Film Extrusion Process . The undertaking of this project is. The first step in blown film manufacturing is extrusion. One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube like a balloon (ibc) • air. The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. Blown films extrusion is one of many polymer manufacturing processes. This method is used to produce commodity and specialized polymer. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder.

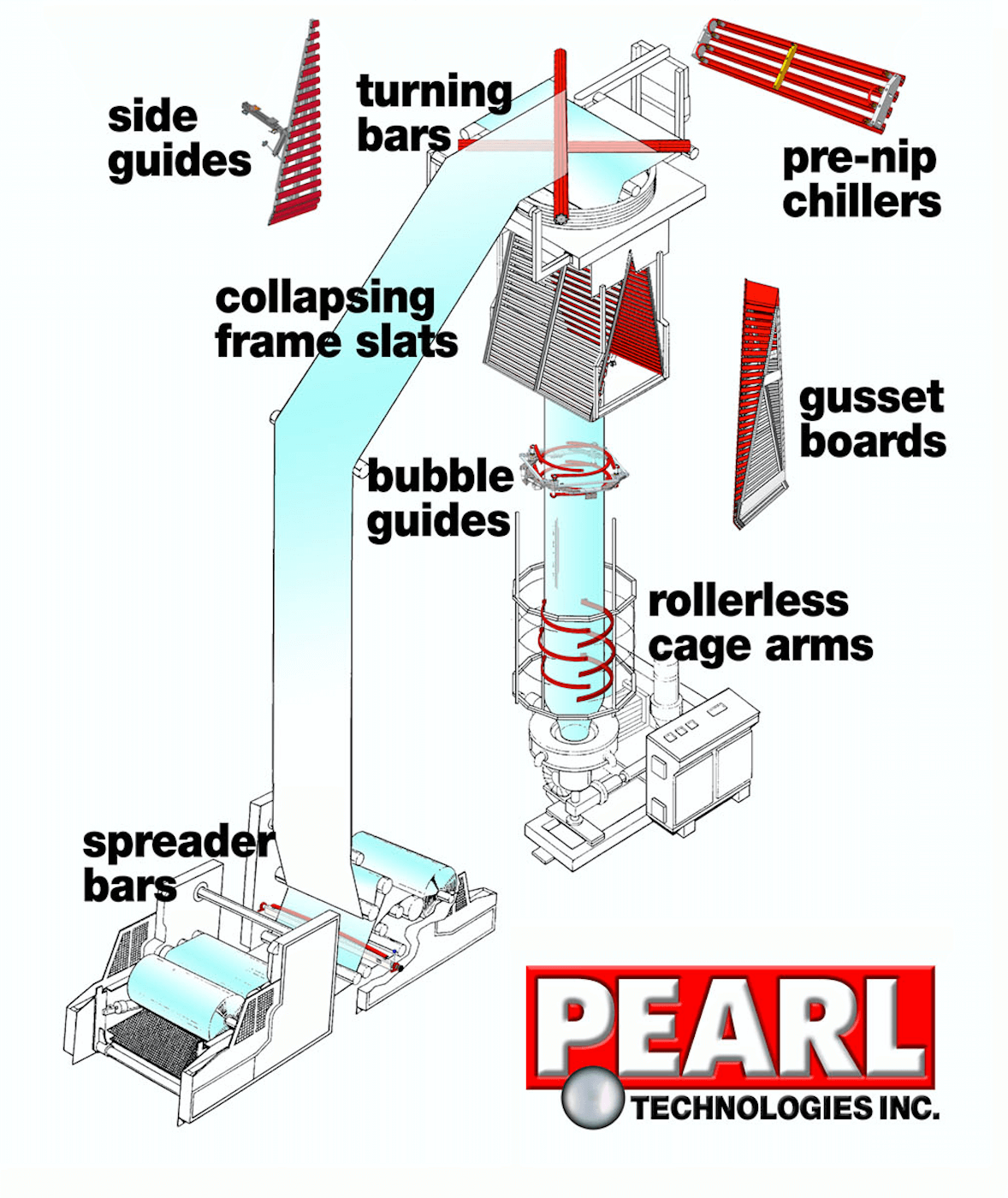

from www.pearltechinc.com

The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. The undertaking of this project is. The first step in blown film manufacturing is extrusion. Blown films extrusion is one of many polymer manufacturing processes. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube like a balloon (ibc) • air. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. This method is used to produce commodity and specialized polymer.

Understanding Blown Film Extrusion The Future of Extrusion Pearl

Film Extrusion Process Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube like a balloon (ibc) • air. The first step in blown film manufacturing is extrusion. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. This method is used to produce commodity and specialized polymer. Blown films extrusion is one of many polymer manufacturing processes. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. The undertaking of this project is.

From fillplas.com

Blown Film and How it works? Film Extrusion Process The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. The undertaking of this project is. Blown films extrusion is one of many polymer manufacturing processes. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. This method. Film Extrusion Process.

From www.fukuvi-usa.com

EXTRUSION 101 Fukuvi USA, manufacturer of highquality extruded Film Extrusion Process Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube like a balloon (ibc) • air. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. One of the. Film Extrusion Process.

From www.youtube.com

Blown Film Extrusion Process Blown Film Extrusion Process In Hindi Film Extrusion Process Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube like a balloon (ibc) • air. This. Film Extrusion Process.

From unitymanufacture.com

Plastic Extrusions Manufacturing Process And Applications Unity Film Extrusion Process The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. This method is used to produce commodity and specialized polymer. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. The first step in blown. Film Extrusion Process.

From www.pearltechinc.com

Understanding Blown Film Extrusion The Future of Extrusion Pearl Film Extrusion Process Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube like a balloon (ibc) • air. Blown films extrusion is one of many polymer manufacturing processes. One of the most common methods of film manufacture is blown. Film Extrusion Process.

From www.researchgate.net

Schematic of a blown film extrusion process. Download Scientific Diagram Film Extrusion Process One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. Blown films extrusion is one of many polymer manufacturing processes. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. The most common method for large scale production of plastic films is. Film Extrusion Process.

From www.youtube.com

The Mechanics of Blown Film Extrusion An Animated Overview for Film Extrusion Process The first step in blown film manufacturing is extrusion. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube like a balloon (ibc) • air. The undertaking of this project is. One of the most common methods. Film Extrusion Process.

From www.youtube.com

Cast Film Extrusion Line YouTube Film Extrusion Process The first step in blown film manufacturing is extrusion. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. Blown films extrusion is. Film Extrusion Process.

From www.mdpi.com

Applied Sciences Free FullText Influence of the Main Blown Film Film Extrusion Process The first step in blown film manufacturing is extrusion. Blown films extrusion is one of many polymer manufacturing processes. The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an. Film Extrusion Process.

From www.njsumino.com

Plastic Film Extrusion Machinery ManufacturerNanjing Sumino Precision Film Extrusion Process Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube like a balloon (ibc) • air. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. The most common. Film Extrusion Process.

From www.mdpi.com

Materials Free FullText Overview of the Cast Polyolefin Film Film Extrusion Process One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. This method is used to produce commodity and specialized polymer. The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. The undertaking of this project is. Film extrusion. Film Extrusion Process.

From www.wanhan-plastic.com

Cooling process of extrusion molding process Film Extrusion Process The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. This method is used to produce commodity and specialized polymer. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die. Film Extrusion Process.

From www.slideserve.com

PPT Polymer and Ceramic Processing PowerPoint Presentation ID153997 Film Extrusion Process The first step in blown film manufacturing is extrusion. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. The undertaking of this project is. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using. Film Extrusion Process.

From www.mech4study.com

Extrusion Process Working, Types, Application, Advantages and Film Extrusion Process The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. This method is used to produce commodity and specialized polymer. The undertaking of this project is. Blown films extrusion is one of many polymer manufacturing processes. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and. Film Extrusion Process.

From www.slideserve.com

PPT Unit Operations in Polymer Processing PowerPoint Presentation Film Extrusion Process This method is used to produce commodity and specialized polymer. The first step in blown film manufacturing is extrusion. The undertaking of this project is. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. One of the most common methods of film manufacture is blown film (also referred to. Film Extrusion Process.

From www.pearltechinc.com

Understanding Blown Film Extrusion The Future of Extrusion Pearl Film Extrusion Process Blown films extrusion is one of many polymer manufacturing processes. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. Extrusion process • plastic melt. Film Extrusion Process.

From www.youtube.com

Blown film extrusion process YouTube Film Extrusion Process Blown films extrusion is one of many polymer manufacturing processes. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. One of the most common methods of film manufacture is blown film. Film Extrusion Process.

From www.weetect.com

Polycarbonate Extrusion A Complete Guide Wee Tect Film Extrusion Process The undertaking of this project is. This method is used to produce commodity and specialized polymer. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. Blown films extrusion is one of many polymer manufacturing processes. The first step in blown film manufacturing is extrusion. Extrusion process • plastic melt is extruded. Film Extrusion Process.

From www.rainbowbelts.com

What Is The Profile Extrusion Process? Film Extrusion Process One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube like a balloon (ibc) • air. The. Film Extrusion Process.

From journals.sagepub.com

Investigations of film thickness variations in blown film extrusion Film Extrusion Process The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. The undertaking of this project is. Blown films extrusion is one of many polymer manufacturing processes. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with. Film Extrusion Process.

From www.slideserve.com

PPT Chapter 15 Polymers Characteristics, Applications, and Film Extrusion Process Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. This method is used to produce commodity and specialized polymer. The first step in blown film manufacturing is extrusion. The blown film. Film Extrusion Process.

From mechanicstips.blogspot.com

Plastic Extrusion MechanicsTips Film Extrusion Process The first step in blown film manufacturing is extrusion. The undertaking of this project is. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to. Film Extrusion Process.

From www.lactips.com

[PROCESS INFO] Our expert talks about Blown Film Extrusion Lactips Film Extrusion Process The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. The undertaking of this project is. One of the most common. Film Extrusion Process.

From www.researchgate.net

2 Different types of dies used for blown film extrusion. Adapted from Film Extrusion Process Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig.. Film Extrusion Process.

From www.propyplast.net

CAST FILM EXTRUSION Propyplast Film Extrusion Process The undertaking of this project is. Blown films extrusion is one of many polymer manufacturing processes. One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air. Film Extrusion Process.

From boppfilms.blogspot.com

BOPP Film Production Process.... Extrusion Process Film Extrusion Process One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. The undertaking of this project is. Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin. Film Extrusion Process.

From www.researchgate.net

Schematic representation of the filmextrusion process. Download Film Extrusion Process This method is used to produce commodity and specialized polymer. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube like a balloon (ibc) • air. The undertaking of this project is. Blown films extrusion is one. Film Extrusion Process.

From www.researchgate.net

Schematic of extrusion film casting process and associated defects Film Extrusion Process The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of the die to blow up the tube. Film Extrusion Process.

From www.euro-machinery.dk

Plast film types and the machines that process plast film Euro Film Extrusion Process The undertaking of this project is. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. Film extrusion manual is the result of. Film Extrusion Process.

From www.youtube.com

Blown film extrusion machine YouTube Film Extrusion Process Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. The first step in blown film manufacturing is extrusion. The most common method for large scale production of plastic films is the. Film Extrusion Process.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Film Extrusion Process The undertaking of this project is. The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. The first step in blown. Film Extrusion Process.

From engineeringlearner.com

Types of Extrusion Process Working, Advantages & Disadvantages Film Extrusion Process The undertaking of this project is. The most common method for large scale production of plastic films is the blown film extrusion process, which is illustrated in fig. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. The blown film process uses extrusion to produce a homogeneous melt that. Film Extrusion Process.

From fillplas.com

Blown Film and How it works? Film Extrusion Process Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. Blown films extrusion is one of many polymer manufacturing processes. The first step in blown film manufacturing is extrusion. The. Film Extrusion Process.

From www.youtube.com

COEXTRUSION CAST LINE FOR STRETCH FILM (LLDPE) YouTube Film Extrusion Process Film extrusion manual is the result of four years of intensive team effort to update the 1992 publication. This method is used to produce commodity and specialized polymer. The undertaking of this project is. Extrusion process • plastic melt is extruded through an annular slit die, vertically to form thin walled tube • air is introduced in the centre of. Film Extrusion Process.

From fillplas.com

Blown film extrusion and CaCO3 filler masterbatch in blown film extrusion Film Extrusion Process The blown film process uses extrusion to produce a homogeneous melt that is fed into a circular die head and fed with pressurised air to form a. One of the most common methods of film manufacture is blown film (also referred to as the tubular film) extrusion. The most common method for large scale production of plastic films is the. Film Extrusion Process.