Bsa Bantam Crankshaft End Float . it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. — according bsa factory service sheet no. Pressing it down pushes down the float and frees the. this is a small plunger in the top of the carburetter float chamber. 208 the maximum end float should be.005 — checking and setting the end float for the crank.interesting that there were no. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. D1 crank end float measurement.

from www.ebay.ie

— checking and setting the end float for the crank.interesting that there were no. 208 the maximum end float should be.005 — according bsa factory service sheet no. D1 crank end float measurement. this is a small plunger in the top of the carburetter float chamber. it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. Pressing it down pushes down the float and frees the.

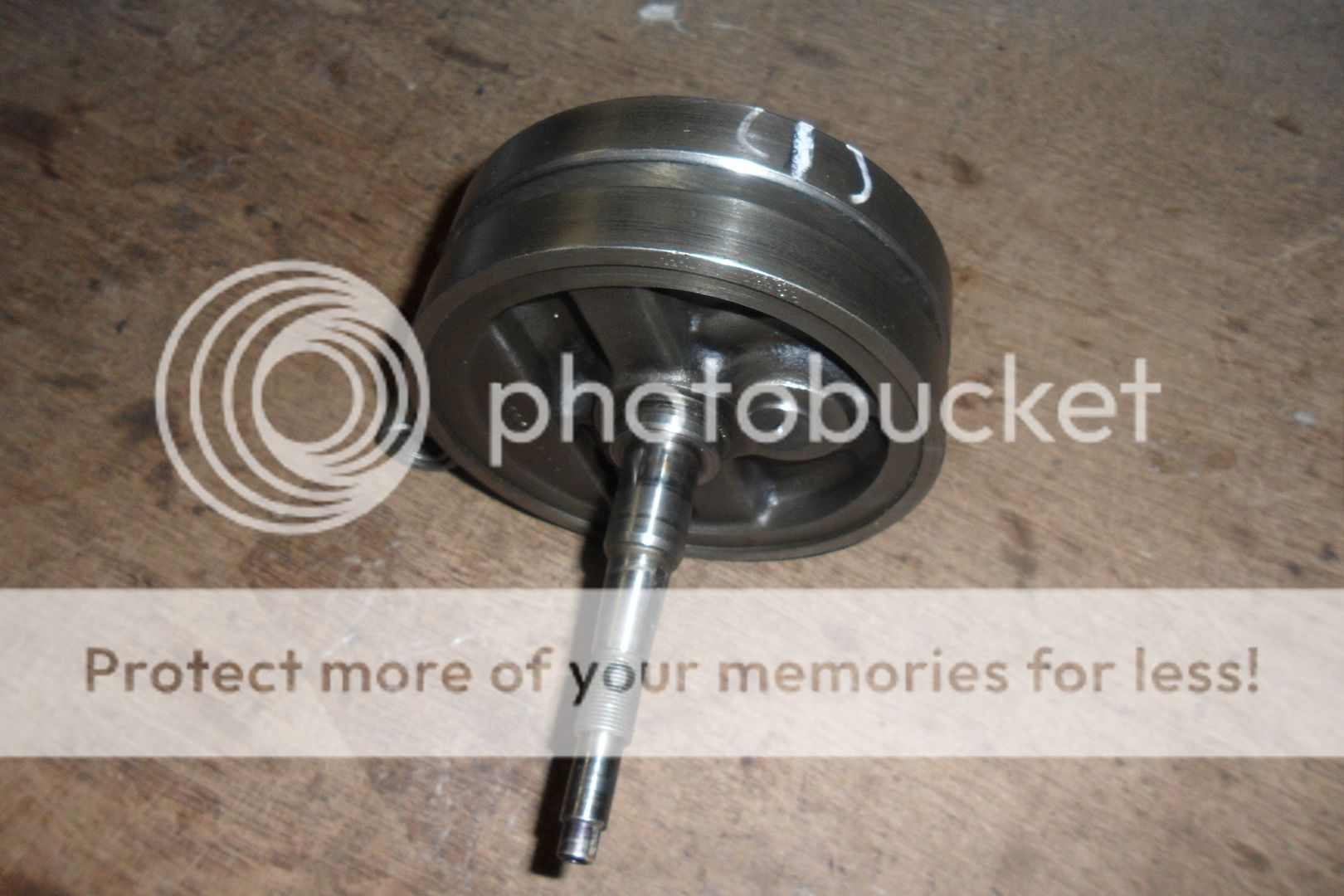

BSA BANTAM D7 175CC CRANKSHAFT ASSEMBLY PART NO 901457 (1) eBay

Bsa Bantam Crankshaft End Float this is a small plunger in the top of the carburetter float chamber. this is a small plunger in the top of the carburetter float chamber. — according bsa factory service sheet no. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. 208 the maximum end float should be.005 — checking and setting the end float for the crank.interesting that there were no. it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. D1 crank end float measurement. — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. Pressing it down pushes down the float and frees the.

From www.ebay.co.uk

BSA Bantam B175 Crankshaft eBay Bsa Bantam Crankshaft End Float D1 crank end float measurement. this is a small plunger in the top of the carburetter float chamber. — checking and setting the end float for the crank.interesting that there were no. — according bsa factory service sheet no. it turned out that the replacement crankshaft had less end float than the original and so needed. Bsa Bantam Crankshaft End Float.

From www.ebay.ie

BSA BANTAM D7 175CC CRANKSHAFT ASSEMBLY PART NO 901457 (1) eBay Bsa Bantam Crankshaft End Float this is a small plunger in the top of the carburetter float chamber. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. D1 crank end float measurement. Pressing it down pushes down the float and frees the. — before assembling the gear box. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA BANTAM D14,D10 CRANKSHAFT COMPLETE eBay Bsa Bantam Crankshaft End Float — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. — checking and setting the end float for the crank.interesting that there were no. 208 the maximum end float should be.005 this is a small plunger in the top of the carburetter float chamber.. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA Bantam Crankshaft PLEASE CONFIRM FIT eBay Bsa Bantam Crankshaft End Float D1 crank end float measurement. 208 the maximum end float should be.005 Pressing it down pushes down the float and frees the. — according bsa factory service sheet no. this is a small plunger in the top of the carburetter float chamber. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA BANTAM B175 CRANKSHAFT PRE65 TRIALS eBay Bsa Bantam Crankshaft End Float — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. 208 the maximum end float should be.005 D1 crank end float measurement. Pressing it down pushes down the float and frees the. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it. Bsa Bantam Crankshaft End Float.

From mikesclassiccyclespares.com

NOS BSA BANTAM CRANK CASES 900162 900163 STAMPED 90157 90156 Bsa Bantam Crankshaft End Float it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. — checking and setting the end float for the crank.interesting that there were. Bsa Bantam Crankshaft End Float.

From ebay.ie

BSA BANTAM D10 D14/4 CRANKSHAFT ASSEMBLY 27 eBay Bsa Bantam Crankshaft End Float — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. — according bsa factory service sheet no. Pressing it down pushes down the float and frees the. 208 the maximum end float should be.005 it turned out that the replacement crankshaft had less end. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA BANTAM CRANKSHAFT TOOL eBay Bsa Bantam Crankshaft End Float this is a small plunger in the top of the carburetter float chamber. 208 the maximum end float should be.005 — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. it turned out that the replacement crankshaft had less end float than the original. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA BANTAM DI CRANKSHAFT eBay Bsa Bantam Crankshaft End Float — according bsa factory service sheet no. Pressing it down pushes down the float and frees the. this is a small plunger in the top of the carburetter float chamber. D1 crank end float measurement. — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. —. Bsa Bantam Crankshaft End Float.

From www.youtube.com

BSA A65T engine bottom end crank end float checking during rebuild Bsa Bantam Crankshaft End Float — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. — according bsa factory service sheet no. it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. 208 the maximum. Bsa Bantam Crankshaft End Float.

From rexcauntracing.com

BSA BANTAM D14/B175 TRIALS CRANKSHAFT Bsa Bantam Crankshaft End Float 208 the maximum end float should be.005 — checking and setting the end float for the crank.interesting that there were no. D1 crank end float measurement. it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. — before assembling the gear box i. Bsa Bantam Crankshaft End Float.

From www.youtube.com

BSA Bantam Crankshaft Rebuild A Tale of Two Flywheels YouTube Bsa Bantam Crankshaft End Float Pressing it down pushes down the float and frees the. this is a small plunger in the top of the carburetter float chamber. — checking and setting the end float for the crank.interesting that there were no. — according bsa factory service sheet no. D1 crank end float measurement. 208 the maximum end float should be.005 . Bsa Bantam Crankshaft End Float.

From britbikes.co.uk

CRANKSHAFT ROLLER BEARING BSA BANTAM TIMING SIDE B31 B33 B32 B34 M20 M Bsa Bantam Crankshaft End Float — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. Pressing it down pushes down the float and frees the. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. — according bsa factory. Bsa Bantam Crankshaft End Float.

From www.youtube.com

B33 crankshaft end float YouTube Bsa Bantam Crankshaft End Float D1 crank end float measurement. — checking and setting the end float for the crank.interesting that there were no. 208 the maximum end float should be.005 — according bsa factory service sheet no. Pressing it down pushes down the float and frees the. — before assembling the gear box i just want to check the crankshaft end. Bsa Bantam Crankshaft End Float.

From rexcauntracing.com

BSA BANTAM D14/B175 TRIALS CRANKSHAFT Bsa Bantam Crankshaft End Float — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. — according bsa factory service sheet no. this is a small plunger in the top of the carburetter float chamber. 208 the maximum end float should be.005 D1 crank end float measurement. — checking and setting. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA Bantam B175 Crankshaft eBay Bsa Bantam Crankshaft End Float 208 the maximum end float should be.005 — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. Pressing it down pushes down the float and frees the. — according bsa factory service sheet no. this is a small plunger in the top of the. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA Bantam B175 Crankshaft eBay Bsa Bantam Crankshaft End Float it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. this is a small plunger in the top of the carburetter float chamber.. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA Bantam D5 D7 Crank Shaft eBay Bsa Bantam Crankshaft End Float 208 the maximum end float should be.005 Pressing it down pushes down the float and frees the. D1 crank end float measurement. — checking and setting the end float for the crank.interesting that there were no. this is a small plunger in the top of the carburetter float chamber. — in this video, i measure the endfloat. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

Vintage BSA Bantam crankshaft for rebuild slight play in big end. eBay Bsa Bantam Crankshaft End Float — checking and setting the end float for the crank.interesting that there were no. D1 crank end float measurement. this is a small plunger in the top of the carburetter float chamber. Pressing it down pushes down the float and frees the. 208 the maximum end float should be.005 — in this video, i measure the endfloat. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA BANTAM D14,D10 CRANKSHAFT COMPLETE eBay Bsa Bantam Crankshaft End Float D1 crank end float measurement. Pressing it down pushes down the float and frees the. this is a small plunger in the top of the carburetter float chamber. — according bsa factory service sheet no. it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA Bantam crankshaft. pre65, Trials eBay Bsa Bantam Crankshaft End Float — checking and setting the end float for the crank.interesting that there were no. it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. D1 crank end float measurement. — according bsa factory service sheet no. 208 the maximum end float should be.005. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA BANTAM D14,D10 CRANKSHAFT COMPLETE eBay Bsa Bantam Crankshaft End Float — according bsa factory service sheet no. it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. — checking and setting the end float for the crank.interesting that there were no. Pressing it down pushes down the float and frees the. D1 crank. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA Bantam D5 D7 Crank Shaft eBay Bsa Bantam Crankshaft End Float it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. Pressing it down pushes down the float and frees the. — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. 208 the maximum end. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA BANTAM CRANKSHAFT TOOL eBay Bsa Bantam Crankshaft End Float 208 the maximum end float should be.005 D1 crank end float measurement. Pressing it down pushes down the float and frees the. — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA Bantam D1 D3 Crankshaft Spares Or Repairs Only Big End Wear eBay Bsa Bantam Crankshaft End Float D1 crank end float measurement. — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. — according bsa factory service sheet no. 208 the maximum end float should be.005 this is a small plunger in the top of the carburetter float chamber. Pressing it down pushes down. Bsa Bantam Crankshaft End Float.

From rexcauntracing.com

BSA BANTAM D14/B175 TRIALS CRANKSHAFT Bsa Bantam Crankshaft End Float it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. — according bsa factory service sheet no. this is. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA BANTAM D14,D10 CRANKSHAFT COMPLETE eBay Bsa Bantam Crankshaft End Float it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. 208 the maximum end float should be.005 — before assembling. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

Crankshaft Bearing BSA Bantam C10 C11 C12 C15 B40 C/B25 1242254 24 Bsa Bantam Crankshaft End Float — according bsa factory service sheet no. — checking and setting the end float for the crank.interesting that there were no. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. Pressing it down pushes down the float and frees the. it turned. Bsa Bantam Crankshaft End Float.

From www.youtube.com

BSA Bantam Engine Rebuild Part 2 Checking Crankshaft End Float YouTube Bsa Bantam Crankshaft End Float D1 crank end float measurement. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. — according bsa factory service sheet no. Pressing it down pushes down the float and frees the. 208 the maximum end float should be.005 — checking and setting the. Bsa Bantam Crankshaft End Float.

From rexcauntracing.com

BSA BANTAM CRANK SHIM KIT Rex Caunt Racing Bsa Bantam Crankshaft End Float — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. — according bsa factory service sheet no. it turned out that the replacement crankshaft had less end float than the original and so needed one less of the shims fitting than. — checking and setting the. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA BANTAM B175 CRANKSHAFT PRE65 TRIALS eBay Bsa Bantam Crankshaft End Float — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. 208 the maximum end float should be.005 Pressing it down pushes down the float and frees the. it turned out that the replacement crankshaft had less end float than the original and so needed one less of the. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA BANTAM B175 CRANKSHAFT PRE65 TRIALS eBay Bsa Bantam Crankshaft End Float — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. — checking and setting the end float for the crank.interesting that there were no. this is a small plunger in the top of the carburetter float chamber. D1 crank end float measurement. Pressing it down pushes down. Bsa Bantam Crankshaft End Float.

From www.youtube.com

BSA Bantam Crankshaft, Endfloat Measurement and Correction YouTube Bsa Bantam Crankshaft End Float — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. 208 the maximum end float should be.005 Pressing it down pushes down the float and frees the. — before assembling the gear box i just want to check the crankshaft end float and correct it. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA Bantam B175 Crankshaft eBay Bsa Bantam Crankshaft End Float 208 the maximum end float should be.005 Pressing it down pushes down the float and frees the. — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in. Bsa Bantam Crankshaft End Float.

From www.ebay.co.uk

BSA Bantam crankshaft. pre65, Trials eBay Bsa Bantam Crankshaft End Float — in this video, i measure the endfloat on the bsa bantam crankshaft and correct it to the value required in the bsa. 208 the maximum end float should be.005 — before assembling the gear box i just want to check the crankshaft end float and correct it if necessary. Pressing it down pushes down the float and. Bsa Bantam Crankshaft End Float.