Milling Tool Path . Generally, these are the x and y axes. The most basic toolpath type is 2d. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. If we look at our machine in the video above, we can see a 2d toolpath in action. When machining, proper speeds and feeds are very important to avoid. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge and better tool life in milling. This article analyzes the different characteristics of the cutting method and some factors that affect its selection, and compares the technological methods and.

from www.youtube.com

When machining, proper speeds and feeds are very important to avoid. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. The most basic toolpath type is 2d. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge and better tool life in milling. This article analyzes the different characteristics of the cutting method and some factors that affect its selection, and compares the technological methods and. Generally, these are the x and y axes. If we look at our machine in the video above, we can see a 2d toolpath in action.

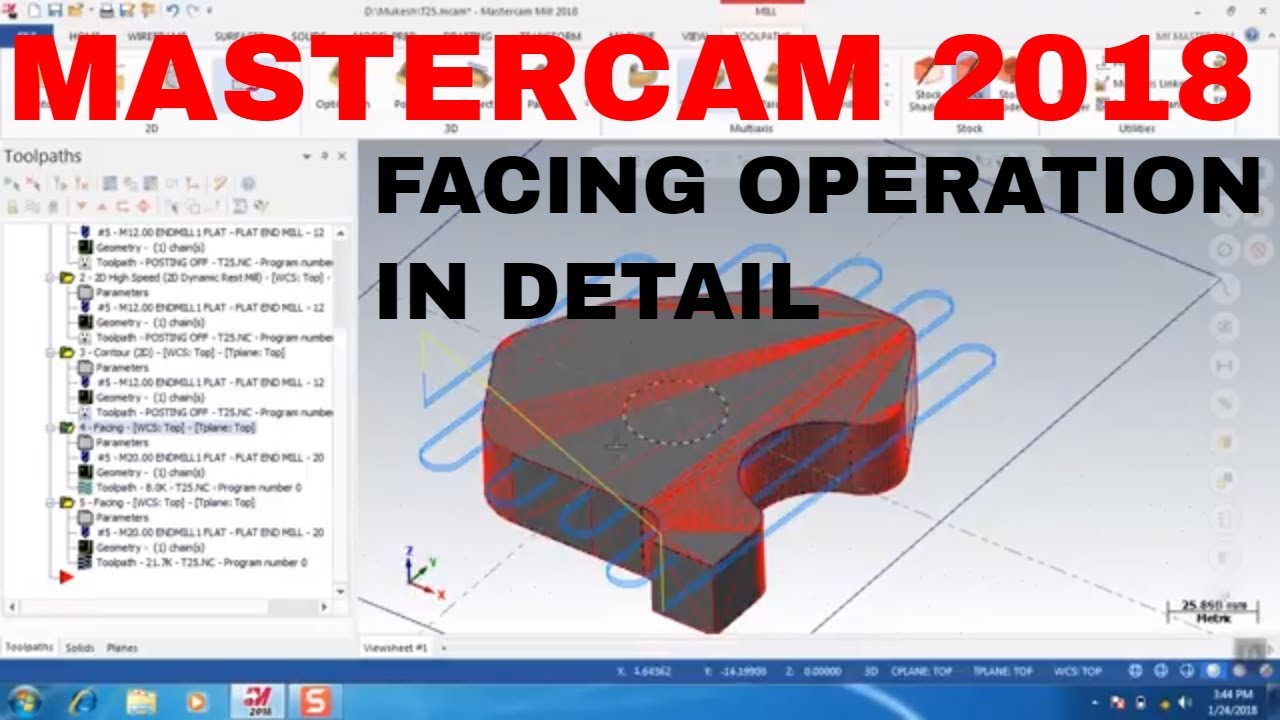

mastercam face milling tool path tutorials for beginners mastercam

Milling Tool Path When machining, proper speeds and feeds are very important to avoid. Generally, these are the x and y axes. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. If we look at our machine in the video above, we can see a 2d toolpath in action. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge and better tool life in milling. When machining, proper speeds and feeds are very important to avoid. The most basic toolpath type is 2d. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. This article analyzes the different characteristics of the cutting method and some factors that affect its selection, and compares the technological methods and.

From www.researchgate.net

a Tool path of rough milling on the upper surface of the part Milling Tool Path Generally, these are the x and y axes. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge and better tool life in milling. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. As its name suggests, 2d toolpaths only ever move in two dimensions,. Milling Tool Path.

From community.sw.siemens.com

Automatic Tool Path Generation Milling Milling Tool Path As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common. Milling Tool Path.

From forums.autodesk.com

Swarf Type Simultaneous Side Milling Tool Path for Haas 4th Axis ? in Milling Tool Path When machining, proper speeds and feeds are very important to avoid. The most basic toolpath type is 2d. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. Generally, these are the x and y axes. If we look at our machine in the video above, we can see a 2d toolpath in. Milling Tool Path.

From www.researchgate.net

a. Milling Tool Path for the Second Route Download Scientific Diagram Milling Tool Path This article analyzes the different characteristics of the cutting method and some factors that affect its selection, and compares the technological methods and. Generally, these are the x and y axes. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. If we look at our machine in the video. Milling Tool Path.

From www.researchgate.net

Tool path planning for fiveaxis Upass milling of an impeller Milling Tool Path The most basic toolpath type is 2d. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge and better tool life in milling. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. When machining,. Milling Tool Path.

From www.researchgate.net

9 Cutting tool path in milling operation. Download Scientific Diagram Milling Tool Path This article analyzes the different characteristics of the cutting method and some factors that affect its selection, and compares the technological methods and. When machining, proper speeds and feeds are very important to avoid. If we look at our machine in the video above, we can see a 2d toolpath in action. The most basic toolpath type is 2d. As. Milling Tool Path.

From www.youtube.com

MASTERCAM 4 Axis Programming Rotary Contour Milling Tool path day 23 Milling Tool Path Generally, these are the x and y axes. The most basic toolpath type is 2d. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge. Milling Tool Path.

From www.researchgate.net

Tool path of milling machine. Download Scientific Diagram Milling Tool Path The most basic toolpath type is 2d. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. If we look at our machine in the. Milling Tool Path.

From www.researchgate.net

The helical milling tool path for Hole generation Download Scientific Milling Tool Path When machining, proper speeds and feeds are very important to avoid. If we look at our machine in the video above, we can see a 2d toolpath in action. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Correct cutter path. Milling Tool Path.

From www.researchgate.net

Schematic diagram of the thread milling toolpath (D = 16 mm, d = 6 mm Milling Tool Path If we look at our machine in the video above, we can see a 2d toolpath in action. When machining, proper speeds and feeds are very important to avoid. The most basic toolpath type is 2d. Generally, these are the x and y axes. This article analyzes the different characteristics of the cutting method and some factors that affect its. Milling Tool Path.

From www.youtube.com

Mesmerizing 5 Axis CNC Machining Tool Path YouTube Milling Tool Path This article analyzes the different characteristics of the cutting method and some factors that affect its selection, and compares the technological methods and. When machining, proper speeds and feeds are very important to avoid. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge and better tool life in milling. The most basic. Milling Tool Path.

From blogs.sw.siemens.com

Manufacturing Engineering Two roads to toolpath evolution NX Milling Tool Path If we look at our machine in the video above, we can see a 2d toolpath in action. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. Generally, these are the x and y axes. Find milling formulas needed for your milling operations, such as how to calculate correct. Milling Tool Path.

From www.researchgate.net

Algorithm flow chart of pocket fiveaxis flank milling tool path Milling Tool Path This article analyzes the different characteristics of the cutting method and some factors that affect its selection, and compares the technological methods and. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. The most basic toolpath type is 2d. When machining,. Milling Tool Path.

From www.mdpi.com

Materials Free FullText MultiResponse Optimization of Face Milling Tool Path Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. When machining, proper speeds and feeds are very important to avoid. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. This article analyzes the different characteristics of the cutting method and some. Milling Tool Path.

From bobcad.com

5 Great Reasons To Use CAM Software SurfaceBased Toolpaths for CNC Milling Tool Path Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. Generally, these are the x and y axes. This article analyzes the. Milling Tool Path.

From www.youtube.com

mastercam face milling tool path tutorials for beginners mastercam Milling Tool Path Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge and better tool life in milling. As its name suggests, 2d toolpaths only ever move. Milling Tool Path.

From www.youtube.com

CNC Milling Program with simulation Cutter Compensation Tool Path Milling Tool Path Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge and better tool life in milling. This article analyzes the different characteristics of the cutting method and some factors that affect its selection, and compares the technological methods and. The most basic toolpath type is 2d. If we look at our machine in. Milling Tool Path.

From tourlomousis.pages.cba.mit.edu

ToolpathPlanning Milling Tool Path Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. The most basic toolpath type is 2d. When machining, proper speeds and feeds are very important to avoid. As its name suggests, 2d toolpaths only ever move in two dimensions, or two. Milling Tool Path.

From www.researchgate.net

Tool path in end milling process Download Scientific Diagram Milling Tool Path This article analyzes the different characteristics of the cutting method and some factors that affect its selection, and compares the technological methods and. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. When machining, proper speeds and feeds are very important to avoid. Correct cutter path and chip formation. Milling Tool Path.

From www.researchgate.net

Microball end milling of the nozzle on different tool path (a) axial Milling Tool Path Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. If we look at our machine in the video above, we can see a 2d toolpath in action. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific. Milling Tool Path.

From www.researchgate.net

Tool path strategies for the face milling in different strategies (a Milling Tool Path Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge and better tool life in milling. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. This article analyzes the different characteristics of the cutting. Milling Tool Path.

From www.youtube.com

4 axis milling tool path mastercam YouTube Milling Tool Path The most basic toolpath type is 2d. Generally, these are the x and y axes. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge. Milling Tool Path.

From www.researchgate.net

Circular end milling tool path and machined workpiece. Download Milling Tool Path When machining, proper speeds and feeds are very important to avoid. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. Learn. Milling Tool Path.

From www.youtube.com

SprutCAM Tutorial 63 Milling 2D Basic Beginnners Toolpath Machining Milling Tool Path When machining, proper speeds and feeds are very important to avoid. The most basic toolpath type is 2d. Generally, these are the x and y axes. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge. Milling Tool Path.

From www.autodesk.com

How to create a Thread Milling toolpath in PowerMill Milling Tool Path The most basic toolpath type is 2d. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. This article analyzes the different characteristics of the. Milling Tool Path.

From www.researchgate.net

Different milling paths for the flexible pocket milling after [216 Milling Tool Path When machining, proper speeds and feeds are very important to avoid. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Generally, these are the x and y axes. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d. Milling Tool Path.

From www.youtube.com

Mastercam 5 Axis Swarf Milling Multiaxis Tool path Tutorial YouTube Milling Tool Path Generally, these are the x and y axes. When machining, proper speeds and feeds are very important to avoid. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. If we look at our machine in the video above, we can see a 2d toolpath in action. This article analyzes. Milling Tool Path.

From tourlomousis.pages.cba.mit.edu

ToolpathPlanning Milling Tool Path Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. The most basic toolpath type is 2d. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. When machining, proper speeds and. Milling Tool Path.

From www.researchgate.net

Two different types of cutting tool paths (a) cutting tool path of Milling Tool Path Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. The most basic toolpath type is 2d. Correct cutter path and chip formation in milling are important factors to ensure a secure cutting edge and better tool life in milling. This article analyzes the different characteristics of the cutting method and some factors. Milling Tool Path.

From www.researchgate.net

Smoothing method of generating flank milling tool paths for fiveaxis Milling Tool Path Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. This article analyzes the different characteristics of the cutting method and some factors that affect its selection, and compares the technological methods and. If we look at our machine in the video above, we can see a 2d toolpath in action. The most. Milling Tool Path.

From www.youtube.com

Mastercam 2021 tutorials Difference Area milling tool path & Pocket Milling Tool Path When machining, proper speeds and feeds are very important to avoid. If we look at our machine in the video above, we can see a 2d toolpath in action. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. Correct cutter path and chip formation in milling are important factors. Milling Tool Path.

From www.javelin-tech.com

Creating Milling Features Interactively with SOLIDWORKS CAM Milling Tool Path Generally, these are the x and y axes. When machining, proper speeds and feeds are very important to avoid. If we look at our machine in the video above, we can see a 2d toolpath in action. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. The most basic. Milling Tool Path.

From www.researchgate.net

Tool path and actual cutting chip thickness of the millingmilling Milling Tool Path Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Generally, these are the x and y axes. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of the machine’s axes, while cutting. When machining, proper speeds. Milling Tool Path.

From www.youtube.com

Unedited Beautiful CNC Machining Tool Path PowerMill YouTube Milling Tool Path Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. As its name suggests, 2d toolpaths only ever move in two dimensions, or two of. Milling Tool Path.

From www.javelin-tech.com

SOLIDWORKS CAM Standard Milling Setup 7/9 Generating Toolpaths Milling Tool Path Learn about cnc milling terminology, chip formation, milling methods, toolpaths, and common 2d and 3d milling operations. Find milling formulas needed for your milling operations, such as how to calculate correct cutting speed, feed per tooth and metal removal rate or specific milling cutter formulas. Generally, these are the x and y axes. This article analyzes the different characteristics of. Milling Tool Path.