Sizing Electric Motor For Hydraulic Pump . If system pressure and flow are constant, motor sizing simply boils down to the standard equation: Sizing electric motors correctly for hydraulic power units can save a sizable amount of money over the life of the equipment. Discover how to correctly size electric motors for hydraulic pump drives with womack's guide. Use this equation to help figure out what electric motor horsepower (hp) is required to drive a hydraulic pump. This technique will produce a reliable power unit, but one that is relatively heavy, bulky, inefficient, and noisy. In part 1 of this post, we discussed the correct way to size an electric motor for a hydraulic pump. If you are accustomed to specifying electric motors for hpus, you may be tempted to size a pump to be driven at 1,800 rpm, then specify an oversized motor that can develop enough torque to drive the pump at this speed. Hp = qp / 1714em. The calculator below can used to calculate the hydraulic and shaft power of a pump using imperial units: To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). Hydraulic pump motor sizing is critical for ensuring that the motor provides adequate power to meet the system’s requirements. Optimize power and efficiency in your hydraulic systems. Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. Now we’re going to take things a step.

from insights.globalspec.com

In part 1 of this post, we discussed the correct way to size an electric motor for a hydraulic pump. If you are accustomed to specifying electric motors for hpus, you may be tempted to size a pump to be driven at 1,800 rpm, then specify an oversized motor that can develop enough torque to drive the pump at this speed. Optimize power and efficiency in your hydraulic systems. Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). If system pressure and flow are constant, motor sizing simply boils down to the standard equation: Hp = qp / 1714em. Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. This technique will produce a reliable power unit, but one that is relatively heavy, bulky, inefficient, and noisy. The calculator below can used to calculate the hydraulic and shaft power of a pump using imperial units: Sizing electric motors correctly for hydraulic power units can save a sizable amount of money over the life of the equipment.

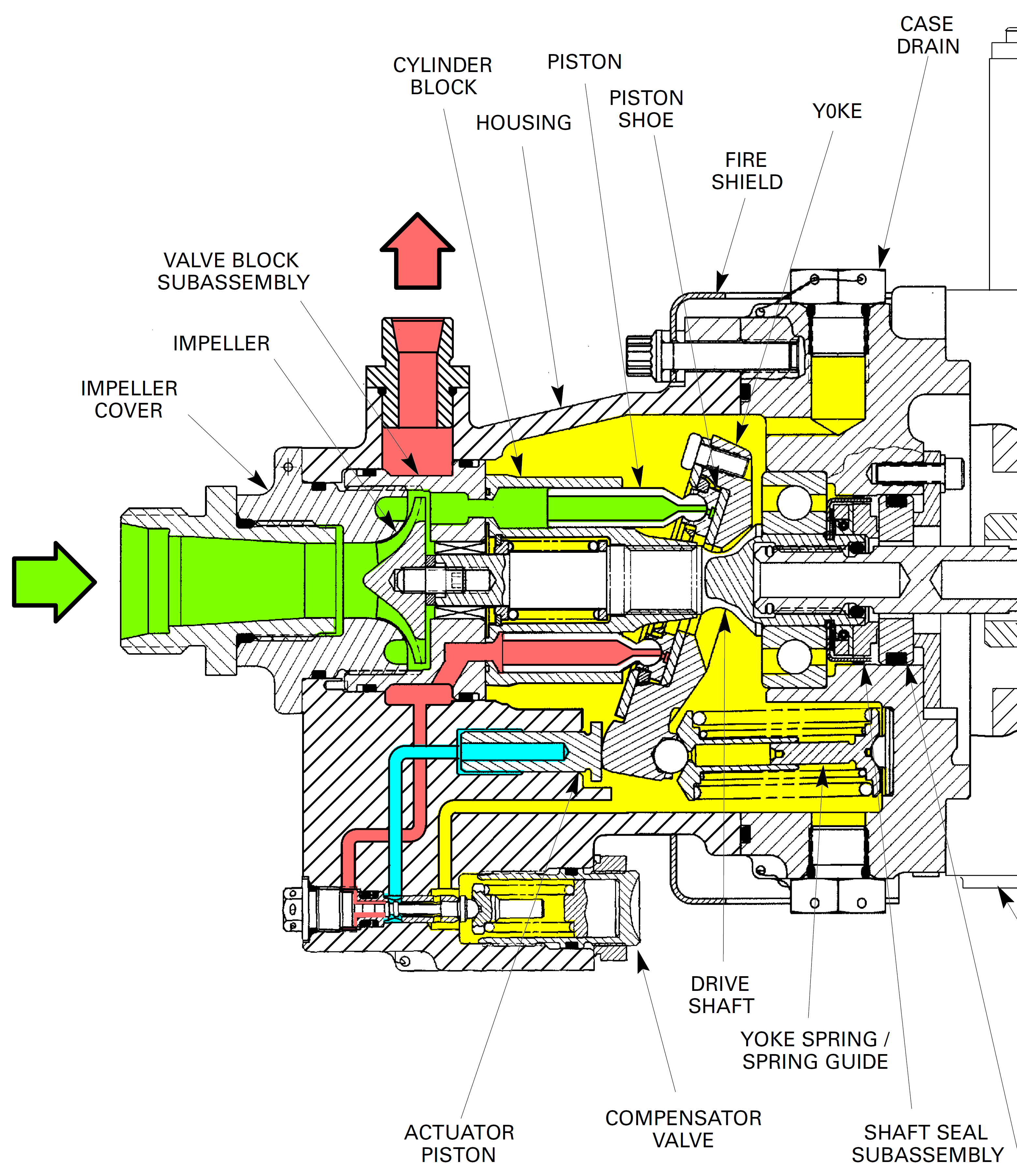

How does a electric motordriven axial piston

Sizing Electric Motor For Hydraulic Pump If you are accustomed to specifying electric motors for hpus, you may be tempted to size a pump to be driven at 1,800 rpm, then specify an oversized motor that can develop enough torque to drive the pump at this speed. Hp = qp / 1714em. If you are accustomed to specifying electric motors for hpus, you may be tempted to size a pump to be driven at 1,800 rpm, then specify an oversized motor that can develop enough torque to drive the pump at this speed. Hydraulic pump motor sizing is critical for ensuring that the motor provides adequate power to meet the system’s requirements. The calculator below can used to calculate the hydraulic and shaft power of a pump using imperial units: Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. This technique will produce a reliable power unit, but one that is relatively heavy, bulky, inefficient, and noisy. Optimize power and efficiency in your hydraulic systems. Now we’re going to take things a step. To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. Use this equation to help figure out what electric motor horsepower (hp) is required to drive a hydraulic pump. Discover how to correctly size electric motors for hydraulic pump drives with womack's guide. In part 1 of this post, we discussed the correct way to size an electric motor for a hydraulic pump. Sizing electric motors correctly for hydraulic power units can save a sizable amount of money over the life of the equipment. If system pressure and flow are constant, motor sizing simply boils down to the standard equation:

From www.hydraulicpumpmotor.com

3 Phase 7.5kw (10HP) Totally Enclosed Type T6B Horizontal Electric Sizing Electric Motor For Hydraulic Pump Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). If you are accustomed to specifying electric motors for hpus, you may be tempted to size a pump to be driven at 1,800 rpm, then specify an oversized motor. Sizing Electric Motor For Hydraulic Pump.

From www.ebay.com

Asea Hydraulic Pump Electric Motor 3470RPM MT71A14F852 eBay Sizing Electric Motor For Hydraulic Pump Hp = qp / 1714em. Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. Discover how to correctly size electric motors for hydraulic pump drives with womack's guide. If you are accustomed to specifying electric motors for hpus, you may be tempted to size a pump to be driven at 1,800 rpm, then. Sizing Electric Motor For Hydraulic Pump.

From www.ebay.com.au

Hydraulic 240V Single Phase Electric Motor Pump Set with 8GPM HiLo Sizing Electric Motor For Hydraulic Pump If system pressure and flow are constant, motor sizing simply boils down to the standard equation: The calculator below can used to calculate the hydraulic and shaft power of a pump using imperial units: Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. Use this equation to help figure out what electric motor. Sizing Electric Motor For Hydraulic Pump.

From www.amazon.ca

BestEquip 12V Hydraulic Pump 15 Quart Metal Reservoir Hydraulic Power Sizing Electric Motor For Hydraulic Pump If system pressure and flow are constant, motor sizing simply boils down to the standard equation: Optimize power and efficiency in your hydraulic systems. Hp = qp / 1714em. Now we’re going to take things a step. Sizing electric motors correctly for hydraulic power units can save a sizable amount of money over the life of the equipment. To size. Sizing Electric Motor For Hydraulic Pump.

From www.flowfitonline.com

Hydraulic 3.7KW 240V 1 PH motor pumpset with 8GPM Hilow Pump 200 Bar Sizing Electric Motor For Hydraulic Pump To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. Optimize power and efficiency in your hydraulic systems. If system pressure and flow are constant, motor sizing simply boils down to the standard equation: Now we’re going to take things a step.. Sizing Electric Motor For Hydraulic Pump.

From taon-hydraulic.com

Electric/hydraulic pump and motor unit 23 L/min 135 Bar Pump Sizing Electric Motor For Hydraulic Pump This technique will produce a reliable power unit, but one that is relatively heavy, bulky, inefficient, and noisy. To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. Sizing electric motors correctly for hydraulic power units can save a sizable amount of. Sizing Electric Motor For Hydraulic Pump.

From klaizhjzx.blob.core.windows.net

Electric Motor Selection For Hydraulic Pump at Coleman blog Sizing Electric Motor For Hydraulic Pump In part 1 of this post, we discussed the correct way to size an electric motor for a hydraulic pump. Hp = qp / 1714em. Optimize power and efficiency in your hydraulic systems. To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the. Sizing Electric Motor For Hydraulic Pump.

From insights.globalspec.com

How does a electric motordriven axial piston Sizing Electric Motor For Hydraulic Pump Hp = qp / 1714em. Hydraulic pump motor sizing is critical for ensuring that the motor provides adequate power to meet the system’s requirements. Optimize power and efficiency in your hydraulic systems. Use this equation to help figure out what electric motor horsepower (hp) is required to drive a hydraulic pump. Where:hp is horsepowerq is flow in gpmp is pressure. Sizing Electric Motor For Hydraulic Pump.

From www.flowfitonline.com

ETElectric 24V DC Hydraulic Motor Pump Set Flowfit Sizing Electric Motor For Hydraulic Pump Hydraulic pump motor sizing is critical for ensuring that the motor provides adequate power to meet the system’s requirements. Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. Discover how to correctly size electric motors for hydraulic pump drives with womack's guide. To size a hydraulic motor or pump to the design of. Sizing Electric Motor For Hydraulic Pump.

From cesmkbik.blob.core.windows.net

Calculate Electric Motor For Hydraulic Pump at Jason Brook blog Sizing Electric Motor For Hydraulic Pump The calculator below can used to calculate the hydraulic and shaft power of a pump using imperial units: To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. If system pressure and flow are constant, motor sizing simply boils down to the. Sizing Electric Motor For Hydraulic Pump.

From www.hannarv.com

KTI 124518 12 Volt Electric Motor for Hydraulic Pumps Hanna Trailer Sizing Electric Motor For Hydraulic Pump If you are accustomed to specifying electric motors for hpus, you may be tempted to size a pump to be driven at 1,800 rpm, then specify an oversized motor that can develop enough torque to drive the pump at this speed. Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. Discover how to. Sizing Electric Motor For Hydraulic Pump.

From joibydrjv.blob.core.windows.net

Electric Motor Sizing For Hydraulic Pumps at Dillon Blair blog Sizing Electric Motor For Hydraulic Pump To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. If system pressure and flow are constant, motor sizing simply boils down to the standard equation: Use this equation to help figure out what electric motor horsepower (hp) is required to drive. Sizing Electric Motor For Hydraulic Pump.

From insights.globalspec.com

How does a electric motordriven axial piston Sizing Electric Motor For Hydraulic Pump Now we’re going to take things a step. This technique will produce a reliable power unit, but one that is relatively heavy, bulky, inefficient, and noisy. In part 1 of this post, we discussed the correct way to size an electric motor for a hydraulic pump. Hydraulic pump motor sizing is critical for ensuring that the motor provides adequate power. Sizing Electric Motor For Hydraulic Pump.

From www.youtube.com

Hydraulic Power Unit Design Step by step Calculation Accumulator Sizing Electric Motor For Hydraulic Pump Hydraulic pump motor sizing is critical for ensuring that the motor provides adequate power to meet the system’s requirements. Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). In part 1 of this post, we discussed the correct. Sizing Electric Motor For Hydraulic Pump.

From www.youtube.com

Comparison Between Hydraulic Pump And Hydraulic Motor YouTube Sizing Electric Motor For Hydraulic Pump If system pressure and flow are constant, motor sizing simply boils down to the standard equation: In part 1 of this post, we discussed the correct way to size an electric motor for a hydraulic pump. The calculator below can used to calculate the hydraulic and shaft power of a pump using imperial units: Simply take the gallons per minute. Sizing Electric Motor For Hydraulic Pump.

From exoveetug.blob.core.windows.net

How To Size A Hydraulic Pump And Motor at Geraldine Crenshaw blog Sizing Electric Motor For Hydraulic Pump To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. Discover how to correctly size electric motors for hydraulic pump drives with womack's guide. Optimize power and efficiency in your hydraulic systems. Hp = qp / 1714em. If you are accustomed to. Sizing Electric Motor For Hydraulic Pump.

From www.gdjuntai.com

Single Phase 1.5KW 2HP4P30L motor For Hydraulic Pump Sizing Electric Motor For Hydraulic Pump In part 1 of this post, we discussed the correct way to size an electric motor for a hydraulic pump. Now we’re going to take things a step. Discover how to correctly size electric motors for hydraulic pump drives with womack's guide. Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. Use this. Sizing Electric Motor For Hydraulic Pump.

From naomabsephira.pages.dev

Electric Motor Sizing Chart Indira Lenore Sizing Electric Motor For Hydraulic Pump Use this equation to help figure out what electric motor horsepower (hp) is required to drive a hydraulic pump. If you are accustomed to specifying electric motors for hpus, you may be tempted to size a pump to be driven at 1,800 rpm, then specify an oversized motor that can develop enough torque to drive the pump at this speed.. Sizing Electric Motor For Hydraulic Pump.

From joibydrjv.blob.core.windows.net

Electric Motor Sizing For Hydraulic Pumps at Dillon Blair blog Sizing Electric Motor For Hydraulic Pump Hp = qp / 1714em. In part 1 of this post, we discussed the correct way to size an electric motor for a hydraulic pump. Sizing electric motors correctly for hydraulic power units can save a sizable amount of money over the life of the equipment. Optimize power and efficiency in your hydraulic systems. Simply take the gallons per minute. Sizing Electric Motor For Hydraulic Pump.

From schematicdiagramswages.z13.web.core.windows.net

Dump Trailer Hydraulic Pump Motor Sizing Electric Motor For Hydraulic Pump Optimize power and efficiency in your hydraulic systems. Hp = qp / 1714em. This technique will produce a reliable power unit, but one that is relatively heavy, bulky, inefficient, and noisy. Use this equation to help figure out what electric motor horsepower (hp) is required to drive a hydraulic pump. Simply take the gallons per minute (gpm) multiplied by the. Sizing Electric Motor For Hydraulic Pump.

From cesmkbik.blob.core.windows.net

Calculate Electric Motor For Hydraulic Pump at Jason Brook blog Sizing Electric Motor For Hydraulic Pump Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. Use. Sizing Electric Motor For Hydraulic Pump.

From klaizhjzx.blob.core.windows.net

Electric Motor Selection For Hydraulic Pump at Coleman blog Sizing Electric Motor For Hydraulic Pump Hydraulic pump motor sizing is critical for ensuring that the motor provides adequate power to meet the system’s requirements. Discover how to correctly size electric motors for hydraulic pump drives with womack's guide. This technique will produce a reliable power unit, but one that is relatively heavy, bulky, inefficient, and noisy. Now we’re going to take things a step. Sizing. Sizing Electric Motor For Hydraulic Pump.

From klaizhjzx.blob.core.windows.net

Electric Motor Selection For Hydraulic Pump at Coleman blog Sizing Electric Motor For Hydraulic Pump Optimize power and efficiency in your hydraulic systems. Sizing electric motors correctly for hydraulic power units can save a sizable amount of money over the life of the equipment. Use this equation to help figure out what electric motor horsepower (hp) is required to drive a hydraulic pump. To size a hydraulic motor or pump to the design of the. Sizing Electric Motor For Hydraulic Pump.

From cesmkbik.blob.core.windows.net

Calculate Electric Motor For Hydraulic Pump at Jason Brook blog Sizing Electric Motor For Hydraulic Pump Hydraulic pump motor sizing is critical for ensuring that the motor provides adequate power to meet the system’s requirements. If system pressure and flow are constant, motor sizing simply boils down to the standard equation: Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. If you are accustomed to specifying electric motors for. Sizing Electric Motor For Hydraulic Pump.

From cesmkbik.blob.core.windows.net

Calculate Electric Motor For Hydraulic Pump at Jason Brook blog Sizing Electric Motor For Hydraulic Pump Discover how to correctly size electric motors for hydraulic pump drives with womack's guide. Now we’re going to take things a step. If system pressure and flow are constant, motor sizing simply boils down to the standard equation: To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it. Sizing Electric Motor For Hydraulic Pump.

From gogogomotor.en.made-in-china.com

Electric Motor for Hydraulic Pump Motor and Electric Motor Sizing Electric Motor For Hydraulic Pump Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). Now we’re going to take things a step. To size a hydraulic motor. Sizing Electric Motor For Hydraulic Pump.

From www.youtube.com

Hydraulic Motor Types and how are they work? hydraulic motors and pumps Sizing Electric Motor For Hydraulic Pump The calculator below can used to calculate the hydraulic and shaft power of a pump using imperial units: Discover how to correctly size electric motors for hydraulic pump drives with womack's guide. Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. Sizing electric motors correctly for hydraulic power units can save a sizable. Sizing Electric Motor For Hydraulic Pump.

From tigerquesttech.com

Sizing a Motor for Hydraulic Pumps Sizing Electric Motor For Hydraulic Pump To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. Optimize power and efficiency in your hydraulic systems. Hydraulic pump motor sizing is critical for ensuring that the motor provides adequate power to meet the system’s requirements. The calculator below can used. Sizing Electric Motor For Hydraulic Pump.

From promotuer.en.made-in-china.com

3 Phase 415 V 50Hz 4kw 5.5 HP AC Electric Motor for Hydraulic Pump Sizing Electric Motor For Hydraulic Pump To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). Hydraulic. Sizing Electric Motor For Hydraulic Pump.

From webmotor.org

Hydraulic Pump Motor Sizing Calculator Sizing Electric Motor For Hydraulic Pump Hydraulic pump motor sizing is critical for ensuring that the motor provides adequate power to meet the system’s requirements. To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. The calculator below can used to calculate the hydraulic and shaft power of. Sizing Electric Motor For Hydraulic Pump.

From zozhimotor.com

Hollow Shaft Electric Motor For Hydraulic Pumps OPSH Series Produces Sizing Electric Motor For Hydraulic Pump To size a hydraulic motor or pump to the design of the machine or application for which it will be used, it is necessary to estimate the required. If you are accustomed to specifying electric motors for hpus, you may be tempted to size a pump to be driven at 1,800 rpm, then specify an oversized motor that can develop. Sizing Electric Motor For Hydraulic Pump.

From iecmotores.com

Unveiling Types of Electric Motors for Hydraulic Pumps Sizing Electric Motor For Hydraulic Pump Hp = qp / 1714em. Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). Discover how to correctly size electric motors for hydraulic pump drives with womack's guide. Use this equation to help figure out what electric motor. Sizing Electric Motor For Hydraulic Pump.

From insights.globalspec.com

How does a electric motordriven axial piston Sizing Electric Motor For Hydraulic Pump Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). The calculator below can used to calculate the hydraulic and shaft power of a pump using imperial units: Discover how to correctly size electric motors for hydraulic pump drives. Sizing Electric Motor For Hydraulic Pump.

From www.alibaba.com

3 Phase 7.5hp Electrical Motor For Hydraulic Pump Buy 3 Phase 7.5hp Sizing Electric Motor For Hydraulic Pump Sizing electric motors correctly for hydraulic power units can save a sizable amount of money over the life of the equipment. Simply take the gallons per minute (gpm) multiplied by the pump pressure psi then divide that number by the result of 1,714 times efficiency (we used 85% effiencey in this case). Use this equation to help figure out what. Sizing Electric Motor For Hydraulic Pump.

From www.rundles.co.uk

Brook Crompton 1000 rpm Aluminium Three Phase Series10 Electric Motor Sizing Electric Motor For Hydraulic Pump Where:hp is horsepowerq is flow in gpmp is pressure in psi, andem is pump’s mechanical efficiency. Use this equation to help figure out what electric motor horsepower (hp) is required to drive a hydraulic pump. If you are accustomed to specifying electric motors for hpus, you may be tempted to size a pump to be driven at 1,800 rpm, then. Sizing Electric Motor For Hydraulic Pump.