Are 3D Printed Gears Durable . In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. The spur gear is highly efficient due to the minimal contact path when the gears are engaged. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. This isn’t to say they’re not good,. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that in fabricating gears, your best bet is to make those with a low error. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. As a result of their tests, they found that the pla gears broke at 1100 rpm. You can watch the following video or read the written tutorial below. What material is strongest for 3d printed gears? We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash.

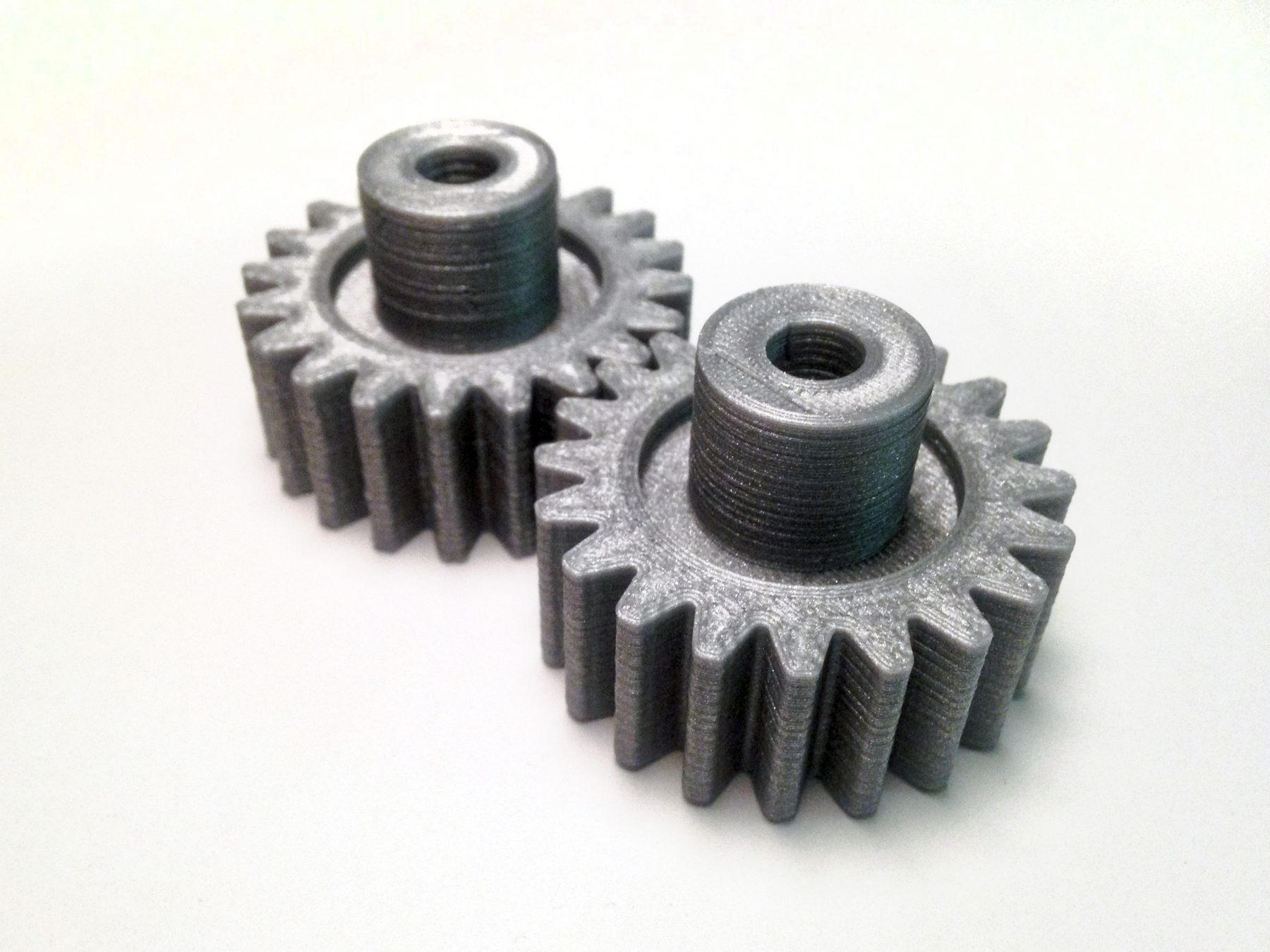

from tvaroch.sk

As a result of their tests, they found that the pla gears broke at 1100 rpm. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. What material is strongest for 3d printed gears? The spur gear is highly efficient due to the minimal contact path when the gears are engaged. This isn’t to say they’re not good,. You can watch the following video or read the written tutorial below. In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that in fabricating gears, your best bet is to make those with a low error. We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash.

gear wheel 3d printing PLA 1 3D printing Tvaroch

Are 3D Printed Gears Durable The spur gear is highly efficient due to the minimal contact path when the gears are engaged. You can watch the following video or read the written tutorial below. This isn’t to say they’re not good,. We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash. What material is strongest for 3d printed gears? The spur gear is highly efficient due to the minimal contact path when the gears are engaged. In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. As a result of their tests, they found that the pla gears broke at 1100 rpm. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that in fabricating gears, your best bet is to make those with a low error. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can.

From ascsepanama.weebly.com

3D Printed Gears ascsepanama Are 3D Printed Gears Durable You can watch the following video or read the written tutorial below. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. The spur gear is highly efficient due to the minimal contact path when the gears are engaged. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting. Are 3D Printed Gears Durable.

From www.dreamstime.com

Thin Green 3D Printed Gear with Visible Layers of Plastic that is Are 3D Printed Gears Durable As a result of their tests, they found that the pla gears broke at 1100 rpm. What material is strongest for 3d printed gears? In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that. Are 3D Printed Gears Durable.

From tvaroch.sk

gear wheel 3d printing PLA 1 3D printing Tvaroch Are 3D Printed Gears Durable In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that in fabricating gears, your best bet is to make those with a low error. What material is strongest for 3d printed gears? The spur gear is highly efficient due to the minimal contact path when the gears are engaged. The paper examines. Are 3D Printed Gears Durable.

From hackaday.com

When 3D Printing Gears, It Pays To Use The Right Resin Hackaday Are 3D Printed Gears Durable The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. This isn’t to say they’re not good,. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that in fabricating gears, your best bet is to make those with a low error. You can watch the. Are 3D Printed Gears Durable.

From www.additive-x.com

How To 3D Print Gears Like A Pro 7 Design Tips and Advice Are 3D Printed Gears Durable The spur gear is highly efficient due to the minimal contact path when the gears are engaged. We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. In. Are 3D Printed Gears Durable.

From admin.cashier.mijndomein.nl

3D Printable Gears Are 3D Printed Gears Durable In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that in fabricating gears, your best bet is to make those with a low error. As a result of their tests, they found that the pla gears broke at 1100 rpm. We will cover which type of gear is best suited for 3d. Are 3D Printed Gears Durable.

From www.additive-x.com

How To 3D Print Gears Like A Pro 7 Design Tips and Advice Are 3D Printed Gears Durable What material is strongest for 3d printed gears? In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash. You can watch the following video or read the. Are 3D Printed Gears Durable.

From admin.cashier.mijndomein.nl

3D Printable Gears Are 3D Printed Gears Durable This isn’t to say they’re not good,. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that in fabricating gears, your best bet is to make those with a low error. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. The paper examines various facets,. Are 3D Printed Gears Durable.

From www.sculpteo.com

Pro Design Tips and Software for 3D Printed Gears Are 3D Printed Gears Durable The spur gear is highly efficient due to the minimal contact path when the gears are engaged. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. You can watch the following video or read the written tutorial below. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting. Are 3D Printed Gears Durable.

From 3dinsider.com

3D Printed Gears What You Need to Know 3D Insider Are 3D Printed Gears Durable In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that in fabricating gears, your best bet is to make those with a low error. As a result of their tests, they found that the. Are 3D Printed Gears Durable.

From www.3d-alchemy.co.uk

3D Printing in Carbon Fibre and Graphite. Gallery. Are 3D Printed Gears Durable In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. You can watch the following video or read the. Are 3D Printed Gears Durable.

From makemendel.com

3D printed gears all you need to create functional, cool gears 3D Are 3D Printed Gears Durable We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash. As a result of their tests, they found that the pla gears broke at 1100 rpm. The spur gear is highly efficient due to the minimal contact path when the gears are engaged. In the. Are 3D Printed Gears Durable.

From www.travisllado.com

General Purpose 3D Printed Gears Are 3D Printed Gears Durable The spur gear is highly efficient due to the minimal contact path when the gears are engaged. As a result of their tests, they found that the pla gears broke at 1100 rpm. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that in fabricating gears, your best bet is to make. Are 3D Printed Gears Durable.

From www.additive-x.com

How To 3D Print Gears Like A Pro 7 Design Tips and Advice Are 3D Printed Gears Durable This isn’t to say they’re not good,. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. You can watch the following video or read the written tutorial below. In the tests, they found the wear coefficient. Are 3D Printed Gears Durable.

From www.youtube.com

Which 3D Printed Gear is Best? YouTube Are 3D Printed Gears Durable In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. You can watch the following video or read the written tutorial below. We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash. However, the sudden contact mechanism,. Are 3D Printed Gears Durable.

From hesajuliawalker.blogspot.com

3d printed gear system Are 3D Printed Gears Durable What material is strongest for 3d printed gears? The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. The spur gear is highly efficient due to the minimal contact path when the gears are engaged. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. In a. Are 3D Printed Gears Durable.

From shutupandtakemymoney.com

3D Printed Mobius Gears Shut Up And Take My Money Are 3D Printed Gears Durable As a result of their tests, they found that the pla gears broke at 1100 rpm. You can watch the following video or read the written tutorial below. We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash. What material is strongest for 3d printed. Are 3D Printed Gears Durable.

From teknoho.com

Cool Best Material For 3D Printed Gears Ideas Are 3D Printed Gears Durable In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. As a result of their tests, they found that the pla gears broke at 1100 rpm. This isn’t to say they’re not good,. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. We will cover. Are 3D Printed Gears Durable.

From blog.igus.co.uk

Find out why 3D printed gears are the future! • Blog igus® UK Ltd Are 3D Printed Gears Durable However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. As a result of their tests, they found that the pla gears broke at 1100 rpm. In the tests, they found the wear coefficient at 600, 800,. Are 3D Printed Gears Durable.

From www.sculpteo.com

Pro Design Tips and Software for 3D Printed Gears Are 3D Printed Gears Durable This isn’t to say they’re not good,. You can watch the following video or read the written tutorial below. The spur gear is highly efficient due to the minimal contact path when the gears are engaged. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. In a recent study by newswatch, they examined. Are 3D Printed Gears Durable.

From hesajuliawalker.blogspot.com

3d printed gear system Are 3D Printed Gears Durable In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. In a recent study by newswatch, they examined the world of 3d printed gears, highlighting the fact that in fabricating gears, your best bet is to make those with a low error. The paper examines various facets, encompassing tailored design considerations for. Are 3D Printed Gears Durable.

From www.youtube.com

3D printed gears in a 3D printer YouTube Are 3D Printed Gears Durable The spur gear is highly efficient due to the minimal contact path when the gears are engaged. In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash.. Are 3D Printed Gears Durable.

From www.pinterest.com

3D Printed Gears Get the Gear That Fits Your Needs All3DP Useful 3d Are 3D Printed Gears Durable As a result of their tests, they found that the pla gears broke at 1100 rpm. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. This isn’t to say they’re not good,. You can watch the. Are 3D Printed Gears Durable.

From hesayvonnepullman.blogspot.com

3d printed metal gears Are 3D Printed Gears Durable However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. This isn’t to say they’re not good,. What material is strongest for 3d printed gears? As a result of their tests, they found that the pla gears broke at 1100 rpm. In a recent study by newswatch, they examined the world of 3d printed. Are 3D Printed Gears Durable.

From www.robives.com

3d Printed Gears Rob Ives Are 3D Printed Gears Durable You can watch the following video or read the written tutorial below. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. This isn’t to say they’re not good,. In the tests, they found the wear coefficient. Are 3D Printed Gears Durable.

From www.youtube.com

3D printed Gears design with fusion 360 YouTube Are 3D Printed Gears Durable What material is strongest for 3d printed gears? The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. This isn’t to say they’re not good,. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. You can watch the following video or read the written tutorial below.. Are 3D Printed Gears Durable.

From airwolf3d.com

3D Printed Herringbone Gears in Red ABS Airwolf 3D Are 3D Printed Gears Durable What material is strongest for 3d printed gears? In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. You can watch the following video or read the written tutorial below. This isn’t to say they’re not good,. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along. Are 3D Printed Gears Durable.

From www.pinterest.se

Nice Gears on Automatic Transmission Model made with 3D Printer (With Are 3D Printed Gears Durable As a result of their tests, they found that the pla gears broke at 1100 rpm. You can watch the following video or read the written tutorial below. In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load,. Are 3D Printed Gears Durable.

From www.fictiv.com

Mechatronica 3D Printing Gears and Robots Fictiv Are 3D Printed Gears Durable As a result of their tests, they found that the pla gears broke at 1100 rpm. The spur gear is highly efficient due to the minimal contact path when the gears are engaged. You can watch the following video or read the written tutorial below. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which. Are 3D Printed Gears Durable.

From www.additive-x.com

How To 3D Print Gears Like A Pro 7 Design Tips and Advice Are 3D Printed Gears Durable The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. This isn’t to say they’re not good,. You can watch the following video or read the written tutorial below. However, the sudden contact mechanism, as. Are 3D Printed Gears Durable.

From www.youtube.com

3d printed gear spins fast (181 gear ratio) YouTube Are 3D Printed Gears Durable In the tests, they found the wear coefficient at 600, 800, and 1100 rpm, and 1.3 nm loads. We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. In. Are 3D Printed Gears Durable.

From www.youtube.com

3D Printed PLA Gear after 2 Years? Spur Gear Tool in Fusion360 YouTube Are 3D Printed Gears Durable However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. What material is strongest for 3d printed gears? This isn’t to say they’re not good,. As a result of their tests, they found that the pla gears broke at 1100 rpm. The spur gear is highly efficient due to the minimal contact path when. Are 3D Printed Gears Durable.

From www.robives.com

3d Printed Gears Rob Ives Are 3D Printed Gears Durable We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. As a result of their tests, they found that the pla gears broke at 1100 rpm. You can watch. Are 3D Printed Gears Durable.

From www.youtube.com

BEST Ways to Connect Your 3D Printed Gears to the Rotating Shaft YouTube Are 3D Printed Gears Durable We will cover which type of gear is best suited for 3d printing, spur, helical or herringbone gear in terms of strength, efficiency and backlash. The paper examines various facets, encompassing tailored design considerations for 3d printed spur gears, along with analytical,. You can watch the following video or read the written tutorial below. This isn’t to say they’re not. Are 3D Printed Gears Durable.

From www.additive-x.com

How To 3D Print Gears Like A Pro 7 Design Tips and Advice Are 3D Printed Gears Durable The spur gear is highly efficient due to the minimal contact path when the gears are engaged. As a result of their tests, they found that the pla gears broke at 1100 rpm. However, the sudden contact mechanism, as the teeth engage, creates a high impulse load, which can. You can watch the following video or read the written tutorial. Are 3D Printed Gears Durable.