Abrasive Wheels Manufacturing Process . Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. The manufacturing process begins with an order for a particular wheel. The specification calls out which abrasive grain and.

from www.dreamstime.com

Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. The specification calls out which abrasive grain and. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. The manufacturing process begins with an order for a particular wheel. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing.

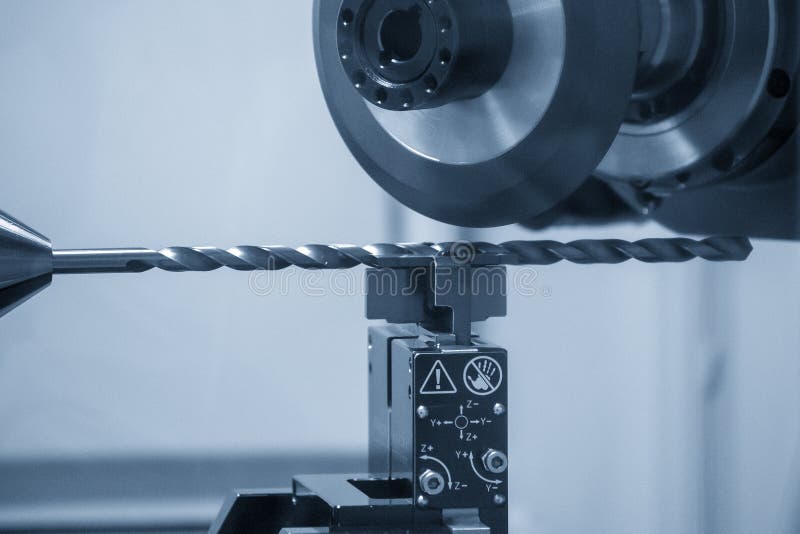

The Drilling Tool Regrinding Process with Abrasive Wheel Stock Photo

Abrasive Wheels Manufacturing Process The specification calls out which abrasive grain and. The specification calls out which abrasive grain and. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. The manufacturing process begins with an order for a particular wheel. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing.

From www.dreamstime.com

Image of Cylindrical Part Being Shaped with Abrasive Wheel in Abrasive Wheels Manufacturing Process Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. The manufacturing process begins with an order for a particular wheel. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The specification calls out which abrasive grain and. The manufacturing process of all grinding wheels is a precise and. Abrasive Wheels Manufacturing Process.

From www.linkedin.com

Manufacturing Process of Superhard Abrasive Tools Abrasive Wheels Manufacturing Process The manufacturing process begins with an order for a particular wheel. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. The specification calls out which abrasive grain and. The manufacturing process. Abrasive Wheels Manufacturing Process.

From depositphotos.com

Abrasives wheel manufacturing Stock Photo by ©nanaboo 117357146 Abrasive Wheels Manufacturing Process The specification calls out which abrasive grain and. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. The. Abrasive Wheels Manufacturing Process.

From www.youtube.com

Abrasive Cutting Wheel And Grinding Wheel Manufacturing Hands on Abrasive Wheels Manufacturing Process The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products.. Abrasive Wheels Manufacturing Process.

From extrudesign.com

Grinding Wheel Abrasives, Properties, Shape and Structures Abrasive Wheels Manufacturing Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The manufacturing process begins with an order for a particular wheel. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Cutting disc/grinding wheel is made of. Abrasive Wheels Manufacturing Process.

From www.dreamstime.com

Image of Cylindrical Part Being Shaped with Abrasive Wheel in Abrasive Wheels Manufacturing Process Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. The manufacturing process begins with an order for a particular wheel. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of. Abrasive Wheels Manufacturing Process.

From www.1training.org

Abrasive Wheels Training Course Online 1Training Abrasive Wheels Manufacturing Process Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. In summary, the digitalisation and iot integration in abrasive. Abrasive Wheels Manufacturing Process.

From www.renwa-abrasive.com

Factors In The Manufacturing Process Need To Be Considered When Abrasive Wheels Manufacturing Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. The manufacturing process begins with an order for a particular wheel. The specification. Abrasive Wheels Manufacturing Process.

From ialtrading.com.au

to IAL Trading Abrasives Abrasive Wheels Manufacturing Process The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. The manufacturing process begins with an order for a particular wheel. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has. Abrasive Wheels Manufacturing Process.

From www.slideserve.com

PPT Abrasive Processes PowerPoint Presentation, free download ID Abrasive Wheels Manufacturing Process Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. Measured amounts of prepared abrasive. Abrasive Wheels Manufacturing Process.

From www.entrepreneurindia.co

The Abrasive Grinding Wheels Manufacturing Business Plan is the perfect Abrasive Wheels Manufacturing Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The manufacturing process begins with an order for a particular wheel. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. Cutting disc/grinding. Abrasive Wheels Manufacturing Process.

From www.slideserve.com

PPT ABRASIVE WHEEL MACHINERY OSHA 29 CFR 1910.215 PowerPoint Abrasive Wheels Manufacturing Process The specification calls out which abrasive grain and. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. The manufacturing process begins with an order for a particular wheel. Cutting disc/grinding wheel is made of resin as binder, fiberglass net. Abrasive Wheels Manufacturing Process.

From www.dreamstime.com

The Solid End Mill Tool Manual Regrinding Process with Abrasive Wheel Abrasive Wheels Manufacturing Process The manufacturing process begins with an order for a particular wheel. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Presents a process flow diagram for the manufacturing of vitrified bonded. Abrasive Wheels Manufacturing Process.

From www.skill-up.org

Abrasive Wheels Skill Up Abrasive Wheels Manufacturing Process Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only. Abrasive Wheels Manufacturing Process.

From www.atfsolutions.com

Abrasive Wheels Training — AT&F Solutions Abrasive Wheels Manufacturing Process The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. The specification calls out which abrasive grain and. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. The manufacturing process begins with an order for a. Abrasive Wheels Manufacturing Process.

From toolsabrasive.com

Zhenzhou Fuifeng Abrasive Wheel Manufacturing Co., LtdCutting and Abrasive Wheels Manufacturing Process The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The manufacturing process begins with an order for a particular wheel. Cutting disc/grinding. Abrasive Wheels Manufacturing Process.

From www.dreamstime.com

The Drilling Tool Regrinding Process with Abrasive Wheel Stock Photo Abrasive Wheels Manufacturing Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to. Abrasive Wheels Manufacturing Process.

From echo-3.co.uk

Guide to Abrasive Wheels What you need to know to work safely Abrasive Wheels Manufacturing Process The manufacturing process begins with an order for a particular wheel. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. The specification calls out which abrasive grain and. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to. Abrasive Wheels Manufacturing Process.

From www.ethiretraining.com

The Safe Use Of Abrasive Wheel ET Hire Training Abrasive Wheels Manufacturing Process Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. The specification calls out. Abrasive Wheels Manufacturing Process.

From www.extremeabrasives.com

Cutting and Grinding Wheels Application Guide Archives Extreme Abrasive Wheels Manufacturing Process Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. The manufacturing process begins with an order for a particular wheel. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of. Abrasive Wheels Manufacturing Process.

From www.dreamstime.com

Image of Cylindrical Part Being Shaped with Abrasive Wheel in Abrasive Wheels Manufacturing Process The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. The specification calls out which abrasive grain and. Cutting disc/grinding wheel is made of resin as binder,. Abrasive Wheels Manufacturing Process.

From mjksafety.com

Abrasive Wheel MJK Safety Abrasive Wheels Manufacturing Process The specification calls out which abrasive grain and. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. The manufacturing process begins with an order for a particular wheel. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. The manufacturing process. Abrasive Wheels Manufacturing Process.

From www.hfabrasive.com

Zhenzhou Fuifeng Abrasive Wheel Manufacturing Co., LtdCutting and Abrasive Wheels Manufacturing Process Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The manufacturing process of all. Abrasive Wheels Manufacturing Process.

From sgr-northamerica.saint-gobain.com

Abrasives SaintGobain Northboro Abrasive Wheels Manufacturing Process Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. The manufacturing process begins with an order for a particular wheel. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high. Abrasive Wheels Manufacturing Process.

From abrasivesleader.wordpress.com

Abrasive Surface Treatment Process Abrasives Manufacturing Abrasive Wheels Manufacturing Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products.. Abrasive Wheels Manufacturing Process.

From www.slideserve.com

PPT Abrasive Machining and Finishing PowerPoint Presentation, free Abrasive Wheels Manufacturing Process Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. The manufacturing process begins with an order for a particular wheel. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. In summary, the digitalisation and iot. Abrasive Wheels Manufacturing Process.

From www.slideserve.com

PPT Abrasive Processes PowerPoint Presentation, free download ID Abrasive Wheels Manufacturing Process Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. In summary, the digitalisation and iot integration in abrasive. Abrasive Wheels Manufacturing Process.

From complisafe.co.uk

Abrasive Wheels Complisafe Abrasive Wheels Manufacturing Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The specification calls out which abrasive grain and. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. Cutting disc/grinding wheel is made. Abrasive Wheels Manufacturing Process.

From www.camarossaudio.com

abrasive grinding wheel manufacturers exclusive designs Abrasive Wheels Manufacturing Process Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. The specification calls out which. Abrasive Wheels Manufacturing Process.

From trimmers-pro.com

Wheel Abrasive Test Abrasive Wheels Manufacturing Process The manufacturing process begins with an order for a particular wheel. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. Cutting disc/grinding wheel is made of. Abrasive Wheels Manufacturing Process.

From www.dreamstime.com

Abrasive Wheel on the Mandrel on the Machine in Front of the Abrasive Wheels Manufacturing Process The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. The manufacturing process begins with an order for a particular wheel. In summary, the digitalisation and iot. Abrasive Wheels Manufacturing Process.

From www.shutterstock.com

2 Abrasive Wheels Geometry Images, Stock Photos & Vectors Shutterstock Abrasive Wheels Manufacturing Process Presents a process flow diagram for the manufacturing of vitrified bonded abrasive products. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The specification calls out which abrasive grain and. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. The manufacturing process of all grinding wheels is a. Abrasive Wheels Manufacturing Process.

From www.kissafety.co.uk

Abrasive Wheels Understanding the Marking System KIS Health and Abrasive Wheels Manufacturing Process In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. The manufacturing process begins with an order for a particular wheel. Measured amounts of prepared abrasive grains are moistened and mixed with porosity media. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has. Abrasive Wheels Manufacturing Process.

From www.hfabrasive.com

Zhenzhou Fuifeng Abrasive Wheel Manufacturing Co., LtdCutting and Abrasive Wheels Manufacturing Process The manufacturing process begins with an order for a particular wheel. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced material, and other abrasives, which has high tensile, impact and bending strength. The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high. Abrasive Wheels Manufacturing Process.

From depositphotos.com

Abrasives wheel manufacturing Stock Photo by ©nanaboo 117357090 Abrasive Wheels Manufacturing Process The manufacturing process of all grinding wheels is a precise and tightly controlled process, due not only to the inherent safety risks of high speed operation of all grinding wheels. In summary, the digitalisation and iot integration in abrasive wheel technology brings transformative benefits to the manufacturing. Cutting disc/grinding wheel is made of resin as binder, fiberglass net as reinforced. Abrasive Wheels Manufacturing Process.