Plastic Injection Molding Bottle . Melt plastic pellets, inject them into a mold, and cool to shape the bottle. In injection molding, polymer granules are first. This process allows for intricate. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. Containers, spawned by human ingenuity, delivering more and more value as they. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. The most common method for producing plastic bottles.

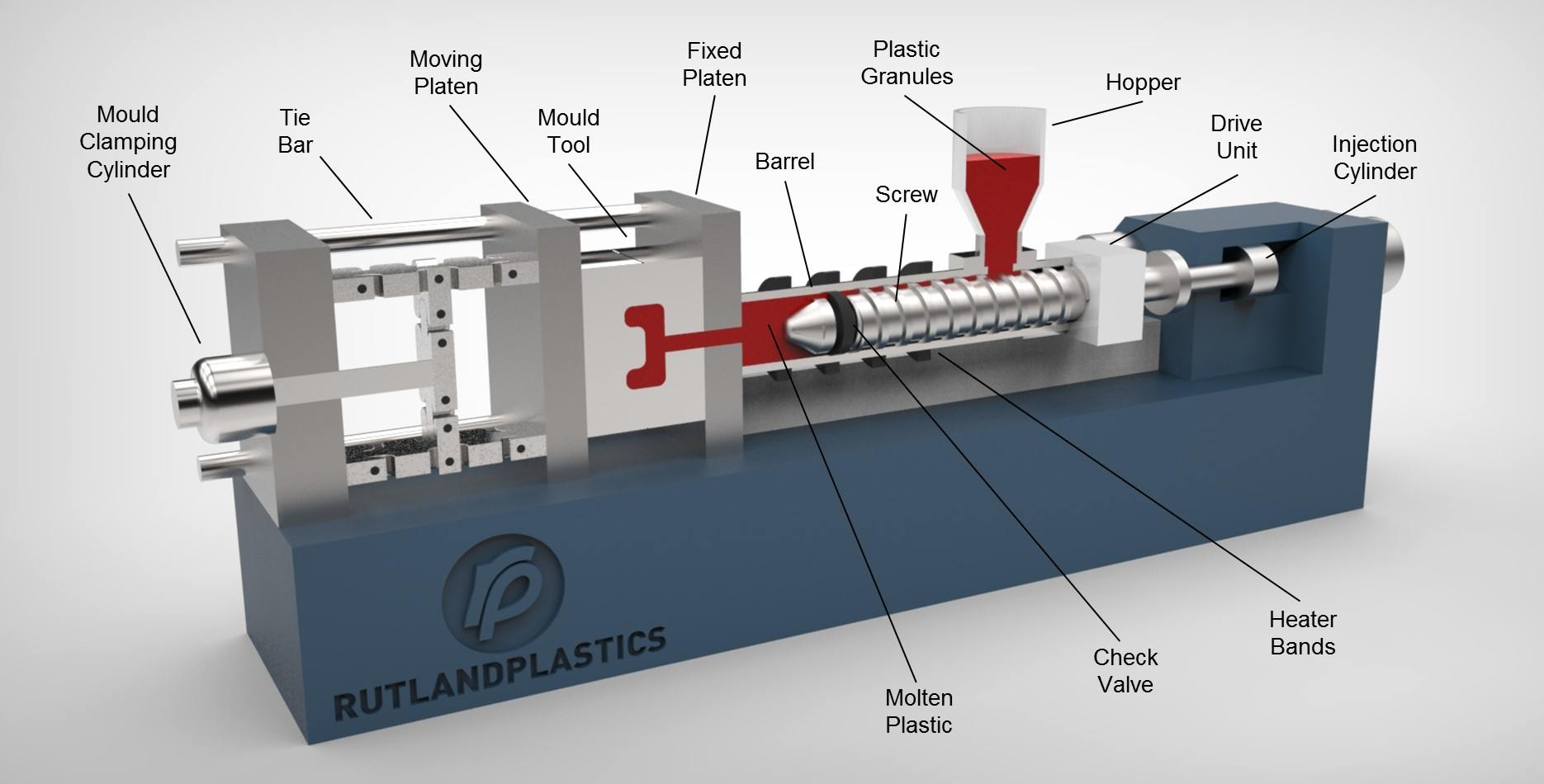

from www.rutlandplastics.co.uk

Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. In injection molding, polymer granules are first. This process allows for intricate. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Containers, spawned by human ingenuity, delivering more and more value as they. The most common method for producing plastic bottles. Melt plastic pellets, inject them into a mold, and cool to shape the bottle.

How does injection moulding work Rutland Plastics

Plastic Injection Molding Bottle The most common method for producing plastic bottles. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. This process allows for intricate. Containers, spawned by human ingenuity, delivering more and more value as they. The most common method for producing plastic bottles. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. In injection molding, polymer granules are first. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding.

From www.zjghuilimachine.com

5 gallon plastic bottle cap making machine Buy bottle injection Plastic Injection Molding Bottle Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. In injection molding, polymer granules are first. Containers, spawned by human ingenuity, delivering more and more value as they. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. This. Plastic Injection Molding Bottle.

From www.apt-mold.com

A Complete Guide to Plastic Injection Molding Plastic Injection Molding Bottle The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. The most common method for producing plastic bottles. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. In injection. Plastic Injection Molding Bottle.

From www.naplasticsltd.com

Blow Molding Process Overview North American Plastics, Ltd. Plastic Injection Molding Bottle Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. The most common method for producing plastic bottles. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. This process allows for intricate. The injection blow moulding process produces bottles. Plastic Injection Molding Bottle.

From www.indiamart.com

Steel Plastic Bottle Injection Blow Mold, Rs 50000 /unit Yogesh Plastic Injection Molding Bottle The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Containers, spawned by human ingenuity, delivering more and more value as they. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. The most common method for producing plastic bottles.. Plastic Injection Molding Bottle.

From www.youtube.com

Which Blow Molding Process is Right for Your Bottle? Drug Plastics Plastic Injection Molding Bottle In injection molding, polymer granules are first. Containers, spawned by human ingenuity, delivering more and more value as they. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Production. Plastic Injection Molding Bottle.

From www.youtube.com

Water Bottle Cap Molding 7200Pcs/Hour YouTube Plastic Injection Molding Bottle The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. The most common method for producing plastic bottles. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. In injection. Plastic Injection Molding Bottle.

From www.dreamstime.com

The Injection Mold Insert Part for Make Plastic Bottle Stock Photo Plastic Injection Molding Bottle Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. This process allows for intricate. The most common method for producing plastic bottles. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. Containers, spawned by human ingenuity, delivering more. Plastic Injection Molding Bottle.

From www.plastic-injectionmoldingmachine.com

Durable Plastic Bottle Injection Molding Machine / Pet Preform Making Plastic Injection Molding Bottle Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. The most common method for producing plastic bottles. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. In injection. Plastic Injection Molding Bottle.

From www.autoinjectionmoldingmachine.com

Customized Plastic Bottle Mould / Multi Cavity Injection Molding With Plastic Injection Molding Bottle Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. The most common method for producing plastic bottles. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. In injection molding, polymer granules are first. Production of pet containers requires injection molding of preforms. Plastic Injection Molding Bottle.

From holdsunv.com

Customized High Quality Multicavity Bottle Container Mould Plastic Injection Molding Bottle Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. In injection molding, polymer granules are first. This process allows for intricate. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. Containers, spawned by human ingenuity, delivering more and more value as they.. Plastic Injection Molding Bottle.

From www.utechmachine.com

Drink Water Bottle Plastic Injection Molding Machine Preform Making Plastic Injection Molding Bottle The most common method for producing plastic bottles. This process allows for intricate. Containers, spawned by human ingenuity, delivering more and more value as they. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes. Plastic Injection Molding Bottle.

From www.indiamart.com

Liquid Injection Molding Rectangular Plastic Bottle Mould, Packaging Plastic Injection Molding Bottle Containers, spawned by human ingenuity, delivering more and more value as they. The most common method for producing plastic bottles. This process allows for intricate. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. In injection molding, polymer granules are first. The injection blow moulding process produces. Plastic Injection Molding Bottle.

From www.autoinjectionmoldingmachine.com

Precise Control Plastic Injection Molding Machine Plastic Cap 5 Gallon Plastic Injection Molding Bottle Melt plastic pellets, inject them into a mold, and cool to shape the bottle. This process allows for intricate. In injection molding, polymer granules are first. The most common method for producing plastic bottles. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. The injection blow moulding process produces bottles of. Plastic Injection Molding Bottle.

From tech-tank.com

What Is Plastic Injection Molding? TechTank Injection Molding Services Plastic Injection Molding Bottle Melt plastic pellets, inject them into a mold, and cool to shape the bottle. The most common method for producing plastic bottles. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. In injection molding, polymer granules are first. Containers, spawned by human ingenuity, delivering more and more. Plastic Injection Molding Bottle.

From www.sourceint.com

Plastic Injection Molding The Manufacturing & Design Guide Source Plastic Injection Molding Bottle Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. This process allows for intricate. In injection molding, polymer granules are first. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. The most common method for producing plastic bottles.. Plastic Injection Molding Bottle.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained Plastic Injection Molding Bottle The most common method for producing plastic bottles. Containers, spawned by human ingenuity, delivering more and more value as they. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Melt plastic pellets, inject. Plastic Injection Molding Bottle.

From www.youtube.com

Injection Molding Machine How to manufacture Plastic bottle Cap Hi Plastic Injection Molding Bottle The most common method for producing plastic bottles. In injection molding, polymer granules are first. This process allows for intricate. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. Injection mold bottle molding. Plastic Injection Molding Bottle.

From www.dreamstime.com

Bottle Injection or Blowing Plastic Mold for Mass Production Industrial Plastic Injection Molding Bottle Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. Containers, spawned by human ingenuity, delivering more and more value as they. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. The most common method for producing plastic bottles. This process allows for. Plastic Injection Molding Bottle.

From www.youtube.com

HDPE bottle injection blow molding process with vertical injection blow Plastic Injection Molding Bottle Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. The most. Plastic Injection Molding Bottle.

From www.rutlandplastics.co.uk

How does injection moulding work Rutland Plastics Plastic Injection Molding Bottle The most common method for producing plastic bottles. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Containers, spawned by human ingenuity, delivering more and more value as they.. Plastic Injection Molding Bottle.

From reliable-machinery.en.made-in-china.com

Plastic Injection Molding Machine for Bottle Cap and Pet Preform Plastic Injection Molding Bottle The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. In injection molding, polymer granules are first. The most common method for producing plastic bottles. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. Melt plastic pellets, inject them. Plastic Injection Molding Bottle.

From www.team-mfg.com

Plastic Injection Molding Buy, Injection Molding, Plastic Injection Plastic Injection Molding Bottle Containers, spawned by human ingenuity, delivering more and more value as they. The most common method for producing plastic bottles. In injection molding, polymer granules are first. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. Injection mold bottle molding is a process where heated plastic is injected into a mold,. Plastic Injection Molding Bottle.

From darrow.en.made-in-china.com

Plastic Injection Mold for HDPE Bottle Injection Mould and Plastic Plastic Injection Molding Bottle This process allows for intricate. The most common method for producing plastic bottles. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. Containers, spawned by human ingenuity, delivering more and more value as they. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Production of pet. Plastic Injection Molding Bottle.

From www.pinterest.com

Blow Mold Stages Plastic moulding, Blow molding, Injection mold design Plastic Injection Molding Bottle Containers, spawned by human ingenuity, delivering more and more value as they. This process allows for intricate. In injection molding, polymer granules are first. The most common method for producing plastic bottles. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. Injection mold bottle molding is a process where heated plastic is injected into a. Plastic Injection Molding Bottle.

From www.blowmoldedplastic.com

Stretch Blow Molding Companies Plastic Injection Molding Bottle The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. This process. Plastic Injection Molding Bottle.

From www.iqsdirectory.com

Plastic Bottles Types, Manufacturing, Uses, and Benefits Plastic Injection Molding Bottle Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. The most common method for producing plastic bottles. This process allows for intricate. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. In injection molding, polymer granules are first. Melt plastic pellets, inject. Plastic Injection Molding Bottle.

From indonesian.automaticbottleblowingmachine.com

Multi Shaped Plastic Injection Molding 1L PET Juice Bottle 2 Juta Kali Plastic Injection Molding Bottle Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. Containers, spawned by human ingenuity, delivering more and more value as they. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Melt plastic pellets, inject them into a mold,. Plastic Injection Molding Bottle.

From www.team-mfg.com

Plastic Injection Molding Buy, Injection Molding, Plastic Injection Plastic Injection Molding Bottle The most common method for producing plastic bottles. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. This process allows for intricate. Production of pet containers requires injection molding of preforms and subsequent. Plastic Injection Molding Bottle.

From prototechasia.com

What is Plastic Injection Molding? Our Comprehensive Overview Plastic Injection Molding Bottle This process allows for intricate. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. The most common method for producing plastic bottles. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. Melt plastic pellets, inject them into a. Plastic Injection Molding Bottle.

From www.autoinjectionmoldingmachine.com

Drink Water Bottle Injection Molding Molds1.5L Capacity Blow / Plastic Plastic Injection Molding Bottle The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. The most common method for producing plastic bottles. This process allows for intricate. Containers, spawned by human ingenuity, delivering more. Plastic Injection Molding Bottle.

From evertop-machinery.en.made-in-china.com

Automatic Injection Molding Machine Plastic Bottle Mold Making China Plastic Injection Molding Bottle Containers, spawned by human ingenuity, delivering more and more value as they. Injection mold bottle molding is a process where heated plastic is injected into a mold, which shapes the plastic into the desired. In injection molding, polymer granules are first. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. The. Plastic Injection Molding Bottle.

From www.injection-plasticmoulds.com

Washing Liquid Bottle Plastic Injection Cap Mould , Injection Molding Plastic Injection Molding Bottle The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. In injection molding, polymer granules are first. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. The most common method for producing plastic bottles. Injection mold bottle molding is a process where heated plastic is injected into. Plastic Injection Molding Bottle.

From fillplas.com

Blow molding for making plastic bottles and plastic bottles Plastic Injection Molding Bottle This process allows for intricate. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. In injection molding, polymer granules are first. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. The most common method for producing plastic bottles. Containers, spawned by human ingenuity, delivering more and. Plastic Injection Molding Bottle.

From www.plasticomould.com

PET Plastic Bottle Blowing Mould Factory and Manufacturers Made in Plastic Injection Molding Bottle This process allows for intricate. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. Containers, spawned by human ingenuity, delivering more and more value as they. Melt plastic pellets, inject them into a. Plastic Injection Molding Bottle.

From www.injection-plasticmoulds.com

Economic Injection Molding Mold , Plastic Bottle Mold Hot Runner Self Plastic Injection Molding Bottle In injection molding, polymer granules are first. The injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. Production of pet containers requires injection molding of preforms and subsequent stretching and blowing of these into bottles. Melt plastic pellets, inject them into a mold, and cool to shape the bottle. Injection mold bottle. Plastic Injection Molding Bottle.