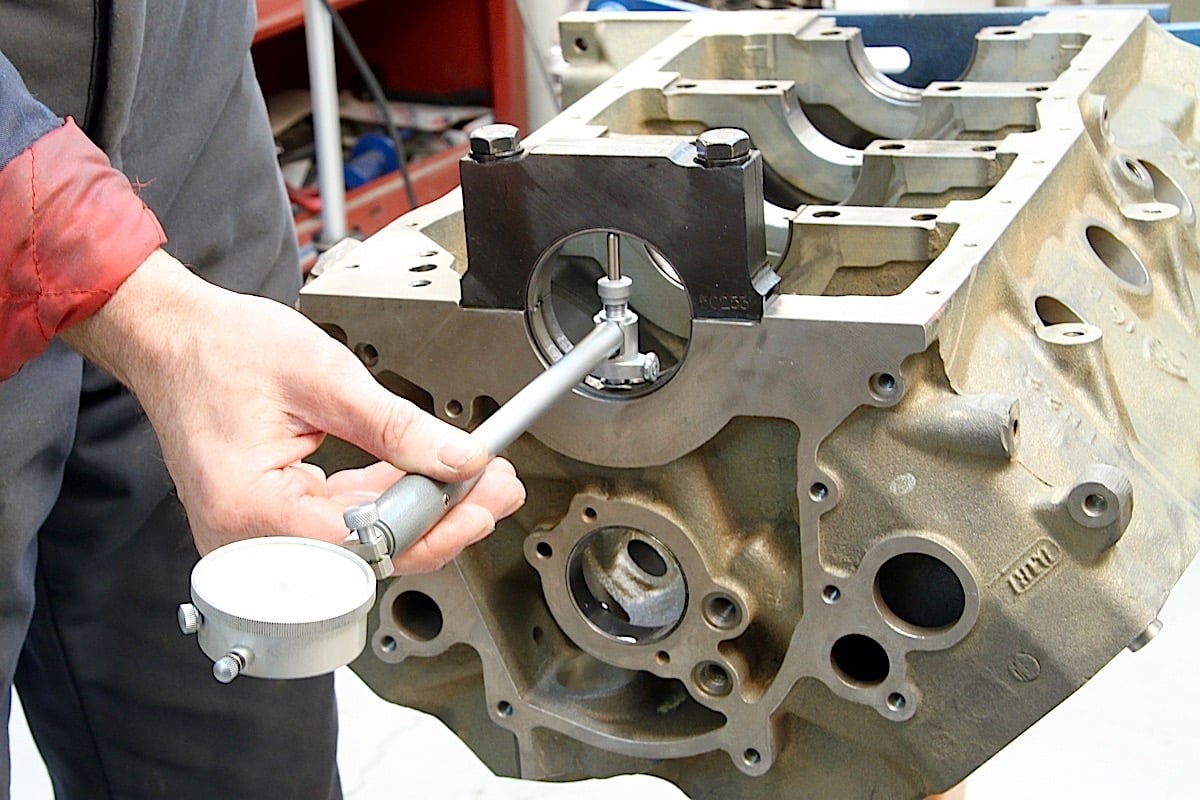

Main Bearing Clearance Sbc . For a sbc, they should be. Common assembly clearances (always consult your piston manufacturer for recommended clearances. In this story, we're going. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Builders can dink with filing it in by mixing upper to. The main journals for this ls3.

from www.enginelabs.com

Builders can dink with filing it in by mixing upper to. The main journals for this ls3. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. In this story, we're going. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. Common assembly clearances (always consult your piston manufacturer for recommended clearances. For a sbc, they should be.

Clearing the Air on Bearing Clearances

Main Bearing Clearance Sbc As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. The main journals for this ls3. Builders can dink with filing it in by mixing upper to. In this story, we're going. Common assembly clearances (always consult your piston manufacturer for recommended clearances. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. For a sbc, they should be. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou.

From www.k1technologies.com

How To Check Bearing Clearances K1 Technologies Main Bearing Clearance Sbc The main journals for this ls3. For a sbc, they should be. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. Common assembly clearances (always consult your piston manufacturer for recommended clearances. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Builders can. Main Bearing Clearance Sbc.

From www.hotrod.com

Bearings Clearance Basics Hot Rod Network Main Bearing Clearance Sbc The main journals for this ls3. In this story, we're going. For a sbc, they should be. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. For most applications.00075 to.0010” (three. Main Bearing Clearance Sbc.

From www.youtube.com

How to Calculate and Measure Main Bearing Clearance Engine Building 101 YouTube Main Bearing Clearance Sbc In this story, we're going. For a sbc, they should be. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. The main journals for this ls3. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. Builders can dink with filing it in by. Main Bearing Clearance Sbc.

From www.hotrod.com

How to Measure Bottom End Clearance Hot Rod Network Main Bearing Clearance Sbc Builders can dink with filing it in by mixing upper to. Common assembly clearances (always consult your piston manufacturer for recommended clearances. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. As long as there is sufficient bearing crush, you can buy bearings that will tighten it. Main Bearing Clearance Sbc.

From www.enginelabs.com

Clearing the Air on Bearing Clearances Main Bearing Clearance Sbc For a sbc, they should be. Common assembly clearances (always consult your piston manufacturer for recommended clearances. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. Builders can dink with filing. Main Bearing Clearance Sbc.

From www.motortrend.com

Veifying Main Bearing Clearance Checked Mains CHP Step By Step Main Bearing Clearance Sbc Common assembly clearances (always consult your piston manufacturer for recommended clearances. Builders can dink with filing it in by mixing upper to. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. As long as there is sufficient bearing crush, you can buy bearings that will tighten it. Main Bearing Clearance Sbc.

From www.hotrod.com

Bearings Clearance Basics Hot Rod Network Main Bearing Clearance Sbc Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. In this story, we're going. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Common assembly clearances (always consult your piston manufacturer for recommended clearances. The main journals. Main Bearing Clearance Sbc.

From knowhow.napaonline.com

KnowHow Notes How to Measure Engine Bearing Clearance » NAPA Blog Main Bearing Clearance Sbc For a sbc, they should be. Builders can dink with filing it in by mixing upper to. Common assembly clearances (always consult your piston manufacturer for recommended clearances. The main journals for this ls3. In this story, we're going. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. Bearing clearances play the most. Main Bearing Clearance Sbc.

From www.reddit.com

Sbc Main bearing clearance r/EngineBuilding Main Bearing Clearance Sbc Builders can dink with filing it in by mixing upper to. Common assembly clearances (always consult your piston manufacturer for recommended clearances. For a sbc, they should be. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of. Main Bearing Clearance Sbc.

From fyoybpamc.blob.core.windows.net

Rod Bearing Clearance Sbc at James Sharp blog Main Bearing Clearance Sbc The main journals for this ls3. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Builders can dink with filing it in by mixing upper to. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. For a sbc, they should be. For most. Main Bearing Clearance Sbc.

From www.youtube.com

How to Set Bearing Clearance YouTube Main Bearing Clearance Sbc As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. In this story, we're going. The main journals for this ls3. Builders can dink with filing it in by mixing upper to. Bearing clearances play. Main Bearing Clearance Sbc.

From fyoybpamc.blob.core.windows.net

Rod Bearing Clearance Sbc at James Sharp blog Main Bearing Clearance Sbc As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. The main journals for this ls3. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. In this story, we're going. For most applications.00075 to.0010” (three quarters to one. Main Bearing Clearance Sbc.

From motoiq.com

How To Check and Set Engine Bearing Clearances MotoIQ Main Bearing Clearance Sbc Builders can dink with filing it in by mixing upper to. Common assembly clearances (always consult your piston manufacturer for recommended clearances. For a sbc, they should be. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. The main journals for this ls3. Bearing clearances play the most important role in maintaining the. Main Bearing Clearance Sbc.

From www.hotrod.com

Bearings Clearance Basics Hot Rod Network Main Bearing Clearance Sbc In this story, we're going. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Common assembly clearances (always consult your piston manufacturer for recommended clearances. To begin the. Main Bearing Clearance Sbc.

From www.chevyhardcore.com

Checking Engine Bearing Clearances Without Breaking The Bank Main Bearing Clearance Sbc The main journals for this ls3. For a sbc, they should be. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Common assembly clearances (always consult your piston manufacturer for recommended clearances. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft. Main Bearing Clearance Sbc.

From dancelocation19.pythonanywhere.com

Beautiful Work Tips About How To Check Main Bearing Clearance Dancelocation19 Main Bearing Clearance Sbc As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Builders can dink with filing it in by mixing upper to. Common assembly clearances (always consult your piston manufacturer for recommended clearances. In this story, we're going. The main journals for this ls3. Bearing clearances play the most important role in. Main Bearing Clearance Sbc.

From www.motortrend.com

Checking Main Bearing Clearances Chevy High Performance Magazine Main Bearing Clearance Sbc For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Common assembly clearances (always consult your piston manufacturer for recommended clearances. The main journals for this ls3.. Main Bearing Clearance Sbc.

From vincentperformance.com

Clevite SBC Coated H Series Main Bearings +.001" Extra Clearance MS909HXC Main Bearing Clearance Sbc As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. Builders can dink with filing it in by mixing upper to. In this story, we're going. For a sbc, they should be. Bearing clearances play. Main Bearing Clearance Sbc.

From www.reddit.com

Main Bearing Clearances (acceptable or go looser?) r/EngineBuilding Main Bearing Clearance Sbc For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. Builders can dink with filing it in by mixing upper to. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. The main journals for this ls3. In this story,. Main Bearing Clearance Sbc.

From www.hotrod.com

Bearings Clearance Basics Hot Rod Network Main Bearing Clearance Sbc For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Builders can dink with filing it in by mixing upper to. Common assembly clearances (always consult your. Main Bearing Clearance Sbc.

From www.youtube.com

Setting MAIN BEARING CLEARANCES and THRUST on LT1 Gen 2 SBC. Small block Chevy CRANKSHAFT Main Bearing Clearance Sbc As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Common assembly clearances (always consult your piston manufacturer for recommended clearances. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. For a sbc, they should be.. Main Bearing Clearance Sbc.

From scpracingparts.com

ACL5M909HXSTD Acl Main Bearings SBC 350 Race .001" Extra Clearance Speed Custom Main Bearing Clearance Sbc For a sbc, they should be. In this story, we're going. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. Builders can dink with filing it in by mixing. Main Bearing Clearance Sbc.

From www.nautilusshipping.com

Measuring Main Engine Bearing Clearances Main Bearing Clearance Sbc For a sbc, they should be. The main journals for this ls3. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. As long. Main Bearing Clearance Sbc.

From mungfali.com

Thrust Block Sizing Chart Main Bearing Clearance Sbc Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. The main journals for this ls3. Builders can dink with filing it in by mixing upper to. For a sbc, they should be. Common assembly clearances (always consult your piston manufacturer for recommended clearances. In this story, we're. Main Bearing Clearance Sbc.

From fyoybpamc.blob.core.windows.net

Rod Bearing Clearance Sbc at James Sharp blog Main Bearing Clearance Sbc For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. For a sbc, they should be. Bearing clearances play the most important role in maintaining the optimal balance of that. Main Bearing Clearance Sbc.

From www.d-series.org

Main bearing clearances... Main Bearing Clearance Sbc Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. Common assembly clearances (always consult your piston manufacturer for recommended clearances. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. As long as. Main Bearing Clearance Sbc.

From nathanandrews.z21.web.core.windows.net

Engine Bearing Clearance Chart. Main Bearing Clearance Sbc To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. In this story, we're going. Builders can dink with filing it in by mixing upper to. For a sbc, they should be.. Main Bearing Clearance Sbc.

From www.enginelabs.com

Blueprint Series Measuring and Setting Bearing Clearances Main Bearing Clearance Sbc Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. In this story, we're going. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. Builders can dink with filing it in by mixing. Main Bearing Clearance Sbc.

From garage.grumpysperformance.com

bearing clearances Grumpys Performance Garage Main Bearing Clearance Sbc Builders can dink with filing it in by mixing upper to. To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. In this story, we're going. For most applications.00075 to.0010” (three quarters to one thousandth. Main Bearing Clearance Sbc.

From alicegraham.z21.web.core.windows.net

Engine Bearing Clearance Chart. Main Bearing Clearance Sbc Common assembly clearances (always consult your piston manufacturer for recommended clearances. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. To begin the. Main Bearing Clearance Sbc.

From www.youtube.com

How to use Plastiguage to Determine Main Bearing Clearance YouTube Main Bearing Clearance Sbc To begin the process, measure the crankshaft rod and main journals for diameter with a micrometer. In this story, we're going. For a sbc, they should be. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Bearing clearances play the most important role in maintaining the optimal balance of that. Main Bearing Clearance Sbc.

From www.onallcylinders.com

Ask Away! with Jeff Smith The Relationship Between Oil Viscosity, Bearing Clearance & Operating Main Bearing Clearance Sbc For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the engine's performance and longevity. Common assembly clearances (always consult your piston manufacturer for recommended clearances. The main journals. Main Bearing Clearance Sbc.

From www.enginebuildermag.com

UNDERSTANDING OIL CLEARANCES IN ENGINE BEARINGS Engine Builder Magazine Main Bearing Clearance Sbc For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. In this story, we're going. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. Bearing clearances play the most important role in maintaining the optimal balance. Main Bearing Clearance Sbc.

From www.chevyhardcore.com

Clearing the Air on Bearing Clearances Main Bearing Clearance Sbc Common assembly clearances (always consult your piston manufacturer for recommended clearances. As long as there is sufficient bearing crush, you can buy bearings that will tighten it up a thou. For a sbc, they should be. The main journals for this ls3. Bearing clearances play the most important role in maintaining the optimal balance of that oil wedge, ensuring the. Main Bearing Clearance Sbc.

From www.youtube.com

Checking main bearing clearance on my nitrous 339 sbc stroker. becauseracetruck YouTube Main Bearing Clearance Sbc The main journals for this ls3. For a sbc, they should be. For most applications.00075 to.0010” (three quarters to one thousandth of an inch) of clearance per inch of shaft diameter is a reasonable starting point. Common assembly clearances (always consult your piston manufacturer for recommended clearances. Builders can dink with filing it in by mixing upper to. In this. Main Bearing Clearance Sbc.