Rivet Inspection Criteria . Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. All holes shall be drilled normal (at 90 degrees) to the. Drilling rivet holes should be drilled in accordance with the following recommendations. The two rivet section loss. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%.

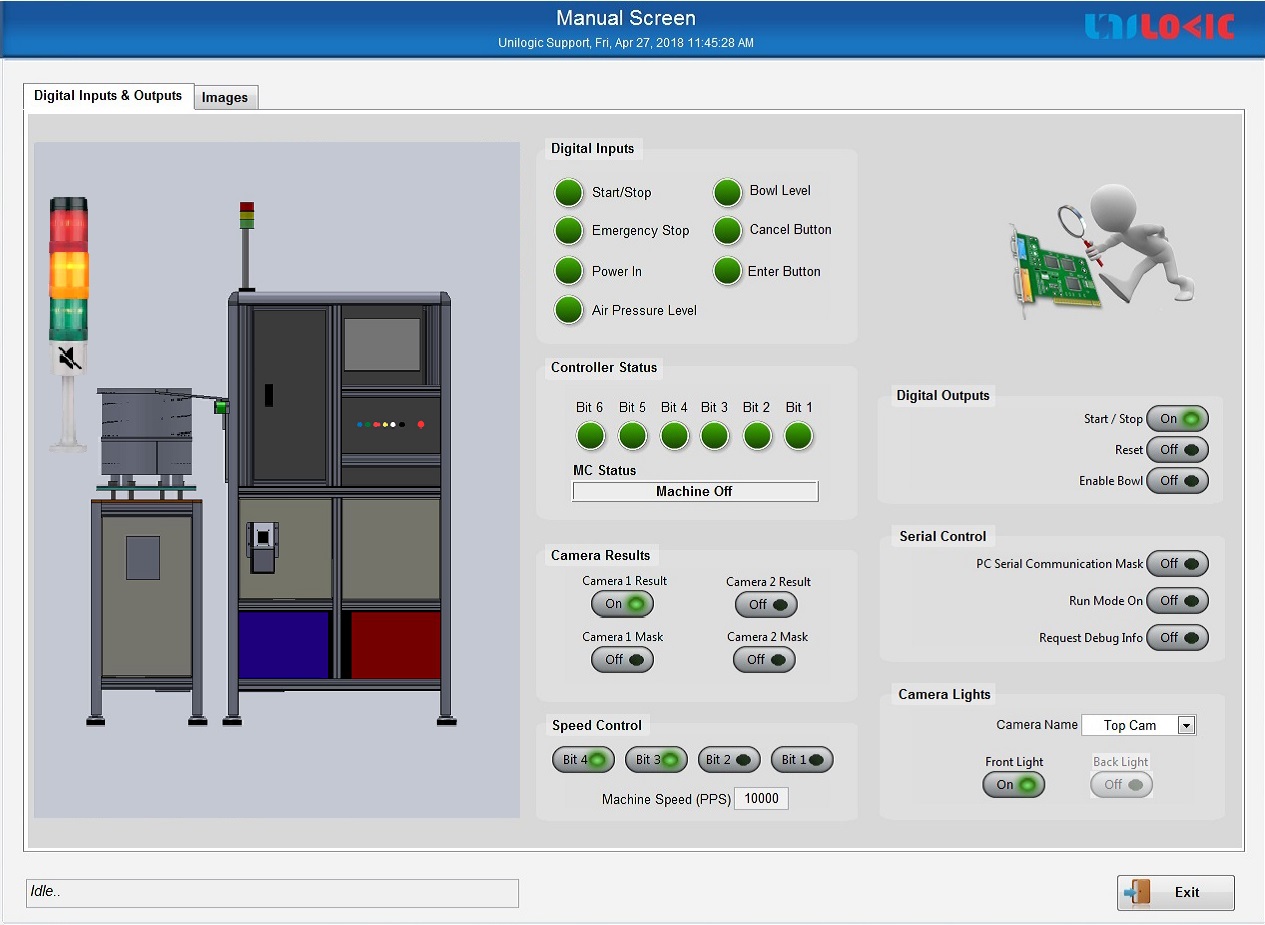

from www.unilogic.in

Drilling rivet holes should be drilled in accordance with the following recommendations. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. The two rivet section loss. All holes shall be drilled normal (at 90 degrees) to the. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification.

Rivet Inspection Unilogic Vision Inspection LabVIEW consultants

Rivet Inspection Criteria An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. The two rivet section loss. Drilling rivet holes should be drilled in accordance with the following recommendations. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. All holes shall be drilled normal (at 90 degrees) to the.

From www.unilogic.in

Rivet Inspection Unilogic Vision Inspection LabVIEW consultants Rivet Inspection Criteria Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. All holes shall be drilled normal (at 90 degrees) to the. The two rivet section loss. Drilling rivet holes should be drilled in accordance with the following recommendations. The rivet type, size, and material shall be as specified. Rivet Inspection Criteria.

From atelier-yuwa.ciao.jp

Rivet Types And Identification atelieryuwa.ciao.jp Rivet Inspection Criteria Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. Drilling rivet holes should be drilled in accordance with the following recommendations. The two rivet section loss. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush. Rivet Inspection Criteria.

From www.slideserve.com

PPT Automated Rivet Inspection System for Aging Aircrafts PowerPoint Rivet Inspection Criteria For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. Riveted joints must be regularly inspected at all stages of production and operation to check for faults. Rivet Inspection Criteria.

From present5.com

Automated Rivet Inspection System for Aging Aircrafts Unsang Rivet Inspection Criteria Drilling rivet holes should be drilled in accordance with the following recommendations. All holes shall be drilled normal (at 90 degrees) to the. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish. Rivet Inspection Criteria.

From www.jc-precisionrivet.com

JC rivets technology JC precision rivet Rivet Inspection Criteria For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. All holes shall be drilled normal (at 90 degrees) to the. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. Drilling rivet holes should be drilled in accordance with the. Rivet Inspection Criteria.

From meblegram.netlify.app

Rivet Gauge Chart Http Www Cherryaerospace Com Docs Catalogs Ca 1011 Pdf Rivet Inspection Criteria All holes shall be drilled normal (at 90 degrees) to the. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. An investigation was made of the. Rivet Inspection Criteria.

From www.unilogic.in

Rivet Inspection Unilogic Vision Inspection LabVIEW consultants Rivet Inspection Criteria Drilling rivet holes should be drilled in accordance with the following recommendations. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. Riveted joints must be regularly inspected at all stages. Rivet Inspection Criteria.

From www.youtube.com

Eddy Current Inspection of Rivets YouTube Rivet Inspection Criteria Drilling rivet holes should be drilled in accordance with the following recommendations. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. For rivets in tension. Rivet Inspection Criteria.

From www.slideserve.com

PPT Automated Rivet Inspection System for Aging Aircrafts PowerPoint Rivet Inspection Criteria The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. The two rivet section loss. All holes shall be drilled normal (at 90 degrees) to the. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. An investigation was made. Rivet Inspection Criteria.

From www.slideserve.com

PPT Automotive Chain Inspection PowerPoint Presentation, free Rivet Inspection Criteria All holes shall be drilled normal (at 90 degrees) to the. The two rivet section loss. Drilling rivet holes should be drilled in accordance with the following recommendations. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. An investigation was made of the existing flush rivet inspection. Rivet Inspection Criteria.

From www.scribd.com

Silo Tips Added Additional Inspection Requirements PDF Spar Rivet Inspection Criteria The two rivet section loss. All holes shall be drilled normal (at 90 degrees) to the. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. An investigation was made. Rivet Inspection Criteria.

From www.slideserve.com

PPT Automotive Chain Inspection PowerPoint Presentation, free Rivet Inspection Criteria An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. The rivet type, size, and material shall be as specified on the engineering drawing, parts list. Rivet Inspection Criteria.

From www.scribd.com

Groove Position Inspection PDF Rivet Inspection Criteria The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. The two rivet section loss. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. All holes shall be drilled normal (at 90 degrees) to the. Drilling rivet holes should. Rivet Inspection Criteria.

From www.slideserve.com

PPT Automated Rivet Inspection System for Aging Aircrafts PowerPoint Rivet Inspection Criteria Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. All holes shall be drilled normal (at 90 degrees) to the. The two rivet section loss.. Rivet Inspection Criteria.

From present5.com

Automated Rivet Inspection System for Aging Aircrafts Unsang Rivet Inspection Criteria Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. Drilling rivet holes should be drilled in accordance with the following recommendations. All holes shall be drilled normal (at 90 degrees) to the. The two rivet section loss. An investigation was made of the existing flush rivet inspection. Rivet Inspection Criteria.

From www.scribd.com

Fuse Inspection Criteria PDF Fuse (Electrical) Rivet Rivet Inspection Criteria The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. The two rivet section loss. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. All holes shall be drilled normal (at 90 degrees) to the. Riveted joints must be regularly. Rivet Inspection Criteria.

From www.scribd.com

Fabric Inspection Criteria 10 Point System Rivet Inspection Criteria Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. All holes shall be drilled normal (at 90 degrees) to the. Drilling rivet holes should be drilled in accordance with the following recommendations. The two rivet section loss. An investigation was made of the existing flush rivet inspection. Rivet Inspection Criteria.

From tentsshelters.tpub.com

Figure 53. Rivet inspection Rivet Inspection Criteria All holes shall be drilled normal (at 90 degrees) to the. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. Drilling rivet holes should be drilled in accordance with the following recommendations. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish. Rivet Inspection Criteria.

From specopsblog.blogspot.com

The Spec Ops Blog SAFETY NOTICE Call for rivet inspection on Petzl Rivet Inspection Criteria The two rivet section loss. Drilling rivet holes should be drilled in accordance with the following recommendations. All holes shall be drilled normal (at 90 degrees) to the. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. An investigation was made of the existing flush rivet inspection criteria. Rivet Inspection Criteria.

From www.slideserve.com

PPT Automated Rivet Inspection System for Aging Aircrafts PowerPoint Rivet Inspection Criteria The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. Drilling rivet holes should be drilled in accordance with the following recommendations. For rivets in tension or tension & shear,. Rivet Inspection Criteria.

From www.slideshare.net

Standard Inspection Method Rivet Inspection Criteria An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. The two rivet section loss. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. The rivet type, size, and material shall be as specified on the. Rivet Inspection Criteria.

From www.scribd.com

Tools Inspection Checklist PDF Mechanical Engineering Equipment Rivet Inspection Criteria For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. Drilling rivet holes should be drilled in accordance with the following recommendations. An investigation was made of. Rivet Inspection Criteria.

From www.youtube.com

Inspection d'un rivet YouTube Rivet Inspection Criteria The two rivet section loss. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. Drilling rivet holes should be drilled in accordance with the following recommendations. An investigation was. Rivet Inspection Criteria.

From www.rivetsonline.com

Rivet Identification Chart Rivet Head Styles and Markings JayCee Rivet Inspection Criteria All holes shall be drilled normal (at 90 degrees) to the. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. An investigation was made of the existing flush rivet. Rivet Inspection Criteria.

From www.laserfocusworld.com

OPTICAL SURFACE INSPECTION Structuredlight 3D scanner speeds aircraft Rivet Inspection Criteria An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. Drilling rivet holes should be drilled in accordance with the following recommendations. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. The two rivet section. Rivet Inspection Criteria.

From www.integro-tech.com

Rivet Inspection Rivet Inspection Criteria Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. All holes shall be drilled normal (at 90 degrees) to the. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. The rivet type, size, and material. Rivet Inspection Criteria.

From www.youtube.com

3D Rivets Inspection YouTube Rivet Inspection Criteria All holes shall be drilled normal (at 90 degrees) to the. The two rivet section loss. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. Riveted. Rivet Inspection Criteria.

From present5.com

Automated Rivet Inspection System for Aging Aircrafts Unsang Rivet Inspection Criteria Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. Drilling rivet holes should be drilled in accordance with the following recommendations. For rivets in tension or tension & shear,. Rivet Inspection Criteria.

From www.slideserve.com

PPT Automated Rivet Inspection System for Aging Aircrafts PowerPoint Rivet Inspection Criteria The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. Drilling rivet holes should be drilled in accordance with the following recommendations. The two rivet section loss. Riveted joints must be. Rivet Inspection Criteria.

From www.unilogic.in

Rivet Inspection Unilogic Vision Inspection LabVIEW consultants Rivet Inspection Criteria The two rivet section loss. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. Drilling rivet holes should be drilled in accordance with the following. Rivet Inspection Criteria.

From www.unilogic.in

Rivet Inspection Unilogic Vision Inspection LabVIEW consultants Rivet Inspection Criteria The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. All holes shall be drilled normal (at 90 degrees) to the. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. Drilling rivet holes should be drilled in accordance with the. Rivet Inspection Criteria.

From www.goebelfasteners.com

Quality Testing High Strength Blind Rivets Goebel Fasteners, Inc Rivet Inspection Criteria An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. The two rivet section loss. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. Drilling rivet holes should be drilled in accordance with the following recommendations. All holes shall. Rivet Inspection Criteria.

From www.youtube.com

Rivet Inspection System by Unilogic Technologies YouTube Rivet Inspection Criteria The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. Drilling rivet holes should be drilled in accordance with the following recommendations. An investigation was made of the existing flush rivet. Rivet Inspection Criteria.

From www.researchgate.net

The rivet inspection experiment system. Download Scientific Diagram Rivet Inspection Criteria For rivets in tension or tension & shear, less section loss can be tolerated and is allowed up to approximately 35%. Riveted joints must be regularly inspected at all stages of production and operation to check for faults like corrosion, fretting, and fatigue. The two rivet section loss. The rivet type, size, and material shall be as specified on the. Rivet Inspection Criteria.

From www.hqts.com

Bearing Third Party Inspection Key Criteria and Checklist HQTS Rivet Inspection Criteria The two rivet section loss. The rivet type, size, and material shall be as specified on the engineering drawing, parts list or specification. All holes shall be drilled normal (at 90 degrees) to the. An investigation was made of the existing flush rivet inspection criteria and inspection methods to establish a norm for commercial flush riveted. Drilling rivet holes should. Rivet Inspection Criteria.