Solder And Its Constituents . This class of low melting point alloys must provide a unique. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. The choice of specific solder alloys depends on their melting. Unlike most metal alloys, an intermetallic compound typically has a fixed. Find answers to common questions about soldering for electrical. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. Imcs have critical roles in the solder joint quality and reliability. 122 rows solder is a metallic material that is used to connect metal workpieces.

from www.sig4cai.com

The choice of specific solder alloys depends on their melting. 122 rows solder is a metallic material that is used to connect metal workpieces. Unlike most metal alloys, an intermetallic compound typically has a fixed. Find answers to common questions about soldering for electrical. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. Imcs have critical roles in the solder joint quality and reliability. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. This class of low melting point alloys must provide a unique.

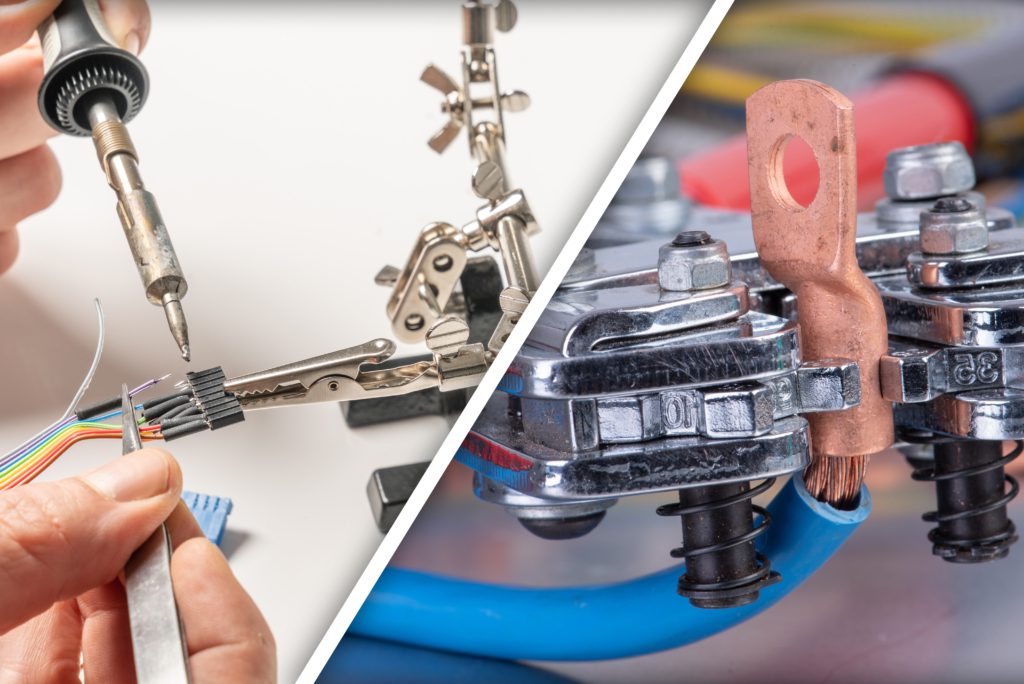

Soldering or Crimping Which Is Better for Your Electrical Needs? CAI

Solder And Its Constituents Imcs have critical roles in the solder joint quality and reliability. 122 rows solder is a metallic material that is used to connect metal workpieces. Find answers to common questions about soldering for electrical. Unlike most metal alloys, an intermetallic compound typically has a fixed. This class of low melting point alloys must provide a unique. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Imcs have critical roles in the solder joint quality and reliability. The choice of specific solder alloys depends on their melting. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and.

From www.researchgate.net

SEM crosssectional images of asreflowed a and b SAC305 solder joint Solder And Its Constituents Imcs have critical roles in the solder joint quality and reliability. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. This class of low melting point alloys must provide a unique. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. 122 rows solder. Solder And Its Constituents.

From data.epo.org

Composition of a solder, and method of manufacturing a solder Solder And Its Constituents Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. Imcs have critical roles in the solder joint quality and reliability. This class of low melting point alloys must provide a unique. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Find answers to. Solder And Its Constituents.

From www.the-diy-life.com

Soldering Components Together The DIY Life Solder And Its Constituents 122 rows solder is a metallic material that is used to connect metal workpieces. Unlike most metal alloys, an intermetallic compound typically has a fixed. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Imcs have critical roles in the solder joint quality and reliability. Solder can be classified based on its. Solder And Its Constituents.

From fyoiusbgp.blob.core.windows.net

Solder And Its Components at Donald Daniels blog Solder And Its Constituents This class of low melting point alloys must provide a unique. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. Unlike most metal alloys, an intermetallic compound typically has a fixed. Imcs have critical roles in the solder joint quality and reliability. Find answers to common questions about soldering for electrical.. Solder And Its Constituents.

From mechathon.com

Soldering vs Brazing; Its Process, Advantages, Disadvantages Solder And Its Constituents Imcs have critical roles in the solder joint quality and reliability. Unlike most metal alloys, an intermetallic compound typically has a fixed. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. 122 rows solder is a metallic material that is used to connect metal workpieces. The choice of specific solder alloys. Solder And Its Constituents.

From solderingironguide.com

How to Solder Aluminum Guide For Beginners Solder And Its Constituents 122 rows solder is a metallic material that is used to connect metal workpieces. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. The choice of specific solder alloys depends on their melting. Imcs have critical roles in the solder joint quality and reliability. Solder can be classified based on its composition,. Solder And Its Constituents.

From in.pinterest.com

Reflow soldering is a process in which a solder paste (a sticky mixture Solder And Its Constituents Find answers to common questions about soldering for electrical. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. This class of low melting point alloys must provide a unique. The choice of specific solder alloys depends on their melting. Learn about solder wire versus solder bar, core types, and essential parameters. Solder And Its Constituents.

From www.google.com

Patent EP1880032A2 Tin alloy solder compositions Google Patents Solder And Its Constituents The choice of specific solder alloys depends on their melting. Find answers to common questions about soldering for electrical. Unlike most metal alloys, an intermetallic compound typically has a fixed. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. 122 rows solder is a metallic material that is used to connect. Solder And Its Constituents.

From www.pcbaaa.com

Comparison of soldering iron, reflow soldering, wave soldering and Solder And Its Constituents Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. The choice of specific solder alloys depends on their melting. Find answers to common questions about soldering for electrical. This class of low melting point. Solder And Its Constituents.

From metallicresources.com

Products Solder And Its Constituents Find answers to common questions about soldering for electrical. 122 rows solder is a metallic material that is used to connect metal workpieces. This class of low melting point alloys must provide a unique. The choice of specific solder alloys depends on their melting. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical. Solder And Its Constituents.

From www.researchgate.net

The solder bulk of joints with a solder ball diameter of (a) 760 lm Solder And Its Constituents Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. Imcs have critical roles in the solder joint quality and reliability. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. The choice of specific solder alloys depends on their melting. This class of low. Solder And Its Constituents.

From eureka.patsnap.com

Composition of a solder, and method of manufacturing a solder Solder And Its Constituents Find answers to common questions about soldering for electrical. The choice of specific solder alloys depends on their melting. 122 rows solder is a metallic material that is used to connect metal workpieces. Unlike most metal alloys, an intermetallic compound typically has a fixed. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right. Solder And Its Constituents.

From www.youtube.com

How to Solder and Desolder Common Components Tutorial YouTube Solder And Its Constituents Imcs have critical roles in the solder joint quality and reliability. This class of low melting point alloys must provide a unique. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Unlike most metal alloys, an intermetallic compound typically has a fixed. 122 rows solder is a metallic material that is used. Solder And Its Constituents.

From thetech.com.vn

Introduction to lead soldering and how to use it TheTech (TH) Co., Ltd Solder And Its Constituents The choice of specific solder alloys depends on their melting. This class of low melting point alloys must provide a unique. Imcs have critical roles in the solder joint quality and reliability. Unlike most metal alloys, an intermetallic compound typically has a fixed. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder.. Solder And Its Constituents.

From www.raypcb.com

The Detailed Comparison of LeadFree and Lead Soldering Phenomenon of PCBs Solder And Its Constituents Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Find answers to common questions about soldering for electrical. 122 rows solder is a metallic material that is used to connect metal workpieces. The choice of specific solder alloys depends on their melting. This class of low melting point alloys must provide a. Solder And Its Constituents.

From components.about.com

Types of Solder for the Right Application Solder And Its Constituents Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. The choice of specific solder alloys depends on their melting. Unlike most metal alloys, an intermetallic compound typically has a fixed. Find answers to common questions about soldering for electrical. 122 rows solder is a metallic material that is used to connect metal. Solder And Its Constituents.

From mechathon.com

Soldering vs Brazing; Its Process, Advantages, Disadvantages Solder And Its Constituents 122 rows solder is a metallic material that is used to connect metal workpieces. The choice of specific solder alloys depends on their melting. Imcs have critical roles in the solder joint quality and reliability. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Find answers to common questions about soldering for. Solder And Its Constituents.

From meritsensor.com

An Introduction to Reflow Soldering and Soldering Methods Merit Sensor Solder And Its Constituents Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. Unlike most metal alloys, an intermetallic compound typically has a fixed. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Imcs have critical roles in the solder joint quality and reliability. The choice of. Solder And Its Constituents.

From medium.com

What is Soldering & Solder and Flux? Fully Knowledge Of( Types of Solder And Its Constituents Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Imcs have critical roles in the solder joint quality and reliability. Find answers to common questions about soldering for electrical. 122 rows solder is a metallic material that is used to connect metal workpieces. This class of low melting point alloys must provide. Solder And Its Constituents.

From reversepcb.com

Solder Paste Optimize Your Soldering Process Reversepcb Solder And Its Constituents 122 rows solder is a metallic material that is used to connect metal workpieces. Find answers to common questions about soldering for electrical. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Unlike most metal alloys, an intermetallic compound typically has a fixed. Imcs have critical roles in the solder joint quality. Solder And Its Constituents.

From www.sig4cai.com

Soldering or Crimping Which Is Better for Your Electrical Needs? CAI Solder And Its Constituents Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. The choice of specific solder alloys depends on their melting. This class of low melting point alloys must provide a unique. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Find answers to common. Solder And Its Constituents.

From www.toppr.com

D. NAME THE CONSTITUENTS OF 1. Duralumin 2. Magnalium 3. Solder 4 Solder And Its Constituents 122 rows solder is a metallic material that is used to connect metal workpieces. The choice of specific solder alloys depends on their melting. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Unlike most metal alloys, an intermetallic compound typically has a fixed. Solder can be classified based on its composition,. Solder And Its Constituents.

From askfilo.com

What are the constituents of solder alloy? Which property of solder makes.. Solder And Its Constituents The choice of specific solder alloys depends on their melting. Imcs have critical roles in the solder joint quality and reliability. 122 rows solder is a metallic material that is used to connect metal workpieces. Find answers to common questions about soldering for electrical. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right. Solder And Its Constituents.

From www.researchgate.net

(PDF) Formation and behavior of Kirkendall voids within intermetallic Solder And Its Constituents 122 rows solder is a metallic material that is used to connect metal workpieces. Find answers to common questions about soldering for electrical. The choice of specific solder alloys depends on their melting. This class of low melting point alloys must provide a unique. Unlike most metal alloys, an intermetallic compound typically has a fixed. Imcs have critical roles in. Solder And Its Constituents.

From www.makerspaces.com

How To Solder A Complete Beginners Guide Solder And Its Constituents Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. Find answers to common questions about soldering for electrical. 122 rows solder is a metallic material that is used to connect metal workpieces. The choice of specific solder alloys depends on their melting. Learn about solder wire versus solder bar, core types,. Solder And Its Constituents.

From web.uvic.ca

Physics 429 Honours Laboratory Solder And Its Constituents Imcs have critical roles in the solder joint quality and reliability. Find answers to common questions about soldering for electrical. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. The choice of specific solder alloys depends on their melting. Unlike most metal alloys, an intermetallic compound typically has a fixed. Learn. Solder And Its Constituents.

From www.reddit.com

Since everyone is asking how good their soldering is r/arduino Solder And Its Constituents Find answers to common questions about soldering for electrical. Unlike most metal alloys, an intermetallic compound typically has a fixed. Imcs have critical roles in the solder joint quality and reliability. This class of low melting point alloys must provide a unique. 122 rows solder is a metallic material that is used to connect metal workpieces. The choice of specific. Solder And Its Constituents.

From mavink.com

Solder Melting Point Chart Solder And Its Constituents Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Unlike most metal alloys, an intermetallic compound typically has a fixed. 122 rows solder is a metallic material that is used to connect metal workpieces. The choice of specific solder alloys depends on their melting. This class of low melting point alloys must. Solder And Its Constituents.

From blog.thepipingmart.com

How to Silver Solder Mild Steel A Complete Guide Solder And Its Constituents 122 rows solder is a metallic material that is used to connect metal workpieces. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. Imcs have critical roles in the solder joint quality and reliability. The choice of specific solder alloys depends on their melting. Learn about solder wire versus solder bar,. Solder And Its Constituents.

From www.pcbaaa.com

Understanding solder joint basics and techniques IBE Electronics Solder And Its Constituents 122 rows solder is a metallic material that is used to connect metal workpieces. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. This class of low melting point alloys must provide a unique. The choice of specific solder alloys depends on their melting. Learn about solder wire versus solder bar,. Solder And Its Constituents.

From components101.com

Solder Types, Uses, and Applications A Comprehensive Guide Solder And Its Constituents The choice of specific solder alloys depends on their melting. Find answers to common questions about soldering for electrical. Unlike most metal alloys, an intermetallic compound typically has a fixed. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. Solder can be classified based on its composition, which determines its melting point,. Solder And Its Constituents.

From www.doubtnut.com

What are the constituents of solder alloy? Which property of soldev ma Solder And Its Constituents Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. 122 rows solder is a metallic material that is used to connect metal workpieces. Unlike most metal alloys, an intermetallic compound typically has a fixed. This class of low melting point alloys must provide a unique. The choice of specific solder alloys. Solder And Its Constituents.

From www.the-diy-life.com

Soldering Components The DIY Life Solder And Its Constituents 122 rows solder is a metallic material that is used to connect metal workpieces. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder. This class of low melting point alloys must provide a unique. Imcs have critical roles in the solder joint quality and reliability. Find answers to common questions about soldering. Solder And Its Constituents.

From www.electronicsandyou.com

Solder Paste and Application in SMT What is Solder Paste & How to Use Solder And Its Constituents The choice of specific solder alloys depends on their melting. Find answers to common questions about soldering for electrical. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. 122 rows solder is a metallic material that is used to connect metal workpieces. Unlike most metal alloys, an intermetallic compound typically has. Solder And Its Constituents.

From www.earthquakerdevices.com

In Flux More Than You Ever Wanted To Know About Crafting Strong Solder Solder And Its Constituents Unlike most metal alloys, an intermetallic compound typically has a fixed. Solder can be classified based on its composition, which determines its melting point, wetting ability, mechanical strength, and. 122 rows solder is a metallic material that is used to connect metal workpieces. Learn about solder wire versus solder bar, core types, and essential parameters for choosing the right solder.. Solder And Its Constituents.