Ultrasonic Inspection Dead Zone . A dead zone is what the name implies: The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. How dead zones occur in ultrasonic testing of austenitic welds. An area in a material that does not provide a reading due to signal interruption. 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. Ultrasonic tests can provide information about several aspects of a material such as: Thickness, attenuation, shape, presence of defects, size.

from www.semanticscholar.org

Ultrasonic tests can provide information about several aspects of a material such as: 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. A dead zone is what the name implies: In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. Thickness, attenuation, shape, presence of defects, size. An area in a material that does not provide a reading due to signal interruption. How dead zones occur in ultrasonic testing of austenitic welds. The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult.

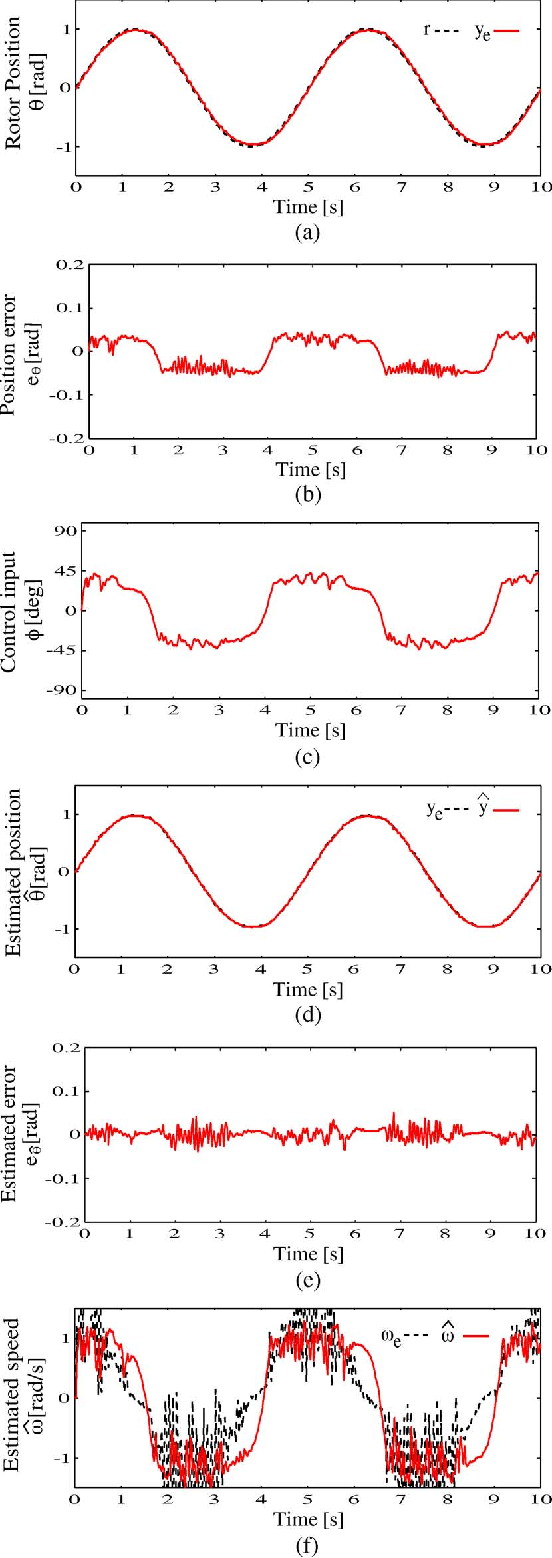

Figure 11 from Adaptive Control of Ultrasonic Motors

Ultrasonic Inspection Dead Zone Ultrasonic tests can provide information about several aspects of a material such as: An area in a material that does not provide a reading due to signal interruption. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. Ultrasonic tests can provide information about several aspects of a material such as: How dead zones occur in ultrasonic testing of austenitic welds. The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. A dead zone is what the name implies: Thickness, attenuation, shape, presence of defects, size. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to.

From www.alibaba.com

3m Short Range Liquid Level Measuring 10cm 4 In Dead Zone Ultrasonic Ultrasonic Inspection Dead Zone In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. Thickness, attenuation,. Ultrasonic Inspection Dead Zone.

From www.mdpi.com

Applied Sciences Free FullText Improved Ultrasonic Dead Zone Ultrasonic Inspection Dead Zone An area in a material that does not provide a reading due to signal interruption. 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. Ultrasonic tests can provide information about several. Ultrasonic Inspection Dead Zone.

From www.tec-science.com

Ultrasonic testing (UT) tecscience Ultrasonic Inspection Dead Zone An area in a material that does not provide a reading due to signal interruption. The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. How dead zones occur in ultrasonic testing of austenitic welds.. Ultrasonic Inspection Dead Zone.

From ppt-online.org

Introduction to ultrasonic testing презентация онлайн Ultrasonic Inspection Dead Zone Ultrasonic tests can provide information about several aspects of a material such as: The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. An area in a material that does not provide a reading due. Ultrasonic Inspection Dead Zone.

From www.tec-science.com

Ultrasonic testing (UT) tecscience Ultrasonic Inspection Dead Zone 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. An area in a. Ultrasonic Inspection Dead Zone.

From www.researchgate.net

Ultrasonic inspection. Download Scientific Diagram Ultrasonic Inspection Dead Zone A dead zone is what the name implies: The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. How dead zones occur in ultrasonic testing of austenitic welds. In austenitic welds, this occurs right below. Ultrasonic Inspection Dead Zone.

From slidetodoc.com

Ultrasonic Inspection UT Ultrasonic Inspection UT Definitions Ultrasonic Ultrasonic Inspection Dead Zone How dead zones occur in ultrasonic testing of austenitic welds. An area in a material that does not provide a reading due to signal interruption. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. The calibration of tofd should be done in such a way so that it determines. Ultrasonic Inspection Dead Zone.

From www.tec-science.com

Ultrasonic testing (UT) tecscience Ultrasonic Inspection Dead Zone Ultrasonic tests can provide information about several aspects of a material such as: The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. A dead zone is what the name implies: 3) is the length. Ultrasonic Inspection Dead Zone.

From www.mdpi.com

Applied Sciences Free FullText Improved Ultrasonic Dead Zone Ultrasonic Inspection Dead Zone Thickness, attenuation, shape, presence of defects, size. Ultrasonic tests can provide information about several aspects of a material such as: An area in a material that does not provide a reading due to signal interruption. A dead zone is what the name implies: In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult.. Ultrasonic Inspection Dead Zone.

From www.slideserve.com

PPT BMFB 4283 NDT & FAILURE ANALYSIS PowerPoint Presentation ID8782413 Ultrasonic Inspection Dead Zone The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. How dead zones occur. Ultrasonic Inspection Dead Zone.

From www.mdpi.com

Applied Sciences Free FullText Improved Ultrasonic Dead Zone Ultrasonic Inspection Dead Zone In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. How dead zones occur in ultrasonic testing of austenitic welds. 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. Ultrasonic tests can provide information about several aspects of a material such. Ultrasonic Inspection Dead Zone.

From www.youtube.com

Ultrasonic Sensor Dead Zone YouTube Ultrasonic Inspection Dead Zone 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. Ultrasonic tests can provide information about several aspects of a material such as: A dead zone is what the name implies: An area in a material that does not provide a reading due to signal interruption. The calibration of. Ultrasonic Inspection Dead Zone.

From www.semanticscholar.org

Figure 11 from Adaptive Control of Ultrasonic Motors Ultrasonic Inspection Dead Zone In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. An area in a material that does not provide a reading due to signal interruption. How dead zones occur in ultrasonic testing of austenitic welds. The calibration of tofd should be done in such a way so that it determines. Ultrasonic Inspection Dead Zone.

From www.youtube.com

Angle Beam Ultrasonic Testing Level 1 Angle Beam Testing YouTube Ultrasonic Inspection Dead Zone An area in a material that does not provide a reading due to signal interruption. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range. Ultrasonic Inspection Dead Zone.

From www.diytrade.com

Small Dead Zone Ultrasonic Level Meter UVUSC ULEVEL (China Ultrasonic Inspection Dead Zone In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. How dead zones occur in ultrasonic testing of. Ultrasonic Inspection Dead Zone.

From www.tec-science.com

Ultrasonic testing (UT) tecscience Ultrasonic Inspection Dead Zone An area in a material that does not provide a reading due to signal interruption. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. How dead zones occur in ultrasonic testing of austenitic welds. 3) is the length in millimetres of the material affected by the emission pulse in which it is. Ultrasonic Inspection Dead Zone.

From www.researchgate.net

Principle of ultrasonic inspection. (a) Ultrasonic inspection of Ultrasonic Inspection Dead Zone 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. In austenitic welds, this. Ultrasonic Inspection Dead Zone.

From www.mdpi.com

Applied Sciences Free FullText Improved Ultrasonic Dead Zone Ultrasonic Inspection Dead Zone 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. How dead zones occur in ultrasonic testing of austenitic welds. In austenitic welds, this occurs right below the surface. Ultrasonic Inspection Dead Zone.

From www.researchgate.net

(PDF) Improved Ultrasonic Dead Zone Detectability of Work Rolls Using a Ultrasonic Inspection Dead Zone The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. An area in a material that does not provide a reading due to signal interruption. A dead zone is what the name implies: How dead. Ultrasonic Inspection Dead Zone.

From www.researchgate.net

(PDF) Improved Ultrasonic Dead Zone Detectability of Work Rolls Using a Ultrasonic Inspection Dead Zone The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. An area in a material that does not provide a reading due to signal interruption. In this study, we investigated a method for improving the. Ultrasonic Inspection Dead Zone.

From www.ndt.net

Dead Zone? Ultrasonic Inspection Dead Zone In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. The calibration. Ultrasonic Inspection Dead Zone.

From www.youtube.com

Defects Types Ultrasonic Testing Defects Types YouTube Ultrasonic Inspection Dead Zone An area in a material that does not provide a reading due to signal interruption. Ultrasonic tests can provide information about several aspects of a material such as: 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. Thickness, attenuation, shape, presence of defects, size. In austenitic welds, this. Ultrasonic Inspection Dead Zone.

From www.researchgate.net

Ultrasonic inspection setup Download Scientific Diagram Ultrasonic Inspection Dead Zone 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. An area in a material that does not provide a reading due to signal interruption. In austenitic welds, this. Ultrasonic Inspection Dead Zone.

From www.youtube.com

Dead zone, near zone, far zone Ultrasonic Testing Dead zone, near zone Ultrasonic Inspection Dead Zone In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. How dead zones occur in ultrasonic testing of austenitic welds. Ultrasonic tests can provide information about several aspects of a material such as: An area in a material that does not provide a reading due to signal interruption. The calibration. Ultrasonic Inspection Dead Zone.

From present5.com

Krautkramer NDT Ultrasonic Systems Introduction to Ultrasonic Testing Ultrasonic Inspection Dead Zone An area in a material that does not provide a reading due to signal interruption. The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. 3) is the length in millimetres of the material affected. Ultrasonic Inspection Dead Zone.

From www.researchgate.net

The schematic diagram of the ultrasonic inspection (AScan Ultrasonic Inspection Dead Zone In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. Thickness, attenuation, shape, presence of defects, size. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. A dead zone is what the name implies: How dead zones occur in ultrasonic testing of. Ultrasonic Inspection Dead Zone.

From novotest.biz

NOVOTEST Ultrasonic Inspection Dead Zone Thickness, attenuation, shape, presence of defects, size. 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. A dead zone is what the name implies: An area in a material that does not provide a reading due to signal interruption. In this study, we investigated a method for improving. Ultrasonic Inspection Dead Zone.

From www.mdpi.com

Applied Sciences Free FullText Improved Ultrasonic Dead Zone Ultrasonic Inspection Dead Zone An area in a material that does not provide a reading due to signal interruption. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over. Ultrasonic Inspection Dead Zone.

From aister.en.made-in-china.com

NonContact Level Transmitter Small Dead Zone LCD Digital Display Ultrasonic Inspection Dead Zone A dead zone is what the name implies: In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. An area in a material that does not provide a reading due to signal interruption. 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible. Ultrasonic Inspection Dead Zone.

From www.zetec.com

Mitigate Dead Zones in Ultrasonic Testing of Austenitic Welds Zetec Ultrasonic Inspection Dead Zone The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone. How dead zones occur in ultrasonic testing of austenitic welds. 3) is the length in millimetres of the material affected by the emission pulse in. Ultrasonic Inspection Dead Zone.

From www.tec-science.com

Ultrasonic testing (UT) tecscience Ultrasonic Inspection Dead Zone A dead zone is what the name implies: Thickness, attenuation, shape, presence of defects, size. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. An area in a material that does not provide a reading due to signal interruption. How dead zones occur in ultrasonic testing of austenitic welds. 3) is the. Ultrasonic Inspection Dead Zone.

From www.youtube.com

Through transmission Ultrasonic Testig Through transmission YouTube Ultrasonic Inspection Dead Zone In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. A dead zone is what the name implies: The calibration of tofd should be done in such a way so that it determines (a) the minimum flaw size that can be measured over the thickness range and (b) limit of the dead zone.. Ultrasonic Inspection Dead Zone.

From ppt-online.org

Introduction to ultrasonic testing презентация онлайн Ultrasonic Inspection Dead Zone 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. A dead zone is what the name implies: An area in a material that does not provide a reading. Ultrasonic Inspection Dead Zone.

From www.slideserve.com

PPT Ultrasonic Testing PowerPoint Presentation, free download ID Ultrasonic Inspection Dead Zone An area in a material that does not provide a reading due to signal interruption. In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. The calibration of tofd should be done in. Ultrasonic Inspection Dead Zone.

From www.slideserve.com

PPT BMFB 4283 NDT & FAILURE ANALYSIS PowerPoint Presentation ID2295903 Ultrasonic Inspection Dead Zone In this study, we investigated a method for improving the detectability in the dead zone for ultrasonic inspection performed to. A dead zone is what the name implies: 3) is the length in millimetres of the material affected by the emission pulse in which it is not possible to. An area in a material that does not provide a reading. Ultrasonic Inspection Dead Zone.