Spiral Bevel Vs Hypoid . Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications.

from bevelgearsindia.com

Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset.

Home Bevel Gears (India) Pvt. Ltd.

Spiral Bevel Vs Hypoid Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears.

From animalia-life.club

Hypoid Bevel Gear Spiral Bevel Vs Hypoid in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. Due to their offset design,. Spiral Bevel Vs Hypoid.

From www.zhygear.com

Straight bevel Gears vs. Hypoid Gears Choosing the Right Gear Type Spiral Bevel Vs Hypoid Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral bevel. Spiral Bevel Vs Hypoid.

From www.jalopyjournal.com

Technical 33 dodge rear gear fluid type The H.A.M.B. Spiral Bevel Vs Hypoid hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Gears are circular mechanisms consisting of evenly spaced teeth. Spiral Bevel Vs Hypoid.

From www.pinterest.com

Different types of Gears. Gears, Spiral bevel gear, Bevel gear Spiral Bevel Vs Hypoid Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. in summary, hypoid gears are advantageous for applications requiring. Spiral Bevel Vs Hypoid.

From www.michiganmech.com

Difference between spiral bevel gear VS straight bevel gear VS face Spiral Bevel Vs Hypoid Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. hypoid gears and spiral bevel. Spiral Bevel Vs Hypoid.

From en.wikipedia.org

Spiral bevel gear Wikipedia Spiral Bevel Vs Hypoid hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Hypoid gears offer high efficiency due to their larger tooth. Spiral Bevel Vs Hypoid.

From www.slideserve.com

PPT Automotive Drivetrains PowerPoint Presentation ID4321154 Spiral Bevel Vs Hypoid hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Gears are circular mechanisms consisting of evenly spaced teeth that. Spiral Bevel Vs Hypoid.

From www.researchgate.net

Solid models of Agroup from bevel to crossed helical gear (worm Spiral Bevel Vs Hypoid Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Due to their offset design, hypoid gears can transmit. Spiral Bevel Vs Hypoid.

From www.eng-tips.com

Hypoid Spiral Bevel Gear Force Math (tooth & bearing) Gear & Pulley Spiral Bevel Vs Hypoid Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Due to their offset design,. Spiral Bevel Vs Hypoid.

From thors.com

Gears Bevel and Hypoid Gear Terminology Course Spiral Bevel Vs Hypoid Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Gears are circular mechanisms consisting of evenly spaced teeth that. Spiral Bevel Vs Hypoid.

From armyordnance.tpub.com

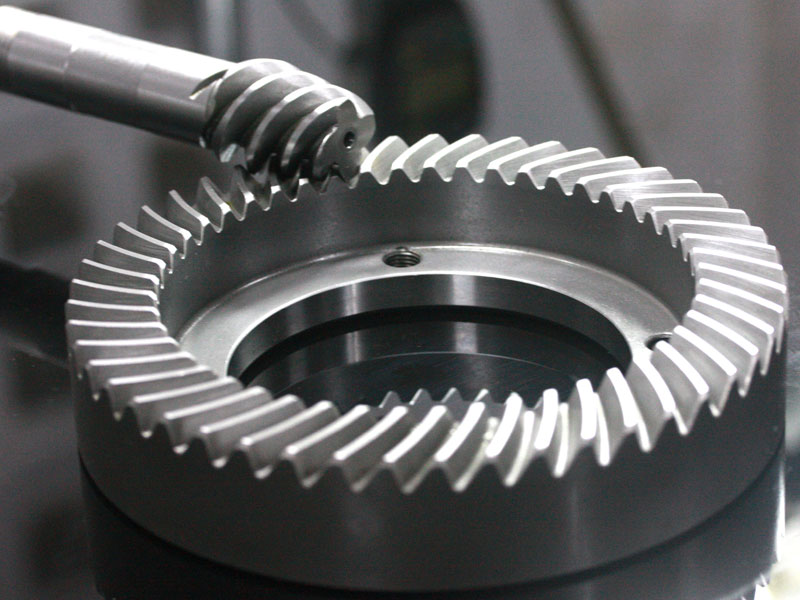

Figure 16. Spiral and Hypoid Gears Spiral Bevel Vs Hypoid hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. in summary, hypoid gears. Spiral Bevel Vs Hypoid.

From www.iqsdirectory.com

Gear Drive What Is It? Types, Uses, Components, Design Spiral Bevel Vs Hypoid in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. hypoid gears and spiral. Spiral Bevel Vs Hypoid.

From www.youtube.com

Hypoid Final Drive, Showing Cornering Differential YouTube Spiral Bevel Vs Hypoid Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral. Spiral Bevel Vs Hypoid.

From dxowwyoaq.blob.core.windows.net

How Does A Bevel Gears System Work at Doris Tate blog Spiral Bevel Vs Hypoid in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Due to their offset design,. Spiral Bevel Vs Hypoid.

From www.youtube.com

Gleason No 16 Hypoid & Spiral Bevel Gear Generator YouTube Spiral Bevel Vs Hypoid Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral. Spiral Bevel Vs Hypoid.

From animalia-life.club

Hypoid Bevel Gear Spiral Bevel Vs Hypoid Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral. Spiral Bevel Vs Hypoid.

From www.youtube.com

Hypoid, Spiral Bevel Tooth Contact Pattern Check before machining YouTube Spiral Bevel Vs Hypoid hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. Hypoid gears offer high efficiency due. Spiral Bevel Vs Hypoid.

From www.youtube.com

GLEASON 114 HYPOID GEAR CUTTING SPIRAL BEVEL YouTube Spiral Bevel Vs Hypoid hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. in summary, hypoid gears are advantageous for applications requiring. Spiral Bevel Vs Hypoid.

From www.zhygear.com

Machining spiral bevel gears and hypoid gears based on the principle of Spiral Bevel Vs Hypoid in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Due to their offset design, hypoid gears can transmit. Spiral Bevel Vs Hypoid.

From www.youtube.com

Hypoid & Spiral Bevel Gear Generator Gleason No. 16 YouTube Spiral Bevel Vs Hypoid Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. in summary, hypoid gears. Spiral Bevel Vs Hypoid.

From www.slideserve.com

PPT Chapter 15 Helical, Bevel, and Worm Gears PowerPoint Spiral Bevel Vs Hypoid Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Due to their offset design,. Spiral Bevel Vs Hypoid.

From www.zhygear.com

Parametric design of hypoid gear ZHY Gear Spiral Bevel Vs Hypoid Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. hypoid gears and spiral. Spiral Bevel Vs Hypoid.

From animalia-life.club

Hypoid Bevel Gear Spiral Bevel Vs Hypoid in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. hypoid gears and spiral bevel gears both have unique. Spiral Bevel Vs Hypoid.

From www.youtube.com

HYPOID SPIRAL BEVEL GEAR GENERATOR, GLEASON 26. YouTube Spiral Bevel Vs Hypoid Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Gears are circular mechanisms consisting of evenly spaced teeth that. Spiral Bevel Vs Hypoid.

From www.lampin.com

Why Choose Spiral Bevel Gears Spiral Bevel Vs Hypoid hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. in summary, hypoid gears are advantageous for applications requiring. Spiral Bevel Vs Hypoid.

From bevelgearsindia.com

Home Bevel Gears (India) Pvt. Ltd. Spiral Bevel Vs Hypoid in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Gears are circular mechanisms consisting of evenly spaced teeth that. Spiral Bevel Vs Hypoid.

From www.scribd.com

Tooth Contact Analyzes (TCA) for Hypoid and Spiral Bevel Gears Gear Spiral Bevel Vs Hypoid Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Due to their offset design,. Spiral Bevel Vs Hypoid.

From www.slideserve.com

PPT Chapter 15 Helical, Bevel, and Worm Gears PowerPoint Spiral Bevel Vs Hypoid hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. Hypoid gears offer high efficiency. Spiral Bevel Vs Hypoid.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Spiral Bevel Vs Hypoid Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. hypoid gears and spiral bevel. Spiral Bevel Vs Hypoid.

From www.semanticscholar.org

Figure 6 from Kinematical Simulation of Face Hobbing Indexing and Tooth Spiral Bevel Vs Hypoid Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Hypoid gears offer high efficiency due to their larger tooth. Spiral Bevel Vs Hypoid.

From www.croixgear.com

Croix Gear Spiral Bevel Spur Gears Helical Gears Hypoid Gears Spiral Bevel Vs Hypoid in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. Gears are circular mechanisms consisting of evenly spaced teeth that. Spiral Bevel Vs Hypoid.

From www.youtube.com

Gleason hypoid spiral bevel gear make YouTube Spiral Bevel Vs Hypoid Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. in summary, hypoid gears are advantageous for applications requiring. Spiral Bevel Vs Hypoid.

From www.researchgate.net

Geometrical model of spiral bevel and hypoid gears Download Spiral Bevel Vs Hypoid in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Due to their offset design, hypoid gears can transmit. Spiral Bevel Vs Hypoid.

From www.slideserve.com

PPT Gears PowerPoint Presentation, free download ID2264746 Spiral Bevel Vs Hypoid Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. in summary, hypoid gears are advantageous for applications requiring high torque transmission and where axial offset. Due to their offset design, hypoid gears can transmit higher torque compared to spiral bevel gears. Gears are circular mechanisms consisting of evenly spaced teeth that. Spiral Bevel Vs Hypoid.

From animalia-life.club

Hypoid Bevel Gear Spiral Bevel Vs Hypoid Gears are circular mechanisms consisting of evenly spaced teeth that mesh with the teeth of other gears to transfer rotational force. hypoid gears and spiral bevel gears both have unique advantages and are suitable for different applications. Hypoid gears offer high efficiency due to their larger tooth contact area, which reduces sliding friction and. Due to their offset design,. Spiral Bevel Vs Hypoid.