Tap Testing Hours . When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. Using digital tap testing to measure machining dynamics. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. The tap can be gentle.

from www.choice.com.au

The tap can be gentle. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. Using digital tap testing to measure machining dynamics. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes.

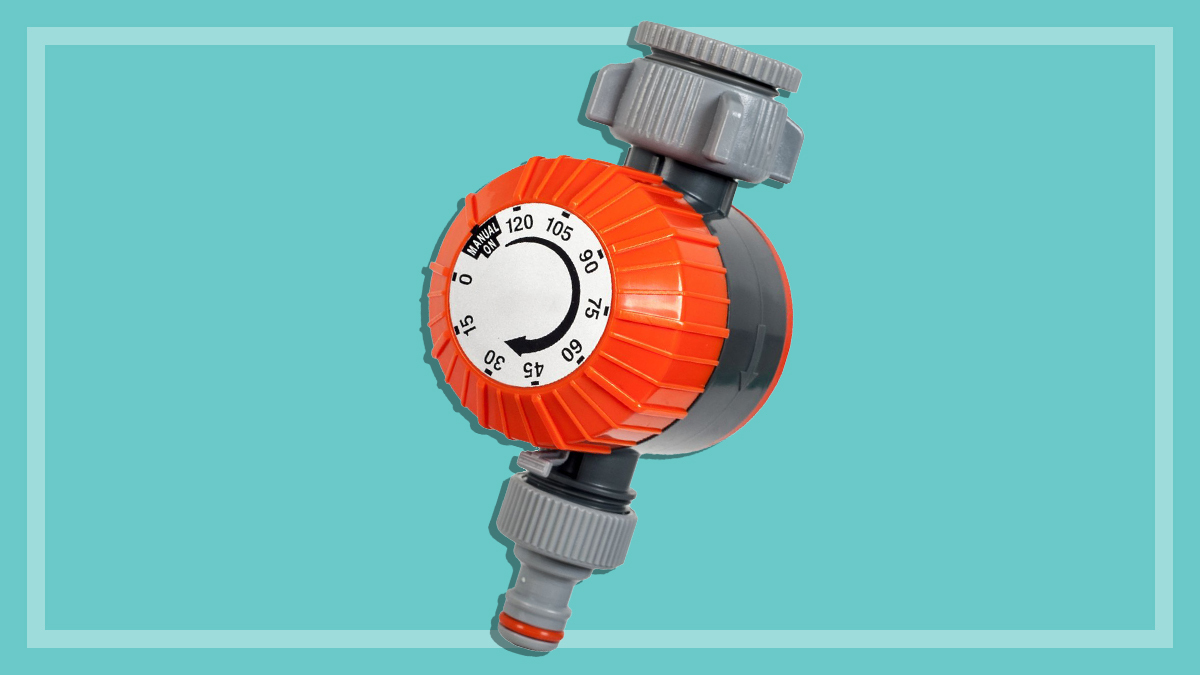

How we test tap timers CHOICE

Tap Testing Hours This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. Using digital tap testing to measure machining dynamics. When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. The tap can be gentle. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing.

From www.dahometerinstrument.com

Tap Density Tester, Tap Density Testing Machine Tap Testing Hours Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. The tap can be gentle. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Using digital tap testing to measure machining dynamics. When performing a tap test, an operator uses a controlled and consistent force to tap. Tap Testing Hours.

From www.youtube.com

How To Do a Tap Test per VHA Service Bulletin SB330004Rx Balance Tap Testing Hours The tap can be gentle. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap. Tap Testing Hours.

From www.mymotherlode.com

Tap Testing Results Tap Testing Hours To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. Using digital tap testing to measure machining dynamics. When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. This. Tap Testing Hours.

From www.cycleinspect.com

Cycle Inspect Tap testing Why it's not a reliable choice for the Tap Testing Hours To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. The tap can be gentle. Using digital tap testing to measure machining dynamics. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. This intricate scientific test is conducted at speed with. Tap Testing Hours.

From www.taptest.co

TrainingNew TAPTEST.CO Tap Testing Hours This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. Using digital tap testing to measure machining dynamics. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. The tap can be. Tap Testing Hours.

From www.youtube.com

TapTest Demonstration YouTube Tap Testing Hours This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Using digital tap testing to measure machining dynamics. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing. Tap Testing Hours.

From wiki.testguy.net

Transformer Tap Changers Basic Principles and Testing Explained Tap Testing Hours Using digital tap testing to measure machining dynamics. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in. Tap Testing Hours.

From productivemachines.co.uk

Productive Machines Tap Testing 2.0 Tap Testing Hours This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead. Tap Testing Hours.

From www.jrtech.co.uk

EVOTIS Acoustic Automated Tap Tester JR Technology Composite test Tap Testing Hours When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. The tap can be gentle. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. This information includes natural frequencies, modal stiffnesses, masses, modal damping. Tap Testing Hours.

From kopolblaster.weebly.com

Un tap drill chart kopolblaster Tap Testing Hours Using digital tap testing to measure machining dynamics. When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. This. Tap Testing Hours.

From aviation.stackexchange.com

safety Can delamination be detected early? Aviation Stack Exchange Tap Testing Hours To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now. Tap Testing Hours.

From www.youtube.com

Tap testing YouTube Tap Testing Hours When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. This intricate scientific test is conducted at speed with cutting tool data and the subsequent. Tap Testing Hours.

From terranicsystems.blogspot.com

Terranic Systems Inc. Chatter Root Cause and Tap Testing Tap Testing Hours Using digital tap testing to measure machining dynamics. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. The tap can be gentle. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. Explore tap testing and how productive machines technology uses. Tap Testing Hours.

From aesndt.com

Non Destructive Testing Services AES NDT Tap Testing Hours To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. This intricate scientific test. Tap Testing Hours.

From www.youtube.com

Patellar Tap Test YouTube Tap Testing Hours Using digital tap testing to measure machining dynamics. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. The tap can be gentle. This intricate scientific test is conducted at speed with cutting tool data and the subsequent. Tap Testing Hours.

From www.youtube.com

Using the Tap Test to verify voids found Ultrasonically YouTube Tap Testing Hours Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. To characterize and quantify the amount of impact noise passing between floors in a building,. Tap Testing Hours.

From www.youtube.com

Lesson 17 Tap Testing on a Machine YouTube Tap Testing Hours Using digital tap testing to measure machining dynamics. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. This. Tap Testing Hours.

From waterdistillers.com

Simple Tap Water Test Kit Tap Testing Hours Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. Using digital tap testing to measure machining dynamics. This information includes natural frequencies, modal stiffnesses, masses, modal damping. Tap Testing Hours.

From www.taptest.co

TrainingNew TAPTEST.CO Tap Testing Hours Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. The tap can be gentle. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. When performing a tap test, an operator uses a controlled and consistent force. Tap Testing Hours.

From orthofixar.com

Patellar Tap Test 2024 OrthoFixar Tap Testing Hours This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. When performing a tap. Tap Testing Hours.

From productivemachines.co.uk

Productive Machines Tap Testing 2.0 Tap Testing Hours The tap can be gentle. When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Using digital tap testing to measure machining dynamics. This intricate scientific test is conducted. Tap Testing Hours.

From www.youtube.com

DO8 Hospital Thermostatic Tap Testing Procedure YouTube Tap Testing Hours This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. Using digital tap testing to measure machining dynamics. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in. Tap Testing Hours.

From www.ingenierosespecialistas.com

Ingenieros Especialistas TAP TEST INSPECTION IN ADVANCE MATERIALS PARTS Tap Testing Hours The tap can be gentle. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with. Tap Testing Hours.

From www.aircraftsystemstech.com

Inspection of Composites Tap Testing Hours To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and. Tap Testing Hours.

From www.youtube.com

Optical TAP A network tap testing with the self developed test gear Tap Testing Hours To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. The tap can be gentle. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Using digital tap testing to measure machining dynamics. Explore tap testing and how productive machines technology uses. Tap Testing Hours.

From www.youtube.com

The Quarter Tap Test II YouTube Tap Testing Hours Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. The tap can be gentle. When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with. Tap Testing Hours.

From www.youtube.com

P2 T3 Composite Tap Test YouTube Tap Testing Hours The tap can be gentle. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. This information includes natural. Tap Testing Hours.

From www.fondriest.com

InHome Water Testing A Talk With the Creator of Tap Score by Tap Testing Hours To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. When performing a tap test, an operator uses a controlled and consistent. Tap Testing Hours.

From www.scribd.com

TAP Testing Toolkit Roaming Computing Tap Testing Hours Using digital tap testing to measure machining dynamics. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing. Tap Testing Hours.

From www.youtube.com

Contactless Tap Testing for Milling Optimization YouTube Tap Testing Hours Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. The tap can be gentle. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode. Tap Testing Hours.

From www.scribd.com

Tap Testing Holography Thermography Tap Testing Hours The tap can be gentle. Using digital tap testing to measure machining dynamics. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Explore tap testing and how productive machines technology uses. Tap Testing Hours.

From www.youtube.com

Span vs Tap Testing YouTube Tap Testing Hours Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. The tap can be gentle. This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. Using digital tap testing to measure machining dynamics. When performing a tap test,. Tap Testing Hours.

From woolfplumbing.com.au

Fix Your Leaking Tap In 5 Simply Steps (DIY GUIDE) ‐ Woolf Plumbing Tap Testing Hours To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Using digital tap testing to measure machining dynamics. Explore tap testing and how productive machines technology uses tap testing to optimize machine. Tap Testing Hours.

From www.choice.com.au

How we test tap timers CHOICE Tap Testing Hours When performing a tap test, an operator uses a controlled and consistent force to tap the surface of the material or component with a digital tap hammer. The tap can be gentle. To characterize and quantify the amount of impact noise passing between floors in a building, acoustics professionals developed a testing method called tap testing. Using digital tap testing. Tap Testing Hours.

From studylib.net

TAP Testing Toolkit Tap Testing Hours This intricate scientific test is conducted at speed with cutting tool data and the subsequent machining parameters now determined in minutes instead of hours. This information includes natural frequencies, modal stiffnesses, masses, modal damping ratios, and mode shapes. Explore tap testing and how productive machines technology uses tap testing to optimize machine settings against chatter vibrations. Using digital tap testing. Tap Testing Hours.