Welding Wire Spool Unwind . If it isn’t preset, set the hub tension on the spool to ensure it doesn’t unwind when welding stops. Half an hour of carefully. This will help prevent wire. The end of the wire has gone under one of the loose loops somewhere. Take it out, unwind it until you find the snag(s) and choonit. However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. Too much or too little can lead to problems. The wire should unwind from the top of the spool and feed into the wire guide without any twists or kinks. Nearing the end of a 2lb spool of 0.030 steel wire in my (miller 211) welder, and the wire is hanging up on the spool. Start by checking the wire spools to ensure the tension is set correctly; Be sure to account for the. Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. A closer look shows that the loop of wire that is one turn away from. This helps maintain the wire tension on the feeder. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder.

from www.amazon.com

Start by checking the wire spools to ensure the tension is set correctly; Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. The wire should unwind from the top of the spool and feed into the wire guide without any twists or kinks. Take it out, unwind it until you find the snag(s) and choonit. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. Be sure to account for the. This will help prevent wire. However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. If it isn’t preset, set the hub tension on the spool to ensure it doesn’t unwind when welding stops. Too much or too little can lead to problems.

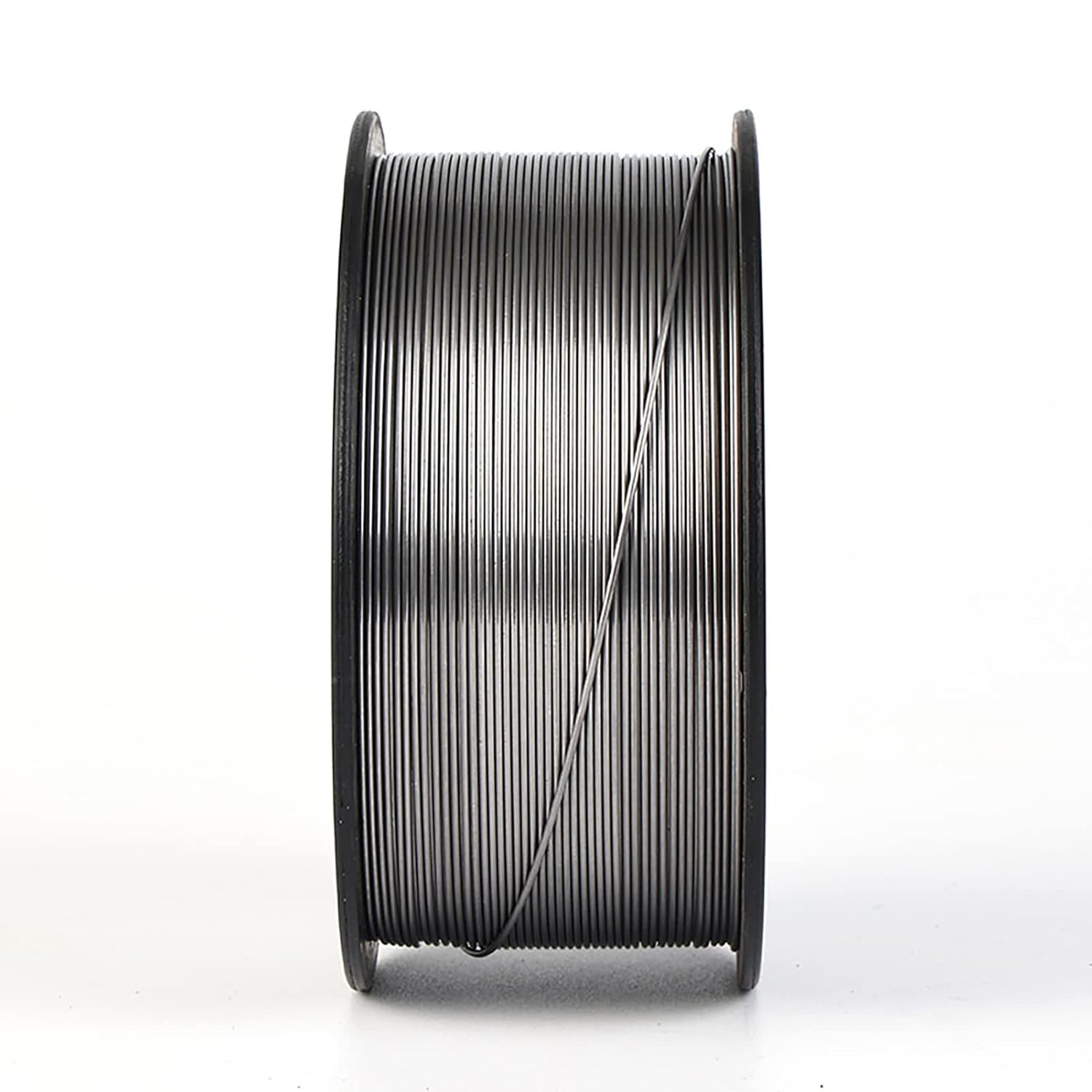

Gasless Flux Core Welding Wire Spool 1mm High Efficiency Automatic Feed

Welding Wire Spool Unwind Start by checking the wire spools to ensure the tension is set correctly; If it isn’t preset, set the hub tension on the spool to ensure it doesn’t unwind when welding stops. Too much or too little can lead to problems. This helps maintain the wire tension on the feeder. Nearing the end of a 2lb spool of 0.030 steel wire in my (miller 211) welder, and the wire is hanging up on the spool. The end of the wire has gone under one of the loose loops somewhere. This will help prevent wire. Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. A closer look shows that the loop of wire that is one turn away from. Take it out, unwind it until you find the snag(s) and choonit. Start by checking the wire spools to ensure the tension is set correctly; However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. The wire should unwind from the top of the spool and feed into the wire guide without any twists or kinks. Be sure to account for the. Half an hour of carefully.

From crownplastics.com.au

Welding Wire Spools Welding Wire Spool Unwind Take it out, unwind it until you find the snag(s) and choonit. A closer look shows that the loop of wire that is one turn away from. Start by checking the wire spools to ensure the tension is set correctly; This will help prevent wire. However, i forgot to order wire, so i pulled the spool from the redundant sip.and. Welding Wire Spool Unwind.

From arcwelders.co.za

Flux Cored Gasless E71T11 15kg MIG Wire Spool Welding Wire Spool Unwind However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. The wire should unwind from the top of the spool and feed into the wire guide without any twists or kinks. This helps maintain the wire tension on the feeder. Be sure to account for the. Too much or too. Welding Wire Spool Unwind.

From www.hampdon.com.au

15kg 1.2mm COBRA E71T1 Flux Cored C/M Welding Wire Spool FCAW Welding Wire Spool Unwind Half an hour of carefully. The wire should unwind from the top of the spool and feed into the wire guide without any twists or kinks. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. Too much or too little. Welding Wire Spool Unwind.

From www.northerntool.com

Hobart MIG Welding Wire — ER70S6 Carbon Steel, .024in., 10Lb. Spool Welding Wire Spool Unwind Half an hour of carefully. Nearing the end of a 2lb spool of 0.030 steel wire in my (miller 211) welder, and the wire is hanging up on the spool. Too much or too little can lead to problems. Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential.. Welding Wire Spool Unwind.

From www.hobartbrothers.com

Best Practices for Welding Wire Spool Selection and SetUp Hobart Welding Wire Spool Unwind Nearing the end of a 2lb spool of 0.030 steel wire in my (miller 211) welder, and the wire is hanging up on the spool. Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. This helps maintain the wire tension on the feeder. The wire should unwind from. Welding Wire Spool Unwind.

From www.wisc-online.com

Welding Wire Spool Installation Instructions OER Welding Wire Spool Unwind Take it out, unwind it until you find the snag(s) and choonit. This helps maintain the wire tension on the feeder. Too much or too little can lead to problems. The end of the wire has gone under one of the loose loops somewhere. Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without. Welding Wire Spool Unwind.

From www.weldingcity.com

WeldingCity® 0.035" ER5356 Aluminum MIG Welding Wire 1lb 4in Spool Welding Wire Spool Unwind Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. The end of the wire has gone under one of the loose loops somewhere. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel. Welding Wire Spool Unwind.

From www.hampdon.com.au

5kg 0.6mm ER70S6 Mild Steel MIG Welding Wire Spool Welding Wire Spool Unwind Too much or too little can lead to problems. Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. The wire should unwind from the top of the spool and feed into the wire guide without any twists or kinks. If it isn’t preset, set the hub tension on. Welding Wire Spool Unwind.

From www.wireproauto.com

PFRS50B max 50kgs wire spool unwind machine prefeeder WIREPRO Welding Wire Spool Unwind However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. Nearing the end of a 2lb spool of 0.030 steel wire in my (miller 211) welder, and the wire is hanging up on the spool. If it isn’t preset, set the hub tension on the spool to ensure it doesn’t. Welding Wire Spool Unwind.

From www.rmwsupplies.co.uk

Mild Steel MIG 1.0mm x 5kg Welding Wire Spool R.M. Williams Welding Wire Spool Unwind Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. Start by checking the wire spools to ensure the tension is set correctly; If it isn’t preset, set the hub tension on the spool to ensure it doesn’t unwind when welding. Welding Wire Spool Unwind.

From www.hampdon.com.au

15kg 1.2mm COBRA E71T1 Flux Cored C/M Welding Wire Spool FCAW Welding Wire Spool Unwind The wire should unwind from the top of the spool and feed into the wire guide without any twists or kinks. A closer look shows that the loop of wire that is one turn away from. However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. Holding the spool from. Welding Wire Spool Unwind.

From www.wireproauto.com

PFS38 max 60kgs wire spool unwind machine prefeeder WIREPRO Welding Wire Spool Unwind However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. The wire should unwind from the top of the spool and feed into the wire guide without any twists. Welding Wire Spool Unwind.

From www.youtube.com

Rewound big spool of welding wire to smaller spool to fit in welder Welding Wire Spool Unwind Be sure to account for the. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. Nearing the end of a 2lb spool of 0.030 steel wire in my (miller 211) welder, and the wire is hanging up on the spool.. Welding Wire Spool Unwind.

From www.forneyind.com

ER70S6, MIG Welding Wire, Mild Steel, .035 in Diameter x 33 Pound Spool Welding Wire Spool Unwind Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. Be sure to account for the. The end of the wire has gone under one of the loose loops somewhere. However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to. Welding Wire Spool Unwind.

From www.wireproauto.com

PFRS50B max 50kgs wire spool unwind machine prefeeder WIREPRO Welding Wire Spool Unwind However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. Be sure to account for the. This will help prevent wire. If it isn’t preset, set the hub tension on the spool to ensure it doesn’t unwind when welding stops. Too much or too little can lead to problems. Take. Welding Wire Spool Unwind.

From www.wireproauto.com

PFRS50 max 50kgs wire spool unwind machine prefeeder WIREPRO Welding Wire Spool Unwind Nearing the end of a 2lb spool of 0.030 steel wire in my (miller 211) welder, and the wire is hanging up on the spool. Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. Be sure to account for the. This helps maintain the wire tension on the. Welding Wire Spool Unwind.

From www.wireproauto.com

PFRS50B max 50kgs wire spool unwind machine prefeeder WIREPRO Welding Wire Spool Unwind Half an hour of carefully. This will help prevent wire. If it isn’t preset, set the hub tension on the spool to ensure it doesn’t unwind when welding stops. However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. The end of the wire has gone under one of the. Welding Wire Spool Unwind.

From www.hampdon.com.au

15kg 0.6mm ER70S6 Mild Steel MIG Welding Wire Spool Welding Wire Spool Unwind This will help prevent wire. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. The wire should unwind from the top of the spool and feed into the wire guide without any twists or kinks. Adjust the spring pressure to. Welding Wire Spool Unwind.

From shop.phxwelding.com

COREONE ER70S6 11lb Welding Wire Spool Phoenix Welding Supply LLC Welding Wire Spool Unwind Take it out, unwind it until you find the snag(s) and choonit. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. This helps maintain the wire tension on the feeder. However, i forgot to order wire, so i pulled the. Welding Wire Spool Unwind.

From www.hampdon.com.au

5kg 0.9mm ER70S6 Mild Steel MIG Welding Wire Spool Welding Wire Spool Unwind Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. If it isn’t preset, set the hub tension on the spool to ensure it doesn’t unwind when welding stops. Half an hour of carefully. A closer look shows that the loop of wire that is one turn away from.. Welding Wire Spool Unwind.

From www.homedepot.com

Lincoln Electric 12.5 lb. Spool Mild Steel MIG Welding WireED023334 Welding Wire Spool Unwind This will help prevent wire. Take it out, unwind it until you find the snag(s) and choonit. Be sure to account for the. The wire should unwind from the top of the spool and feed into the wire guide without any twists or kinks. Holding the spool from below (rather than by the rim), place it on the spool assembly,. Welding Wire Spool Unwind.

From www.hampdon.com.au

6kg 1.2mm ER5356 Aluminium MIG Welding Wire Spool Welding Wire Spool Unwind Start by checking the wire spools to ensure the tension is set correctly; Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. A closer look shows that the. Welding Wire Spool Unwind.

From www.amazon.com

Gasless Flux Core Welding Wire Spool 1mm High Efficiency Automatic Feed Welding Wire Spool Unwind This helps maintain the wire tension on the feeder. The end of the wire has gone under one of the loose loops somewhere. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. The wire should unwind from the top of. Welding Wire Spool Unwind.

From www.farmandfleet.com

Hobart 2 lb .035 ga Mild Steel Welding Wire Spool H305408R19 Blain Welding Wire Spool Unwind Be sure to account for the. Half an hour of carefully. The end of the wire has gone under one of the loose loops somewhere. Take it out, unwind it until you find the snag(s) and choonit. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with. Welding Wire Spool Unwind.

From www.grainger.com

LINCOLN ELECTRIC 25 lb Steel Spool Mig Welding Wire with 0.072 in Welding Wire Spool Unwind Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. Start by checking the wire spools to ensure the tension is set correctly; Half an hour of carefully. Nearing the end of a 2lb spool of 0.030 steel wire in my. Welding Wire Spool Unwind.

From www.grainger.com

WESTWARD 2 lb Carbon Steel Spool Mig Welding Wire with 0.03 in Diameter Welding Wire Spool Unwind Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. This helps maintain the wire tension on the feeder. If it isn’t preset, set the hub tension on the spool to ensure it doesn’t unwind when welding stops. Adjust the spring. Welding Wire Spool Unwind.

From www.grainger.com

LINCOLN ELECTRIC 44 lb Carbon Steel Spool Mig Welding Wire with 0.045 Welding Wire Spool Unwind Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. This will help prevent wire. Take it out, unwind it until you find the snag(s) and choonit. Adjust the spring pressure to get the tension just right—a balance that allows consistent. Welding Wire Spool Unwind.

From www.grainger.com

WESTWARD 1 lb Stainless Steel Spool Mig Welding Wire with 0.035 in Welding Wire Spool Unwind Nearing the end of a 2lb spool of 0.030 steel wire in my (miller 211) welder, and the wire is hanging up on the spool. This helps maintain the wire tension on the feeder. Take it out, unwind it until you find the snag(s) and choonit. Be sure to account for the. Start by checking the wire spools to ensure. Welding Wire Spool Unwind.

From www.wireproauto.com

PFS38 max 60kgs wire spool unwind machine prefeeder WIREPRO Welding Wire Spool Unwind Take it out, unwind it until you find the snag(s) and choonit. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on the wire feeder. If it isn’t preset, set the hub tension on the spool to ensure it doesn’t unwind when welding stops.. Welding Wire Spool Unwind.

From www.youtube.com

PFRS50 max 50kgs wire spool unwind machine prefeeder YouTube Welding Wire Spool Unwind Take it out, unwind it until you find the snag(s) and choonit. Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. A closer look shows that the loop of wire that is one turn away from. Start by checking the wire spools to ensure the tension is set. Welding Wire Spool Unwind.

From www.coastmachinery.com

Assorted Spools of Welding Wires Coast Machinery Group Welding Wire Spool Unwind Half an hour of carefully. Start by checking the wire spools to ensure the tension is set correctly; Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. The end of the wire has gone under one of the loose loops somewhere. Take it out, unwind it until you. Welding Wire Spool Unwind.

From www.hampdon.com.au

1kg 0.8mm ER70S6 Mild Steel MIG Welding Wire Spool Welding Wire Spool Unwind Half an hour of carefully. Start by checking the wire spools to ensure the tension is set correctly; Adjust the spring pressure to get the tension just right—a balance that allows consistent feeding without crushing the wire is essential. This helps maintain the wire tension on the feeder. The end of the wire has gone under one of the loose. Welding Wire Spool Unwind.

From www.shopjfi.com

0.035" ER316L Stainless Steel Mig Welding Wire Spool (10 lb) Welding Wire Spool Unwind Start by checking the wire spools to ensure the tension is set correctly; Take it out, unwind it until you find the snag(s) and choonit. Too much or too little can lead to problems. Holding the spool from below (rather than by the rim), place it on the spool assembly, aligning the hole on the spool with the dowel on. Welding Wire Spool Unwind.

From www.alamy.com

Welding wire spool on a white background Stock Photo Alamy Welding Wire Spool Unwind This helps maintain the wire tension on the feeder. If it isn’t preset, set the hub tension on the spool to ensure it doesn’t unwind when welding stops. However, i forgot to order wire, so i pulled the spool from the redundant sip.and found it rusted to hell. Nearing the end of a 2lb spool of 0.030 steel wire in. Welding Wire Spool Unwind.

From harrisweldingsupplies.com

Lincoln ER70S6 SuperArc L56 MIG Welding Wire .035 on 33 lb. Steel Spools Welding Wire Spool Unwind This helps maintain the wire tension on the feeder. The wire should unwind from the top of the spool and feed into the wire guide without any twists or kinks. Half an hour of carefully. Start by checking the wire spools to ensure the tension is set correctly; A closer look shows that the loop of wire that is one. Welding Wire Spool Unwind.