Gate In Parts . Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. Consider gate options and location when designing parts for injection molding. Understanding the different types of gates and their impact on the final product is critical to achieving the best results. In injection molding, each cavity in a mold must contain a small. The right gate and overflow plan will help you create better parts, save money, and reduce production time. In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. The gate is the entrance where molten plastic enters the mold cavity. Consider gate options and location when designing parts for injection moulding. A critical aspect of successful injection molding is gate design and placement.

from cantilevergateparts.com

The gate is the entrance where molten plastic enters the mold cavity. The right gate and overflow plan will help you create better parts, save money, and reduce production time. In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. Consider gate options and location when designing parts for injection molding. Consider gate options and location when designing parts for injection moulding. A critical aspect of successful injection molding is gate design and placement. Understanding the different types of gates and their impact on the final product is critical to achieving the best results. In injection molding, each cavity in a mold must contain a small. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts.

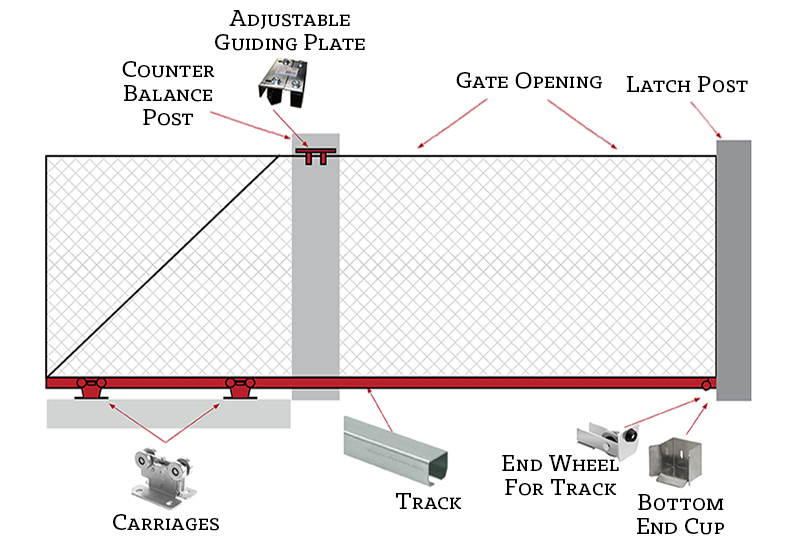

Cantilever Gate Components Information Cantilever Gate Parts

Gate In Parts In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. Consider gate options and location when designing parts for injection moulding. In injection molding, each cavity in a mold must contain a small. In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. The gate is the entrance where molten plastic enters the mold cavity. Understanding the different types of gates and their impact on the final product is critical to achieving the best results. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. Consider gate options and location when designing parts for injection molding. The right gate and overflow plan will help you create better parts, save money, and reduce production time. A critical aspect of successful injection molding is gate design and placement.

From www.rodneyhunt.com

Radial Gates Gate In Parts Understanding the different types of gates and their impact on the final product is critical to achieving the best results. The gate is the entrance where molten plastic enters the mold cavity. The right gate and overflow plan will help you create better parts, save money, and reduce production time. Consider gate options and location when designing parts for injection. Gate In Parts.

From foundtheworld.com

Arc De Triomphe, Biggest Gate In Paris, France Found The World Gate In Parts Consider gate options and location when designing parts for injection molding. Understanding the different types of gates and their impact on the final product is critical to achieving the best results. The right gate and overflow plan will help you create better parts, save money, and reduce production time. Consider gate options and location when designing parts for injection moulding.. Gate In Parts.

From custom-driveway-gates.com

DIY Driveway Gate Installation Installing Driveway Gates Tips & Info Gate In Parts Consider gate options and location when designing parts for injection molding. The gate is the entrance where molten plastic enters the mold cavity. A critical aspect of successful injection molding is gate design and placement. In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. Understanding the different types of gates. Gate In Parts.

From www.plastopialtd.com

Injection Molding Gate & Gate Design Plastopia Gate In Parts The gate is the entrance where molten plastic enters the mold cavity. A critical aspect of successful injection molding is gate design and placement. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. The right gate and overflow plan will help you create better parts, save money, and reduce production time. In. Gate In Parts.

From www.myplasticmold.com

Principle Of Gate Design Gate In Parts Consider gate options and location when designing parts for injection moulding. The gate is the entrance where molten plastic enters the mold cavity. A critical aspect of successful injection molding is gate design and placement. Consider gate options and location when designing parts for injection molding. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of. Gate In Parts.

From foundtheworld.com

Arc De Triomphe, Biggest Gate In Paris, France Found The World Gate In Parts The gate is the entrance where molten plastic enters the mold cavity. Consider gate options and location when designing parts for injection moulding. The right gate and overflow plan will help you create better parts, save money, and reduce production time. In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot.. Gate In Parts.

From www.burlycorp.com

Chain Link Parts Gate In Parts Consider gate options and location when designing parts for injection moulding. The gate is the entrance where molten plastic enters the mold cavity. Consider gate options and location when designing parts for injection molding. A critical aspect of successful injection molding is gate design and placement. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of. Gate In Parts.

From www.plastopialtd.com

Injection Molding Gate & Gate Design Plastopia Gate In Parts In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. The right gate and overflow plan will help you create better parts, save money, and reduce production time. In injection molding, each cavity in a mold must contain a small. A critical aspect of successful injection molding is gate design and. Gate In Parts.

From engineeringdiscoveries.com

Different Types Of Sliding Gates Engineering Discoveries Gate In Parts In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. The right gate and overflow plan will help you create better parts, save money, and reduce production time. A critical aspect of successful injection molding is gate design and placement. In injection molding, each cavity in a mold must contain a. Gate In Parts.

From chieftalk.chiefarchitect.com

Highly Ornate Wrought Iron Driveway Gate Part II Symbols and Content Gate In Parts Consider gate options and location when designing parts for injection moulding. In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. In injection molding, each cavity in a mold must contain a small. A critical aspect of successful injection molding is gate design and placement. The right gate and overflow plan. Gate In Parts.

From mungfali.com

Cantilever Gate Diagram Gate In Parts Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. The right gate and overflow plan will help you create better parts, save money, and reduce production time. In injection molding, each cavity in a mold must contain a small. In injection moulding, each cavity in a mould must contain a small opening. Gate In Parts.

From www.pipajaya.com

types of gate valves Gate valves with other ends types Gate In Parts A critical aspect of successful injection molding is gate design and placement. Understanding the different types of gates and their impact on the final product is critical to achieving the best results. Consider gate options and location when designing parts for injection moulding. The gate is the entrance where molten plastic enters the mold cavity. Injection molding gate design is. Gate In Parts.

From foundtheworld.com

Arc De Triomphe, Biggest Gate In Paris, France Found The World Gate In Parts Understanding the different types of gates and their impact on the final product is critical to achieving the best results. Consider gate options and location when designing parts for injection moulding. The right gate and overflow plan will help you create better parts, save money, and reduce production time. A critical aspect of successful injection molding is gate design and. Gate In Parts.

From www.gatemotors.co.uk

Sliding Gate Buying Guide Gate Motors UK Gate In Parts The gate is the entrance where molten plastic enters the mold cavity. In injection molding, each cavity in a mold must contain a small. Understanding the different types of gates and their impact on the final product is critical to achieving the best results. In injection moulding, each cavity in a mould must contain a small opening called a gate,. Gate In Parts.

From cantilevergateparts.com

Cantilever Gate Components Information Cantilever Gate Parts Gate In Parts The gate is the entrance where molten plastic enters the mold cavity. The right gate and overflow plan will help you create better parts, save money, and reduce production time. In injection molding, each cavity in a mold must contain a small. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. A. Gate In Parts.

From www.moldplasticinjection.com

Injection Molding Gate Location 5 Tips To Choose The Right Gate Gate In Parts Understanding the different types of gates and their impact on the final product is critical to achieving the best results. The right gate and overflow plan will help you create better parts, save money, and reduce production time. A critical aspect of successful injection molding is gate design and placement. Consider gate options and location when designing parts for injection. Gate In Parts.

From www.hpdconsult.com

Parts of Gate Valve Plus Functions of Gate Valves [ Helpful Guide] Gate In Parts In injection molding, each cavity in a mold must contain a small. A critical aspect of successful injection molding is gate design and placement. Consider gate options and location when designing parts for injection molding. Understanding the different types of gates and their impact on the final product is critical to achieving the best results. Injection molding gate design is. Gate In Parts.

From lovepik.com

Gate In Paris France Picture And HD Photos Free Download On Gate In Parts The right gate and overflow plan will help you create better parts, save money, and reduce production time. A critical aspect of successful injection molding is gate design and placement. In injection molding, each cavity in a mold must contain a small. Consider gate options and location when designing parts for injection molding. In injection moulding, each cavity in a. Gate In Parts.

From buildersvilla.com

How to build a gate for chain link fence Builders Villa Gate In Parts The right gate and overflow plan will help you create better parts, save money, and reduce production time. Understanding the different types of gates and their impact on the final product is critical to achieving the best results. In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. Consider gate options. Gate In Parts.

From schematicextinnylivytw.z22.web.core.windows.net

Parts For Sliding Gate Gate In Parts Understanding the different types of gates and their impact on the final product is critical to achieving the best results. A critical aspect of successful injection molding is gate design and placement. In injection molding, each cavity in a mold must contain a small. The right gate and overflow plan will help you create better parts, save money, and reduce. Gate In Parts.

From www.homestratosphere.com

How to Design and Build a Wooden Gate (Illustrated Guide) Gate In Parts Consider gate options and location when designing parts for injection molding. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. The right gate and overflow plan will help you create better parts, save money, and reduce production time. Understanding the different types of gates and their impact on the final product is. Gate In Parts.

From fineartamerica.com

Saint Denis Gate in Paris Photograph by Arkitekta Art Fine Art America Gate In Parts Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. A critical aspect of successful injection molding is gate design and placement. Understanding the different types of gates and their impact on the final product is critical to achieving the best results. In injection moulding, each cavity in a mould must contain a. Gate In Parts.

From blog.ironfenceshop.com

What Do I Need to DIY Install an Iron or Aluminum Gate? Iron Fence Gate In Parts The gate is the entrance where molten plastic enters the mold cavity. The right gate and overflow plan will help you create better parts, save money, and reduce production time. In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. Understanding the different types of gates and their impact on the. Gate In Parts.

From www.pinterest.com

Cool historical gate in Paris... Paris, France, Historical Gate In Parts A critical aspect of successful injection molding is gate design and placement. Consider gate options and location when designing parts for injection molding. Consider gate options and location when designing parts for injection moulding. The gate is the entrance where molten plastic enters the mold cavity. In injection moulding, each cavity in a mould must contain a small opening called. Gate In Parts.

From roaringwaterjournal.com

A Gate Post (Vernacular Gates of West Cork) Roaringwater Journal Gate In Parts In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. A critical aspect of successful injection molding is gate design and placement. The gate is the entrance where molten plastic enters the mold cavity. Consider gate options and location when designing parts for injection molding. Consider gate options and location when. Gate In Parts.

From viajonarios.com

France Visit to the Arc de Triomphe in Paris Travelers Gate In Parts Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. In injection molding, each cavity in a mold must contain a small. The right gate and overflow plan will help you create better parts, save money, and reduce production time. Understanding the different types of gates and their impact on the final product. Gate In Parts.

From www.acfoldinggates.com

Gate Specifications Gate In Parts In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. A critical aspect of successful injection molding is gate design and placement. Consider gate options and location when designing parts for injection moulding. Understanding the different types of gates and their impact on the final product is critical to achieving the. Gate In Parts.

From www.alamy.com

Arc de Triomphe in Paris , France Stock Photo Alamy Gate In Parts In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. In injection molding, each cavity in a mold must contain a small. The right gate and overflow plan will help you create better parts, save money, and reduce production time. Understanding the different types of gates and their impact on the. Gate In Parts.

From www.linkedin.com

Maintenance Of Gate Valves Gate In Parts In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. In injection molding, each cavity in a mold must contain a small. The gate is the entrance where molten plastic enters the mold cavity. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts.. Gate In Parts.

From cadbull.com

Metallic sliding gate constructive section and structure cad drawing Gate In Parts In injection molding, each cavity in a mold must contain a small. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. Consider gate options and location when designing parts for injection molding. The gate is the entrance where molten plastic enters the mold cavity. A critical aspect of successful injection molding is. Gate In Parts.

From straightgatefence.com

Anatomy Of Our Gates Custom Steel Framed and Wood Framed Gates In Gate In Parts Consider gate options and location when designing parts for injection molding. In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. The right gate and overflow plan will help you create better parts, save money, and reduce production time. Injection molding gate design is critical to ensuring the quality, efficiency, and. Gate In Parts.

From www.pinterest.com

Customer Questions What hardware to use for a double outswinging gate Gate In Parts In injection molding, each cavity in a mold must contain a small. Consider gate options and location when designing parts for injection moulding. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. The right gate and overflow plan will help you create better parts, save money, and reduce production time. Consider gate. Gate In Parts.

From shorelinevinyl.com

Gates & Hardware Shoreline Vinyl Gate In Parts The gate is the entrance where molten plastic enters the mold cavity. Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. The right gate and overflow plan will help you create better parts, save money, and reduce production time. Consider gate options and location when designing parts for injection moulding. A critical. Gate In Parts.

From www.britannica.com

Arc de Triomphe History, Location, & Facts Britannica Gate In Parts Injection molding gate design is critical to ensuring the quality, efficiency, and aesthetics of your molded parts. In injection moulding, each cavity in a mould must contain a small opening called a gate, which allows hot. Understanding the different types of gates and their impact on the final product is critical to achieving the best results. Consider gate options and. Gate In Parts.

From www.alekoproducts.com

Sliding Gate Roll Hardware Kit ALEKO Gate In Parts Understanding the different types of gates and their impact on the final product is critical to achieving the best results. The gate is the entrance where molten plastic enters the mold cavity. The right gate and overflow plan will help you create better parts, save money, and reduce production time. Injection molding gate design is critical to ensuring the quality,. Gate In Parts.