Should You Peck Drill With Carbide . Here's how to improve tool life and overcome common challenges. Ideally, the center of a carbide drill should always be the first point to contact your part. Common drill point angles range from 118° to 140° and larger. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Typically you don't want to peck with carbide unless you absolutely have to. Thru spindle coolant makes it so we don't need to. You are wasting valuable cycle time and not even realizing it!

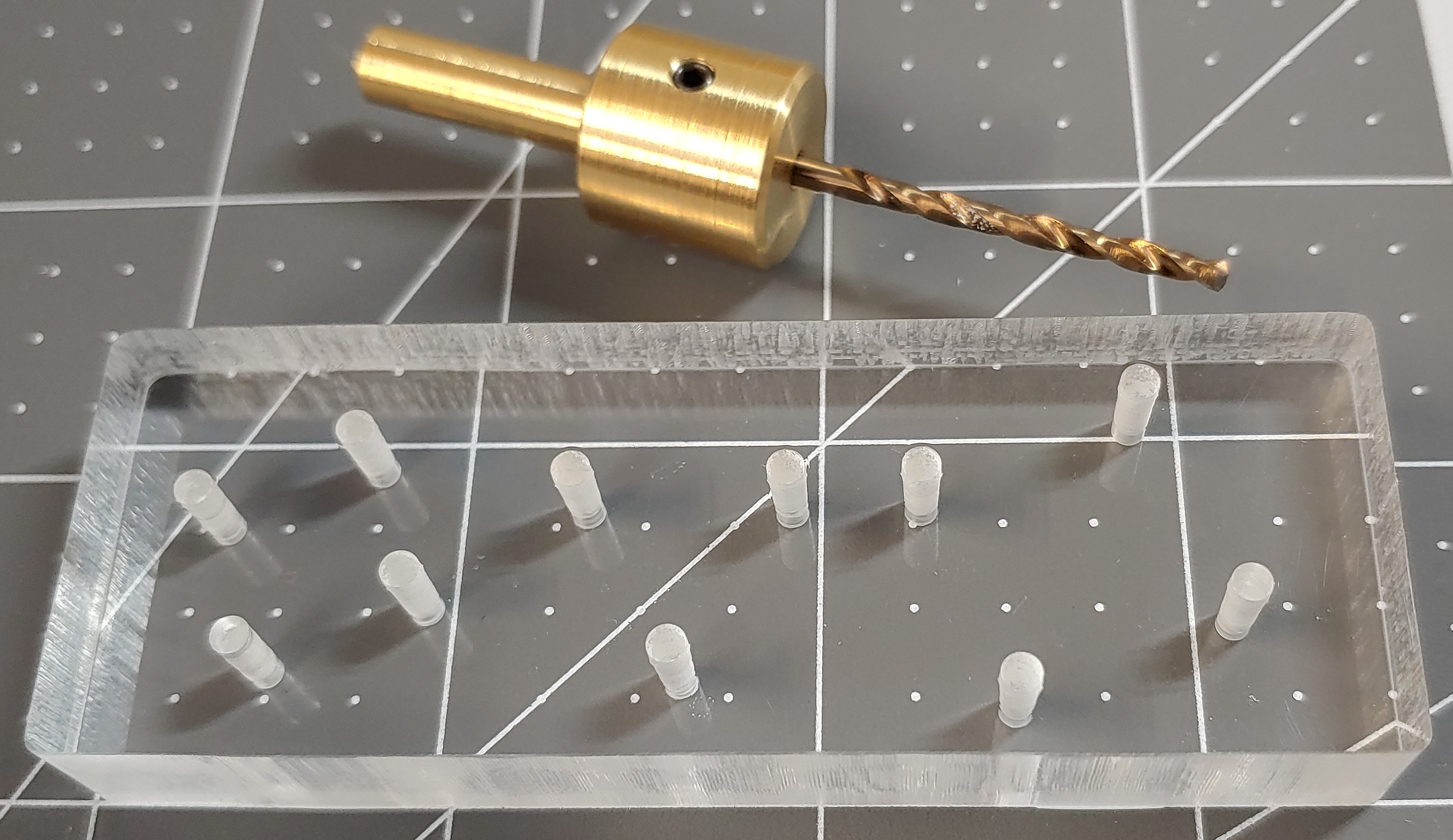

from community.carbide3d.com

Typically you don't want to peck with carbide unless you absolutely have to. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Ideally, the center of a carbide drill should always be the first point to contact your part. Thru spindle coolant makes it so we don't need to. Common drill point angles range from 118° to 140° and larger. You are wasting valuable cycle time and not even realizing it! Here's how to improve tool life and overcome common challenges.

Drilling 3/32" Holes Shapeoko Carbide 3D Community Site

Should You Peck Drill With Carbide Typically you don't want to peck with carbide unless you absolutely have to. Typically you don't want to peck with carbide unless you absolutely have to. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. You are wasting valuable cycle time and not even realizing it! Ideally, the center of a carbide drill should always be the first point to contact your part. Here's how to improve tool life and overcome common challenges. Thru spindle coolant makes it so we don't need to. Common drill point angles range from 118° to 140° and larger.

From www.jaringfacades.com

Carbide drill bit for dry cuttingJARING FACADES Should You Peck Drill With Carbide Typically you don't want to peck with carbide unless you absolutely have to. Ideally, the center of a carbide drill should always be the first point to contact your part. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Thru spindle coolant makes it so we don't need to. Common drill point angles. Should You Peck Drill With Carbide.

From mindworks.shoutwiki.com

Mastercam Drilling Operations Mindworks Should You Peck Drill With Carbide Typically you don't want to peck with carbide unless you absolutely have to. You are wasting valuable cycle time and not even realizing it! Ideally, the center of a carbide drill should always be the first point to contact your part. Here's how to improve tool life and overcome common challenges. Thru spindle coolant makes it so we don't need. Should You Peck Drill With Carbide.

From www.indiamart.com

Carbide Tipped Drill at best price in New Delhi by S S Enterprises ID Should You Peck Drill With Carbide Thru spindle coolant makes it so we don't need to. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Typically you don't want to peck with carbide unless you absolutely have to. You are wasting valuable cycle time and not even realizing it! Here's how to improve tool life and overcome common challenges.. Should You Peck Drill With Carbide.

From carbidenz.co.nz

Carbidenz 2mm CARBIDE STUB DRILL Should You Peck Drill With Carbide Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Common drill point angles range from 118° to 140° and larger. Typically you don't want to peck with carbide unless you absolutely have to. Ideally, the center of a carbide drill should always be the first point to contact your part. You are wasting. Should You Peck Drill With Carbide.

From shuntool.com

Using A Peck Cycle Can Carbide Drills Handle The Task? ShunTool Should You Peck Drill With Carbide You are wasting valuable cycle time and not even realizing it! Here's how to improve tool life and overcome common challenges. Ideally, the center of a carbide drill should always be the first point to contact your part. Thru spindle coolant makes it so we don't need to. Therefore, a spotting drill should have a slightly larger point angle than. Should You Peck Drill With Carbide.

From jaimecostiglio.com

Drilling and driving into common materials Jaime Costiglio Should You Peck Drill With Carbide Ideally, the center of a carbide drill should always be the first point to contact your part. You are wasting valuable cycle time and not even realizing it! Thru spindle coolant makes it so we don't need to. Here's how to improve tool life and overcome common challenges. Typically you don't want to peck with carbide unless you absolutely have. Should You Peck Drill With Carbide.

From www.thefabricator.com

Solidcarbide drills offer fast time The Fabricator Should You Peck Drill With Carbide Common drill point angles range from 118° to 140° and larger. Typically you don't want to peck with carbide unless you absolutely have to. Ideally, the center of a carbide drill should always be the first point to contact your part. Here's how to improve tool life and overcome common challenges. Thru spindle coolant makes it so we don't need. Should You Peck Drill With Carbide.

From www.vegatools.co.in

Solid Carbide Reamers Carbide Combination Reamer Drill Manufacturer Should You Peck Drill With Carbide Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Common drill point angles range from 118° to 140° and larger. Thru spindle coolant makes it so we don't need to. Typically you don't want to peck with carbide unless you absolutely have to. You are wasting valuable cycle time and not even realizing. Should You Peck Drill With Carbide.

From innovativetooling.com

ITPMPF Power Feed Manual Peck Drillmotor Should You Peck Drill With Carbide You are wasting valuable cycle time and not even realizing it! Typically you don't want to peck with carbide unless you absolutely have to. Common drill point angles range from 118° to 140° and larger. Thru spindle coolant makes it so we don't need to. Therefore, a spotting drill should have a slightly larger point angle than that of your. Should You Peck Drill With Carbide.

From www.shop-apt.co.uk

EDSD3D04024 2.4mm Diameter Carbide Drill 4mm Shank 10mm Flute Length Should You Peck Drill With Carbide Typically you don't want to peck with carbide unless you absolutely have to. You are wasting valuable cycle time and not even realizing it! Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Here's how to improve tool life and overcome common challenges. Common drill point angles range from 118° to 140° and. Should You Peck Drill With Carbide.

From gcodetutor.com

G73 and G83 Peck Drilling Cycles Should You Peck Drill With Carbide Thru spindle coolant makes it so we don't need to. Typically you don't want to peck with carbide unless you absolutely have to. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Ideally, the center of a carbide drill should always be the first point to contact your part. You are wasting valuable. Should You Peck Drill With Carbide.

From johnsoncarbide.com

Solid Carbide Drills & Step Drills Johnson Carbide Should You Peck Drill With Carbide You are wasting valuable cycle time and not even realizing it! Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Thru spindle coolant makes it so we don't need to. Here's how to improve tool life and overcome common challenges. Common drill point angles range from 118° to 140° and larger. Typically you. Should You Peck Drill With Carbide.

From precimactool.com

Custom Designed Carbide Drills Precimac Tool Ltd. Should You Peck Drill With Carbide Common drill point angles range from 118° to 140° and larger. Ideally, the center of a carbide drill should always be the first point to contact your part. Here's how to improve tool life and overcome common challenges. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Typically you don't want to peck. Should You Peck Drill With Carbide.

From www.youtube.com

UCCNC Peck Drilling! G73 Drilling Cycle on DIY CNC Mill! YouTube Should You Peck Drill With Carbide Typically you don't want to peck with carbide unless you absolutely have to. Thru spindle coolant makes it so we don't need to. Ideally, the center of a carbide drill should always be the first point to contact your part. Here's how to improve tool life and overcome common challenges. Common drill point angles range from 118° to 140° and. Should You Peck Drill With Carbide.

From www.indiamart.com

6mm Carbide Drill Bit at best price in Faridabad by Haryana Tools ID Should You Peck Drill With Carbide Common drill point angles range from 118° to 140° and larger. You are wasting valuable cycle time and not even realizing it! Typically you don't want to peck with carbide unless you absolutely have to. Ideally, the center of a carbide drill should always be the first point to contact your part. Therefore, a spotting drill should have a slightly. Should You Peck Drill With Carbide.

From benchmarkinstitute.org

carbide drill Cheaper Than Retail Price> Buy Clothing, Accessories and Should You Peck Drill With Carbide Thru spindle coolant makes it so we don't need to. Here's how to improve tool life and overcome common challenges. Typically you don't want to peck with carbide unless you absolutely have to. Ideally, the center of a carbide drill should always be the first point to contact your part. Therefore, a spotting drill should have a slightly larger point. Should You Peck Drill With Carbide.

From www.youtube.com

Peck Drill using MX CNC Masters YouTube Should You Peck Drill With Carbide Thru spindle coolant makes it so we don't need to. You are wasting valuable cycle time and not even realizing it! Here's how to improve tool life and overcome common challenges. Ideally, the center of a carbide drill should always be the first point to contact your part. Common drill point angles range from 118° to 140° and larger. Typically. Should You Peck Drill With Carbide.

From www.pinterest.nz

Drill bit angles 'Easily Explained', angles for materials Should You Peck Drill With Carbide Thru spindle coolant makes it so we don't need to. Typically you don't want to peck with carbide unless you absolutely have to. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Here's how to improve tool life and overcome common challenges. Ideally, the center of a carbide drill should always be the. Should You Peck Drill With Carbide.

From shuntool.com

The Hazards Of Using Carbide In Hand Drills Why You Should Avoid Them Should You Peck Drill With Carbide Common drill point angles range from 118° to 140° and larger. You are wasting valuable cycle time and not even realizing it! Typically you don't want to peck with carbide unless you absolutely have to. Here's how to improve tool life and overcome common challenges. Therefore, a spotting drill should have a slightly larger point angle than that of your. Should You Peck Drill With Carbide.

From www.youtube.com

3 create the peck drill operation YouTube Should You Peck Drill With Carbide Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Here's how to improve tool life and overcome common challenges. Common drill point angles range from 118° to 140° and larger. Thru spindle coolant makes it so we don't need to. You are wasting valuable cycle time and not even realizing it! Ideally, the. Should You Peck Drill With Carbide.

From shopee.sg

Pearl Drill Carbide Bits 1.1mm / 1.5mm/ 2mm/ Precision Carbide Bit Should You Peck Drill With Carbide Thru spindle coolant makes it so we don't need to. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Typically you don't want to peck with carbide unless you absolutely have to. You are wasting valuable cycle time and not even realizing it! Here's how to improve tool life and overcome common challenges.. Should You Peck Drill With Carbide.

From www.machinistguides.com

Quick Guide to the G83 CNC Code [Peck Drilling] Should You Peck Drill With Carbide Here's how to improve tool life and overcome common challenges. Typically you don't want to peck with carbide unless you absolutely have to. Common drill point angles range from 118° to 140° and larger. Ideally, the center of a carbide drill should always be the first point to contact your part. You are wasting valuable cycle time and not even. Should You Peck Drill With Carbide.

From www.indiamart.com

Carbide Drill Bit at Rs 2750/piece in Aurangabad ID 26448244697 Should You Peck Drill With Carbide Common drill point angles range from 118° to 140° and larger. Here's how to improve tool life and overcome common challenges. Ideally, the center of a carbide drill should always be the first point to contact your part. Thru spindle coolant makes it so we don't need to. Therefore, a spotting drill should have a slightly larger point angle than. Should You Peck Drill With Carbide.

From www.autodesk.com

12peckdrillcycle Fusion 360 Blog Should You Peck Drill With Carbide Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Common drill point angles range from 118° to 140° and larger. You are wasting valuable cycle time and not even realizing it! Thru spindle coolant makes it so we don't need to. Here's how to improve tool life and overcome common challenges. Typically you. Should You Peck Drill With Carbide.

From www.indiamart.com

Solid Carbide Tipped Drill at Rs 1000/unit कार्बाइड टिपड ड्रिल in Should You Peck Drill With Carbide Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Ideally, the center of a carbide drill should always be the first point to contact your part. Thru spindle coolant makes it so we don't need to. Common drill point angles range from 118° to 140° and larger. You are wasting valuable cycle time. Should You Peck Drill With Carbide.

From huanatools.com

How To Make A Great Carbide Drills? Huana Tools Should You Peck Drill With Carbide Common drill point angles range from 118° to 140° and larger. Thru spindle coolant makes it so we don't need to. Ideally, the center of a carbide drill should always be the first point to contact your part. Typically you don't want to peck with carbide unless you absolutely have to. Here's how to improve tool life and overcome common. Should You Peck Drill With Carbide.

From community.carbide3d.com

Drilling 3/32" Holes Shapeoko Carbide 3D Community Site Should You Peck Drill With Carbide Typically you don't want to peck with carbide unless you absolutely have to. Common drill point angles range from 118° to 140° and larger. Thru spindle coolant makes it so we don't need to. Ideally, the center of a carbide drill should always be the first point to contact your part. You are wasting valuable cycle time and not even. Should You Peck Drill With Carbide.

From www.cnccarbideinserts.com

High Precision Solid Carbide Drill , Carbide Micro Drills With High Should You Peck Drill With Carbide Therefore, a spotting drill should have a slightly larger point angle than that of your drill. You are wasting valuable cycle time and not even realizing it! Ideally, the center of a carbide drill should always be the first point to contact your part. Typically you don't want to peck with carbide unless you absolutely have to. Thru spindle coolant. Should You Peck Drill With Carbide.

From pdqtoolinc.com

Carbide Drills PDQ TOOLING INC. Should You Peck Drill With Carbide You are wasting valuable cycle time and not even realizing it! Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Ideally, the center of a carbide drill should always be the first point to contact your part. Common drill point angles range from 118° to 140° and larger. Here's how to improve tool. Should You Peck Drill With Carbide.

From www.tradeindia.com

Peck Drilling Machine at Best Price in Bhosari, Maharashtra Nimako Spm Should You Peck Drill With Carbide Thru spindle coolant makes it so we don't need to. Typically you don't want to peck with carbide unless you absolutely have to. Here's how to improve tool life and overcome common challenges. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Common drill point angles range from 118° to 140° and larger.. Should You Peck Drill With Carbide.

From larrywbartono.blob.core.windows.net

Drill Bit Set Sizes at larrywbartono blog Should You Peck Drill With Carbide Thru spindle coolant makes it so we don't need to. Ideally, the center of a carbide drill should always be the first point to contact your part. You are wasting valuable cycle time and not even realizing it! Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Here's how to improve tool life. Should You Peck Drill With Carbide.

From mhcc.pressbooks.pub

Deep Holes and G83 MultiPeck Drill Cycle Support for CNC Should You Peck Drill With Carbide Typically you don't want to peck with carbide unless you absolutely have to. Here's how to improve tool life and overcome common challenges. You are wasting valuable cycle time and not even realizing it! Ideally, the center of a carbide drill should always be the first point to contact your part. Therefore, a spotting drill should have a slightly larger. Should You Peck Drill With Carbide.

From www.aliexpress.com

1pcsCNCSpotDrillCarbideStubCenterBit6090120Degree0520mm Should You Peck Drill With Carbide Thru spindle coolant makes it so we don't need to. Typically you don't want to peck with carbide unless you absolutely have to. Common drill point angles range from 118° to 140° and larger. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Ideally, the center of a carbide drill should always be. Should You Peck Drill With Carbide.

From www.indiamart.com

True Size HSS and Carbide Drills at Rs 1500 in Faridabad ID 19258071497 Should You Peck Drill With Carbide Typically you don't want to peck with carbide unless you absolutely have to. Thru spindle coolant makes it so we don't need to. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. Ideally, the center of a carbide drill should always be the first point to contact your part. Here's how to improve. Should You Peck Drill With Carbide.

From www.hmntool.com

Offer Hss twist drill Carbide drill Should You Peck Drill With Carbide Ideally, the center of a carbide drill should always be the first point to contact your part. Here's how to improve tool life and overcome common challenges. Common drill point angles range from 118° to 140° and larger. Thru spindle coolant makes it so we don't need to. You are wasting valuable cycle time and not even realizing it! Therefore,. Should You Peck Drill With Carbide.