used to connect component leads to signal traces or planes or to allow a. Drill Hole Vias.

From www.raypcb.com

3 Treatment Methods for PCB Vias Printed Circuit Board Manufacturing & PCB Assembly RayMing Drill Hole Vias A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). There are three main types of pcb. Drill Hole Vias.

From processphotonics.com

The Benefits of Dual Laser Microvia Drilling • PPI dual laser via drilling Drill Hole Vias There are three main types of pcb vias used: Through hole vias, buried vias, and blind vias. A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. It is this parameter that is an important determinant of via reliability.. Drill Hole Vias.

From www.hylax.com

Laser drilling Hylax Technology Laser Solution Provider Drill Hole Vias When a via is placed in a pcb, the drill size and the depth into the pcb define a via's aspect ratio. The ability to reliably fabricate vias with different aspect ratios depends on several factors. By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. These. Drill Hole Vias.

From www.versalogic.com

Clash Between IPC Class 3 Requirements & Shrinking Geometries VersaLogic Drill Hole Vias A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. Through hole vias, buried vias, and blind vias. Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal. Drill Hole Vias.

From www.pcbgogo.com

Back drilling,PCB Drill Hole Vias Find out the considerations for aspect ratio, annular ring, signal integrity, and fabrication cost of vias. These are referred to as blind vias (from a surface layer to the next layer in) and buried vias (between two internal layers). Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal. Drill Hole Vias.

From www.raypcb.com

How to Choose for Standard Via Drill Sizes for Your PCB RAYPCB Drill Hole Vias These are referred to as blind vias (from a surface layer to the next layer in) and buried vias (between two internal layers). Through hole vias, buried vias, and blind vias. The ability to reliably fabricate vias with different aspect ratios depends on several factors. It is this parameter that is an important determinant of via reliability. By drilling vias. Drill Hole Vias.

From www.protoexpress.com

Drills and ThroughHole Plating Sierra Circuits Drill Hole Vias Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal layers. Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). There are three main types of pcb vias used: The ability to reliably fabricate vias with. Drill Hole Vias.

From itchol.com

PCB Vias An InDepth Guide (2022) Drill Hole Vias These are referred to as blind vias (from a surface layer to the next layer in) and buried vias (between two internal layers). A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. Vias can be used to connect. Drill Hole Vias.

From www.youtube.com

Voltera Drill Attachment for vias and through holes YouTube Drill Hole Vias It is this parameter that is an important determinant of via reliability. Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal layers. By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. There are three. Drill Hole Vias.

From www.protoexpress.com

PCB Backdrilling Process Sierra Circuits Drill Hole Vias Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. Find out the considerations for aspect ratio,. Drill Hole Vias.

From www.viasion.com

PCB Vias Types PTH Vias, Blind Vias, Buried Vias, and Back Drill Vias Viasion Drill Hole Vias The ability to reliably fabricate vias with different aspect ratios depends on several factors. Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal layers. A via. Drill Hole Vias.

From www.reddit.com

Eagle CAD tent the bottom of THT pads? r/PrintedCircuitBoard Drill Hole Vias The ability to reliably fabricate vias with different aspect ratios depends on several factors. By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. Find out the considerations for aspect ratio, annular ring, signal integrity, and fabrication cost of vias. Learn the difference between blind and buried. Drill Hole Vias.

From www.pinterest.com

Multilayer PCB with Blind and Buried Vias Laser drill or Mechanical drill Blinds, Technology, Bury Drill Hole Vias Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal layers. It is this parameter that is an important determinant of via reliability. Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). Through hole vias, buried. Drill Hole Vias.

From www.pcb-hero.com

PCB Drilling PCB HERO Drill Hole Vias Through hole vias, buried vias, and blind vias. The ability to reliably fabricate vias with different aspect ratios depends on several factors. It is this parameter that is an important determinant of via reliability. Find out the considerations for aspect ratio, annular ring, signal integrity, and fabrication cost of vias. Where and how to use them. Vias can be used. Drill Hole Vias.

From www.vse.com

How are PCB Vias Plated? VSE Drill Hole Vias Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). Find out the considerations for aspect ratio, annular ring, signal integrity, and fabrication cost of vias. There are three main types of pcb vias used: Where and how to use them. The ability to reliably fabricate vias with. Drill Hole Vias.

From epp-europe-news.com

Blind, buried vias, stacked microvias with laser drilling Drill Hole Vias Through hole vias, buried vias, and blind vias. A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent. Drill Hole Vias.

From blog.epectec.com

PCB Vias Everything You Need To Know Drill Hole Vias By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. Where and how to use them. It is this parameter that is an important determinant of via reliability. The ability to reliably fabricate vias with different aspect ratios depends on several factors. Vias can be used to. Drill Hole Vias.

From circuitdigest.com

Understanding Blind, Buried, and Throughhole vias in PCB Drill Hole Vias Through hole vias, buried vias, and blind vias. Where and how to use them. When a via is placed in a pcb, the drill size and the depth into the pcb define a via's aspect ratio. These are referred to as blind vias (from a surface layer to the next layer in) and buried vias (between two internal layers). Find. Drill Hole Vias.

From www.protoexpress.com

What is PCB Back Drilling? Sierra Circuits Drill Hole Vias A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other or to an inner layer. The ability to reliably fabricate vias with different aspect ratios depends on several factors. When a via is placed in a pcb, the drill size and the depth into. Drill Hole Vias.

From www.electronicsforu.com

Via Hole Types And Their Use In PCBs Design Guide Drill Hole Vias Vias can be used to connect component leads to signal traces or planes or to allow a signal to change signal layers. It is this parameter that is an important determinant of via reliability. Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). By drilling vias at. Drill Hole Vias.

From resources.altium.com

Plated ThroughHole Vias in mmWave PCBs PCB Design Blog Altium Designer Drill Hole Vias By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. It is this parameter that is an important determinant of via reliability. When a via is placed in a pcb, the drill size and the depth into the pcb define a via's aspect ratio. Vias can be. Drill Hole Vias.

From electronics.stackexchange.com

pcb design Manually Drill Vias into PCB Electrical Engineering Stack Exchange Drill Hole Vias By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. Where and how to use them. Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). A via is a drilled and plated hole in. Drill Hole Vias.

From www.pcbelec.com

What is Backdrilling of Vias and Why it Matters for PCBs JHYPCB Drill Hole Vias Find out the considerations for aspect ratio, annular ring, signal integrity, and fabrication cost of vias. When a via is placed in a pcb, the drill size and the depth into the pcb define a via's aspect ratio. The ability to reliably fabricate vias with different aspect ratios depends on several factors. A via is a drilled and plated hole. Drill Hole Vias.

From pcbdesignsdl.blogspot.com

Pcb Via Drill Size PCB Designs Drill Hole Vias It is this parameter that is an important determinant of via reliability. Learn the difference between blind and buried vias, two types of holes that connect different layers of a printed circuit board (pcb). A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the other. Drill Hole Vias.

From www.viasion.com

PCB Vias Types PTH Vias, Blind Vias, Buried Vias, and Back Drill Vias Viasion Drill Hole Vias By drilling vias at certain points during the fabrication process, it was possible to create vias that only spanned two adjacent signal layers. It is this parameter that is an important determinant of via reliability. A via is a drilled and plated hole in a pcb that allows a signal to pass from one side of a pcb to the. Drill Hole Vias.