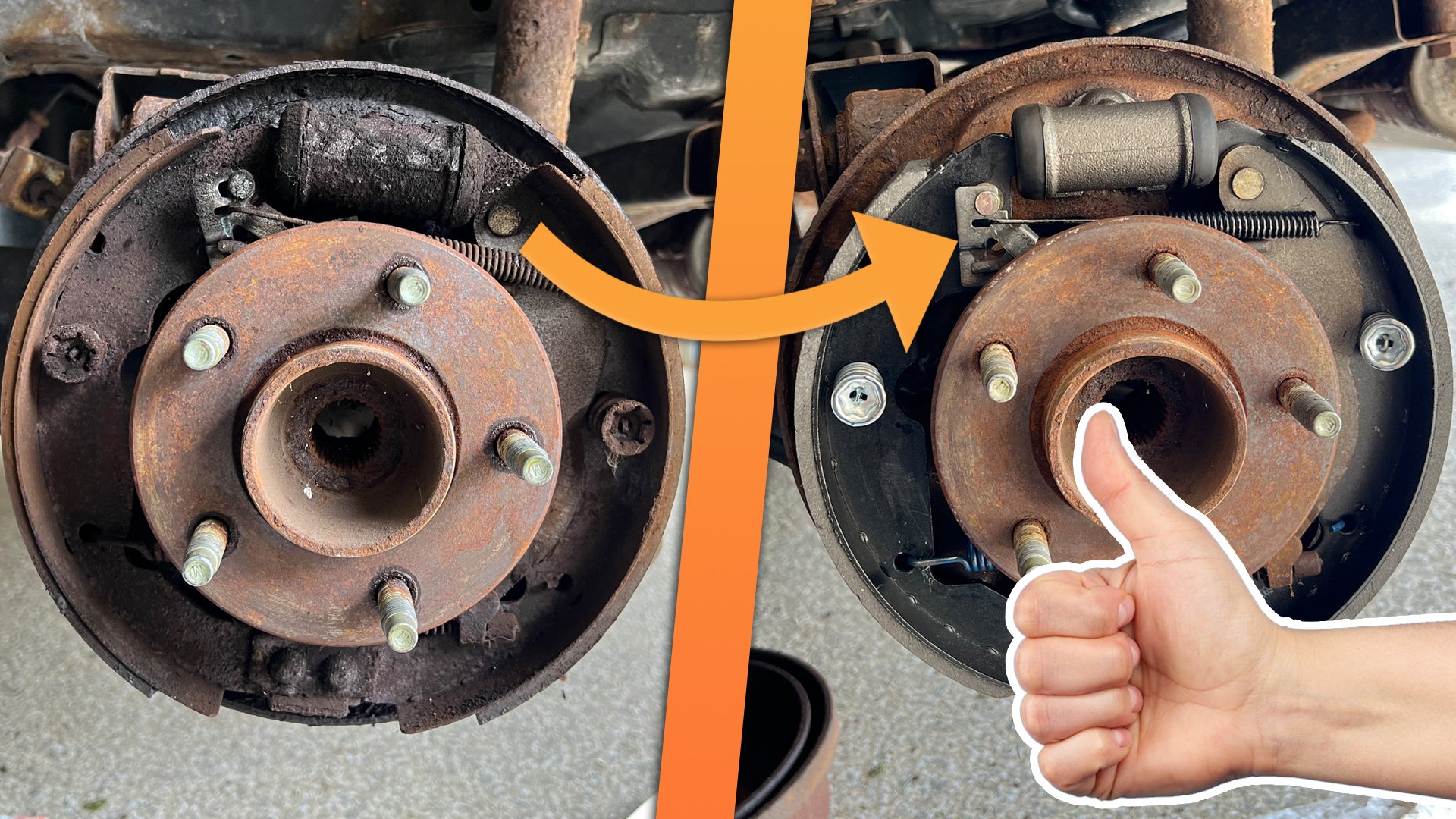

Brake Drum Assembly . Pull out on the drum to remove it from the hub. Adjust the brakes through the drum. Get a detailed rear drum brake. Loosen the lug nuts but don’t remove them. The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of the brake system. To do so, reinstall the wheel and tire with several lug nuts. Now, use a brake adjusting tool or large flathead screwdriver now to adjust the brakes. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. If you replaced the wheel cylinders, bleed them now. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides over. Drum brake systems typically use or contain a variety of wheel cylinder types. (image/wayne scraba) here’s a look at the collection of little parts you’ll need in order to assemble (and completely rebuild) one. Park the vehicle on a level surface. Install lock screws in drum if equipped. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion.

from

To do so, reinstall the wheel and tire with several lug nuts. Now, use a brake adjusting tool or large flathead screwdriver now to adjust the brakes. Adjust the brakes through the drum. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. If you replaced the wheel cylinders, bleed them now. Install lock screws in drum if equipped. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. Pull out on the drum to remove it from the hub. Drum brake systems typically use or contain a variety of wheel cylinder types. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides over.

Brake Drum Assembly Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. Drum brake systems typically use or contain a variety of wheel cylinder types. You can hit the drum with a rubber mallet if needed, but don’t. Park the vehicle on a level surface. If you replaced the wheel cylinders, bleed them now. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides over. Loosen the lug nuts but don’t remove them. Pull out on the drum to remove it from the hub. Now, use a brake adjusting tool or large flathead screwdriver now to adjust the brakes. Adjust the brakes through the drum. To do so, reinstall the wheel and tire with several lug nuts. Slide the new or resurfaced drum over the wheel studs. (image/wayne scraba) here’s a look at the collection of little parts you’ll need in order to assemble (and completely rebuild) one. Get a detailed rear drum brake.

From

Brake Drum Assembly If you replaced the wheel cylinders, bleed them now. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. Install lock screws in drum if equipped. Park the vehicle on a level surface. Now, use a brake adjusting tool or large flathead screwdriver now to adjust the. Brake Drum Assembly.

From

Brake Drum Assembly The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of the brake system. Park the vehicle on a level surface. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. To do so, reinstall the wheel and tire. Brake Drum Assembly.

From www.youtube.com

How to Assemble Drum Brakes YouTube Brake Drum Assembly Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. Install lock screws in drum if equipped. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. (image/wayne scraba) here’s a look at the collection of little parts you’ll need in. Brake Drum Assembly.

From

Brake Drum Assembly If you replaced the wheel cylinders, bleed them now. To do so, reinstall the wheel and tire with several lug nuts. Loosen the lug nuts but don’t remove them. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides over. You can hit the drum with a rubber mallet if needed,. Brake Drum Assembly.

From

Brake Drum Assembly To do so, reinstall the wheel and tire with several lug nuts. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. Install lock screws in drum if equipped. The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning. Brake Drum Assembly.

From www.lesschwab.com

Cat Brakes Brake Drum Assembly Get a detailed rear drum brake. Drum brake systems typically use or contain a variety of wheel cylinder types. If you replaced the wheel cylinders, bleed them now. Now, use a brake adjusting tool or large flathead screwdriver now to adjust the brakes. Park the vehicle on a level surface. To do so, reinstall the wheel and tire with several. Brake Drum Assembly.

From

Brake Drum Assembly Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of the brake system. Drum brake systems typically use or contain a variety of wheel cylinder types. To do so, reinstall the wheel and tire with. Brake Drum Assembly.

From www.autozone.com

Repair Guides Rear Drum Brakes Brake Drum Brake Drum Assembly Get a detailed rear drum brake. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. Loosen the lug nuts but don’t remove them. To do so, reinstall the wheel and tire with several lug nuts. Drum brake systems typically use or contain a variety of wheel cylinder types. (image/wayne scraba) here’s a look. Brake Drum Assembly.

From www.onallcylinders.com

How to Assemble Drum Brakes (A StepbyStep Guide) OnAllCylinders Brake Drum Assembly (image/wayne scraba) here’s a look at the collection of little parts you’ll need in order to assemble (and completely rebuild) one. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. Adjust the brakes through the drum. Now, use a brake adjusting tool or large flathead screwdriver. Brake Drum Assembly.

From

Brake Drum Assembly Loosen the lug nuts but don’t remove them. Install lock screws in drum if equipped. To do so, reinstall the wheel and tire with several lug nuts. Drum brake systems typically use or contain a variety of wheel cylinder types. The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of the. Brake Drum Assembly.

From www.familyhandyman.com

What are Drum Brakes and How Do They Work? Family Handyman Brake Drum Assembly If you replaced the wheel cylinders, bleed them now. Now, use a brake adjusting tool or large flathead screwdriver now to adjust the brakes. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. Loosen the lug nuts but don’t remove them. Pull out on the drum. Brake Drum Assembly.

From altra9.com.au

HQWB Holden Rear 10" Drum Brake Kit Brake Drum Assembly The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of the brake system. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides over. Park the vehicle on a level surface. Slide the new or resurfaced drum over the wheel studs. (image/wayne. Brake Drum Assembly.

From www.akebono-brake.com

Drum Brakes|Brakes for Automobiles|Product|Products and Technologies Brake Drum Assembly Adjust the brakes through the drum. Install lock screws in drum if equipped. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. To do so, reinstall the wheel and tire with several lug nuts. The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of. Brake Drum Assembly.

From yourbrakes.com

Brake System Guides Your Brakes Brake Drum Assembly To do so, reinstall the wheel and tire with several lug nuts. Loosen the lug nuts but don’t remove them. Now, use a brake adjusting tool or large flathead screwdriver now to adjust the brakes. (image/wayne scraba) here’s a look at the collection of little parts you’ll need in order to assemble (and completely rebuild) one. Drum brake components, such. Brake Drum Assembly.

From

Brake Drum Assembly To do so, reinstall the wheel and tire with several lug nuts. Loosen the lug nuts but don’t remove them. Pull out on the drum to remove it from the hub. If you replaced the wheel cylinders, bleed them now. Get a detailed rear drum brake. Drum brake systems typically use or contain a variety of wheel cylinder types. Park. Brake Drum Assembly.

From

Brake Drum Assembly Install lock screws in drum if equipped. You can hit the drum with a rubber mallet if needed, but don’t. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. Get a detailed rear drum brake. Loosen the lug nuts but don’t remove them. (image/wayne scraba) here’s a look at the collection of little. Brake Drum Assembly.

From crankit.in

Drum Brake Diagram & Working Explained Brake Drum Assembly Install lock screws in drum if equipped. Park the vehicle on a level surface. Drum brake systems typically use or contain a variety of wheel cylinder types. You can hit the drum with a rubber mallet if needed, but don’t. Adjust the brakes through the drum. If you replaced the wheel cylinders, bleed them now. Due to its frequent use. Brake Drum Assembly.

From

Brake Drum Assembly Loosen the lug nuts but don’t remove them. Pull out on the drum to remove it from the hub. Slide the new or resurfaced drum over the wheel studs. To do so, reinstall the wheel and tire with several lug nuts. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides. Brake Drum Assembly.

From

Brake Drum Assembly Loosen the lug nuts but don’t remove them. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides over. Drum brake systems typically use or contain a variety of wheel cylinder types. Adjust the brakes through the drum. Now, use a brake adjusting tool or large flathead screwdriver now to adjust. Brake Drum Assembly.

From

Brake Drum Assembly Slide the new or resurfaced drum over the wheel studs. (image/wayne scraba) here’s a look at the collection of little parts you’ll need in order to assemble (and completely rebuild) one. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides over. Get a detailed rear drum brake. You can hit. Brake Drum Assembly.

From

Brake Drum Assembly You can hit the drum with a rubber mallet if needed, but don’t. The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of the brake system. (image/wayne scraba) here’s a look at the collection of little parts you’ll need in order to assemble (and completely rebuild) one. Loosen the lug nuts. Brake Drum Assembly.

From

Brake Drum Assembly Pull out on the drum to remove it from the hub. Slide the new or resurfaced drum over the wheel studs. Get a detailed rear drum brake. You can hit the drum with a rubber mallet if needed, but don’t. The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of the. Brake Drum Assembly.

From

Brake Drum Assembly Park the vehicle on a level surface. If you replaced the wheel cylinders, bleed them now. Slide the new or resurfaced drum over the wheel studs. Install lock screws in drum if equipped. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. To do so, reinstall. Brake Drum Assembly.

From

Brake Drum Assembly Loosen the lug nuts but don’t remove them. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides over. You can hit the drum with a rubber mallet if needed, but don’t. Adjust the brakes through the drum. (image/wayne scraba) here’s a look at the collection of little parts you’ll need. Brake Drum Assembly.

From www.onallcylinders.com

How to Assemble Drum Brakes (A StepbyStep Guide) OnAllCylinders Brake Drum Assembly Park the vehicle on a level surface. Get a detailed rear drum brake. Slide the new or resurfaced drum over the wheel studs. Install lock screws in drum if equipped. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. You can hit the drum with a rubber mallet if needed, but don’t. If. Brake Drum Assembly.

From www.onallcylinders.com

How to Assemble Drum Brakes (A StepbyStep Guide) OnAllCylinders Brake Drum Assembly Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. Now, use a brake adjusting tool or large flathead screwdriver now to adjust the brakes. Pull out on the drum to remove it from the hub. You can hit the drum with a rubber mallet if needed,. Brake Drum Assembly.

From

Brake Drum Assembly Get a detailed rear drum brake. To do so, reinstall the wheel and tire with several lug nuts. If you replaced the wheel cylinders, bleed them now. The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of the brake system. Loosen the lug nuts but don’t remove them. Park the vehicle. Brake Drum Assembly.

From www.partsforhotrods.com.au

FORD 11 x 21/4 inch Drum Brake Kit Ford/Chev Stud Pattern Brake Drum Assembly Park the vehicle on a level surface. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. You can hit the drum with a rubber mallet if needed, but don’t. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. If. Brake Drum Assembly.

From

Brake Drum Assembly If you replaced the wheel cylinders, bleed them now. Slide the new or resurfaced drum over the wheel studs. Drum brake systems typically use or contain a variety of wheel cylinder types. Adjust the brakes through the drum. Get a detailed rear drum brake. The drum brake assembly diagram consists of several key components, each playing a crucial role in. Brake Drum Assembly.

From crankit.in

Drum Brake Diagram & Working Explained Brake Drum Assembly Slide the new or resurfaced drum over the wheel studs. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. Drum brake systems typically use or contain a variety of wheel cylinder types. Get a detailed rear drum brake. Loosen the lug nuts but don’t remove them. Install lock screws in drum if equipped.. Brake Drum Assembly.

From

Brake Drum Assembly You can hit the drum with a rubber mallet if needed, but don’t. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides over. Get a detailed rear drum brake. Drum brake systems typically use. Brake Drum Assembly.

From

Brake Drum Assembly The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of the brake system. Due to its frequent use in conjunction with leading and trailing drum types, the dual piston wheel cylinder type is the most common. If you replaced the wheel cylinders, bleed them now. Drum brake systems typically use or. Brake Drum Assembly.

From www.speedwaymotors.com

Ford 9 Inch Drum Brake Kit, Big Ford New Style, 4.5x5/4.75x5 BP Brake Drum Assembly Now, use a brake adjusting tool or large flathead screwdriver now to adjust the brakes. Pull out on the drum to remove it from the hub. If the drum won’t fit, adjust the star wheel to collapse the shoes farther in, so the drum slides over. You can hit the drum with a rubber mallet if needed, but don’t. The. Brake Drum Assembly.

From

Brake Drum Assembly Slide the new or resurfaced drum over the wheel studs. Drum brake components, such as wheel cylinders, are useful for transforming fluid pressure into mechanical motion. Park the vehicle on a level surface. Now, use a brake adjusting tool or large flathead screwdriver now to adjust the brakes. Adjust the brakes through the drum. Drum brake systems typically use or. Brake Drum Assembly.

From

Brake Drum Assembly Loosen the lug nuts but don’t remove them. To do so, reinstall the wheel and tire with several lug nuts. The drum brake assembly diagram consists of several key components, each playing a crucial role in the functioning of the brake system. (image/wayne scraba) here’s a look at the collection of little parts you’ll need in order to assemble (and. Brake Drum Assembly.