Vibration Of Control Valve . the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. The faults being considered are inflow and insufficient supply pressure

from www.mdpi.com

the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. The faults being considered are inflow and insufficient supply pressure in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small.

Applied Sciences Free FullText Design and Implementation of an

Vibration Of Control Valve in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. The faults being considered are inflow and insufficient supply pressure a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve.

From www.emerson.com

Control Valve Vibration Emerson NO Vibration Of Control Valve a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. The faults being considered are inflow and insufficient supply pressure the inherent. Vibration Of Control Valve.

From fluidcontrolsolutions.com

Analyzing vibration in and around control valves分析控制阀内部和周围的振动 We Vibration Of Control Valve in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the. Vibration Of Control Valve.

From automationforum.co

What is control valve stroke checking, and how is it done? Vibration Of Control Valve the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in order that the optimum force incurring the minimum vibration could be. Vibration Of Control Valve.

From www.youtube.com

The Right way to calibrate and maintenance control valve! Control valve Vibration Of Control Valve in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the. Vibration Of Control Valve.

From www.chegg.com

Solved Problem 8. In the study of vibrations of valves used Vibration Of Control Valve the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. the fault diagnosis. Vibration Of Control Valve.

From www.processingmagazine.com

Q&A How does vibration affect valve performance? Processing Magazine Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in this paper, taking the sleeve control valve as the research object, lift. Vibration Of Control Valve.

From automationforum.co

How to do Control Valve Preventive Maintenance? Vibration Of Control Valve the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. The faults being considered are inflow and insufficient supply pressure in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. in order that the optimum force incurring the minimum. Vibration Of Control Valve.

From www.mdpi.com

Electronics Free FullText Fault Detection of a Flow Control Valve Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the inherent. Vibration Of Control Valve.

From automationforum.co

Control valve Calibration Procedure Vibration Of Control Valve the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. the inherent throttling action and complex. Vibration Of Control Valve.

From exofpjdzv.blob.core.windows.net

Valve Actuator With Manual Override at Vivian Atkins blog Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control. Vibration Of Control Valve.

From vibration.co.th

Modulating control float valve (model VBEACV210) Vibration Vibration Of Control Valve a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. the inherent throttling action and complex 3d flow in control valves result. Vibration Of Control Valve.

From automationforum.co

control valve Instrumentation and Control Engineering Vibration Of Control Valve a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. the inherent throttling action and complex 3d flow in control valves result. Vibration Of Control Valve.

From eureka.patsnap.com

Twoway cartridge type vibration control valve with simple structure Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. the fault diagnosis of the valve is carried out by analyzing the change. Vibration Of Control Valve.

From www.controlglobal.com

Vibration of Valves and Piping Control Global Vibration Of Control Valve the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due. Vibration Of Control Valve.

From szdelanvalve.en.made-in-china.com

Pn16 SS304L Control Valves Steam Flow Pneumatic Cylinder Globe Control Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. the inherent throttling action and complex 3d flow in control valves result in. Vibration Of Control Valve.

From instrumentationtools.com

Control Valve Study Material Instrumentation Tools Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control. Vibration Of Control Valve.

From www.semanticscholar.org

Figure 2 from Simulation study on vibration characteristics of Vibration Of Control Valve in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. the. Vibration Of Control Valve.

From www.emerson.com

Control Valve Vibration Emerson US Vibration Of Control Valve in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. The faults. Vibration Of Control Valve.

From www.emerson.com

Control Valve Vibration Emerson HU Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. the fault diagnosis of the valve is. Vibration Of Control Valve.

From www.piprocessinstrumentation.com

Analyzing vibration in and around control valves P.I. Process Vibration Of Control Valve a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. The faults. Vibration Of Control Valve.

From theinstrumentguru.com

How to Do Maintenance of Control Valve Which is Stuck in Field? Vibration Of Control Valve a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. in this paper, taking the sleeve control valve as the research object,. Vibration Of Control Valve.

From www.dombor.com

Control Valve Types A Basic Guide Basic Guide Control Vibration Of Control Valve in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. The faults being considered are inflow and insufficient supply pressure a rotary valve control vibration system experimental. Vibration Of Control Valve.

From www.chinagoolevalve.com

Solutions To Control Valve VibrationI Valve Application News Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the fault diagnosis of the valve is carried out by analyzing. Vibration Of Control Valve.

From instrumentationtools.com

Control Valve in Nutshell Valve Design and Selection Factors Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made. Vibration Of Control Valve.

From www.powermag.com

Avoiding FlowInduced Sympathetic Vibration in Control Valves Vibration Of Control Valve the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. The faults being considered are inflow and insufficient supply pressure in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and. Vibration Of Control Valve.

From www.youtube.com

Control Valve Positioner Working Principle and Parts Fischer 3850 Vibration Of Control Valve the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. The faults being considered are inflow and insufficient supply pressure the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control. Vibration Of Control Valve.

From automationcommunity.com

Calibration Procedure of a Control Valve Vibration Of Control Valve the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the. Vibration Of Control Valve.

From www.scientific.net

Vibration Study on the Modal of the Control Valve Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. the fault diagnosis of the valve is carried out by analyzing the change. Vibration Of Control Valve.

From fluidhandlingpro.com

How Does Vibration Affect Valve Performance? • Fluid Handling Pro Vibration Of Control Valve the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise at small. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field. Vibration Of Control Valve.

From www.mdpi.com

Applied Sciences Free FullText Design and Implementation of an Vibration Of Control Valve the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the inherent throttling action and complex 3d flow in control valves result. Vibration Of Control Valve.

From www.mdpi.com

Electronics Free FullText Fault Detection of a Flow Control Valve Vibration Of Control Valve in this paper, taking the sleeve control valve as the research object, lift coefficient of flow field and vibration. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. the inherent throttling action and complex 3d flow in control valves result in vibration and intolerable noise. Vibration Of Control Valve.

From theinstrumentguru.com

Control valve Calibration Vibration Of Control Valve a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the. Vibration Of Control Valve.

From www.emersonautomationexperts.com

Solving Control Valve Vibration Challenges Vibration Of Control Valve the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the inherent throttling action and complex 3d flow in control valves result. Vibration Of Control Valve.

From www.youtube.com

How to do Control Valve Calibration? Control valve calibration Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure a rotary valve control vibration system experimental bench was constructed to experimentally verify the output. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by the control valve. the inherent. Vibration Of Control Valve.

From www.researchgate.net

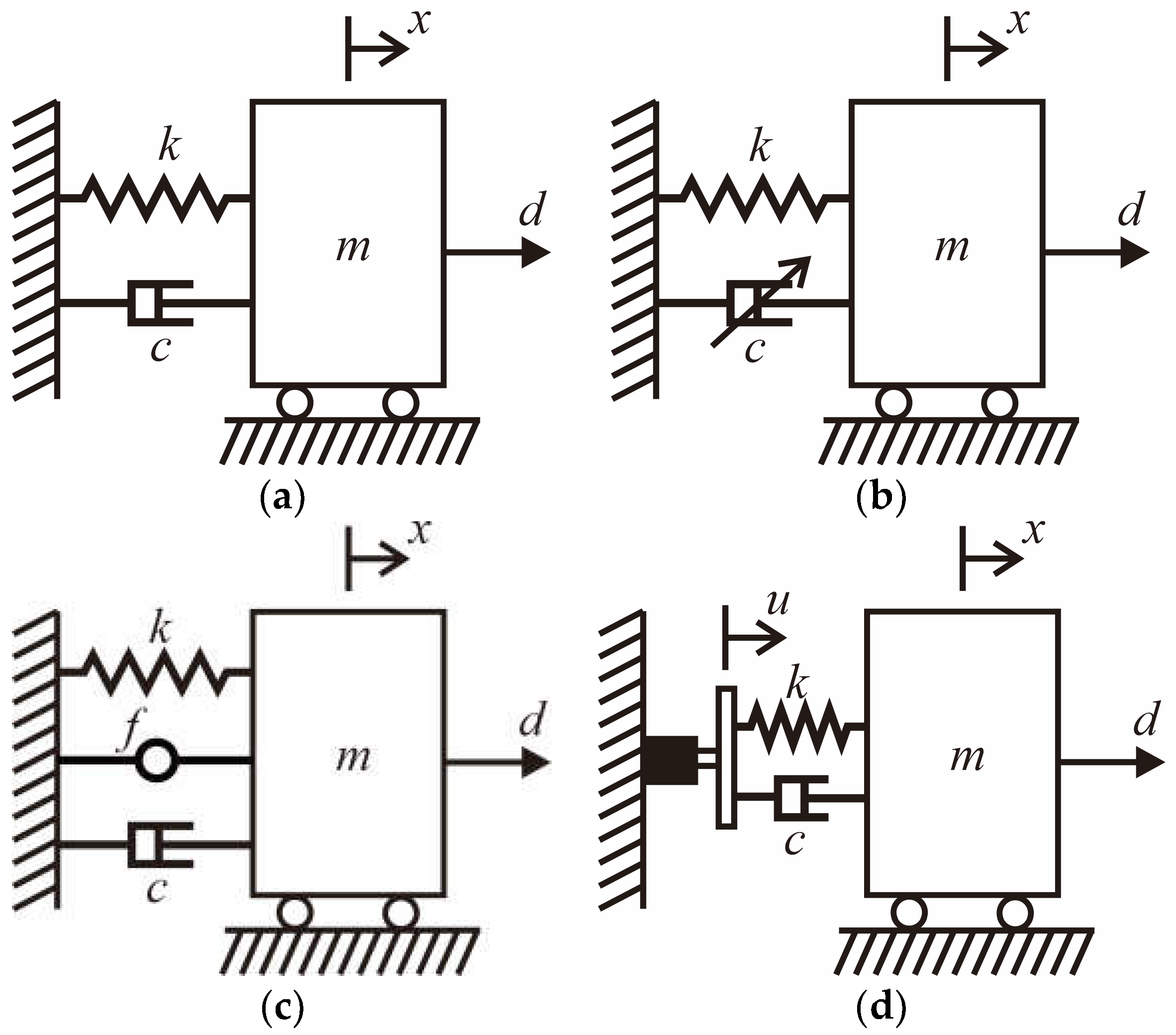

(PDF) Vibration Control of Mechanical Suspension System Using Active Vibration Of Control Valve The faults being considered are inflow and insufficient supply pressure in order that the optimum force incurring the minimum vibration could be obtained, a use has been made of fluid structure. the fault diagnosis of the valve is carried out by analyzing the change in vibration of the pipe due to the change in flow pattern induced by. Vibration Of Control Valve.