Cracked Cap Connecting Rods . The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. One of the main causes of connecting rod failures is improper bearing clearance. One of the most important aspects of rebuilding an engine is to recondition the connecting rods. It’s a fast, easy way to make high volume connecting. Cracking doesn't have any disadvantages but it does have one major advantage: If the bore is out of round, the rod. If you were to take a close look at the fracture site, you’d find it to be irregular, jagged, and generally not something you’d expect to see. It ensures that the connecting rod shank and the bearing cap fit precisely. But what should you watch out for.

from packardinfo.com

The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. It’s a fast, easy way to make high volume connecting. It ensures that the connecting rod shank and the bearing cap fit precisely. The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. One of the most important aspects of rebuilding an engine is to recondition the connecting rods. But what should you watch out for. Cracking doesn't have any disadvantages but it does have one major advantage: If you were to take a close look at the fracture site, you’d find it to be irregular, jagged, and generally not something you’d expect to see. One of the main causes of connecting rod failures is improper bearing clearance. If the bore is out of round, the rod.

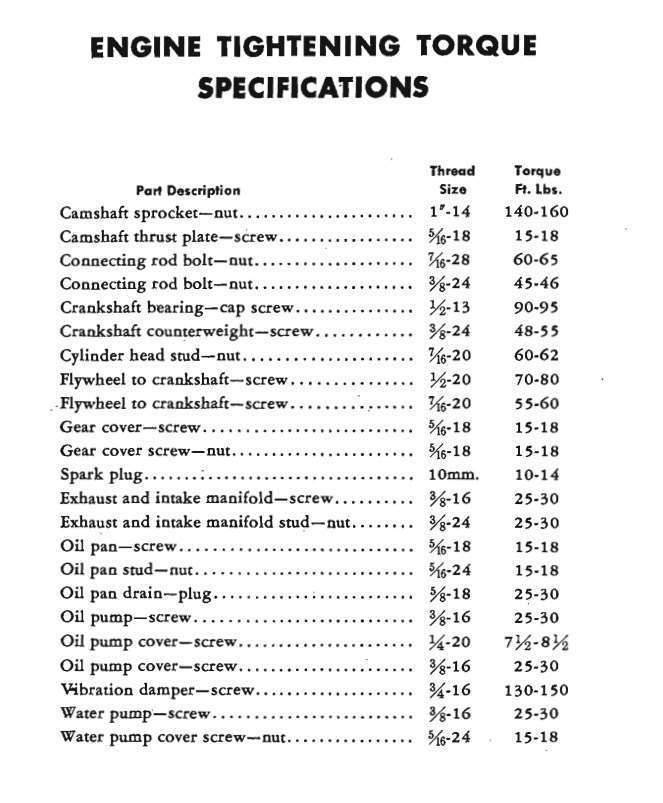

Connecting rod bolt torque specifications !947 taxi 6 cyl [General

Cracked Cap Connecting Rods One of the main causes of connecting rod failures is improper bearing clearance. If you were to take a close look at the fracture site, you’d find it to be irregular, jagged, and generally not something you’d expect to see. The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. One of the main causes of connecting rod failures is improper bearing clearance. But what should you watch out for. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. Cracking doesn't have any disadvantages but it does have one major advantage: One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. If the bore is out of round, the rod. It’s a fast, easy way to make high volume connecting. It ensures that the connecting rod shank and the bearing cap fit precisely. One of the most important aspects of rebuilding an engine is to recondition the connecting rods.

From www.2carpros.com

Inserts (connecting Rods) Torque Specs Needed What Are the Torque... Cracked Cap Connecting Rods Cracking doesn't have any disadvantages but it does have one major advantage: One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. It’s a fast, easy way to make high volume connecting. One of the most important aspects of rebuilding an engine is to recondition. Cracked Cap Connecting Rods.

From www.sellaband.com

Which Way Does the Connecting Rod Go Cracked Cap Connecting Rods The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. It’s a fast, easy way to make high volume connecting. One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. But what should you watch out for.. Cracked Cap Connecting Rods.

From www.2carpros.com

Inserts (connecting Rods) Torque Specs Needed What Are the Torque... Cracked Cap Connecting Rods One of the main causes of connecting rod failures is improper bearing clearance. If the bore is out of round, the rod. It ensures that the connecting rod shank and the bearing cap fit precisely. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. Cracking doesn't have any disadvantages but it. Cracked Cap Connecting Rods.

From www.ls1.com

Question replacing rod and main bearings...do's and dont's? Cracked Cap Connecting Rods It’s a fast, easy way to make high volume connecting. One of the most important aspects of rebuilding an engine is to recondition the connecting rods. One of the main causes of connecting rod failures is improper bearing clearance. One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the. Cracked Cap Connecting Rods.

From www.facebook.com

Regular Church Service Regular Church Service By Community Baptist Cracked Cap Connecting Rods One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. One of the main causes of connecting rod failures is improper bearing clearance. It ensures that the. Cracked Cap Connecting Rods.

From giodcgmfc.blob.core.windows.net

Installing Main Bearings at Denise Nichols blog Cracked Cap Connecting Rods Cracking doesn't have any disadvantages but it does have one major advantage: One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. If the bore is out of round, the rod. One of the most important aspects of rebuilding an engine is to recondition the. Cracked Cap Connecting Rods.

From www.hotrod.com

Flatheads in WWII, Chevy 427 Oil Pressure, and Cracked Powdered Cracked Cap Connecting Rods Cracking doesn't have any disadvantages but it does have one major advantage: The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. If the bore is out of round, the rod. If you were to take a close look at the fracture site, you’d find it to be irregular, jagged,. Cracked Cap Connecting Rods.

From www.youtube.com

Cracked Rod Explaination YouTube Cracked Cap Connecting Rods One of the main causes of connecting rod failures is improper bearing clearance. Cracking doesn't have any disadvantages but it does have one major advantage: One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. It’s a fast, easy way to make high volume connecting.. Cracked Cap Connecting Rods.

From www.facebook.com

Psalms 10/20/2024 Sometimes we sign up for difficult things Cracked Cap Connecting Rods The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. If the bore is out of round, the rod. But what should you watch out for. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. Cracking doesn't have any disadvantages but. Cracked Cap Connecting Rods.

From packardinfo.com

Connecting rod bolt torque specifications !947 taxi 6 cyl [General Cracked Cap Connecting Rods One of the most important aspects of rebuilding an engine is to recondition the connecting rods. It ensures that the connecting rod shank and the bearing cap fit precisely. If the bore is out of round, the rod. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. One of the drawbacks. Cracked Cap Connecting Rods.

From www.youtube.com

8 Tips For Installing Connecting Rods Integrated Engineering YouTube Cracked Cap Connecting Rods If you were to take a close look at the fracture site, you’d find it to be irregular, jagged, and generally not something you’d expect to see. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. The only trade off is that a cracked cap can’t be machined if the rod. Cracked Cap Connecting Rods.

From paradigmkonzeption101.blogspot.com

Big End Cap Of Connecting Rod / Connecting Rods Jim McFarland Cracked Cap Connecting Rods But what should you watch out for. It’s a fast, easy way to make high volume connecting. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. If you were to take a close look at the fracture site, you’d find it to be irregular, jagged, and generally not something you’d expect. Cracked Cap Connecting Rods.

From ls1tech.com

Pics of stock LS1 "cracked" rod caps inside LS1TECH Camaro and Cracked Cap Connecting Rods It’s a fast, easy way to make high volume connecting. One of the main causes of connecting rod failures is improper bearing clearance. One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. If the bore is out of round, the rod. If you were. Cracked Cap Connecting Rods.

From www.youtube.com

Fractured Con rods But why? YouTube Cracked Cap Connecting Rods One of the most important aspects of rebuilding an engine is to recondition the connecting rods. But what should you watch out for. One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. It’s a fast, easy way to make high volume connecting. It ensures. Cracked Cap Connecting Rods.

From parts.jdna.com

CONNECTING ROD CAP Cracked Cap Connecting Rods One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. One of the most important aspects of rebuilding an engine is to recondition the connecting rods. One of the main causes of connecting rod failures is improper bearing clearance. The cracked fracture surfaces achieve an. Cracked Cap Connecting Rods.

From www.varadforge.com

Connecting Rod (Fractured) Varad Pvt. Ltd. Cracked Cap Connecting Rods One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. If you were to take a close look at the fracture site, you’d find it to be irregular, jagged, and generally not something you’d expect to see. The cracked fracture surfaces achieve an excellent fit. Cracked Cap Connecting Rods.

From pauter.com

Aluminum Connecting Rods Pauter Cracked Cap Connecting Rods One of the most important aspects of rebuilding an engine is to recondition the connecting rods. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. It’s a fast, easy way to make high volume connecting. One of the main causes of connecting rod failures is improper bearing clearance. If you were. Cracked Cap Connecting Rods.

From www.hotrod.com

How to Select and Install HighPerformance Engine Bearings Hot Rod Cracked Cap Connecting Rods One of the main causes of connecting rod failures is improper bearing clearance. Cracking doesn't have any disadvantages but it does have one major advantage: One of the most important aspects of rebuilding an engine is to recondition the connecting rods. It ensures that the connecting rod shank and the bearing cap fit precisely. If you were to take a. Cracked Cap Connecting Rods.

From www.youtube.com

How to handle cracked connecting rods correctly YouTube Cracked Cap Connecting Rods Cracking doesn't have any disadvantages but it does have one major advantage: The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. One of the main causes of connecting rod failures is improper bearing clearance. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and. Cracked Cap Connecting Rods.

From cfmotousaparts.com

Diagram 2022 CFMoto ZFORCE 800 Trail CF800USA CRANKSHAFT Cracked Cap Connecting Rods Cracking doesn't have any disadvantages but it does have one major advantage: It ensures that the connecting rod shank and the bearing cap fit precisely. It’s a fast, easy way to make high volume connecting. If the bore is out of round, the rod. If you were to take a close look at the fracture site, you’d find it to. Cracked Cap Connecting Rods.

From www.facebook.com

Regular Church Service Regular Church Service By Community Baptist Cracked Cap Connecting Rods It’s a fast, easy way to make high volume connecting. The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. If you were to take a close look at the fracture site, you’d find it to be irregular, jagged, and generally not something you’d expect to see. But what should. Cracked Cap Connecting Rods.

From www.roadandtrack.com

FirstEver TwoPiece Connecting Rod Is Intriguing Piece of Tech Cracked Cap Connecting Rods One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. If you were to take a close look at the fracture site, you’d find it to be. Cracked Cap Connecting Rods.

From www.youtube.com

What is a Fractured Connecting Rod? Cracked Rod? Advantages and Cracked Cap Connecting Rods The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. If the bore is out of round, the rod. If you were to take a close look at the fracture site, you’d find it to be irregular, jagged, and generally not something you’d expect to see. The only trade off is that. Cracked Cap Connecting Rods.

From www.youtube.com

How to remove a connecting rod from an engine YouTube Cracked Cap Connecting Rods One of the most important aspects of rebuilding an engine is to recondition the connecting rods. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. It’s a fast, easy way to make high volume connecting. If you were to take a close look at the fracture site, you’d find it to. Cracked Cap Connecting Rods.

From www.facebook.com

Psalms 10/20/2024 Sometimes we sign up for difficult things Cracked Cap Connecting Rods One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. Cracking doesn't have any disadvantages but it does have one major advantage: The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. If you were. Cracked Cap Connecting Rods.

From www.reddit.com

Cracked Connecting Rod Damage r/EngineBuilding Cracked Cap Connecting Rods One of the most important aspects of rebuilding an engine is to recondition the connecting rods. It’s a fast, easy way to make high volume connecting. If the bore is out of round, the rod. But what should you watch out for. It ensures that the connecting rod shank and the bearing cap fit precisely. The only trade off is. Cracked Cap Connecting Rods.

From www.facebook.com

A Witness to the Resurrection In Loving Memory Marian Alice Huston Cracked Cap Connecting Rods It’s a fast, easy way to make high volume connecting. One of the most important aspects of rebuilding an engine is to recondition the connecting rods. But what should you watch out for. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. It ensures that the connecting rod shank and the. Cracked Cap Connecting Rods.

From fulltimemotos.com.ar

Biela Y Pistón De Motocicleta Funciones Y Características Full Time Cracked Cap Connecting Rods The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap. It’s a fast, easy way to make high volume connecting. One of the main causes of connecting rod failures is improper bearing clearance. If the bore is out of round, the rod. It ensures that the connecting rod shank and the bearing. Cracked Cap Connecting Rods.

From eeuroparts.com

Cracked Connecting Rods It’s not a Defect, It’s a Feature! eEuroparts Cracked Cap Connecting Rods The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. One of the main causes of connecting rod failures is improper bearing clearance. If the bore is out of round, the rod. The cracked fracture surfaces achieve an excellent fit precision between the connecting rod shank and the bearing cap.. Cracked Cap Connecting Rods.

From www.ebay.com

MERCURY OUTBOARD RACING Piston Connecting Rods 44ci Cracked Cap Type Cracked Cap Connecting Rods Cracking doesn't have any disadvantages but it does have one major advantage: It ensures that the connecting rod shank and the bearing cap fit precisely. If the bore is out of round, the rod. One of the drawbacks of powder metal rods is that the rod caps are cracked to separate the cap from the rest of the rod. One. Cracked Cap Connecting Rods.

From www.facebook.com

Regular Church Service Regular Church Service By Community Baptist Cracked Cap Connecting Rods Cracking doesn't have any disadvantages but it does have one major advantage: The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. One of the most important aspects of rebuilding an engine is to recondition the connecting rods. The cracked fracture surfaces achieve an excellent fit precision between the connecting. Cracked Cap Connecting Rods.

From www.facebook.com

A Witness to the Resurrection In Loving Memory Marian Alice Huston Cracked Cap Connecting Rods One of the main causes of connecting rod failures is improper bearing clearance. If you were to take a close look at the fracture site, you’d find it to be irregular, jagged, and generally not something you’d expect to see. Cracking doesn't have any disadvantages but it does have one major advantage: One of the drawbacks of powder metal rods. Cracked Cap Connecting Rods.

From www.mdpi.com

Metals Free FullText Study on FractureSplit Performance of Cracked Cap Connecting Rods If the bore is out of round, the rod. The only trade off is that a cracked cap can’t be machined if the rod later needs to be reconditioned. Cracking doesn't have any disadvantages but it does have one major advantage: One of the main causes of connecting rod failures is improper bearing clearance. One of the most important aspects. Cracked Cap Connecting Rods.