Sealing Flared Copper Fittings . The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. Water service applications generally use a flare to iron pipe. The reason for the warning against. Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. A nut draws the flared tubing against a correspondingly shaped fitting, creating an extremely strong joint. During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare nut. The flared end, i assume, is copper which is a soft metal and should seal with no problem. Flare connections work by creating a seal between the flare nut and the flare fitting. The primary advantage of flare connections is that they form a relatively. The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. The flare nut has a tapered bore that fits over the end of the pipe.

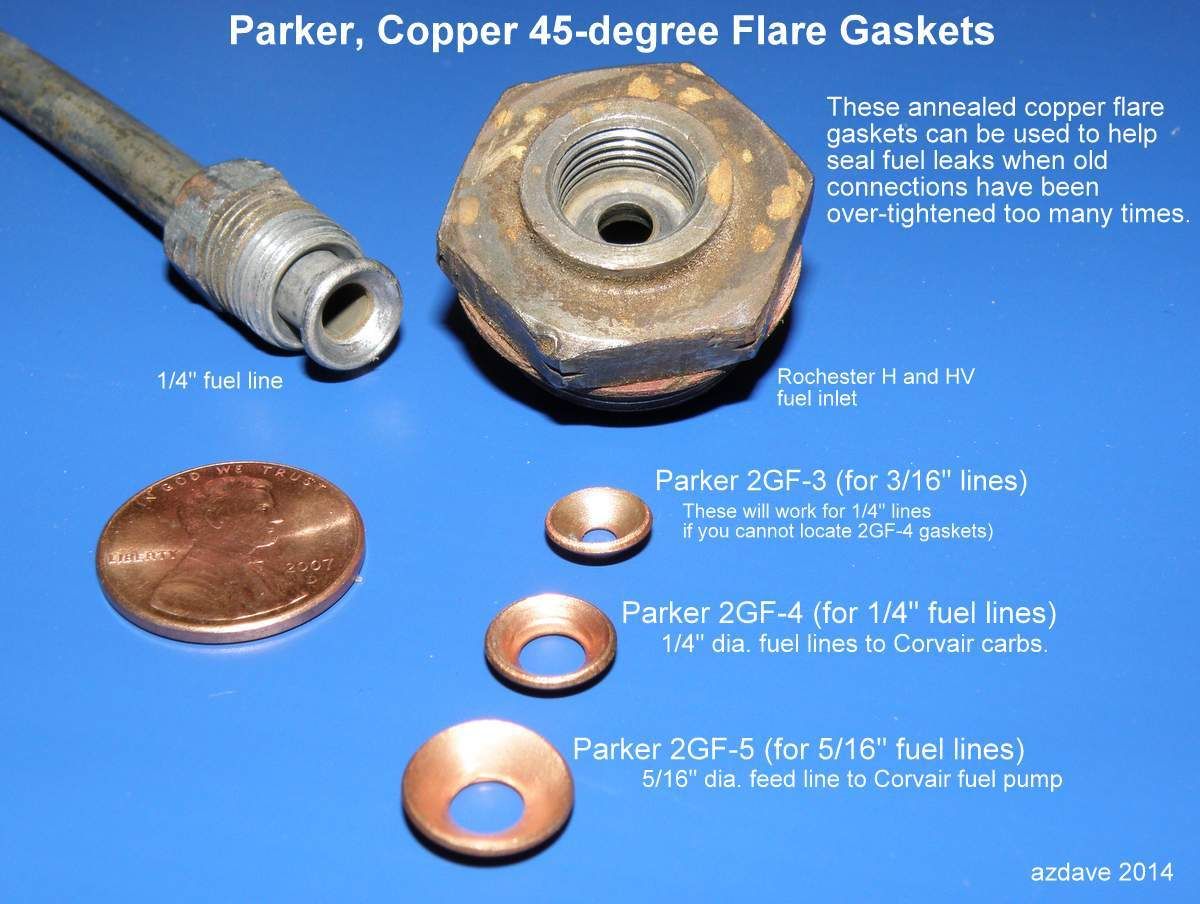

from s1273.photobucket.com

The reason for the warning against. The flare nut has a tapered bore that fits over the end of the pipe. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare nut. A nut draws the flared tubing against a correspondingly shaped fitting, creating an extremely strong joint. The primary advantage of flare connections is that they form a relatively. The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. The flared end, i assume, is copper which is a soft metal and should seal with no problem. Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. Flare connections work by creating a seal between the flare nut and the flare fitting.

Copper Flare Line Gaskets Corvair Photo by 1964MSC Photobucket

Sealing Flared Copper Fittings The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. Flare connections work by creating a seal between the flare nut and the flare fitting. During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare nut. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. The reason for the warning against. The flared end, i assume, is copper which is a soft metal and should seal with no problem. Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. A nut draws the flared tubing against a correspondingly shaped fitting, creating an extremely strong joint. The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. The flare nut has a tapered bore that fits over the end of the pipe. The primary advantage of flare connections is that they form a relatively. Water service applications generally use a flare to iron pipe.

From www.walmart.com

Uxcell U Shape Elbow 180 Degree Copper Pipe Fitting Sweat Welding Sealing Flared Copper Fittings The reason for the warning against. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. The primary advantage of flare connections is that they form a relatively. Flare connections work by creating a seal between the flare nut and the flare fitting. The flared. Sealing Flared Copper Fittings.

From www.finehomebuilding.com

Make a Flare Connection Fine Homebuilding Sealing Flared Copper Fittings The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. A nut draws the flared tubing against a correspondingly shaped fitting, creating an extremely strong joint. During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare. Sealing Flared Copper Fittings.

From www.youtube.com

How to Repair Leaky Flare Fittings YouTube Sealing Flared Copper Fittings The flare nut has a tapered bore that fits over the end of the pipe. The reason for the warning against. Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. The primary advantage of flare connections is that they form a relatively. Water service applications generally use. Sealing Flared Copper Fittings.

From www.grainger.com

MUELLER Copper Flare Seal 1/4 in Connection Size, 700 psi Max Sealing Flared Copper Fittings Flare connections work by creating a seal between the flare nut and the flare fitting. The reason for the warning against. During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare nut. Water service applications generally use a flare to iron pipe. The only thing you can do to help a flare. Sealing Flared Copper Fittings.

From www.fleetmaintenance.com

Flared Seals Fleet Maintenance Sealing Flared Copper Fittings The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. Water service applications generally use a flare to iron pipe. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops. Sealing Flared Copper Fittings.

From exoxpyhhu.blob.core.windows.net

Copper Gas Line Flare Fittings at David Collado blog Sealing Flared Copper Fittings The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. Flare connections work by creating a seal between the flare nut and the flare fitting. The reason for the warning against. The 1/4 flareseal clips on the fitting and the brass flare cap secures. Sealing Flared Copper Fittings.

From www.plasticpprpipe.com

1/8' Male Female Brass Flared Fittings Copper Pipe Flare Fitting For Gas Sealing Flared Copper Fittings The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. The flared end, i assume, is copper which is a soft metal and should seal with no problem. The reason for the warning against. The primary advantage of flare connections is that they form. Sealing Flared Copper Fittings.

From omega1.com

OmegaFlare Omega One Sealing Flared Copper Fittings Flare connections work by creating a seal between the flare nut and the flare fitting. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. The flared end, i assume, is copper which is a soft metal and should seal with no problem. The only. Sealing Flared Copper Fittings.

From www.youtube.com

How to make a flare fitting copper washer to seal a seeping fuel line Sealing Flared Copper Fittings The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. A nut draws the flared tubing against a correspondingly shaped fitting, creating an extremely strong joint. The flare nut has a tapered bore that fits over the end of the pipe. During assembly, the flared. Sealing Flared Copper Fittings.

From www.mytub.co.uk

Bullfinch Lgl Copper Flared Seal Cap 1/4 Inch Bull Sealing Flared Copper Fittings A nut draws the flared tubing against a correspondingly shaped fitting, creating an extremely strong joint. Flare connections work by creating a seal between the flare nut and the flare fitting. Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. The only thing you can do to. Sealing Flared Copper Fittings.

From www.youtube.com

How To Flare Copper Water Tubing Learn From A Plumbing Professional Sealing Flared Copper Fittings Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. The primary advantage of flare connections is that they form a relatively.. Sealing Flared Copper Fittings.

From tectran.com

SAE 45° Flared Fittings Male Elbow Tectran Manufacturing Inc Sealing Flared Copper Fittings The flare nut has a tapered bore that fits over the end of the pipe. Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. The reason for the warning against. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a. Sealing Flared Copper Fittings.

From hvacrschool.com

Swaging Copper Best Practices HVAC School Sealing Flared Copper Fittings The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. The flared end, i assume, is copper which is a soft metal and should seal with no problem. During assembly, the flared end of the copper pipe is secured to the tapered fitting by the. Sealing Flared Copper Fittings.

From www.ebay.com

1/4" Male Flare Access Fitting with 1/4" Copper Tube Extension BesTech Sealing Flared Copper Fittings The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare nut. The flared end, i assume, is copper which is a soft metal and should seal. Sealing Flared Copper Fittings.

From www.finehomebuilding.com

Make a Flare Connection Fine Homebuilding Sealing Flared Copper Fittings The flared end, i assume, is copper which is a soft metal and should seal with no problem. Flare connections work by creating a seal between the flare nut and the flare fitting. The flare nut has a tapered bore that fits over the end of the pipe. During assembly, the flared end of the copper pipe is secured to. Sealing Flared Copper Fittings.

From wintecheng.com.my

Flare Tube Connector & Insert Fittings Wintech Engineering Supply Sealing Flared Copper Fittings During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare nut. A nut draws the flared tubing against a correspondingly shaped fitting, creating an extremely strong joint. Flare connections work by creating a seal between the flare nut and the flare fitting. Flared fittings (figures 9.1 and 9.2) are an alternative when. Sealing Flared Copper Fittings.

From s1273.photobucket.com

Copper Flare Line Gaskets Corvair Photo by 1964MSC Photobucket Sealing Flared Copper Fittings During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare nut. Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. The flared end, i assume, is copper which is a soft metal and should seal with no problem. Flare. Sealing Flared Copper Fittings.

From www.mytub.co.uk

Bullfinch Lgl Copper Flared Seal Cap 5/8 Inch Bull Sealing Flared Copper Fittings Water service applications generally use a flare to iron pipe. Flare connections work by creating a seal between the flare nut and the flare fitting. During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare nut. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating. Sealing Flared Copper Fittings.

From www.aliexpress.com

Flared Copper Pipe Fittings Tube Od 6/8/10/12/14mm Brass Connector Sealing Flared Copper Fittings The flare nut has a tapered bore that fits over the end of the pipe. The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. The flared end, i assume, is copper which is a soft metal and should seal with no problem. Flare. Sealing Flared Copper Fittings.

From fluiddrivecoupling.com

JIS vs JIC fitting standards Knowledge EVERPOWER GROUP CO., LTD. Sealing Flared Copper Fittings The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. The primary advantage of flare connections is that they form a relatively. The flared end, i assume, is copper which is a soft metal and should seal with no problem. The 1/4 flareseal clips. Sealing Flared Copper Fittings.

From exothermic.tech

Copper Flare Seals Exothermic Technologies Sealing Flared Copper Fittings The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. A nut draws the flared tubing against a correspondingly shaped fitting, creating an extremely strong joint. Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not. Sealing Flared Copper Fittings.

From www.aliexpress.com

Flared copper pipe fittings Tube OD 6/8/10/12/14/16/19mm Brass Sealing Flared Copper Fittings The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. The flared end, i assume, is copper which is a soft metal and should seal with no problem. The only thing you can do to help a flare is to put a tiny drop of. Sealing Flared Copper Fittings.

From www.achrnews.com

RectorSeal LLC Flared Tubing Seal 20190812 ACHR News Sealing Flared Copper Fittings Flare connections work by creating a seal between the flare nut and the flare fitting. The primary advantage of flare connections is that they form a relatively. The flare nut has a tapered bore that fits over the end of the pipe. The flared end, i assume, is copper which is a soft metal and should seal with no problem.. Sealing Flared Copper Fittings.

From www.plumbingsupply.com

Flare Fittings Sealing Flared Copper Fittings During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare nut. Flare connections work by creating a seal between the flare nut and the flare fitting. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. Water. Sealing Flared Copper Fittings.

From www.youtube.com

How To Flare Copper Tubing Plumbing 101 YouTube Sealing Flared Copper Fittings The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. The flared end, i assume, is copper which is a soft metal and should seal with no problem. The reason for the warning against. Water service applications generally use a flare to iron pipe.. Sealing Flared Copper Fittings.

From hvacrschool.com

Making a Flare Quick Tips HVAC School Sealing Flared Copper Fittings The primary advantage of flare connections is that they form a relatively. Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. The flare nut has a tapered bore that fits over the end of the pipe. A nut draws the flared tubing against a correspondingly shaped fitting,. Sealing Flared Copper Fittings.

From www.lowes.com

Shop NIBCO 1/2in x 1/2in Copper Slip Union Fittings at Sealing Flared Copper Fittings Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. Water service applications generally use a flare to iron pipe. The flare nut. Sealing Flared Copper Fittings.

From pacesupply.com

Pace Supply Seal Combo Kit, For Use With 45 deg SAE Flared Sealing Flared Copper Fittings The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. The flare nut has a tapered bore that fits over the end. Sealing Flared Copper Fittings.

From www.balkanplumbing.com

How To Flare Copper 5 Step Guide With Tools and Techniques Sealing Flared Copper Fittings A nut draws the flared tubing against a correspondingly shaped fitting, creating an extremely strong joint. During assembly, the flared end of the copper pipe is secured to the tapered fitting by the flare nut. Water service applications generally use a flare to iron pipe. The primary advantage of flare connections is that they form a relatively. Flare connections work. Sealing Flared Copper Fittings.

From www.balkanplumbing.com

How To Flare Copper 5 Step Guide With Tools and Techniques Sealing Flared Copper Fittings The flared end, i assume, is copper which is a soft metal and should seal with no problem. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. Flare connections work by creating a seal between the flare nut and the flare fitting. The only. Sealing Flared Copper Fittings.

From hvacrschool.com

Making a Flare Quick Tips HVAC School Sealing Flared Copper Fittings The flare nut has a tapered bore that fits over the end of the pipe. Water service applications generally use a flare to iron pipe. The flared end, i assume, is copper which is a soft metal and should seal with no problem. During assembly, the flared end of the copper pipe is secured to the tapered fitting by the. Sealing Flared Copper Fittings.

From www.youtube.com

How to make a flare fitting seal YouTube Sealing Flared Copper Fittings Flared fittings (figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical. The flare nut has a tapered bore that fits over the end of the pipe. The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts. Sealing Flared Copper Fittings.

From www.pipsisland.com

7 Simple Steps To Flare Copper Pipe Sealing Flared Copper Fittings The flare nut has a tapered bore that fits over the end of the pipe. The flared end, i assume, is copper which is a soft metal and should seal with no problem. The primary advantage of flare connections is that they form a relatively. A nut draws the flared tubing against a correspondingly shaped fitting, creating an extremely strong. Sealing Flared Copper Fittings.

From www.youtube.com

how to flare copper pipe tubing YouTube Sealing Flared Copper Fittings The primary advantage of flare connections is that they form a relatively. The only thing you can do to help a flare is to put a tiny drop of oil where the flare nut contacts the copper flare. The flared end, i assume, is copper which is a soft metal and should seal with no problem. During assembly, the flared. Sealing Flared Copper Fittings.

From gootutorials.blogspot.com

How To Use A Flaring Tool For Gas Lines Sealing Flared Copper Fittings The primary advantage of flare connections is that they form a relatively. Water service applications generally use a flare to iron pipe. The 1/4 flareseal clips on the fitting and the brass flare cap secures the connection creating a crush seal eliminating all leaks, even stops the. The flare nut has a tapered bore that fits over the end of. Sealing Flared Copper Fittings.