Visual Inspection Detection Rating . There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products should mean. It’s often the first step in inspection. That rating really highlights where the risks are, as experience has shown us. The pfmea also tracks improvements through risk priority number (rpn). Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. We use 8 if the detection is visual inspection only. The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. It is obvious by the fact of.

from mobidev.biz

There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products should mean. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. We use 8 if the detection is visual inspection only. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. The pfmea also tracks improvements through risk priority number (rpn). It’s often the first step in inspection. That rating really highlights where the risks are, as experience has shown us. It is obvious by the fact of. The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,.

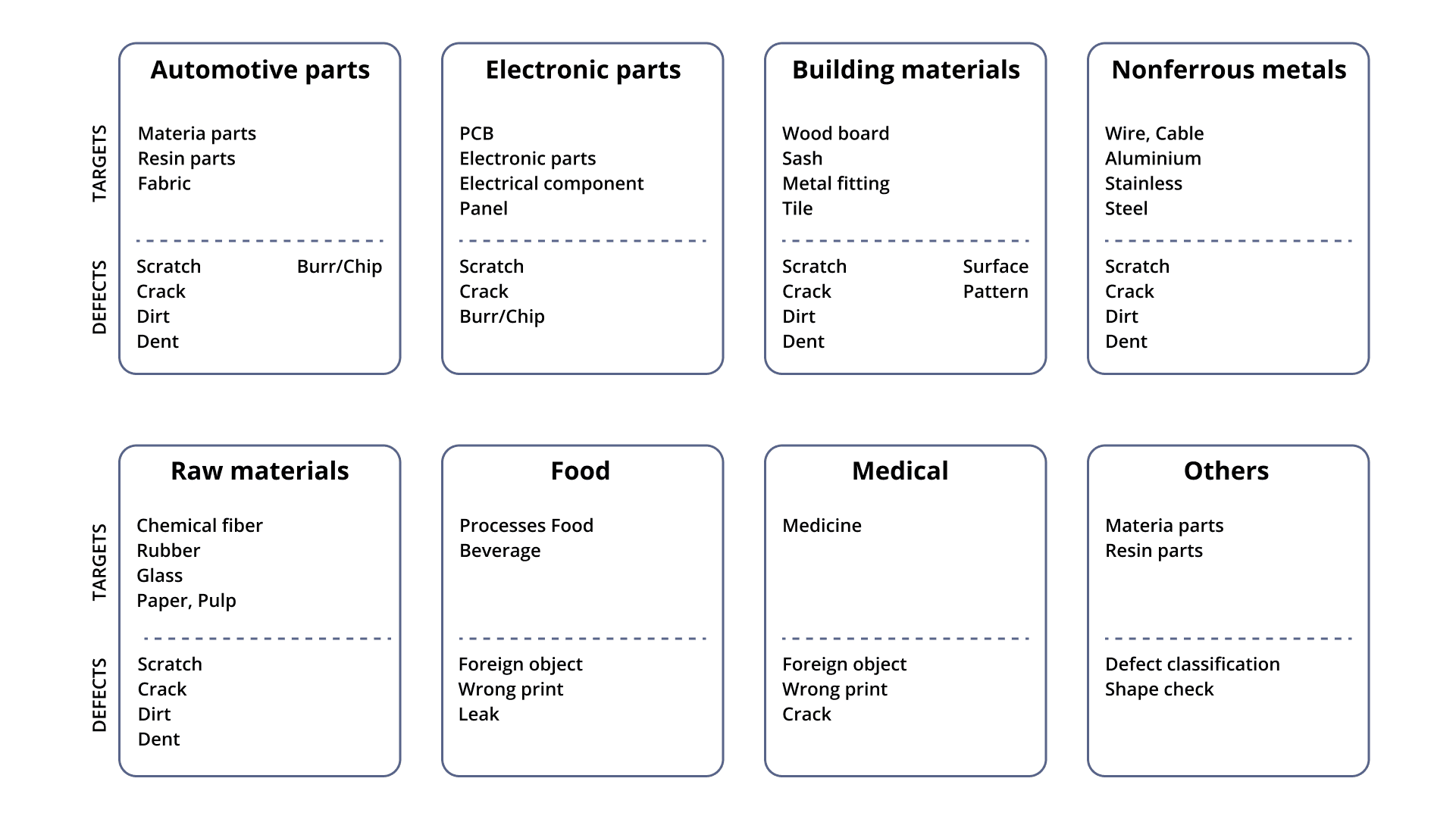

AI Visual Inspection For Defect Detection in Manufacturing

Visual Inspection Detection Rating The pfmea also tracks improvements through risk priority number (rpn). The pfmea also tracks improvements through risk priority number (rpn). The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. It’s often the first step in inspection. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products should mean. There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. That rating really highlights where the risks are, as experience has shown us. It is obvious by the fact of. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. We use 8 if the detection is visual inspection only.

From exonlvzdb.blob.core.windows.net

Fmea Detection Rating Table at Alma Hall blog Visual Inspection Detection Rating Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. That. Visual Inspection Detection Rating.

From www.youtube.com

Types of visual inspection visual inspection in hindi non destructive Visual Inspection Detection Rating There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. That rating really highlights where the risks are, as experience has shown us. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for. Visual Inspection Detection Rating.

From www.patlabelsonline.co.uk

Visual Inspection Labels for Portable Appliances Pat Labels Visual Inspection Detection Rating Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. It is obvious by the fact of. There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. That rating really highlights where the risks are, as experience has shown us. The pfmea. Visual Inspection Detection Rating.

From www.leisurepro.com

Visual Inspection Certificate Inspection Sticker Visual Inspection Detection Rating There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products should mean. We use 8 if the detection is visual inspection only. The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. It’s often the first step in inspection. That rating really highlights where the risks are, as experience. Visual Inspection Detection Rating.

From www.resco.net

Visual inspection Resco Visual Inspection Detection Rating It’s often the first step in inspection. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. That rating really highlights where the risks are, as experience has shown us. The pfmea also tracks improvements through risk priority number (rpn). Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids. Visual Inspection Detection Rating.

From www.researchgate.net

Performance Rating Scale for Visual Inspection Using Climbers Visual Inspection Detection Rating There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. We use 8 if the detection is visual inspection only. There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products should mean. Deming's statement that visual inspection is 85% effective and juran's 87%. Visual Inspection Detection Rating.

From www.scribd.com

Rmu Visual Inspection Checklist Visual Inspection Detection Rating We use 8 if the detection is visual inspection only. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. It’s often the first step in inspection. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. The pfmea. Visual Inspection Detection Rating.

From www.scribd.com

“Visual Inspection …. examination …. by Nondestructive Testing Visual Inspection Detection Rating It’s often the first step in inspection. We use 8 if the detection is visual inspection only. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. That rating really highlights where the risks are, as experience has. Visual Inspection Detection Rating.

From marutitech.com

What is AI Visual Inspection for Defect Detection? A Deep Dive Visual Inspection Detection Rating Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. That rating really highlights where the risks are, as experience has shown us. It is obvious by the fact of. It’s often the first step in inspection. There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products should mean. The detection ranking determines. Visual Inspection Detection Rating.

From fifendt.imeche.org

Visual Testing Level 2 IMechE FIFE NDT Visual Inspection Detection Rating The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. It is obvious by the fact of. The pfmea also tracks improvements through risk priority number (rpn). Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. We use 8 if the detection is visual inspection only. There. Visual Inspection Detection Rating.

From www.studocu.com

Visual Inspection useful study materials Visual Inspection Most Visual Inspection Detection Rating The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. That rating really highlights where the risks are, as experience has shown us. It is. Visual Inspection Detection Rating.

From limblecmms.com

How To Properly Perform DFMEA & PFMEA [Examples Included] Visual Inspection Detection Rating Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. The pfmea also tracks improvements through risk priority number (rpn). The detection ranking determines the ability of specific tests. Visual Inspection Detection Rating.

From www.zzfmdn.com

Everything you need to know about Visual Inspection with AI Visual Inspection Detection Rating Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. We use 8 if the detection is visual inspection only. That rating really highlights where the risks are, as experience has shown us. It is obvious by the fact of. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids. Visual Inspection Detection Rating.

From facilio.com

Visual Inspection What Is It, Benefits, and more! Visual Inspection Detection Rating The pfmea also tracks improvements through risk priority number (rpn). Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. That rating really highlights where the risks are, as experience has shown us. We use 8 if the detection is visual inspection only.. Visual Inspection Detection Rating.

From ndttrainingonline.com

Visual Inspection Course Visual Inspection Detection Rating Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. It is obvious by the fact of. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or. Visual Inspection Detection Rating.

From mobidev.biz

AI Visual Inspection For Defect Detection in Manufacturing Visual Inspection Detection Rating There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. Visual inspection is a. Visual Inspection Detection Rating.

From egac.co

Visual Inspection Test (Level I & II) VT Egyptian Academy Visual Inspection Detection Rating It’s often the first step in inspection. The pfmea also tracks improvements through risk priority number (rpn). Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. That rating really highlights where the risks are, as experience has shown us. Deming's statement that. Visual Inspection Detection Rating.

From weldingclarity.com

Visual Inspection in Weld Quality Testing How it Works? Visual Inspection Detection Rating Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. We use 8 if the detection is visual inspection only. It is obvious by the fact of. There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. It’s often the first step. Visual Inspection Detection Rating.

From mobidev.biz

AI Visual Inspection For Defect Detection in Manufacturing Visual Inspection Detection Rating Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. The pfmea also tracks improvements through risk priority number (rpn). We use 8 if the detection is visual inspection only. There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products. Visual Inspection Detection Rating.

From goonline.io

Revolutionizing Manufacturing with AIbased Defect Detection Inspection Visual Inspection Detection Rating It is obvious by the fact of. We use 8 if the detection is visual inspection only. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. The pfmea also tracks improvements through risk priority number (rpn). It’s often the first step in. Visual Inspection Detection Rating.

From www.slideserve.com

PPT Six Most Common NDT Methods PowerPoint Presentation, free Visual Inspection Detection Rating Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems. Visual Inspection Detection Rating.

From ndtblog-us.fujifilm.com

What Is Visual Testing? Visual NonDestructive Examination Visual Inspection Detection Rating It is obvious by the fact of. It’s often the first step in inspection. We use 8 if the detection is visual inspection only. That rating really highlights where the risks are, as experience has shown us. There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products should mean. The detection ranking determines the ability of specific. Visual Inspection Detection Rating.

From www.aiophotoz.com

Fmea Detection Scale Fmea Detection Rating Scale Understanding Fmea Visual Inspection Detection Rating Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. That rating really highlights where the risks are, as experience has shown us. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. There are processes where visual inspection. Visual Inspection Detection Rating.

From www.scribd.com

AWS D1.1 Visual Inspection Acceptance Criteria Visual Inspection Detection Rating Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. It’s often the first step in inspection. It is obvious by the fact of. That rating really highlights where the risks are, as experience has shown us. The pfmea also tracks improvements through. Visual Inspection Detection Rating.

From www.vrogue.co

How To Properly Perform Dfmea Pfmea Examples Included vrogue.co Visual Inspection Detection Rating It’s often the first step in inspection. The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. The pfmea also tracks improvements through risk priority number (rpn). It is obvious by the fact of. There are processes where visual inspection might be used to determine whether a thing is red or blue. Visual Inspection Detection Rating.

From www.slideserve.com

PPT Chapter 2 Visual Inspection PowerPoint Presentation, free Visual Inspection Detection Rating That rating really highlights where the risks are, as experience has shown us. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. It’s often the first step in inspection. The pfmea also tracks improvements through risk priority number (rpn). There is a. Visual Inspection Detection Rating.

From marutitech.com

What is AI Visual Inspection for Defect Detection? A Deep Dive Visual Inspection Detection Rating There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products should mean. That rating really highlights where the risks are, as experience has shown us. The pfmea also tracks improvements through risk priority number (rpn). Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems. Visual Inspection Detection Rating.

From www.etsy.com

Visual Vehicle Inspection Report Vehicle Inspection Etsy Visual Inspection Detection Rating It’s often the first step in inspection. There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products should mean. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. The pfmea also tracks improvements through risk priority number (rpn). That rating really highlights where the risks are, as experience has shown us. It. Visual Inspection Detection Rating.

From www.researchgate.net

Rating values for visual inspection data Download Scientific Diagram Visual Inspection Detection Rating There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. We use 8 if the detection is visual inspection only. Visual inspection is a fundamental ndt method that involves using the naked. Visual Inspection Detection Rating.

From www.slideteam.net

Visual Inspection System For Quality Control Deploying Automation Visual Inspection Detection Rating There is a common misunderstanding that 100% visual inspection (vi) of biopharmaceutical products should mean. We use 8 if the detection is visual inspection only. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. There are processes where visual inspection might be used to determine whether a thing is red or blue from a group. Visual Inspection Detection Rating.

From saxon.ai

AIbased visual inspection for defect detection Visual Inspection Detection Rating We use 8 if the detection is visual inspection only. That rating really highlights where the risks are, as experience has shown us. The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. The pfmea also tracks improvements through risk priority number (rpn). It’s often the first step in inspection. There is. Visual Inspection Detection Rating.

From www.testevolve.com

Visual Regression Testing Tool Automated Visual Regression Testing Visual Inspection Detection Rating It is obvious by the fact of. The pfmea also tracks improvements through risk priority number (rpn). The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. That. Visual Inspection Detection Rating.

From www.etsy.com

27 Point Visual Vehicle Inspection Form Fillable PDF Multipoint Visual Inspection Detection Rating It’s often the first step in inspection. Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. The detection ranking determines the ability of specific tests to confirm the failure mode / causes are eliminated. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or. Visual Inspection Detection Rating.

From www.scribd.com

NDT & Visual Inspection.ppt Nondestructive Testing Radiography Visual Inspection Detection Rating There are processes where visual inspection might be used to determine whether a thing is red or blue from a group of five objects,. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. There is a common misunderstanding that 100% visual inspection. Visual Inspection Detection Rating.

From sharpml.com

AI Will Transform Your Visual Inspection Workflows SharpML Visual Inspection Detection Rating It is obvious by the fact of. The pfmea also tracks improvements through risk priority number (rpn). Deming's statement that visual inspection is 85% effective and juran's 87% effective are false. Visual inspection is a fundamental ndt method that involves using the naked eye or visual aids to examine materials, components, or systems for any defects or irregularities. It’s often. Visual Inspection Detection Rating.