Blind Hole Feature . A blind hole is a hole that does not go all the way through a part. Designers often use blind holes when they need precision and depth without piercing the. What is a blind hole? This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Holes that go all the way through the component are known as through holes. Thru holes get drilled all the way through a part. Learn more about the uses of blind holes in machining. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. Holes that do not go completely through the material are known as blind holes. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. Blind holes are essential features in various engineering applications, offering unique benefits and advantages over through holes. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or. A blind hole goes to a specified depth and stops. Blind holes are holes drilled in a material that does not have an exit from the other side.

from www.researchgate.net

Thru holes get drilled all the way through a part. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. A blind hole is a hole that does not go all the way through a part. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Blind holes are holes drilled in a material that does not have an exit from the other side. What is a blind hole? Holes that go all the way through the component are known as through holes. Holes that do not go completely through the material are known as blind holes. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth.

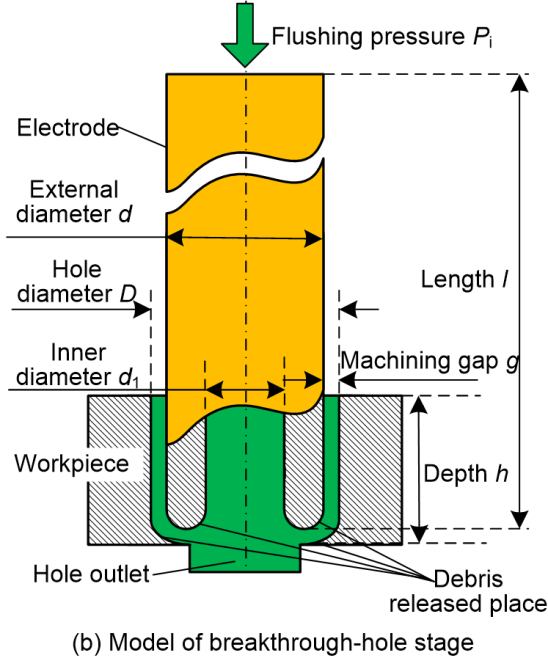

Fast hole EDM drilling models of blindhole stage and breakthroughhole

Blind Hole Feature Blind holes are holes drilled in a material that does not have an exit from the other side. A blind hole is a hole that does not go all the way through a part. Blind holes are essential features in various engineering applications, offering unique benefits and advantages over through holes. A blind hole goes to a specified depth and stops. Holes that do not go completely through the material are known as blind holes. Holes that go all the way through the component are known as through holes. Designers often use blind holes when they need precision and depth without piercing the. Learn more about the uses of blind holes in machining. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. What is a blind hole? A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or. Blind holes are holes drilled in a material that does not have an exit from the other side. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Thru holes get drilled all the way through a part.

From www.youtube.com

How to Bottom Tap a Blind Hole Bottom Tapping Basics YouTube Blind Hole Feature A blind hole is a hole that does not go all the way through a part. What is a blind hole? Thru holes get drilled all the way through a part. Learn more about the uses of blind holes in machining. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only. Blind Hole Feature.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Feature This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Blind holes are essential features in various engineering applications, offering unique benefits and advantages over through holes. Blind holes are holes drilled in a material that does not have an exit from the other side. Blind holes are holes. Blind Hole Feature.

From www.researchgate.net

The cathode plate features three blind holes with a diameter of 25.1 Blind Hole Feature Holes that do not go completely through the material are known as blind holes. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. Blind holes are holes drilled in a material that does not have an exit from the other side. A blind hole is a. Blind Hole Feature.

From www.xometry.com

What Are Blind Holes in Engineering and Machining? Xometry Blind Hole Feature A blind hole is a hole that does not go all the way through a part. What is a blind hole? To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. Thru holes get drilled all the way through a part. A blind hole goes to a specified depth and stops.. Blind Hole Feature.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible Blind Hole Feature Holes that do not go completely through the material are known as blind holes. Learn more about the uses of blind holes in machining. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or. A blind hole goes to a specified depth and stops. Holes that go all. Blind Hole Feature.

From www.youtube.com

To cut a through hole, blind hole and half hole by Nine9 hole making Blind Hole Feature Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. Holes that do not go completely through the material are known as blind holes. Designers often use blind holes when they need precision and depth without piercing the. What is a blind hole? Holes that go all. Blind Hole Feature.

From www.researchgate.net

Fast hole EDM drilling models of blindhole stage and breakthroughhole Blind Hole Feature Holes that do not go completely through the material are known as blind holes. Thru holes get drilled all the way through a part. Holes that go all the way through the component are known as through holes. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or.. Blind Hole Feature.

From www.youtube.com

Blind Hole Thread repair How to install a Helicoil thread insert Blind Hole Feature This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Holes that do not go completely through the material are known as blind holes. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or. Blind holes are. Blind Hole Feature.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Feature A blind hole is a hole that does not go all the way through a part. Holes that go all the way through the component are known as through holes. Designers often use blind holes when they need precision and depth without piercing the. Blind holes are holes drilled in a material that does not have an exit from the. Blind Hole Feature.

From www.mscdirect.com

Made in USA 11 Piece Blind Hole Lap Set MSC Direct Blind Hole Feature What is a blind hole? Holes that do not go completely through the material are known as blind holes. A blind hole is a hole that does not go all the way through a part. Holes that go all the way through the component are known as through holes. A blind hole goes to a specified depth and stops. Blind. Blind Hole Feature.

From solidcam.help

Introduction and Basic Concepts Blind Hole Feature Holes that go all the way through the component are known as through holes. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. A blind hole is a hole that does not go all the way through a part. A blind hole goes to a specified. Blind Hole Feature.

From www.youtube.com

Blind hole broaching with a CNC mill YouTube Blind Hole Feature Blind holes are holes drilled in a material that does not have an exit from the other side. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. A blind hole goes to a specified depth and stops. Holes that do not go completely through the material. Blind Hole Feature.

From www.machinistguides.com

Blind Holes All About Machinist Guides Blind Hole Feature Designers often use blind holes when they need precision and depth without piercing the. Blind holes are holes drilled in a material that does not have an exit from the other side. Thru holes get drilled all the way through a part. To specify a blind hole requires listing the diameter of the hole and a dimension to control the. Blind Hole Feature.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Blind Hole Feature Blind holes are essential features in various engineering applications, offering unique benefits and advantages over through holes. A blind hole goes to a specified depth and stops. Thru holes get drilled all the way through a part. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part.. Blind Hole Feature.

From www.youtube.com

Spare Parts 2 Drilling And Tapping A Small Blind Hole On The Mill Blind Hole Feature What is a blind hole? Holes that go all the way through the component are known as through holes. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. Learn more about the uses of blind holes in machining. This article will explore what a blind hole. Blind Hole Feature.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Feature Blind holes are holes drilled in a material that does not have an exit from the other side. What is a blind hole? A blind hole is a hole that does not go all the way through a part. Learn more about the uses of blind holes in machining. Blind holes are essential features in various engineering applications, offering unique. Blind Hole Feature.

From www.cnccookbook.com

Blind Hole Tapping Secrets [ Stop Breaking Taps! ] Blind Hole Feature Learn more about the uses of blind holes in machining. What is a blind hole? Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Holes. Blind Hole Feature.

From www.youtube.com

4 tips for perfect blind hole threads! YouTube Blind Hole Feature A blind hole goes to a specified depth and stops. What is a blind hole? A blind hole is a hole that does not go all the way through a part. Blind holes are essential features in various engineering applications, offering unique benefits and advantages over through holes. A blind hole refers to a hole that does not pass completely. Blind Hole Feature.

From www.slideserve.com

PPT Holes PowerPoint Presentation ID2107959 Blind Hole Feature Designers often use blind holes when they need precision and depth without piercing the. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. A blind hole is a. Blind Hole Feature.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Blind Hole Feature Learn more about the uses of blind holes in machining. A blind hole goes to a specified depth and stops. Designers often use blind holes when they need precision and depth without piercing the. A blind hole is a hole that does not go all the way through a part. Thru holes get drilled all the way through a part.. Blind Hole Feature.

From slideplayer.com

IENG 475 ComputerControlled Manufacturing Systems ppt download Blind Hole Feature A blind hole goes to a specified depth and stops. Holes that do not go completely through the material are known as blind holes. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or. A blind hole is a hole that does not go all the way through. Blind Hole Feature.

From www.machinistguides.com

Guide to Holes on Blueprints [Types, Symbols & Features] Machinist Guides Blind Hole Feature Learn more about the uses of blind holes in machining. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. Holes that do not go completely through the material are. Blind Hole Feature.

From www.youtube.com

Sir Meccanica S.p.A. In line boring and overlay welding on a blind Blind Hole Feature Blind holes are holes drilled in a material that does not have an exit from the other side. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. Blind holes. Blind Hole Feature.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 Blind Hole Feature Learn more about the uses of blind holes in machining. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or. Blind holes are essential features in various engineering applications, offering unique benefits and advantages over through holes. Blind holes are holes that get drilled or milled to a. Blind Hole Feature.

From www.sansmachining.com

Understanding Blind Holes in Machining SANS Blind Hole Feature Holes that go all the way through the component are known as through holes. What is a blind hole? This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Learn more about the uses of blind holes in machining. Thru holes get drilled all the way through a part.. Blind Hole Feature.

From www.degruyter.com

Improving the precision of microEDM for blind holes in titanium alloy Blind Hole Feature What is a blind hole? Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. A blind hole is a hole that does not go all the way through a part. Blind holes are essential features in various engineering applications, offering unique benefits and advantages over through. Blind Hole Feature.

From toolsmechanism.com

How to Mark Blind Holes for Drilling? Tools Mechanism Blind Hole Feature Blind holes are holes drilled in a material that does not have an exit from the other side. A blind hole goes to a specified depth and stops. Learn more about the uses of blind holes in machining. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or.. Blind Hole Feature.

From www.youtube.com

Marking and drilling blind holes YouTube Blind Hole Feature Designers often use blind holes when they need precision and depth without piercing the. Holes that go all the way through the component are known as through holes. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or. Blind holes are holes that get drilled or milled to. Blind Hole Feature.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Blind Hole Feature A blind hole is a hole that does not go all the way through a part. What is a blind hole? Holes that do not go completely through the material are known as blind holes. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. A blind hole refers. Blind Hole Feature.

From drillvalley.com

How to Mark Blind Holes for Drilling 12 Expert Methods Blind Hole Feature Learn more about the uses of blind holes in machining. A blind hole refers to a hole that does not pass completely through a part, i.e., it is only drilled, reamed, or. Holes that do not go completely through the material are known as blind holes. Blind holes are essential features in various engineering applications, offering unique benefits and advantages. Blind Hole Feature.

From www.coursehero.com

[Solved] Using appropriate sketch explain method to drill a blind hole Blind Hole Feature What is a blind hole? A blind hole is a hole that does not go all the way through a part. Learn more about the uses of blind holes in machining. Holes that do not go completely through the material are known as blind holes. A blind hole goes to a specified depth and stops. Blind holes are holes drilled. Blind Hole Feature.

From at-machining.com

The Engineer's Guide to Blind Holes in Machining ATMachining Blind Hole Feature Blind holes are holes drilled in a material that does not have an exit from the other side. Blind holes are essential features in various engineering applications, offering unique benefits and advantages over through holes. Thru holes get drilled all the way through a part. To specify a blind hole requires listing the diameter of the hole and a dimension. Blind Hole Feature.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Blind Hole Feature Blind holes are essential features in various engineering applications, offering unique benefits and advantages over through holes. Thru holes get drilled all the way through a part. What is a blind hole? Holes that do not go completely through the material are known as blind holes. A blind hole refers to a hole that does not pass completely through a. Blind Hole Feature.

From www.slideserve.com

PPT Holes In AutoCAD PowerPoint Presentation, free download ID5331488 Blind Hole Feature Holes that do not go completely through the material are known as blind holes. Holes that go all the way through the component are known as through holes. What is a blind hole? Blind holes are holes drilled in a material that does not have an exit from the other side. Blind holes are essential features in various engineering applications,. Blind Hole Feature.

From www.wevolver.com

Everything you need to know about Injection Molded Holes Blind Hole Feature Designers often use blind holes when they need precision and depth without piercing the. Blind holes are holes drilled in a material that does not have an exit from the other side. Thru holes get drilled all the way through a part. A blind hole is a hole that does not go all the way through a part. A blind. Blind Hole Feature.