Large Ship Crankshaft . There are two primary types of crankshafts used in ship engines: The engine produces 109,000 hp,. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. Its primary function is to convert the reciprocating motion of the pistons into a rotary. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. See diagrams and descriptions of each part's function and working. As of 2006, over 300.

from ifunny.co

The engine produces 109,000 hp,. Its primary function is to convert the reciprocating motion of the pistons into a rotary. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. As of 2006, over 300. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. There are two primary types of crankshafts used in ship engines: See diagrams and descriptions of each part's function and working.

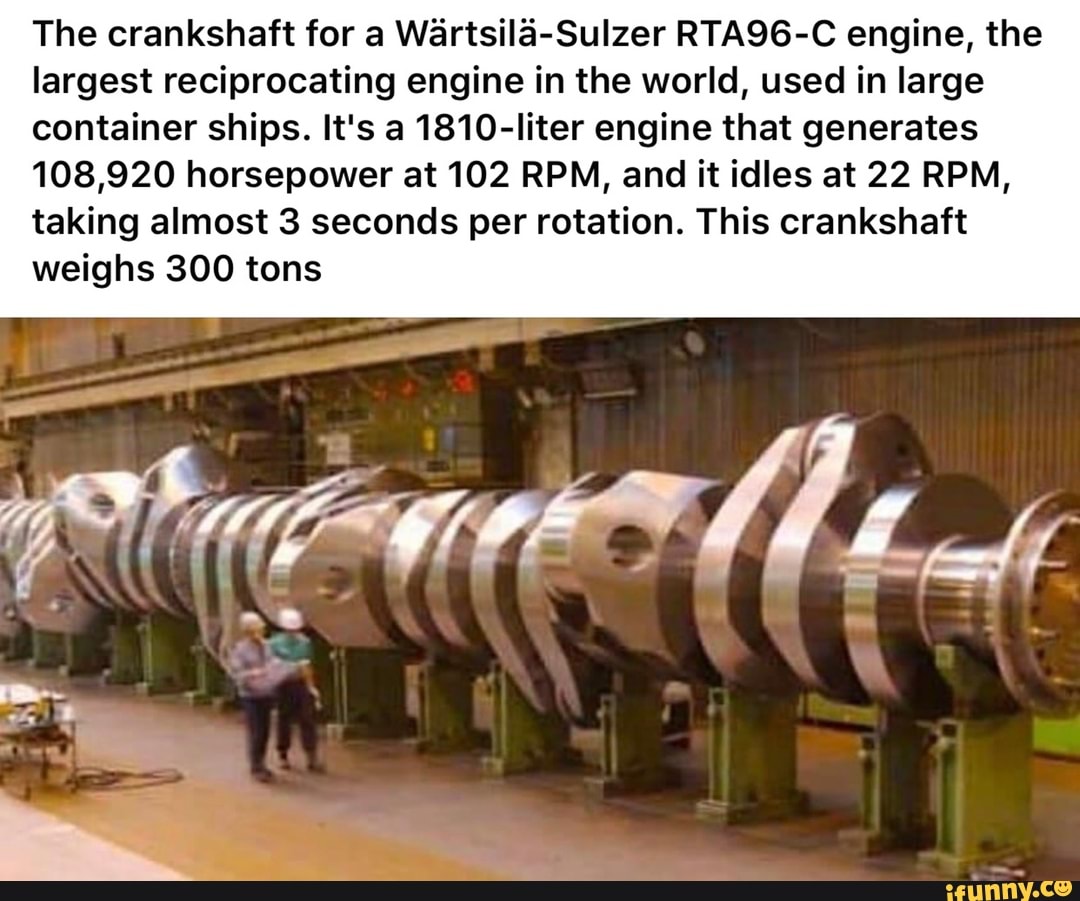

The crankshaft for a WartsilaSulzer RTAQ6C engine, the largest reciprocating engine in the

Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. See diagrams and descriptions of each part's function and working. Its primary function is to convert the reciprocating motion of the pistons into a rotary. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. As of 2006, over 300. The engine produces 109,000 hp,. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. There are two primary types of crankshafts used in ship engines:

From www.skylineships.com

Marine Offshore Ship Engine Spare Parts Crankshaft Large Ship Crankshaft See diagrams and descriptions of each part's function and working. As of 2006, over 300. Its primary function is to convert the reciprocating motion of the pistons into a rotary. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. Forged crankshafts are made by heating a solid. Large Ship Crankshaft.

From www.alamy.com

Crankshaft Ship High Resolution Stock Photography and Images Alamy Large Ship Crankshaft The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. Cast crankshafts, on the other hand, are created by pouring molten. Large Ship Crankshaft.

From www.goltens.com

Bergen Crankshaft Replacement on General Cargo Ship Goltens Large Ship Crankshaft Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. There are. Large Ship Crankshaft.

From marineandoffshoreinsight.com

Guide On How To Take Crankshaft Deflection Marine And Offshore Insight Large Ship Crankshaft As of 2006, over 300. The engine produces 109,000 hp,. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. See diagrams and descriptions of each part's function and working. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined. Large Ship Crankshaft.

From www.rapowersolutions.com

Crankshaft Grinding Crankshaft Repair Marine Crankshaft Repair on Board A Vessel Large Ship Crankshaft The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. The engine produces 109,000 hp,. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to. Large Ship Crankshaft.

From www.youtube.com

The Biggest Ship Engine In The World and Incredible Crankshaft exchange and assembled on the Large Ship Crankshaft Its primary function is to convert the reciprocating motion of the pistons into a rotary. There are two primary types of crankshafts used in ship engines: The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. Forged crankshafts are made by heating a solid piece of metal and then hammering it. Large Ship Crankshaft.

From www.pinterest.com

Large Ship Engine Crankshaft Used As Parking Curb Photo by Jon Large ship engine crankshaft Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: Its primary function is to convert the reciprocating motion of the pistons into a rotary. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. As of. Large Ship Crankshaft.

From decho-marine.com

Camshafts and Crankshafts Explained A Comprehensive Guide Decho Marine Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: As of 2006, over 300. The engine produces 109,000 hp,. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. Cast crankshafts, on the other hand, are. Large Ship Crankshaft.

From www.dreamstime.com

Crankshaft of a Great Lakes Freighter Ship Stock Image Image of shipping, william 265364495 Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: As of 2006, over 300. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. The engine produces 109,000 hp,. See diagrams and descriptions of each part's. Large Ship Crankshaft.

From marinerspointpro.com

Crankshaft Types, Parts, Function, Sensor, Images Marinerspoint Pro Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of. Large Ship Crankshaft.

From www.tigmarine.com

Crankshaft Replacements TIG marine Large Ship Crankshaft The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. The engine produces 109,000 hp,. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. Its primary function is to convert the reciprocating motion of the pistons into a rotary. The largest crankshafts produced. Large Ship Crankshaft.

From bangshift.com

Watching This Crew Remove And Replace A 7.5 Ton Cruise Ship Engine Crankshaft Is Large Ship Crankshaft Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. The crankshaft alone weighs 300 tonnes,. Large Ship Crankshaft.

From www.alamy.com

Ships crankshaft hires stock photography and images Alamy Large Ship Crankshaft See diagrams and descriptions of each part's function and working. As of 2006, over 300. Its primary function is to convert the reciprocating motion of the pistons into a rotary. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. Forged crankshafts are made by heating a solid piece of metal. Large Ship Crankshaft.

From www.alamy.com

Crankshaft ship hires stock photography and images Alamy Large Ship Crankshaft Its primary function is to convert the reciprocating motion of the pistons into a rotary. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and. Large Ship Crankshaft.

From www.reddit.com

Big Ship = Big Crankshaft (cargo ship engine crankshaft) r/AbsoluteUnits Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: The engine produces 109,000 hp,. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. See diagrams and descriptions of each part's function and working. The largest crankshafts produced so far for marine engines are built in. Large Ship Crankshaft.

From www.alamy.com

Crankshaft Ship High Resolution Stock Photography and Images Alamy Large Ship Crankshaft See diagrams and descriptions of each part's function and working. The engine produces 109,000 hp,. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. There are two primary types of crankshafts used in ship engines: The crankshaft. Large Ship Crankshaft.

From www.pinterest.com

You will be shocked when see this giant factory machines. Crazy machines Marine engineering Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: The engine produces 109,000 hp,. See diagrams and descriptions of each part's function and working. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. The crankshaft. Large Ship Crankshaft.

From www.alamy.com

Ships crankshaft hires stock photography and images Alamy Large Ship Crankshaft As of 2006, over 300. There are two primary types of crankshafts used in ship engines: Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. See diagrams and descriptions of each part's function and working. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing. Large Ship Crankshaft.

From www.youtube.com

The world's largest crankshaft manufacturing & assembly process by & heavyduty CNC Large Ship Crankshaft The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. See diagrams and descriptions of each part's function and working. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly. Large Ship Crankshaft.

From www.alamy.com

Crankshaft Ship High Resolution Stock Photography and Images Alamy Large Ship Crankshaft See diagrams and descriptions of each part's function and working. As of 2006, over 300. There are two primary types of crankshafts used in ship engines: The engine produces 109,000 hp,. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes. Large Ship Crankshaft.

From www.alamy.com

Crankshaft ship hires stock photography and images Alamy Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. As of 2006, over 300. See diagrams and descriptions of each part's function and working. The engine. Large Ship Crankshaft.

From mechanicstips.blogspot.com

Crankshaft of Ship Engine MechanicsTips Large Ship Crankshaft The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. As of 2006, over 300. The engine produces 109,000 hp,. Its primary function is to convert the reciprocating motion of the pistons into a rotary. Cast crankshafts, on. Large Ship Crankshaft.

From www.goltens.com

Bergen Crankshaft Replacement on General Cargo Ship Goltens Large Ship Crankshaft Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. As of 2006, over 300. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. Its primary function is to convert the reciprocating motion of the pistons into a. Large Ship Crankshaft.

From ifunny.co

September 10,2019 This is the crankshaft for a WartsilaSulzer RTA96C engine, the largest Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. See diagrams and descriptions of each part's function. Large Ship Crankshaft.

From www.a1autotransport.com

Expert Tips How to Ship a Crankshaft Safely and Efficiently Large Ship Crankshaft The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. Its primary function is to convert the reciprocating motion of the pistons into a rotary. The largest crankshafts produced so far for marine engines. Large Ship Crankshaft.

From www.reddit.com

The open crankcase and crankshaft of a WärtsiläSulzer 12 cylinder marine diesel[1229x1639] r Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: Its primary function is to convert the reciprocating motion of the pistons into a rotary. See diagrams and descriptions of each part's function and working. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. The crankshaft. Large Ship Crankshaft.

From marinersgalaxy.com

Crankshaft Types, Stress and Deflections marinersgalaxy Large Ship Crankshaft Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. There are two primary types of crankshafts used in ship engines: The engine produces 109,000 hp,. See diagrams and descriptions of each part's function and working. Its primary function is to convert the reciprocating motion of the pistons into a rotary. The largest. Large Ship Crankshaft.

From www.dreamstime.com

Crankshaft Engine Steam Ship Stock Photo Image of port, netherlands 65418762 Large Ship Crankshaft There are two primary types of crankshafts used in ship engines: The engine produces 109,000 hp,. Its primary function is to convert the reciprocating motion of the pistons into a rotary. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. The crankshaft alone weighs 300 tonnes, and. Large Ship Crankshaft.

From journals.sagepub.com

A Human Reliability Analysis to Crankshaft Overhauling in DryDocking of a General Cargo Ship Large Ship Crankshaft Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. There are two primary types of crankshafts used in ship engines: Its primary function is to convert the reciprocating motion of the pistons into a rotary. The engine produces 109,000 hp,. The crankshaft alone weighs 300 tonnes, and. Large Ship Crankshaft.

From www.heavy-steelforgings.com

Ship Inspection Crankshaft Custom With Heavy Diesel Engine Large Ship Crankshaft As of 2006, over 300. The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. Its primary function is. Large Ship Crankshaft.

From discover.hubpages.com

World’s Biggest Engine Most Powerful Engine Emma Maersk’s 170 Million Investment and Large Ship Crankshaft Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. There are two primary types of crankshafts used in ship engines: As of 2006, over 300. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of. Large Ship Crankshaft.

From www.pinterest.com

Crankshaft for the diesel engine of the Seawise Giant, the longest ship in the world engines Large Ship Crankshaft The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from a huge cast part of forged steel to truly exacting. As of 2006, over 300. There are two primary types of crankshafts used in ship engines: Forged crankshafts are made by heating a solid piece of metal and. Large Ship Crankshaft.

From ifunny.co

The crankshaft for a WartsilaSulzer RTAQ6C engine, the largest reciprocating engine in the Large Ship Crankshaft As of 2006, over 300. There are two primary types of crankshafts used in ship engines: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. The largest crankshafts produced so far for marine engines are built in three sections, each of which has to be machined from. Large Ship Crankshaft.

From www.alamy.com

Ships crankshaft hires stock photography and images Alamy Large Ship Crankshaft The engine produces 109,000 hp,. There are two primary types of crankshafts used in ship engines: As of 2006, over 300. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape.. Large Ship Crankshaft.

From www.indiamart.com

Used Reconditioned Marine Ship Crankshaft at Rs 45000 Used Marine Ship Crankshaft in Bhavnagar Large Ship Crankshaft Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. There are two primary types of crankshafts used in ship engines: The crankshaft alone weighs 300 tonnes, and each piston weighs 5.5 tonnes and has a height of 6 meters. The engine produces 109,000 hp,. Its primary function is to convert the reciprocating. Large Ship Crankshaft.