Reaming Formula . Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. To find the right drill size for reaming, follow this formula: First, decide on the final hole size, which is usually the reamer. Reaming speeds & feeds carbide tipped Proper speeds & feeds must be run to. Regardless of the reaming application, some maintain only an actual reamer will do the job properly. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. The speeds and feeds calculator uses the following formulas: “it is dangerous to say.

from www.melfredborzall.com

Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. To find the right drill size for reaming, follow this formula: First, decide on the final hole size, which is usually the reamer. Reaming speeds & feeds carbide tipped Regardless of the reaming application, some maintain only an actual reamer will do the job properly. The speeds and feeds calculator uses the following formulas: “it is dangerous to say. Proper speeds & feeds must be run to.

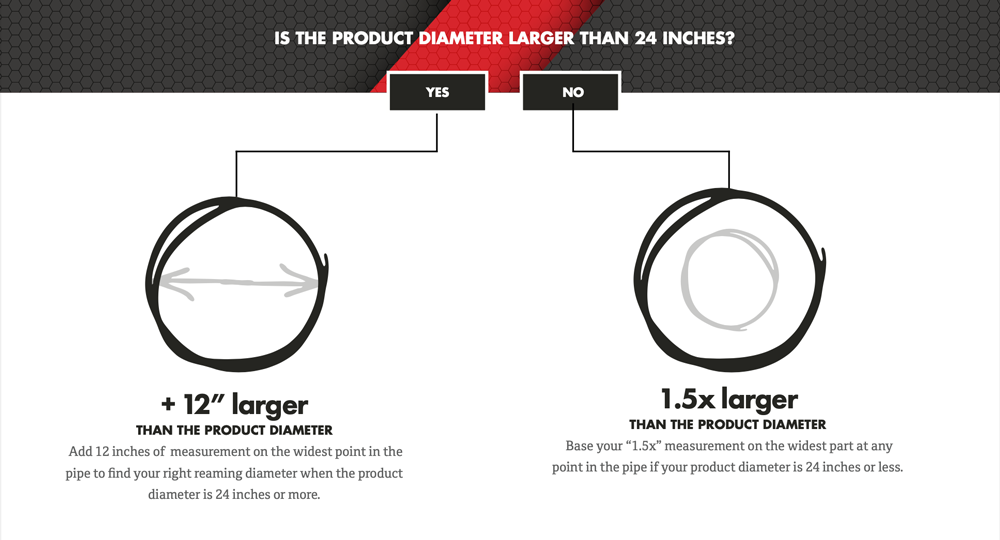

How to Properly Measure Your Reamer and Choose the Right Size for the Job

Reaming Formula To find the right drill size for reaming, follow this formula: Reaming speeds & feeds carbide tipped Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. Proper speeds & feeds must be run to. First, decide on the final hole size, which is usually the reamer. “it is dangerous to say. Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. To find the right drill size for reaming, follow this formula: Regardless of the reaming application, some maintain only an actual reamer will do the job properly. The speeds and feeds calculator uses the following formulas:

From slideplayer.com

Manufacturing Processes ppt download Reaming Formula The speeds and feeds calculator uses the following formulas: Proper speeds & feeds must be run to. Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. Reaming speeds & feeds carbide tipped Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. First, decide on. Reaming Formula.

From mechutopia.com

Reaming Cycle With G85 Mechutopia Reaming Formula Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. Reaming speeds & feeds carbide tipped To find the right drill size for reaming, follow this formula: Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. “it is dangerous to say. Learn when and how to. Reaming Formula.

From www.mdpi.com

Materials Free FullText Study on Characteristics for Reaming Titanium Alloy Ti6Al4V with Reaming Formula Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. Proper speeds & feeds must be run to. First, decide on the final hole size, which is usually the reamer. Regardless of the reaming application, some maintain only an actual reamer will do the job properly. The speeds and feeds calculator uses. Reaming Formula.

From www.researchgate.net

Design of We in reaming process Download Scientific Diagram Reaming Formula Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. Reaming speeds & feeds carbide tipped Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. First, decide on the final hole size, which is usually the. Reaming Formula.

From www.scribd.com

Reaming Tolerance Reaming Formula Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. “it is. Reaming Formula.

From www.youtube.com

Reaming Process Reaming Operation What is Reaming Reaming process kya hai In Hindi YouTube Reaming Formula Proper speeds & feeds must be run to. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. Regardless of the reaming application, some maintain only. Reaming Formula.

From www.youtube.com

1 reaming process YouTube Reaming Formula Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. Reaming speeds & feeds carbide tipped To find the right drill size for reaming, follow this formula: Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. First, decide on. Reaming Formula.

From mechutopia.com

13 Types of Reamers and Reaming Operation Mechutopia Reaming Formula Proper speeds & feeds must be run to. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. First, decide on the final hole size, which is usually the reamer. Reaming is a finishing operation and the correct combination of speed and feed is critical. Reaming Formula.

From issuu.com

Boring Or Reaming Which Procedure To Choose? by Issuu Reaming Formula To find the right drill size for reaming, follow this formula: The speeds and feeds calculator uses the following formulas: “it is dangerous to say. Proper speeds & feeds must be run to. Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. Learn when and how to use a reamer including reamer speeds and. Reaming Formula.

From www.melfredborzall.com

How to Properly Measure Your Reamer and Choose the Right Size for the Job Reaming Formula Regardless of the reaming application, some maintain only an actual reamer will do the job properly. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Reaming speeds & feeds carbide tipped Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. Reaming is a finishing. Reaming Formula.

From www.slideserve.com

PPT Machine Reaming PowerPoint Presentation, free download ID1290175 Reaming Formula Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. “it is dangerous to say. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. To find the right drill size for reaming, follow this formula: Regardless of the reaming application, some maintain. Reaming Formula.

From www.cnccookbook.com

Comparing Reaming vs Boring What's the Difference? CNCCookbook Be A Better CNC'er Reaming Formula To find the right drill size for reaming, follow this formula: “it is dangerous to say. Regardless of the reaming application, some maintain only an actual reamer will do the job properly. Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. The speeds and feeds calculator uses the following formulas: Watch this video and. Reaming Formula.

From jmproto.com

What is reaming and how is it done? Jmproto Reaming Formula To find the right drill size for reaming, follow this formula: The speeds and feeds calculator uses the following formulas: First, decide on the final hole size, which is usually the reamer. Regardless of the reaming application, some maintain only an actual reamer will do the job properly. Reaming is a finishing operation and the correct combination of speed and. Reaming Formula.

From tubingchina.com

Speeds and Feeds for Drilling and Reaming Stainless Steel Reaming Formula First, decide on the final hole size, which is usually the reamer. Proper speeds & feeds must be run to. Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Reaming speeds & feeds carbide tipped. Reaming Formula.

From www.slideserve.com

PPT Machine Reaming PowerPoint Presentation, free download ID1290175 Reaming Formula The speeds and feeds calculator uses the following formulas: First, decide on the final hole size, which is usually the reamer. Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. “it is dangerous to say. To find the right drill size for reaming, follow this formula: Learn when and how to use a reamer. Reaming Formula.

From www.youtube.com

G85 Quick and Easy Reamer Drill Size Calculation Formula YouTube Reaming Formula Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. First, decide on the final hole size, which is usually the reamer. The speeds and feeds calculator uses the following formulas: Reaming is a finishing operation and the correct combination of speed and feed is. Reaming Formula.

From www.mathscinotes.com

Electrical Conduit Math Math Encounters Blog Reaming Formula Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. Regardless of the reaming application, some maintain only an actual reamer will do the job properly.. Reaming Formula.

From tubingchina.com

Speeds and Feeds for Drilling and Reaming Stainless Steel Reaming Formula First, decide on the final hole size, which is usually the reamer. “it is dangerous to say. Proper speeds & feeds must be run to. To find the right drill size for reaming, follow this formula: Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. Regardless of the reaming application, some maintain only an. Reaming Formula.

From www.slideserve.com

PPT Machine Reaming PowerPoint Presentation, free download ID5389429 Reaming Formula The speeds and feeds calculator uses the following formulas: Reaming speeds & feeds carbide tipped Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. “it is dangerous to say. First, decide on the final hole size, which is usually the reamer. Learn when and. Reaming Formula.

From www.youtube.com

What is Reamer Types of Reamer Uses of Reamer Reaming formula in Hindi . reamer YouTube Reaming Formula To find the right drill size for reaming, follow this formula: First, decide on the final hole size, which is usually the reamer. Regardless of the reaming application, some maintain only an actual reamer will do the job properly. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming. Reaming Formula.

From www.drillingformulas.com

Directional Drilling Drilling Formulas and Drilling Calculations Reaming Formula To find the right drill size for reaming, follow this formula: The speeds and feeds calculator uses the following formulas: “it is dangerous to say. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. First, decide on the final hole size, which is usually. Reaming Formula.

From mechutopia.com

13 Types of Reamers and Reaming Operation Mechutopia Reaming Formula Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. First, decide on the final hole size, which is usually the reamer. Proper speeds & feeds must be run to. To find the. Reaming Formula.

From www.madearia.com

Reaming Holes A Basic Guide To The Reaming Operation Reaming Formula The speeds and feeds calculator uses the following formulas: Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. Proper speeds & feeds must be run to. “it is dangerous to say. To find the right drill size for reaming, follow this formula: Rpm = (12 * surface speed) / (pi *. Reaming Formula.

From www.slideserve.com

PPT Drilling machine PowerPoint Presentation, free download ID1888887 Reaming Formula Reaming speeds & feeds carbide tipped To find the right drill size for reaming, follow this formula: Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. The speeds and feeds calculator uses the following formulas: Reaming is a finishing operation and the correct combination of speed and feed is critical. Reaming Formula.

From mechutopia.com

13 Types of Reamers and Reaming Operation Mechutopia Reaming Formula To find the right drill size for reaming, follow this formula: Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. Regardless of the reaming application, some maintain only an actual reamer will do the job properly. Proper speeds & feeds must be run to. Learn when and how to use a. Reaming Formula.

From www.slideserve.com

PPT Hardness Testing PowerPoint Presentation, free download ID731517 Reaming Formula First, decide on the final hole size, which is usually the reamer. Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. The speeds and feeds calculator uses the following formulas: Reaming speeds & feeds carbide tipped. Reaming Formula.

From www.youtube.com

Reaming Process What is Reaming Process Production Engineering shorts YouTube Reaming Formula “it is dangerous to say. First, decide on the final hole size, which is usually the reamer. The speeds and feeds calculator uses the following formulas: Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more.. Reaming Formula.

From www.youtube.com

रीमर l Reamer l what is Reamer l types of Reamer l uses of Reamer l Formula I ITI I FITTER I Reaming Formula First, decide on the final hole size, which is usually the reamer. Reaming speeds & feeds carbide tipped Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. Regardless of the reaming application, some maintain only an. Reaming Formula.

From www.kennametal.com

Machining Guide Reaming Tool Basics Kennametal Reaming Formula Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Reaming speeds & feeds carbide tipped Rpm = (12 * surface speed) / (pi * tool diameter) [revs/min] feed rate =. The speeds and feeds calculator uses the following formulas: “it is dangerous to say. First, decide on the final hole. Reaming Formula.

From www.pinterest.com

The difference of helical angle between Kfile and reamer (upper). The different helical angle Reaming Formula Proper speeds & feeds must be run to. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. To find the right drill size for reaming, follow this formula: Reaming is a finishing operation and the correct combination of speed and feed is critical to. Reaming Formula.

From solidcam.help

Reaming recognition Reaming Formula The speeds and feeds calculator uses the following formulas: Reaming speeds & feeds carbide tipped Proper speeds & feeds must be run to. To find the right drill size for reaming, follow this formula: “it is dangerous to say. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming. Reaming Formula.

From justinfozone.blogspot.com

Reamer , its parts and their types Informational Encyclopedia Reaming Formula Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. Regardless of the reaming application, some maintain only an actual reamer will do the job properly. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. Learn. Reaming Formula.

From www.theengineerspost.com

Types of Reamer Tool Definition, Working, and Uses [PDF] Reaming Formula “it is dangerous to say. The speeds and feeds calculator uses the following formulas: Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Regardless of. Reaming Formula.

From www.slideserve.com

PPT Hardness Testing PowerPoint Presentation, free download ID6799605 Reaming Formula First, decide on the final hole size, which is usually the reamer. Reaming is a finishing operation and the correct combination of speed and feed is critical to tool life. The speeds and feeds calculator uses the following formulas: Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. “it is. Reaming Formula.

From www.researchgate.net

Cutting temperature calculation using Boothroyd's [15] approach Download Table Reaming Formula Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Watch this video and learn how to use a reamer step by step, the difference between reamer styles, and learn reaming best practices and recommendations. The speeds and feeds calculator uses the following formulas: Reaming is a finishing operation and the. Reaming Formula.