Chill Bars For Welding . Chill blocks for welding can help to prevent these issues in welding when they are most critical. They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. They can also be integral with a. Save time and make more. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. That means you get the. While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. Chill bars can be separate components used to help control interpass temperature.

from www.weldingtipsandtricks.com

Save time and make more. They can also be integral with a. A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. That means you get the. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. Chill blocks for welding can help to prevent these issues in welding when they are most critical. Chill bars can be separate components used to help control interpass temperature. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a.

Aerospace Welding Test and Fixture

Chill Bars For Welding That means you get the. Save time and make more. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. That means you get the. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. Chill blocks for welding can help to prevent these issues in welding when they are most critical. Chill bars can be separate components used to help control interpass temperature. They can also be integral with a.

From www.cwbgroup.org

How It Works What is a Backing Strip for a Welded Joint? CWB Group Chill Bars For Welding While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. They provide an effective. Chill Bars For Welding.

From www.youtube.com

Flash Tacks & Chill Bars on 18 Gauge Steel Welding Tips & Tricks Chill Bars For Welding A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. That means you get the. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. Save time and make more. They can also be integral with a. Chill. Chill Bars For Welding.

From www.weldingtipsandtricks.com

Edge Welds and Edge Joints Tig Welded on Aluminum, SS, and Carbon Chill Bars For Welding They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. They can also be integral with a. Chill blocks for welding can help to prevent these issues in welding when they are most critical. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding. Chill Bars For Welding.

From www.pinterest.co.uk

Pin on Texture Reference Chill Bars For Welding While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. Chill bars can be separate components used to help control interpass temperature. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. They provide an effective way to dissipate heat actively and allow wider tolerances. Chill Bars For Welding.

From www.weldingtipsandtricks.com

Backstep Technique for TIg Welding Chill Bars For Welding They can also be integral with a. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. That means you get the. A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. One method used at all metals. Chill Bars For Welding.

From www.motortrend.com

Using a Copper Backing Strip When Filling Holes by Welding Chill Bars For Welding Industries can also make use of external welding chillers along the workpiece to keep the heat in check. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. While cutting some aluminum. Chill Bars For Welding.

From www.youtube.com

Easy learning in welding angle bar YouTube Chill Bars For Welding One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. Save time and make more. Chill bars can be separate components used. Chill Bars For Welding.

From www.weldingtipsandtricks.com

18ga CRS Cube Chill Bars For Welding That means you get the. A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. Chill bars can be separate components used to help control interpass temperature. They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. Welded chill. Chill Bars For Welding.

From www.youtube.com

How to Weld on 6Inch 3 16 Stainless with a Chill Ring Part 1 YouTube Chill Bars For Welding Industries can also make use of external welding chillers along the workpiece to keep the heat in check. While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. That means you get the. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is. Chill Bars For Welding.

From www.weldingtipsandtricks.com

TIG Welding Training Exercise for 11 ga carbon steel Chill Bars For Welding Chill blocks for welding can help to prevent these issues in welding when they are most critical. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. One method used at. Chill Bars For Welding.

From www.cwbgroup.org

How It Works What is a Backing Strip for a Welded Joint? CWB Group Chill Bars For Welding While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. That means you get the. Save time and make more. Chill bars can be separate components used to help control interpass temperature. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the. Chill Bars For Welding.

From www.weldingtipsandtricks.com

Aerospace Welding Test and Fixture Chill Bars For Welding Save time and make more. That means you get the. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. While cutting some aluminum bar for a welding. Chill Bars For Welding.

From www.sme.org

From Multispot Welding to Limiting Soot Tips for Optimal Laser Joins Chill Bars For Welding They can also be integral with a. Chill blocks for welding can help to prevent these issues in welding when they are most critical. Chill bars can be separate components used to help control interpass temperature. They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. A chill block has been seen as. Chill Bars For Welding.

From steeltubeinstitute.org

CJP HSS Welds Be Informed Before You Specify Steel Tube Institute Chill Bars For Welding Save time and make more. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration. Chill Bars For Welding.

From www.weldingtipsandtricks.com

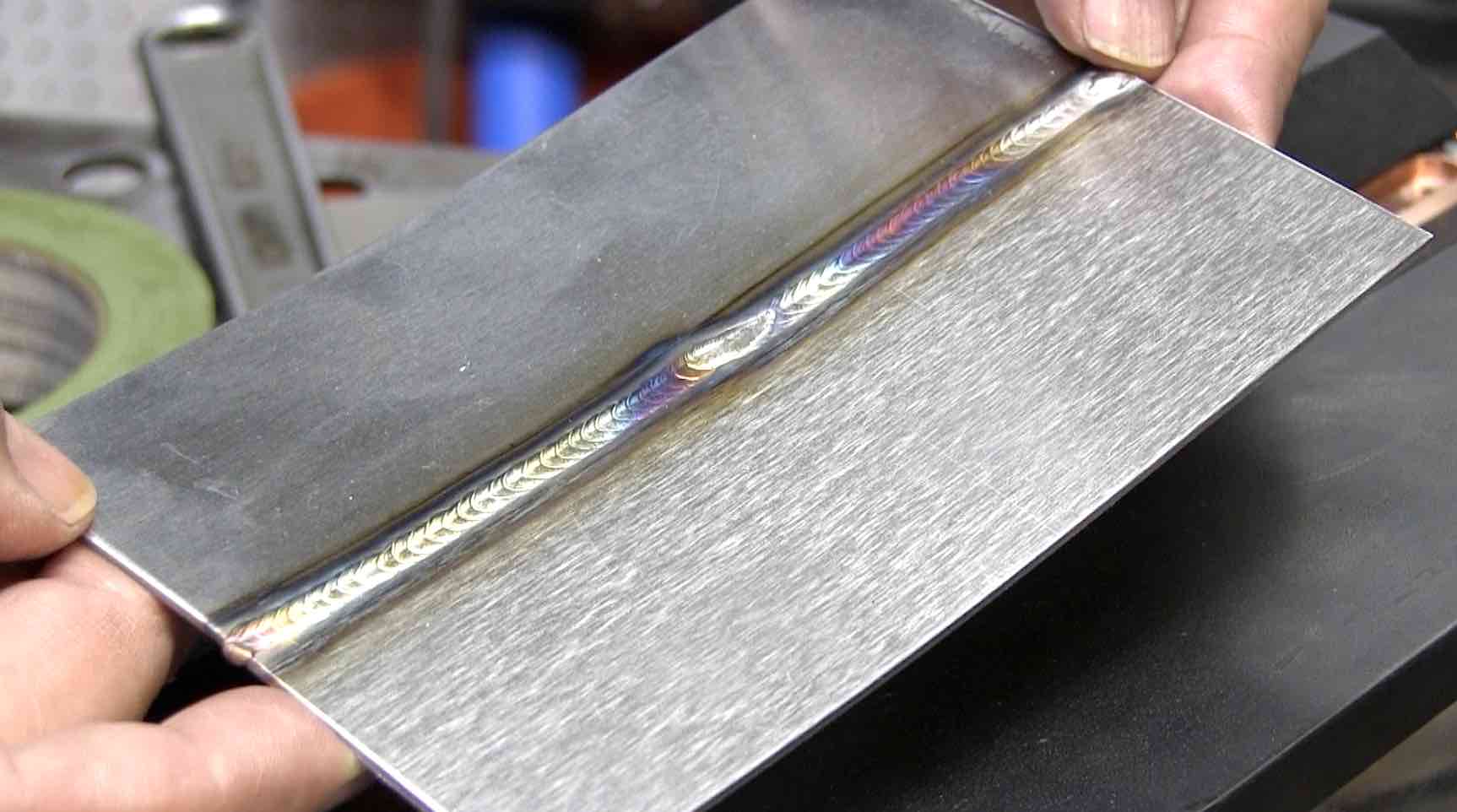

Tig Welding Stainless 18ga outside corner with chill bars and pulse Chill Bars For Welding Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. Chill bars can be separate components used to help control interpass temperature. While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. That means you get the. They provide an effective way. Chill Bars For Welding.

From www.piletips.com

Pile Tips, Points, Splicers, and Rings Chill Bars For Welding That means you get the. They can also be integral with a. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. Save time and make more. While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. A chill. Chill Bars For Welding.

From www.youtube.com

round bar welding technique that few people know, why don't welders Chill Bars For Welding Chill blocks for welding can help to prevent these issues in welding when they are most critical. That means you get the. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat. Chill Bars For Welding.

From www.youtube.com

How to Weld on 6Inch 3 16 Stainless with a Chill Ring Part 2 YouTube Chill Bars For Welding One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. Chill blocks for welding can help to prevent these issues in welding when they are most critical. Chill bars can be separate components used to help control interpass temperature. That means you get the. Industries can. Chill Bars For Welding.

From www.youtube.com

Tig Welding TIPS🔥🔥FILL AND CHILL! Tig welding tips to get great starts Chill Bars For Welding Chill blocks for welding can help to prevent these issues in welding when they are most critical. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application. Chill Bars For Welding.

From www.youtube.com

Sheet metal MIG Welding 101 YouTube Chill Bars For Welding They can also be integral with a. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. Chill blocks for welding can help to prevent these issues in welding when they are most critical. A chill block has been seen as an effective way to position. Chill Bars For Welding.

From www.weldingtipsandtricks.com

Tig Welding Carbon Steel 18ga 2f outside corner using chill bars Chill Bars For Welding Industries can also make use of external welding chillers along the workpiece to keep the heat in check. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. Save time and make more. A chill block has been seen as an effective way to position and hold the workpiece. Chill Bars For Welding.

From www.youtube.com

Backing Bars For Stainless Steel Welding YouTube Chill Bars For Welding Chill bars can be separate components used to help control interpass temperature. While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. Save time and make more. They provide. Chill Bars For Welding.

From www.weldingtipsandtricks.com

Aerospace Welding Test and Fixture Chill Bars For Welding Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. They can also be integral with a. Chill blocks for welding can help to prevent these issues in welding when they are most critical. While cutting some aluminum bar for a welding project we cut a bunch to the. Chill Bars For Welding.

From www.youtube.com

Steel bar , two powerful joint welding tricks that few people know Chill Bars For Welding Save time and make more. Chill blocks for welding can help to prevent these issues in welding when they are most critical. They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. A chill block. Chill Bars For Welding.

From www.youtube.com

TIG Welding 1/4" 6061 Aluminum Flat Bar Part 3 YouTube Chill Bars For Welding Save time and make more. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. That means you get the. Chill blocks for welding can help to prevent these issues in. Chill Bars For Welding.

From www.weldingtipsandtricks.com

Tig Welding Carbon Steel outside corner without chill bars Chill Bars For Welding That means you get the. Chill blocks for welding can help to prevent these issues in welding when they are most critical. They can also be integral with a. Save time and make more. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. Chill bars can be separate components used to. Chill Bars For Welding.

From www.bgstructuralengineering.com

Welding Intro Chill Bars For Welding Save time and make more. While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. Chill bars can be separate components used to help control interpass temperature. A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. They provide. Chill Bars For Welding.

From resources.arcmachines.com

Chill Blocks for Welding Arc Machines Chill Bars For Welding They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. That means you get the. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat. Chill Bars For Welding.

From www.weldingtipsandtricks.com

Tig Welding a Stainless Steel Purge Box Chill Bars For Welding One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. Chill bars can be separate components used to help control interpass temperature. Chill blocks for welding can help to prevent these issues in welding when they are most critical. Welded chill plate (or permanent backing strip,. Chill Bars For Welding.

From www.dreamstime.com

Worker welding steel bar. editorial stock image. Image of protection Chill Bars For Welding They can also be integral with a. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. That means you get the. Chill bars can be separate components used to help control interpass temperature. While cutting some aluminum bar for a welding project we cut a. Chill Bars For Welding.

From www.superiorweldandfab.com

Aluminum Chill Blocks Superior Welding & Fabrication Supply, LLC Chill Bars For Welding They can also be integral with a. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. A chill block has been seen as an effective way to position and hold the. Chill Bars For Welding.

From www.rocheindustry.com

Essential Design Tips You Should Know About Welding Sheet Metal Chill Bars For Welding A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. Chill bars can be separate components used to help control interpass temperature. Industries can also make use of external welding chillers along the workpiece to keep the heat in check. Save time and make more. Chill. Chill Bars For Welding.

From getpipe.com

Weld Backing / Chill Rings GETPIPE Chill Bars For Welding They can also be integral with a. A chill block has been seen as an effective way to position and hold the workpiece steady during welding, while also ensuring heat management. Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. Industries can also make use of external welding. Chill Bars For Welding.

From www.superiorweldandfab.com

Aluminum Chill Blocks Superior Welding & Fabrication Supply, LLC Chill Bars For Welding Industries can also make use of external welding chillers along the workpiece to keep the heat in check. That means you get the. While cutting some aluminum bar for a welding project we cut a bunch to the incorrect length. They provide an effective way to dissipate heat actively and allow wider tolerances for heat minimization strategies. Chill blocks for. Chill Bars For Welding.

From www.machinemfg.com

Copper Busbar Welding Techniques and Best Practices MachineMFG Chill Bars For Welding Welded chill plate (or permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint. That means you get the. They can also be integral with a. One method used at all metals fabrication to reduce metal warping and weld distortion caused by heat during welding is the application of a. Chill blocks for. Chill Bars For Welding.