Ball Detent Design . in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. Inside of this plunger is a small ball and spring,. i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. design guidelines for ball plungers.

from cults3d.com

in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. Inside of this plunger is a small ball and spring,. design guidelines for ball plungers. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent.

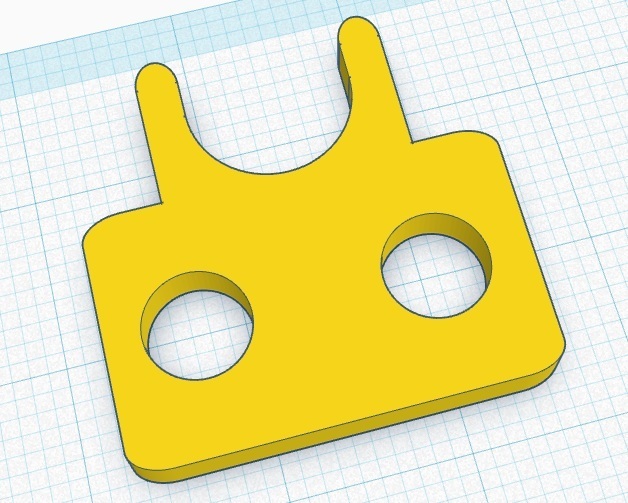

STL file Sheridan VM 68 detent , ball latch・3D print design to download

Ball Detent Design ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. design guidelines for ball plungers. Inside of this plunger is a small ball and spring,. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag.

From outofdarts.com

Ball Bearing Detent 6x7mm Out of Darts Ball Detent Design our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. in knife making,. Ball Detent Design.

From www.youtube.com

DIY Knife Tips.......How to make a Detent Ball Ramp! And make your wife Ball Detent Design in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. Inside of this plunger is a small ball and spring,. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. In order to calculate the. Ball Detent Design.

From www.planet-paintball.eu

Ball Detents Dangerous Power FX Paintball Ball Detent Design design guidelines for ball plungers. ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. i am trying to figure out how to. Ball Detent Design.

From cults3d.com

STL file Sheridan VM 68 detent , ball latch・3D print design to download Ball Detent Design i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. torque limiters come in several designs and methods. Ball Detent Design.

From nuclear-paintball-supply.myshopify.com

Old School Ball Detent Inception Designs Nuclear Paintball Supply Ball Detent Design our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. Inside of this plunger is a small ball and spring,. i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. torque limiters come in several designs and. Ball Detent Design.

From www.unisontek.com.tw

Quick release detent pin installed with ball and spring UNISON TEK CO Ball Detent Design torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. Inside of this plunger is a small ball and spring,. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. i am trying to figure out how to design a ball. Ball Detent Design.

From www.youtube.com

How To Repair a Hand Tool Ball Detent YouTube Ball Detent Design i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent.. Ball Detent Design.

From www.researchgate.net

Figure. Schematic representation of an individual springball detent Ball Detent Design torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. design guidelines for ball plungers. ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. our line of ball plungers is distinguished by its superior construction and materials, providing smooth. Ball Detent Design.

From www.made-in-china.com

SmallSize Precision HeavyDuty BallDetent Design Torque Limiter Ball Detent Design Inside of this plunger is a small ball and spring,. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. our line of ball plungers is distinguished by its superior construction and. Ball Detent Design.

From magnet-schultzamerica.com

Part Two High Security, Robust Locking Applications, BallDetent Ball Detent Design Inside of this plunger is a small ball and spring,. ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. design guidelines for ball plungers. our. Ball Detent Design.

From www.motioncontroltips.com

Ball detent torque limiters How do they work and when are they used? Ball Detent Design our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. torque limiters come in several designs. Ball Detent Design.

From www.researchgate.net

Figure. Schematic representation of an individual springball detent Ball Detent Design our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. Inside of this plunger is. Ball Detent Design.

From www.youtube.com

3d printed 3 position detent mechanism YouTube Ball Detent Design Inside of this plunger is a small ball and spring,. in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. design guidelines. Ball Detent Design.

From atelier-yuwa.ciao.jp

Balldetent Locking Mechanism For The Sample Stage Sample Mount Ball Detent Design ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. Inside of this plunger is a small ball and spring,. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. torque limiters come in several designs and methods of operation, including ball detent, shear. Ball Detent Design.

From www.framingtech.com

Ball Detent Latch Framing Technology Ball Detent Design design guidelines for ball plungers. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. Inside of this plunger is a small ball and spring,. our line of ball plungers is. Ball Detent Design.

From hyquip.co.uk

Carr Lane Ball Detents HYQUIP Limited Ball Detent Design Inside of this plunger is a small ball and spring,. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. ball plungers are commonly used for notching. Ball Detent Design.

From www.youtube.com

What is a Detent Ball? There’s a Ball in your Knife and it Lives in a Ball Detent Design in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. design guidelines for ball plungers. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. ball plungers are commonly used for notching and. Ball Detent Design.

From autocockerparts.com

Inception Designs Ball Detent Ball Detent Design i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. our line of ball plungers is distinguished by. Ball Detent Design.

From www.youtube.com

Detent ball set YouTube Ball Detent Design in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. ball plungers are commonly used for notching and indexing where they are released with predetermined. Ball Detent Design.

From magnet-schultzamerica.com

Part Two High Security, Robust Locking Applications, BallDetent Ball Detent Design In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. in knife making, the. Ball Detent Design.

From www.youtube.com

Ball and Detent YouTube Ball Detent Design In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. Inside of this plunger is a small ball and spring,. design guidelines for ball plungers. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. i am trying to figure out how to. Ball Detent Design.

From atelier-yuwa.ciao.jp

Balldetent Locking Mechanism For The Sample Stage Sample Mount Ball Detent Design in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. design guidelines for ball plungers. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. Inside of this plunger is a small ball and spring,.. Ball Detent Design.

From www.practicalmachinist.com

How To Make Spring Mechanism (Laser Cut) Ball Detent Design i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. Inside of this plunger is a small ball and spring,. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. ball plungers are commonly used. Ball Detent Design.

From blog.rw-america.com

Coupling Technology Blog by R+W ball detent coupling Ball Detent Design ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. Inside of this plunger is a small ball and spring,. i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. torque limiters come in several designs and. Ball Detent Design.

From www.ebay.com

Inception Designs Old School Style Ball Detent eBay Ball Detent Design Inside of this plunger is a small ball and spring,. in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. i am trying to. Ball Detent Design.

From www.herooutdoors.com

BT4/ SW1 Ball Detent 75 Hero Outdoors Ball Detent Design design guidelines for ball plungers. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. in knife making, the ball is often press fit into a. Ball Detent Design.

From forum.onshape.com

How to Mate Ball Detent Mechanism? — Onshape Ball Detent Design our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. design guidelines for ball plungers. in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. torque limiters come in several designs and methods. Ball Detent Design.

From sandum.en.made-in-china.com

Customized Ball Plunger and Detent Design China Spring Loaded Ball Ball Detent Design i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed and the ti is. our line of ball plungers is distinguished by. Ball Detent Design.

From diequa.com

Adjustable BallDetent Torque Limiter Design Couplings & More Ball Detent Design In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. Inside. Ball Detent Design.

From www.carrlane.com

Ball Detents Carr Lane Ball Detent Design i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. Inside of this plunger is a small ball and spring,. torque limiters come in several designs and methods. Ball Detent Design.

From forum.onshape.com

How to Mate Ball Detent Mechanism? — Onshape Ball Detent Design In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. in knife making, the ball is often press fit into a piece ot 6/4 ti such that half the ball remains exposed. Ball Detent Design.

From www.designworldonline.com

Safety coupling basics What does a balldetent do? Ball Detent Design design guidelines for ball plungers. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and. Ball Detent Design.

From www.made-in-china.com

Precision HeavyDuty Ball Detent Design Torque Limiter China Ball Detent Design ball plungers are commonly used for notching and indexing where they are released with predetermined side loads. design guidelines for ball plungers. our line of ball plungers is distinguished by its superior construction and materials, providing smooth operation, consistent. Inside of this plunger is a small ball and spring,. i am trying to figure out how. Ball Detent Design.

From www.paintballgateway.com

Ball Detents paintballgateway Ball Detent Design i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. In order to calculate the side force, fs, necessary to disengage a ball plunger from the detent. torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and. Ball Detent Design.

From www.youtube.com

D.I.Y. Ball Detent YouTube Ball Detent Design torque limiters come in several designs and methods of operation, including ball detent, shear pin, permanent magnet, and sprag. design guidelines for ball plungers. i am trying to figure out how to design a ball detent retention system that works well, but am having a difficult time. ball plungers are commonly used for notching and indexing. Ball Detent Design.