Press Stroke Length . In blanking formation, the stroke length is short being on the order of 10. The stroke length of a press machine is selected depending on the details of the job at hand. The tonnage capacity would remain. The stroke length must be long. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. Let’s discuss four reasons to minimize press stroke length: Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly.

from automotive.technolab.org

The tonnage capacity would remain. The stroke length must be long. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. Let’s discuss four reasons to minimize press stroke length: The stroke length of a press machine is selected depending on the details of the job at hand. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. In blanking formation, the stroke length is short being on the order of 10.

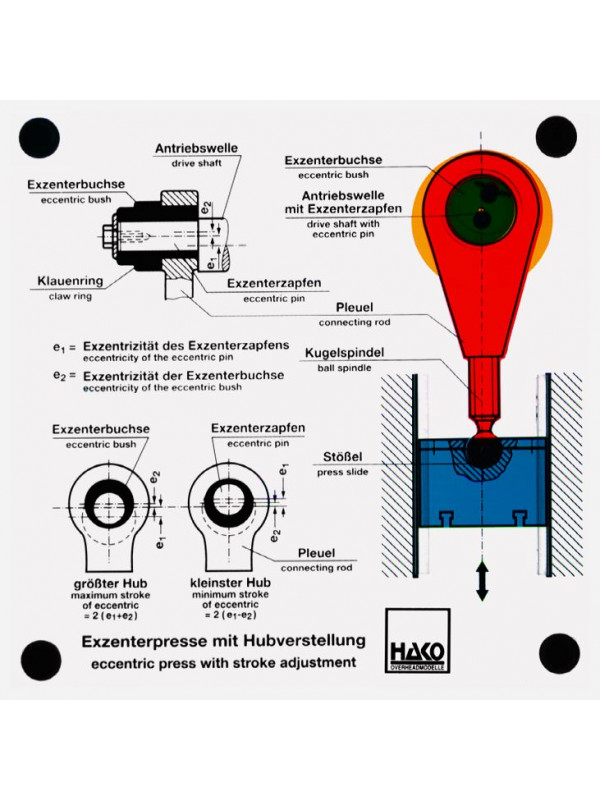

Eccentric press with stroke adjustment 810000265 HAKO

Press Stroke Length Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. The stroke length of a press machine is selected depending on the details of the job at hand. The stroke length must be long. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. The tonnage capacity would remain. Let’s discuss four reasons to minimize press stroke length: In blanking formation, the stroke length is short being on the order of 10. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in.

From www.indiamart.com

120 Tons 2 Station Rubber Molding Press, Stroke Length 350mm, Model Press Stroke Length The stroke length of a press machine is selected depending on the details of the job at hand. The tonnage capacity would remain. Let’s discuss four reasons to minimize press stroke length: This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. Stroke calibration is the process of setting the correct stroke. Press Stroke Length.

From www.youtube.com

Linear Actuator Stroke Length Explained How it Effects Overall Press Stroke Length The stroke length of a press machine is selected depending on the details of the job at hand. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material. Press Stroke Length.

From www.youtube.com

HOW TO ADJUST STROKE LENGTH IN POWER PRESS MACHINE ARJUN ENGINEERING Press Stroke Length Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. The tonnage capacity. Press Stroke Length.

From www.researchgate.net

(a) Load and tractional force as a function of stroke length of the Pt Press Stroke Length The tonnage capacity would remain. In blanking formation, the stroke length is short being on the order of 10. The stroke length must be long. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. Reduce wasted time and energy, minimize forces in the. Press Stroke Length.

From www.worldpowerpress.com

C Frame Eccentric Variable Stroke Press Machine WORLD MACHINERY Press Stroke Length In blanking formation, the stroke length is short being on the order of 10. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. The tonnage capacity would remain. The stroke length must be long. Let’s discuss four reasons to minimize press stroke length: The stroke length of. Press Stroke Length.

From www.indiamart.com

700 Tons Rubber Sheet Hydraulic Press, Stroke Length 385 Mm at best Press Stroke Length Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. The stroke length must be long. In blanking formation, the stroke length is short being on the order of 10. Reduce wasted time and energy, minimize forces in the press, allow more time for. Press Stroke Length.

From www.indiamart.com

60 Ton Hydraulic Rubber Molding Press Machine, Stroke Length 150mm at Press Stroke Length The tonnage capacity would remain. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. The stroke length of a press machine is selected depending on the details of the job at hand. Let’s discuss four reasons to minimize press stroke length: In blanking. Press Stroke Length.

From www.youtube.com

TecHome How To Measure The Stroke Length of An Actuator YouTube Press Stroke Length In blanking formation, the stroke length is short being on the order of 10. The tonnage capacity would remain. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. The stroke length must be long. This article presents a precise method for calculating the optimal press brake stroke. Press Stroke Length.

From www.indiamart.com

3500 Tons Hydraulic Rubber Press, Stroke Length 200mm at best price in Press Stroke Length Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. Let’s discuss four reasons to minimize press stroke length: This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. Reduce wasted time and energy, minimize forces in the press, allow. Press Stroke Length.

From formingworld.com

The Press Itself the Overlooked Part of the Press Shop FormingWorld Press Stroke Length The stroke length must be long. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. The stroke length of a press machine is selected depending on the details of the job at hand. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually. Press Stroke Length.

From www.indiamart.com

200 Tons Hydraulic Rubber Molding Press, Stroke Length 500mm at Rs Press Stroke Length The tonnage capacity would remain. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. The stroke length must be long. The stroke length of a press machine is selected depending. Press Stroke Length.

From www.indiamart.com

50 Tons Hydraulic Rubber Press, Stroke Length 300mm at Rs 200000 in Press Stroke Length In blanking formation, the stroke length is short being on the order of 10. Let’s discuss four reasons to minimize press stroke length: Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. This article presents a precise method for calculating the optimal press brake stroke length using. Press Stroke Length.

From sapphirehydraulics.com

How Does a Hydraulic Press Work? Sapphire Hydraulics Press Stroke Length Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. The stroke length of a press machine is selected depending on the details of the job at hand. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. In blanking formation,. Press Stroke Length.

From www.insideneedleknowledge.com

Tattoo Machine Stroke Length Press Stroke Length Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. The stroke length of a press machine is selected depending on the details of the job at hand. Let’s discuss four. Press Stroke Length.

From www.worldpowerpress.com

How to adjust the press machine stroke length WORLD MACHINERY Press Stroke Length Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. In blanking formation, the stroke length is short being on the order of 10. Reduce wasted. Press Stroke Length.

From grabcad.com

Design of Press tools GrabCAD Tutorials Press Stroke Length Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. In blanking formation, the stroke length is short being on the order of 10. The tonnage capacity would remain. The. Press Stroke Length.

From www.researchgate.net

Stroke length as a function of ZnO and Recovery Download Scientific Press Stroke Length The stroke length of a press machine is selected depending on the details of the job at hand. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. Let’s discuss four reasons to minimize press stroke length: Stroke calibration is the process of setting the correct stroke length for the press, which. Press Stroke Length.

From help.summitracing.com

What is an Engines Stroke Length? · Help Center Press Stroke Length The stroke length must be long. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. Let’s discuss four reasons to minimize press stroke length: In blanking formation, the stroke length is short being on the order of 10. Stroke calibration is the process of setting the correct. Press Stroke Length.

From ahssinsights.org

Press Requirements AHSS Guidelines Press Stroke Length Let’s discuss four reasons to minimize press stroke length: Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. The stroke length of a press machine is selected depending on the details of the job at hand. Stroke calibration is the process of setting the correct stroke length. Press Stroke Length.

From www.indiamart.com

200 Tons Hydraulic Rubber Moulding Press, Stroke Length 400 Onwards at Press Stroke Length In blanking formation, the stroke length is short being on the order of 10. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. The stroke length of a press machine is selected depending on the details of the job at hand. This article presents a precise method. Press Stroke Length.

From www.youtube.com

FluidCustom Measurement Guide Stroke Length YouTube Press Stroke Length The stroke length must be long. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. Let’s discuss four reasons to minimize press stroke length: The tonnage capacity would remain. Reduce wasted time and energy, minimize forces in the press, allow more time for. Press Stroke Length.

From www.harsle.com

How to Change The Stroke And Die of Power Press HARSLE Press Stroke Length Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. The tonnage capacity would remain. Let’s discuss four reasons to minimize press stroke length: Reduce wasted. Press Stroke Length.

From www.sangiacomo-presses.com

How to extend the life of an adjustable stroke press Press Stroke Length The stroke length must be long. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. Let’s discuss four reasons to minimize press stroke length: In blanking. Press Stroke Length.

From helecu.com

How to Choose a Drill Press The Ultimate Guide ToolCrowd (2022) Press Stroke Length In blanking formation, the stroke length is short being on the order of 10. The stroke length of a press machine is selected depending on the details of the job at hand. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. The tonnage capacity would remain. Stroke calibration is the process. Press Stroke Length.

From www.indiamart.com

50 Tons Rubber Press, Stroke Length 300mm at Rs 250000/piece in Howrah Press Stroke Length The tonnage capacity would remain. The stroke length must be long. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. This article presents a precise method. Press Stroke Length.

From www.researchgate.net

Relationship between stroke rate, stroke length, and velocity Press Stroke Length In blanking formation, the stroke length is short being on the order of 10. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. The stroke length must be long. The stroke length of a press machine is selected depending on the details of the job at hand. Let’s discuss four reasons to. Press Stroke Length.

From www.directindustry.com

Pneumatic press DA 1300 series mäder Pressen punching / ram Press Stroke Length Let’s discuss four reasons to minimize press stroke length: The stroke length of a press machine is selected depending on the details of the job at hand. Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. The tonnage capacity would remain. The stroke length must be long.. Press Stroke Length.

From www.worldpowerpress.com

How to adjust the press machine stroke length WORLD MACHINERY Press Stroke Length This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. Let’s discuss four reasons to minimize press stroke length: The stroke length must be long. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. In. Press Stroke Length.

From automotive.technolab.org

Eccentric press with stroke adjustment 810000265 HAKO Press Stroke Length Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. The stroke length must be long. In blanking formation, the stroke length is short being on the order of 10. Let’s. Press Stroke Length.

From www.alamy.com

The stroke length is determined by the cranks on the crankshaft. Stroke Press Stroke Length Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. The stroke length of a press machine is selected depending on the details of the job at hand. Reduce wasted. Press Stroke Length.

From www.indiamart.com

250 Tons Hydraulic Rubber Press Machine, Stroke Length 450mm at best Press Stroke Length The tonnage capacity would remain. The stroke length of a press machine is selected depending on the details of the job at hand. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die forms the material properly. Reduce wasted time and energy, minimize forces in the press, allow. Press Stroke Length.

From www.indiamart.com

120 Tons 2 Station Rubber Molding Press, Stroke Length 350mm, Model Press Stroke Length The stroke length must be long. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. The stroke length of a press machine is selected depending on the details of the job at hand. The tonnage capacity would remain. This article presents a precise method for calculating the optimal press brake stroke length. Press Stroke Length.

From www.progressiveautomations.ca

How to Adjust Linear Actuator Stroke Length Progressive Automations Press Stroke Length The stroke length must be long. The stroke length of a press machine is selected depending on the details of the job at hand. The tonnage capacity would remain. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. This article presents a precise method for calculating the optimal press brake stroke length. Press Stroke Length.

From www.indiamart.com

120 Tons 2 Station Rubber Molding Press, Stroke Length 350mm, Model Press Stroke Length The tonnage capacity would remain. This article presents a precise method for calculating the optimal press brake stroke length using a specific formula. Let’s discuss four reasons to minimize press stroke length: The stroke length must be long. Stroke calibration is the process of setting the correct stroke length for the press, which is essential for ensuring that the die. Press Stroke Length.

From www.indiamart.com

400 Tons Rubber Hydraulic Press, Stroke Length 400mm & 350mm at Rs Press Stroke Length Let’s discuss four reasons to minimize press stroke length: Tonnage ratings for mechanical presses are specified at a small distance above the bottom of the press stroke, usually between 1⁄32 in. Reduce wasted time and energy, minimize forces in the press, allow more time for forming operations, and. The tonnage capacity would remain. This article presents a precise method for. Press Stroke Length.