Slip Casting Drying Time . Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. A deflocculated (low water content) slurry is poured into absorbent plaster molds. The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. Do not allow the casting to become completely solid. Here are a few of the major slip casting. A method of forming ceramics. As it sits in the. This drying time will depend on the. Humidity and other weather conditions can affect drying time.

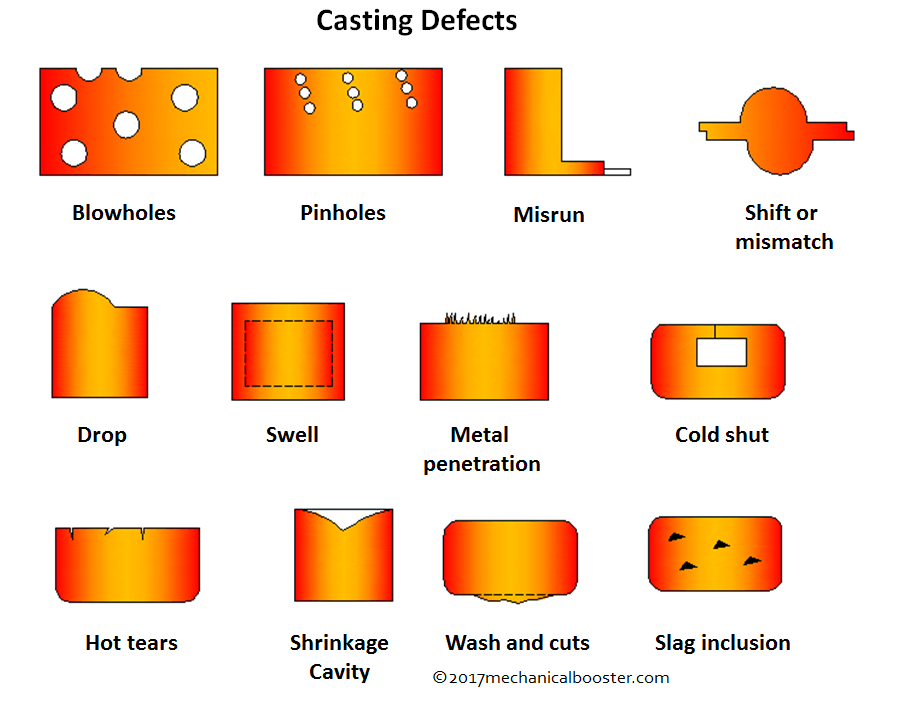

from www.mechanicalbooster.com

Do not allow the casting to become completely solid. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. This drying time will depend on the. A method of forming ceramics. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. Here are a few of the major slip casting. A deflocculated (low water content) slurry is poured into absorbent plaster molds. As it sits in the.

What is Casting Defects Types, Causes and Remedies? Mechanical Booster

Slip Casting Drying Time A method of forming ceramics. The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. A deflocculated (low water content) slurry is poured into absorbent plaster molds. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. Do not allow the casting to become completely solid. Humidity and other weather conditions can affect drying time. Here are a few of the major slip casting. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. As it sits in the. A method of forming ceramics. This drying time will depend on the.

From www.open.edu

Slipcasting OpenLearn Open University Slip Casting Drying Time The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. A deflocculated (low water content) slurry is poured into absorbent plaster. Slip Casting Drying Time.

From www.youtube.com

How to Cure Resin Castings Faster Resin Casting Quick Tips YouTube Slip Casting Drying Time Here are a few of the major slip casting. Humidity and other weather conditions can affect drying time. Do not allow the casting to become completely solid. The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. When trying to slip. Slip Casting Drying Time.

From www.researchgate.net

Trends in drying times versus drying temperatures at different Slip Casting Drying Time A deflocculated (low water content) slurry is poured into absorbent plaster molds. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. As it sits in the. A method of forming ceramics. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. The time. Slip Casting Drying Time.

From robertcomptonpottery.com

Slip Casting Robert Compton Pottery Slip Casting Drying Time When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. A method of forming ceramics. Do not allow the casting to become completely solid. Humidity and other weather conditions can affect drying time. Problems with plaster ceramic casting molds and casting slip can be interesting for sure,. Slip Casting Drying Time.

From www.slideserve.com

PPT Casting Techniques PowerPoint Presentation ID5564594 Slip Casting Drying Time The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. A deflocculated (low water content) slurry is poured into absorbent plaster molds. Here are a few of the major slip casting. This drying time will depend on the. Allow the mold. Slip Casting Drying Time.

From www.thecrucible.org

You Will Be Slip Casting Ceramics With These 5 Easy Steps The Crucible Slip Casting Drying Time Humidity and other weather conditions can affect drying time. A deflocculated (low water content) slurry is poured into absorbent plaster molds. As it sits in the. This drying time will depend on the. Here are a few of the major slip casting. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. A method. Slip Casting Drying Time.

From elba.sg

Time Drying ELBA SINGAPORE Slip Casting Drying Time Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. Do not allow the casting to become completely solid. Humidity and other weather conditions can affect drying time. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. A method of. Slip Casting Drying Time.

From cuplomacy.com

Slip Casting in Progress Cuplomacy Blog Slip Casting Drying Time The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. Here are a few of the major slip casting. Humidity and other weather conditions can affect drying time. Do not allow the casting to become completely solid. This drying time will. Slip Casting Drying Time.

From www.slideserve.com

PPT Lecture 7 PROCESSING OF CERAMICS AND CERMETS PowerPoint Slip Casting Drying Time Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. This drying time will depend on the. The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. Humidity and other weather conditions can affect drying. Slip Casting Drying Time.

From www.researchgate.net

The moisture content of P. Amarus in three drying modes versus drying Slip Casting Drying Time This drying time will depend on the. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. Do not allow the casting to become completely solid. A deflocculated (low water content) slurry is poured into absorbent plaster molds. Humidity and other weather conditions can affect drying time.. Slip Casting Drying Time.

From jackygao.com

Simple Guidance For You In Ceramic Items Process Part 2 Produce Clay Slip Casting Drying Time A method of forming ceramics. This drying time will depend on the. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. Humidity and other weather conditions can affect drying time. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they. Slip Casting Drying Time.

From mungfali.com

Concrete Drying Time Chart Slip Casting Drying Time This drying time will depend on the. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. A deflocculated (low water content) slurry is poured into absorbent plaster molds. Here are a few of the major slip casting. Problems with plaster ceramic casting molds and casting slip. Slip Casting Drying Time.

From civiljungle.com

Understanding Quikrete Drying Times and Application Tips Slip Casting Drying Time Do not allow the casting to become completely solid. A deflocculated (low water content) slurry is poured into absorbent plaster molds. Here are a few of the major slip casting. Humidity and other weather conditions can affect drying time. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. As it sits in the.. Slip Casting Drying Time.

From www.researchgate.net

Moisture loss curves of solids during drying under different operating Slip Casting Drying Time A method of forming ceramics. Here are a few of the major slip casting. The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. When trying to slip cast the part, there was probably too much water used when mixing the. Slip Casting Drying Time.

From ceramicsmokeware.com

How slip casting and plaster molds work Ceramic Smokeware Slip Casting Drying Time As it sits in the. Do not allow the casting to become completely solid. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. A deflocculated (low water content) slurry is poured into absorbent plaster molds. Allow the mold to dry until it can be disassembled without tearing or collapsing. Slip Casting Drying Time.

From toolnotes.com

Ceramic (Slip) Casting ToolNotes Slip Casting Drying Time Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. A method of forming ceramics. A deflocculated (low water content) slurry is poured into absorbent plaster molds. Do not allow the casting to become completely solid. The time required for a slip to set up in a plaster mold to. Slip Casting Drying Time.

From www.researchgate.net

Drying rate versus Drying time Download Scientific Diagram Slip Casting Drying Time Here are a few of the major slip casting. A deflocculated (low water content) slurry is poured into absorbent plaster molds. A method of forming ceramics. Humidity and other weather conditions can affect drying time. The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may. Slip Casting Drying Time.

From www.scribd.com

Estimating Drying Times and Rates from Moisture Content Curves and Slip Casting Drying Time A method of forming ceramics. Do not allow the casting to become completely solid. Humidity and other weather conditions can affect drying time. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. Allow the mold to dry until it can be disassembled without tearing or collapsing. Slip Casting Drying Time.

From recipeprojectblog.com

Plumbers Putty Drying Time (Full Guidances) Slip Casting Drying Time When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. Here are a few of the major slip casting. A deflocculated (low water content) slurry is poured. Slip Casting Drying Time.

From cuplomacy.com

Slip Casting in Progress Cuplomacy Blog Slip Casting Drying Time As it sits in the. This drying time will depend on the. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. Do not allow the casting to become completely solid. Here are a few of the major slip casting. Humidity and other weather conditions can affect. Slip Casting Drying Time.

From www.researchgate.net

Experimental drying (relationship between MR and drying time Slip Casting Drying Time Here are a few of the major slip casting. Do not allow the casting to become completely solid. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. A method of forming ceramics. A deflocculated (low water content) slurry is poured into absorbent plaster molds. The time required for a slip to set up. Slip Casting Drying Time.

From www.chegg.com

3) As explained in the video, the increase in Slip Casting Drying Time Humidity and other weather conditions can affect drying time. Here are a few of the major slip casting. A method of forming ceramics. As it sits in the. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. This drying time will depend on the. The time. Slip Casting Drying Time.

From sudentas.com

Slip casting at Greenwich Pottery House Sudentas Slip Casting Drying Time When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. A deflocculated (low water content) slurry is poured into absorbent plaster molds. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. The time required for a slip to set up. Slip Casting Drying Time.

From mycarsfirst.com

Caiman TOTAL DRYING AGENT Slip Casting Drying Time This drying time will depend on the. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. Humidity and other weather conditions can affect drying time. The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its. Slip Casting Drying Time.

From deckdoyen.com

How do I know if my deck is dry enough to stain? Slip Casting Drying Time Humidity and other weather conditions can affect drying time. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. As it sits in the. Allow the mold. Slip Casting Drying Time.

From www.researchgate.net

4 Drying times according to the heating process employed. (From Dostie Slip Casting Drying Time Here are a few of the major slip casting. Humidity and other weather conditions can affect drying time. Do not allow the casting to become completely solid. As it sits in the. The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its. Slip Casting Drying Time.

From www.mechanicalbooster.com

What is Casting Defects Types, Causes and Remedies? Mechanical Booster Slip Casting Drying Time A method of forming ceramics. This drying time will depend on the. As it sits in the. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. A deflocculated (low water content) slurry is poured into absorbent plaster molds. When trying to slip cast the part, there was probably too much water used when. Slip Casting Drying Time.

From www.semanticscholar.org

Figure 2 from The effect of wetwood on lumber drying times and rates Slip Casting Drying Time Do not allow the casting to become completely solid. The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and. Slip Casting Drying Time.

From toolnotes.com

Ceramic (Slip) Casting ToolNotes Slip Casting Drying Time This drying time will depend on the. As it sits in the. Do not allow the casting to become completely solid. Humidity and other weather conditions can affect drying time. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. Here are a few of the major. Slip Casting Drying Time.

From www.open.edu

Ceramic mould casting OpenLearn Open University Slip Casting Drying Time Do not allow the casting to become completely solid. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. Humidity and other weather conditions can affect drying time. As it sits in the. A. Slip Casting Drying Time.

From www.slideserve.com

PPT Casting Techniques PowerPoint Presentation, free download ID Slip Casting Drying Time As it sits in the. Allow the mold to dry until it can be disassembled without tearing or collapsing the casting. Here are a few of the major slip casting. Do not allow the casting to become completely solid. The time required for a slip to set up in a plaster mold to produce a green object of a given. Slip Casting Drying Time.

From www.researchgate.net

Variations in LHV (a) with drying time at different temperatures and Slip Casting Drying Time Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually be rectified. This drying time will depend on the. A deflocculated (low water content) slurry is poured into absorbent plaster molds. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder. Slip Casting Drying Time.

From www.youtube.com

Ceramic automatic slip casting Sunny Group factory YouTube Slip Casting Drying Time A method of forming ceramics. Here are a few of the major slip casting. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. As it sits in the. Problems with plaster ceramic casting molds and casting slip can be interesting for sure, but they can usually. Slip Casting Drying Time.

From cuplomacy.com

Slip Casting in Progress Cuplomacy Blog Slip Casting Drying Time The time required for a slip to set up in a plaster mold to produce a green object of a given size and shape may be called its casting. A method of forming ceramics. A deflocculated (low water content) slurry is poured into absorbent plaster molds. When trying to slip cast the part, there was probably too much water used. Slip Casting Drying Time.

From eugenehon.blogspot.com

EUGENE HŐN CERAMIC ARTIST Slipcasting the decoyduck; stepbystep Slip Casting Drying Time Do not allow the casting to become completely solid. This drying time will depend on the. A deflocculated (low water content) slurry is poured into absorbent plaster molds. When trying to slip cast the part, there was probably too much water used when mixing the plaster of paris powder and water. Problems with plaster ceramic casting molds and casting slip. Slip Casting Drying Time.