Camshaft Design Pdf . Hence the determination of exact load values becomes the. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. Identify force closed and form closed followers and explain the. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. A projection on a rotating part in machinery, designed to make sliding contact with another part while. Open a valve 0.05 inches in 0.0025 seconds 2. a full 3×3×3×2 factorial experimental design based on complete randomized block design with 54. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. camshafts are rotating components with critical loads. • design a cam system to: explain what a cam is, how it is used, and the typical types of cams. Stay open for 0.0050 seconds 3.

from innovationdiscoveries.space

camshafts are rotating components with critical loads. A projection on a rotating part in machinery, designed to make sliding contact with another part while. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. a full 3×3×3×2 factorial experimental design based on complete randomized block design with 54. Open a valve 0.05 inches in 0.0025 seconds 2. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. Identify force closed and form closed followers and explain the. • design a cam system to: Stay open for 0.0050 seconds 3.

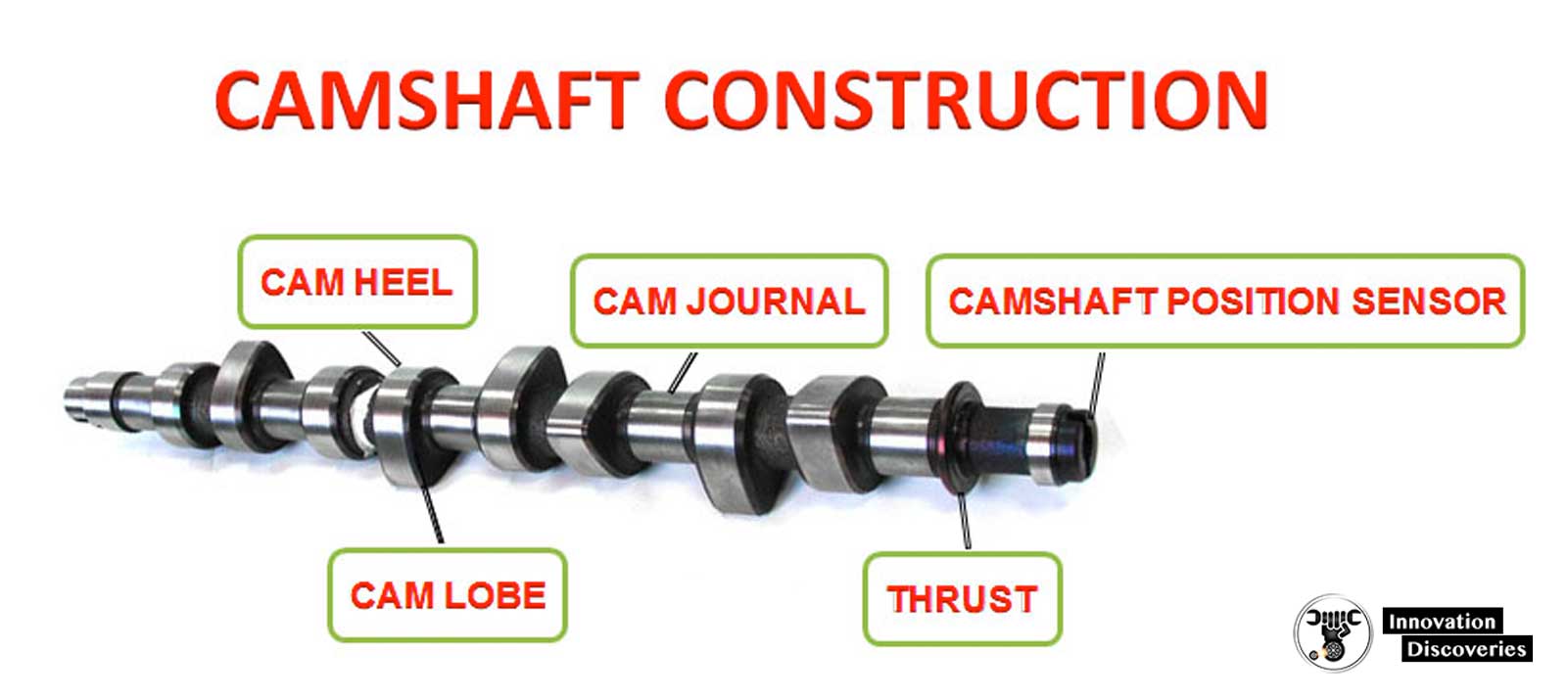

Back To Basics Camshaft and Terminology

Camshaft Design Pdf A projection on a rotating part in machinery, designed to make sliding contact with another part while. a full 3×3×3×2 factorial experimental design based on complete randomized block design with 54. • design a cam system to: Open a valve 0.05 inches in 0.0025 seconds 2. explain what a cam is, how it is used, and the typical types of cams. camshafts are rotating components with critical loads. A projection on a rotating part in machinery, designed to make sliding contact with another part while. Stay open for 0.0050 seconds 3. Hence the determination of exact load values becomes the. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. Identify force closed and form closed followers and explain the. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and.

From www.hemmings.com

What to consider when selecting a highperformance camshaft Hemmings Camshaft Design Pdf • design a cam system to: Open a valve 0.05 inches in 0.0025 seconds 2. a full 3×3×3×2 factorial experimental design based on complete randomized block design with 54. A projection on a rotating part in machinery, designed to make sliding contact with another part while. Stay open for 0.0050 seconds 3. kinematics, fluid dynamics and metallurgy. Camshaft Design Pdf.

From www.cmsnl.com

1271132411 Camshaft Suzuki buy the 1271132411 at CMSNL Camshaft Design Pdf the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. explain what a cam is, how it is used, and the typical types of cams. Open a valve 0.05 inches in 0.0025 seconds 2. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer. Camshaft Design Pdf.

From engineeringlearn.com

Camshaft Working and Types Details] Engineering Learn Camshaft Design Pdf the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. explain what a cam is, how it is used, and the typical types of cams. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. Identify. Camshaft Design Pdf.

From www.hemmings.com

What to consider when selecting a highperformance camshaft Hemmings Camshaft Design Pdf A projection on a rotating part in machinery, designed to make sliding contact with another part while. Open a valve 0.05 inches in 0.0025 seconds 2. a full 3×3×3×2 factorial experimental design based on complete randomized block design with 54. Hence the determination of exact load values becomes the. Stay open for 0.0050 seconds 3. camshafts are rotating. Camshaft Design Pdf.

From www.mjpsoft.dk

camshaft designer software instructions Camshaft Design Pdf camshafts are rotating components with critical loads. • design a cam system to: Open a valve 0.05 inches in 0.0025 seconds 2. A projection on a rotating part in machinery, designed to make sliding contact with another part while. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam. Camshaft Design Pdf.

From studiousguy.com

Camshaft Types, Functions & Examples StudiousGuy Camshaft Design Pdf Open a valve 0.05 inches in 0.0025 seconds 2. A projection on a rotating part in machinery, designed to make sliding contact with another part while. camshafts are rotating components with critical loads. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. Hence the determination of. Camshaft Design Pdf.

From www.theengineerspost.com

Camshaft Definition, Parts and Function with [Diagram & PDF] Camshaft Design Pdf the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. Hence the determination of exact load values becomes the. Identify force closed and form closed followers and explain the. explain what a cam is, how it is used, and the typical types of cams. A projection on. Camshaft Design Pdf.

From www.emanualonline.com

Camshaft 101 The Complete Guide Blog Camshaft Design Pdf Open a valve 0.05 inches in 0.0025 seconds 2. Stay open for 0.0050 seconds 3. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. Identify force closed and form closed followers and explain the. Hence the determination of exact load values becomes the.. Camshaft Design Pdf.

From www.racingjunk.com

Camshafts What You Need to Know, Part 2 RacingJunk News Camshaft Design Pdf camshafts are rotating components with critical loads. Identify force closed and form closed followers and explain the. Hence the determination of exact load values becomes the. Stay open for 0.0050 seconds 3. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. explain what a cam. Camshaft Design Pdf.

From www.hemmings.com

What to consider when selecting a highperformance camshaft Hemmings Camshaft Design Pdf the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. A projection on a rotating part in machinery, designed to make sliding contact with another part while. explain what a cam is, how it is used, and the typical types of cams. Stay open for 0.0050 seconds. Camshaft Design Pdf.

From www.scribd.com

Camshafts PDF Camshaft Design Pdf Stay open for 0.0050 seconds 3. explain what a cam is, how it is used, and the typical types of cams. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. camshafts are rotating components with critical loads. the third edition. Camshaft Design Pdf.

From gtautomotiveparts.co.uk

Camshafts GT Automotive Camshaft Design Pdf Stay open for 0.0050 seconds 3. camshafts are rotating components with critical loads. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. Hence the determination of exact load values. Camshaft Design Pdf.

From www.hemmings.com

What to consider when selecting a highperformance camshaft Hemmings Camshaft Design Pdf camshafts are rotating components with critical loads. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. Stay open for 0.0050. Camshaft Design Pdf.

From www.onallcylinders.com

How to Read a Cam Card to Understand Camshaft Specs Camshaft Design Pdf Identify force closed and form closed followers and explain the. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. a full 3×3×3×2 factorial experimental design based on complete randomized. Camshaft Design Pdf.

From www.researchgate.net

Design of the new camshaft. Download Scientific Diagram Camshaft Design Pdf the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. Identify force closed and form closed followers and explain the. • design a cam system to: a full 3×3×3×2 factorial experimental design based on complete randomized block design with 54. camshafts are rotating components with. Camshaft Design Pdf.

From workshopbarend7rm.z13.web.core.windows.net

Do Overhead Cam Engines Have Lifters Camshaft Design Pdf A projection on a rotating part in machinery, designed to make sliding contact with another part while. Hence the determination of exact load values becomes the. Open a valve 0.05 inches in 0.0025 seconds 2. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. Identify force closed. Camshaft Design Pdf.

From wellness-wednesday-tips-for-students.blogspot.com

camshaft lobe design software wellnesswednesdaytipsforstudents Camshaft Design Pdf camshafts are rotating components with critical loads. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. • design a cam system to: the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. explain what a cam is,. Camshaft Design Pdf.

From www.simscale.com

Camshaft Structural Analysis by MCA SimScale Camshaft Design Pdf Hence the determination of exact load values becomes the. a full 3×3×3×2 factorial experimental design based on complete randomized block design with 54. • design a cam system to: camshafts are rotating components with critical loads. Stay open for 0.0050 seconds 3. A projection on a rotating part in machinery, designed to make sliding contact with another. Camshaft Design Pdf.

From www.hemmings.com

What to consider when selecting a highperformance camshaft Hemmings Camshaft Design Pdf Open a valve 0.05 inches in 0.0025 seconds 2. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. Identify force closed and form closed followers and explain the. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. •. Camshaft Design Pdf.

From www.carblogindia.com

Camshafts And Valves Working And Classification! » Car Blog India Camshaft Design Pdf Stay open for 0.0050 seconds 3. explain what a cam is, how it is used, and the typical types of cams. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower,. Camshaft Design Pdf.

From www.cartechbooks.com

Camshafts Demystified Camshaft Design Pdf camshafts are rotating components with critical loads. Identify force closed and form closed followers and explain the. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a. Camshaft Design Pdf.

From encyclopedia.pub

Overhead Camshaft Encyclopedia MDPI Camshaft Design Pdf Open a valve 0.05 inches in 0.0025 seconds 2. camshafts are rotating components with critical loads. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. kinematics, fluid dynamics. Camshaft Design Pdf.

From www.mjpsoft.dk

camshaft designer software instructions Camshaft Design Pdf Stay open for 0.0050 seconds 3. a full 3×3×3×2 factorial experimental design based on complete randomized block design with 54. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. the third edition of cam design and manufacturing handbook brings together the. Camshaft Design Pdf.

From www.melling.com

Camshafts Melling Camshaft Design Pdf A projection on a rotating part in machinery, designed to make sliding contact with another part while. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. Open a valve 0.05. Camshaft Design Pdf.

From grabcad.com

can anyone help me designing a camshaft blank in solidworks or any Camshaft Design Pdf A projection on a rotating part in machinery, designed to make sliding contact with another part while. camshafts are rotating components with critical loads. Stay open for 0.0050 seconds 3. Hence the determination of exact load values becomes the. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design. Camshaft Design Pdf.

From www.mjpsoft.dk

camshaft designer software instructions Camshaft Design Pdf camshafts are rotating components with critical loads. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. Hence the determination of exact load values becomes the. A projection on a rotating part in machinery, designed to make sliding contact with another part while.. Camshaft Design Pdf.

From www.mjpsoft.dk

camshaft designer software instructions Camshaft Design Pdf camshafts are rotating components with critical loads. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. the paper presents. Camshaft Design Pdf.

From www.mjpsoft.dk

camshaft designer software instructions Camshaft Design Pdf Identify force closed and form closed followers and explain the. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. the. Camshaft Design Pdf.

From www.researchgate.net

(PDF) Camshaft Design for an InletRestricted FSAE Engine Camshaft Design Pdf Identify force closed and form closed followers and explain the. Hence the determination of exact load values becomes the. camshafts are rotating components with critical loads. A projection on a rotating part in machinery, designed to make sliding contact with another part while. Open a valve 0.05 inches in 0.0025 seconds 2. Stay open for 0.0050 seconds 3. . Camshaft Design Pdf.

From www.mjpsoft.dk

camshaft designer software instructions Camshaft Design Pdf kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. a full 3×3×3×2 factorial experimental design based on complete randomized block. Camshaft Design Pdf.

From mostplusauto.com

What does a camshaft do? MOSTPLUS Camshaft Design Pdf Stay open for 0.0050 seconds 3. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. Identify force closed and form closed followers and explain the. • design a cam system to: camshafts are rotating components with critical loads. explain what. Camshaft Design Pdf.

From www.enginebuildermag.com

Camshaft Selection and Design Engine Builder Magazine Camshaft Design Pdf the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design methods and. the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. Hence the determination of exact load values becomes the. explain what a cam is, how it is used, and the. Camshaft Design Pdf.

From www.hemmings.com

What to consider when selecting a highperformance camshaft Hemmings Camshaft Design Pdf explain what a cam is, how it is used, and the typical types of cams. Stay open for 0.0050 seconds 3. camshafts are rotating components with critical loads. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion profile for a high. Hence the determination of. Camshaft Design Pdf.

From www.targetmust.com

What is thе Working Principlе of Camshafts & Efficient 2024 Camshaft Design Pdf A projection on a rotating part in machinery, designed to make sliding contact with another part while. Stay open for 0.0050 seconds 3. a full 3×3×3×2 factorial experimental design based on complete randomized block design with 54. kinematics, fluid dynamics and metallurgy must all be mastered by any engineer that sets out to design a successful valve motion. Camshaft Design Pdf.

From innovationdiscoveries.space

Back To Basics Camshaft and Terminology Camshaft Design Pdf the paper presents some aspects concerning the design of cam mechanisms with oscillating flat facedfollower, using. explain what a cam is, how it is used, and the typical types of cams. • design a cam system to: the third edition of cam design and manufacturing handbook brings together the latest cam design technology, proper cam design. Camshaft Design Pdf.