Piezoelectric Nozzle . In 2010, yoo et al. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top of the. At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all.

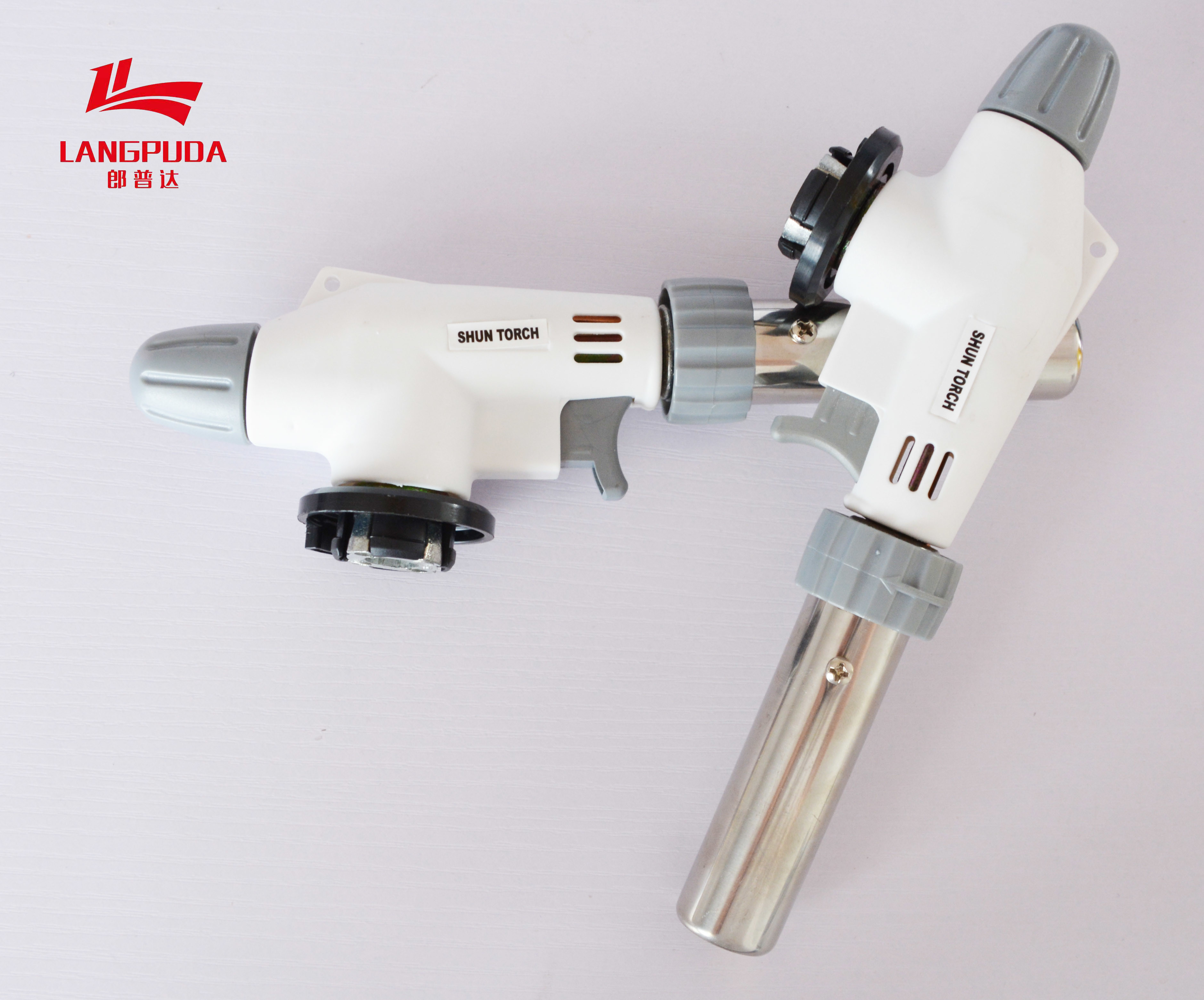

from www.gastorchgun.com

At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. In 2010, yoo et al. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top of the. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all.

Piezoelectric Mini Ceramic Nozzle Kitchen Torch Gun 19.5cm

Piezoelectric Nozzle Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. In 2010, yoo et al. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top of the.

From www.lcdrkj.com

China Bosch piezoelectric nozzle factory and suppliers Derun Piezoelectric Nozzle (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top of the. In 2010, yoo et al. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and. Piezoelectric Nozzle.

From www.china-balin.com

BOSCH Piezo Nozzles F00VX20017 [PEF17] Piezoelectric Nozzle Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top of the. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of. Piezoelectric Nozzle.

From eureka.patsnap.com

Piezoelectric nozzle for bone cement 3D printing Eureka Piezoelectric Nozzle Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). (1997) which. Piezoelectric Nozzle.

From www.commonrailinjectorparts.com

F00VX40029 Bosch Piezo Nozzles For 0445116004/ 0445116005/ 0445116029 Piezoelectric Nozzle In 2010, yoo et al. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. (1997) which ejects a droplet from a nozzle at the. Piezoelectric Nozzle.

From www.researchgate.net

Driving waveform of the piezoelectric nozzle Download Scientific Diagram Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top. Piezoelectric Nozzle.

From www.diytrade.com

Piezoelectric nozzle F186000 epson (China Manufacturer) Other Piezoelectric Nozzle In 2010, yoo et al. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the. Piezoelectric Nozzle.

From eureka.patsnap.com

Piezoelectric nozzle for bone cement 3D printing Eureka Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. In 2010,. Piezoelectric Nozzle.

From www.researchgate.net

Schematic diagram of a piezoelectric inkjet nozzle mechanism [33 Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. In 2010,. Piezoelectric Nozzle.

From www.diytrade.com

Piezoelectric nozzle DX6 EPSON (China Manufacturer) Other Office Piezoelectric Nozzle (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top of the. In 2010, yoo et al. At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. Epson micro piezo printheads achieve superb. Piezoelectric Nozzle.

From www.lcdrkj.com

China Bosch piezoelectric nozzle factory and suppliers Derun Piezoelectric Nozzle Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). At voltage. Piezoelectric Nozzle.

From www.diytrade.com

Piezoelectric nozzle F186000 epson (China Manufacturer) Other Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. (1997) which. Piezoelectric Nozzle.

From www.china-balin.com

BOSCH Piezo Nozzles F00VX20017 [PEF17] Piezoelectric Nozzle Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). (1997) which. Piezoelectric Nozzle.

From www.diytrade.com

DX5 piezoelectric nozzle 02029018163 EPSON (China Trading Company Piezoelectric Nozzle In 2010, yoo et al. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size. Piezoelectric Nozzle.

From www.alamy.com

piezoelectric inkjet nozzle of an Epson printer printhead closeup Piezoelectric Nozzle Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top of the. In 2010, yoo et al. At voltage amplitude of 200 v and. Piezoelectric Nozzle.

From www.lcdrkj.com

China Bosch piezoelectric nozzle factory and suppliers Derun Piezoelectric Nozzle At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. (1997) which ejects a droplet from a nozzle at the base of a fluid chamber. Piezoelectric Nozzle.

From www.diytrade.com

MIMAKI piezoelectric nozzle M13129388942 (China Manufacturer) Other Piezoelectric Nozzle (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top of the. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. In 2010, yoo et al. Epson micro piezo printheads achieve superb placement. Piezoelectric Nozzle.

From www.lcdrkj.com

China Bosch piezoelectric nozzle factory and suppliers Derun Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. (1997). Piezoelectric Nozzle.

From www.researchgate.net

Droplet formation process in a thermal and piezoelectric inkjet nozzle Piezoelectric Nozzle In 2010, yoo et al. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus. Piezoelectric Nozzle.

From www.gastorchgun.com

Piezoelectric Mini Ceramic Nozzle Kitchen Torch Gun 19.5cm Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). In 2010, yoo et al. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus. Piezoelectric Nozzle.

From www.lcdrkj.com

China Bosch piezoelectric nozzle factory and suppliers Derun Piezoelectric Nozzle (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top of the. At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. Epson micro piezo printheads achieve superb placement accuracy with fast ejection. Piezoelectric Nozzle.

From www.researchgate.net

(Colour online) (a) Structure of the piezonozzle, (b) the early Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). In 2010, yoo et al. (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric. Piezoelectric Nozzle.

From www.diytrade.com

Five generation piezoelectric nozzle DX5 EPSON (China Trading Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top. Piezoelectric Nozzle.

From yinchuang.en.made-in-china.com

Custom Micro Dispense Nozzle Piezoelectric Jet Nozzle for Vermes Piezoelectric Nozzle Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. In 2010, yoo et al. Epson micro piezo printheads achieve superb placement accuracy with fast. Piezoelectric Nozzle.

From www.researchgate.net

a) Photograph of the piezoelectric nozzle. b) Nanosilver dispersion Piezoelectric Nozzle In 2010, yoo et al. At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable. Piezoelectric Nozzle.

From www.diytrade.com

Seven generation piezoelectric nozzle DX7 EPSON (China Trading Piezoelectric Nozzle Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000. Piezoelectric Nozzle.

From www.diytrade.com

Piezoelectric nozzle DX7 EPSON (China Trading Company) Other Piezoelectric Nozzle At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000. Piezoelectric Nozzle.

From www.lcdrkj.com

China Bosch piezoelectric nozzle factory and suppliers Derun Piezoelectric Nozzle Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. In 2010, yoo et al. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size. Piezoelectric Nozzle.

From www.diytrade.com

Epson 4720 piezoelectric nozzle I3200 EPSON (China Trading Company Piezoelectric Nozzle At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). In. Piezoelectric Nozzle.

From www.aliexpress.com

Piezoelectric Nozzle Printhead Cable Lines For Epson Printers TX800 Piezoelectric Nozzle In 2010, yoo et al. At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the droplet velocity and diameter. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable. Piezoelectric Nozzle.

From www.lcdrkj.com

China Bosch piezoelectric nozzle factory and suppliers Derun Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top. Piezoelectric Nozzle.

From www.diytrade.com

EPSON piezoelectric nozzle DX6 (China Trading Company) Other Office Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). In 2010, yoo et al. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus. Piezoelectric Nozzle.

From www.researchgate.net

Structure of a nozzlediffuser piezoelectric valveless micropump. (a Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top. Piezoelectric Nozzle.

From www.researchgate.net

3D piezoelectric nozzle model (left) and (right Piezoelectric Nozzle (1997) which ejects a droplet from a nozzle at the base of a fluid chamber by contracting a piezoelectric disk sealed to the top of the. Designed a piezoelectric nozzle using mems technology, and found that the nozzle structure, driving voltage, ink viscosity, and meniscus vibration mode all. In 2010, yoo et al. Epson micro piezo printheads achieve superb placement. Piezoelectric Nozzle.

From www.researchgate.net

a Schematic representation of piezoelectric dropondemand inkjet Piezoelectric Nozzle In 2010, yoo et al. Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the. Piezoelectric Nozzle.

From www.researchgate.net

Schematic of CRI3 piezoelectric injector. Download Scientific Diagram Piezoelectric Nozzle Epson micro piezo printheads achieve superb placement accuracy with fast ejection of up to 50,000 droplets per second by controlling the meniscus at the tip of each nozzle and by using variable size dot technology (vsdt). In 2010, yoo et al. At voltage amplitude of 200 v and dwell time (80 μs), the effects of drive jetting frequency on the. Piezoelectric Nozzle.