A2-6 Taper Dimensions . Tapped holes in fl ange (outer bolt circle) and in. Make the necessary measurements after analyzing the. Select the spindle nose size for your chuck. To establish the type of spindle nose you have, look through the diagrams below. Look at the diagrams below to determine what kind of spindle nose you have. Chuck diameter and spindle nose by model. For the long taper spindle noses type l, check pilot diameter, length and. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. Analyze the associated chart, then take the required measurements. *when two chuck sizes are listed, the smaller diameter is standard. Consult the diagrams and charts below to find the right mounting for your spindle. The easiest way to determine the spindle type and size is to remove the chuck and/or adapter plate from the spindle nose and measure.

from klaladedq.blob.core.windows.net

Make the necessary measurements after analyzing the. To establish the type of spindle nose you have, look through the diagrams below. Chuck diameter and spindle nose by model. Select the spindle nose size for your chuck. Analyze the associated chart, then take the required measurements. Consult the diagrams and charts below to find the right mounting for your spindle. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. For the long taper spindle noses type l, check pilot diameter, length and. Look at the diagrams below to determine what kind of spindle nose you have.

Morse Taper Sizes at Christine Pierce blog

A2-6 Taper Dimensions For the long taper spindle noses type l, check pilot diameter, length and. The easiest way to determine the spindle type and size is to remove the chuck and/or adapter plate from the spindle nose and measure. For the long taper spindle noses type l, check pilot diameter, length and. Look at the diagrams below to determine what kind of spindle nose you have. Analyze the associated chart, then take the required measurements. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. Select the spindle nose size for your chuck. Tapped holes in fl ange (outer bolt circle) and in. Consult the diagrams and charts below to find the right mounting for your spindle. To establish the type of spindle nose you have, look through the diagrams below. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. Make the necessary measurements after analyzing the. *when two chuck sizes are listed, the smaller diameter is standard. Chuck diameter and spindle nose by model.

From www.practicalmachinist.com

Jacobs Taper and chuck runout question A2-6 Taper Dimensions Chuck diameter and spindle nose by model. Make the necessary measurements after analyzing the. Tapped holes in fl ange (outer bolt circle) and in. Select the spindle nose size for your chuck. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. Consult the diagrams and charts below to find the right mounting for your spindle. To establish. A2-6 Taper Dimensions.

From mungfali.com

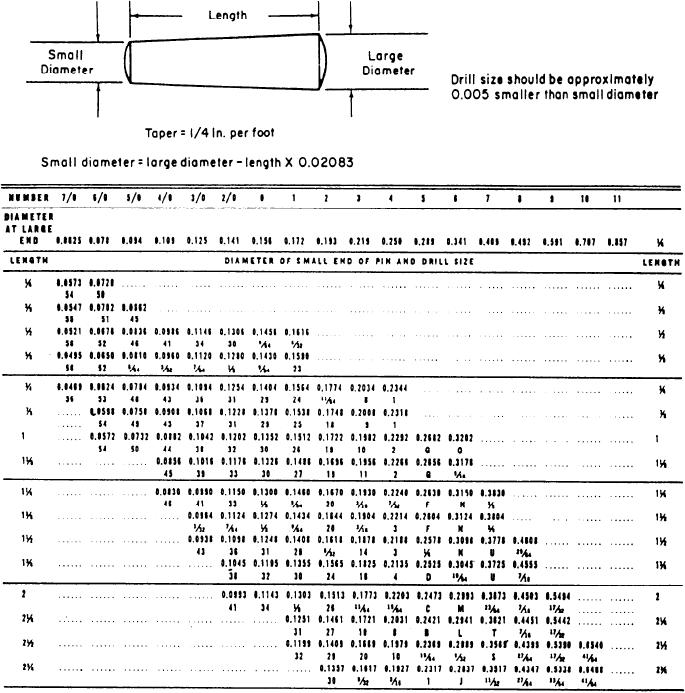

Taper Pin Dimensions Chart A2-6 Taper Dimensions Tapped holes in fl ange (outer bolt circle) and in. *when two chuck sizes are listed, the smaller diameter is standard. Look at the diagrams below to determine what kind of spindle nose you have. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. The easiest way to determine the spindle type and size is to remove. A2-6 Taper Dimensions.

From mavink.com

Morse Taper Sizes A2-6 Taper Dimensions For the long taper spindle noses type l, check pilot diameter, length and. To establish the type of spindle nose you have, look through the diagrams below. Make the necessary measurements after analyzing the. Tapped holes in fl ange (outer bolt circle) and in. Chuck diameter and spindle nose by model. Analyze the associated chart, then take the required measurements.. A2-6 Taper Dimensions.

From www.smartlathe.com

Lathe Spindle Nose Identification Chart A2-6 Taper Dimensions Select the spindle nose size for your chuck. Chuck diameter and spindle nose by model. Analyze the associated chart, then take the required measurements. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. Tapped holes in fl ange (outer bolt circle). A2-6 Taper Dimensions.

From www.usarollerchain.com

Taper Lock Bushing & Size Chart USA Roller Chain & Sprocket A2-6 Taper Dimensions All chucks with a2 mount can be installed on either a1 or a2 spindle nose. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. To establish the type of spindle nose you have, look through the diagrams below. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or. A2-6 Taper Dimensions.

From www.fitsch.cn

DIN 1581 Taper Metric Thread Dimension Chart For Lubrication Tube A2-6 Taper Dimensions To establish the type of spindle nose you have, look through the diagrams below. Look at the diagrams below to determine what kind of spindle nose you have. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. Select the spindle nose. A2-6 Taper Dimensions.

From metal-kovis.hr

16102506 Back Plate for Taper Spindle Nose A26 250MM Boehringer D420 A2-6 Taper Dimensions All chucks with a2 mount can be installed on either a1 or a2 spindle nose. Look at the diagrams below to determine what kind of spindle nose you have. Select the spindle nose size for your chuck. Make the necessary measurements after analyzing the. *when two chuck sizes are listed, the smaller diameter is standard. For the long taper spindle. A2-6 Taper Dimensions.

From www.toolmex.com

Spindle Type and Size Guide Toolmex Industrial Solutions A2-6 Taper Dimensions All chucks with a2 mount can be installed on either a1 or a2 spindle nose. Consult the diagrams and charts below to find the right mounting for your spindle. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. Chuck diameter and spindle nose by model. Look at the diagrams below to determine what kind of spindle nose. A2-6 Taper Dimensions.

From thehabitofwoodworking.com

How Are Lathe Chucks Measured? The Habit of Woodworking A2-6 Taper Dimensions *when two chuck sizes are listed, the smaller diameter is standard. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. Select the spindle nose size for your chuck. Analyze the associated chart, then take the required measurements. All chucks with a2. A2-6 Taper Dimensions.

From www.scribd.com

Basic Dimensions American National Standard Taper Thread A2-6 Taper Dimensions Consult the diagrams and charts below to find the right mounting for your spindle. The easiest way to determine the spindle type and size is to remove the chuck and/or adapter plate from the spindle nose and measure. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from. A2-6 Taper Dimensions.

From joirfzipg.blob.core.windows.net

Dimensioning Tapers at Arlene Dukes blog A2-6 Taper Dimensions All chucks with a2 mount can be installed on either a1 or a2 spindle nose. To establish the type of spindle nose you have, look through the diagrams below. Tapped holes in fl ange (outer bolt circle) and in. Chuck diameter and spindle nose by model. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. Look at. A2-6 Taper Dimensions.

From www.fitsch.cn

DIN 1581 Taper Metric Thread Dimension Chart For Lubrication Tube A2-6 Taper Dimensions *when two chuck sizes are listed, the smaller diameter is standard. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. Make the necessary measurements after analyzing the. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure. A2-6 Taper Dimensions.

From alterplayground.blogspot.com

A2 6 Spindle Nose Dimensions alter playground A2-6 Taper Dimensions To establish the type of spindle nose you have, look through the diagrams below. Analyze the associated chart, then take the required measurements. For the long taper spindle noses type l, check pilot diameter, length and. Chuck diameter and spindle nose by model. Select the spindle nose size for your chuck. Look at the diagrams below to determine what kind. A2-6 Taper Dimensions.

From www.scribd.com

Taper Lock Bush Dimensions. A2-6 Taper Dimensions Look at the diagrams below to determine what kind of spindle nose you have. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. Make the necessary measurements after analyzing the. Chuck diameter and spindle nose by model. Consult the diagrams and. A2-6 Taper Dimensions.

From www.gdandtbasics.com

Conical Taper GD&T Basics A2-6 Taper Dimensions Tapped holes in fl ange (outer bolt circle) without inner bolt circle. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. For the long taper spindle noses type l, check pilot diameter, length and. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter. A2-6 Taper Dimensions.

From klaladedq.blob.core.windows.net

Morse Taper Sizes at Christine Pierce blog A2-6 Taper Dimensions Analyze the associated chart, then take the required measurements. The easiest way to determine the spindle type and size is to remove the chuck and/or adapter plate from the spindle nose and measure. For the long taper spindle noses type l, check pilot diameter, length and. Tapped holes in fl ange (outer bolt circle) and in. The easiest way to. A2-6 Taper Dimensions.

From joirfzipg.blob.core.windows.net

Dimensioning Tapers at Arlene Dukes blog A2-6 Taper Dimensions For the long taper spindle noses type l, check pilot diameter, length and. Analyze the associated chart, then take the required measurements. The easiest way to determine the spindle type and size is to remove the chuck and/or adapter plate from the spindle nose and measure. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. Make the. A2-6 Taper Dimensions.

From mavink.com

Taper Lock Dimensions A2-6 Taper Dimensions Analyze the associated chart, then take the required measurements. Chuck diameter and spindle nose by model. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. Make the necessary measurements after analyzing the. Tapped holes in fl ange (outer bolt circle) and in. Tapped holes in fl ange (outer bolt circle) without inner bolt circle.. A2-6 Taper Dimensions.

From uwoodcraft.com

Morse Taper Dimensions A2-6 Taper Dimensions *when two chuck sizes are listed, the smaller diameter is standard. Consult the diagrams and charts below to find the right mounting for your spindle. Make the necessary measurements after analyzing the. Select the spindle nose size for your chuck. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter. A2-6 Taper Dimensions.

From mungfali.com

Taper Pin Dimensions Chart A2-6 Taper Dimensions The easiest way to determine the spindle type and size is to remove the chuck and/or adapter plate from the spindle nose and measure. Chuck diameter and spindle nose by model. To establish the type of spindle nose you have, look through the diagrams below. *when two chuck sizes are listed, the smaller diameter is standard. Look at the diagrams. A2-6 Taper Dimensions.

From mavink.com

Morse Taper Dimensions Chart A2-6 Taper Dimensions Tapped holes in fl ange (outer bolt circle) and in. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. For the long taper spindle noses type l, check pilot diameter, length and. *when two chuck sizes are listed, the smaller diameter is standard. The easiest way to determine which type of spindle nose your. A2-6 Taper Dimensions.

From www.zpag.net

Tapers and Angles A2-6 Taper Dimensions The easiest way to determine the spindle type and size is to remove the chuck and/or adapter plate from the spindle nose and measure. *when two chuck sizes are listed, the smaller diameter is standard. Tapped holes in fl ange (outer bolt circle) and in. Chuck diameter and spindle nose by model. The easiest way to determine which type of. A2-6 Taper Dimensions.

From mavink.com

Morse Taper Dimensions Chart A2-6 Taper Dimensions The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. Consult the diagrams and charts below to find the right mounting for your spindle. Chuck diameter and spindle nose by model. Analyze the associated chart, then take the required measurements. Tapped holes. A2-6 Taper Dimensions.

From www.electricsolenoidvalves.com

NPT Threading Explained A2-6 Taper Dimensions Analyze the associated chart, then take the required measurements. *when two chuck sizes are listed, the smaller diameter is standard. For the long taper spindle noses type l, check pilot diameter, length and. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. Make the necessary measurements after analyzing the. The easiest way to determine. A2-6 Taper Dimensions.

From www.mscdirect.com

How to measure a Jacobs Taper Better MRO A2-6 Taper Dimensions For the long taper spindle noses type l, check pilot diameter, length and. *when two chuck sizes are listed, the smaller diameter is standard. The easiest way to determine the spindle type and size is to remove the chuck and/or adapter plate from the spindle nose and measure. The easiest way to determine which type of spindle nose your lathe. A2-6 Taper Dimensions.

From www.medzushealth.com

6 (Luer) Taper Reference Conical Fittings / Gauges Medzus Healthcare A2-6 Taper Dimensions Look at the diagrams below to determine what kind of spindle nose you have. Tapped holes in fl ange (outer bolt circle) and in. Select the spindle nose size for your chuck. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it.. A2-6 Taper Dimensions.

From ar.inspiredpencil.com

Tapers Sizes A2-6 Taper Dimensions Look at the diagrams below to determine what kind of spindle nose you have. Tapped holes in fl ange (outer bolt circle) and in. Chuck diameter and spindle nose by model. *when two chuck sizes are listed, the smaller diameter is standard. The easiest way to determine the spindle type and size is to remove the chuck and/or adapter plate. A2-6 Taper Dimensions.

From www.practicalmachinist.com

Does anyone know the type of spindle fitting? A2-6 Taper Dimensions Make the necessary measurements after analyzing the. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. Select the spindle nose size for your chuck. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. Consult the. A2-6 Taper Dimensions.

From materialcampuskoch.z13.web.core.windows.net

Taper Pin Sizes Chart A2-6 Taper Dimensions The easiest way to determine the spindle type and size is to remove the chuck and/or adapter plate from the spindle nose and measure. Look at the diagrams below to determine what kind of spindle nose you have. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. *when two chuck sizes are listed, the smaller diameter is. A2-6 Taper Dimensions.

From klaladedq.blob.core.windows.net

Morse Taper Sizes at Christine Pierce blog A2-6 Taper Dimensions Analyze the associated chart, then take the required measurements. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. *when two chuck sizes are listed, the smaller diameter is standard. Look at the diagrams below to determine what kind of spindle nose you have. Make the necessary measurements after analyzing the. The easiest way to determine which type. A2-6 Taper Dimensions.

From www.universaldevlieg.com

Universal Devlieg Jacobs Taper Dimensions A2-6 Taper Dimensions All chucks with a2 mount can be installed on either a1 or a2 spindle nose. Tapped holes in fl ange (outer bolt circle) and in. To establish the type of spindle nose you have, look through the diagrams below. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. The easiest way to determine which type of spindle. A2-6 Taper Dimensions.

From cdctelecom.com

Fasteners & Hardware M16 GB853 304 A2 Taper washer Beveled Washer A2-6 Taper Dimensions The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. Look at the diagrams below to determine what kind of spindle nose you have. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. Make the necessary. A2-6 Taper Dimensions.

From mavink.com

Morse Taper Dimensions Chart A2-6 Taper Dimensions Select the spindle nose size for your chuck. Make the necessary measurements after analyzing the. Tapped holes in fl ange (outer bolt circle) without inner bolt circle. Analyze the associated chart, then take the required measurements. Look at the diagrams below to determine what kind of spindle nose you have. *when two chuck sizes are listed, the smaller diameter is. A2-6 Taper Dimensions.

From mavink.com

Morse Taper Dimensions Chart A2-6 Taper Dimensions Look at the diagrams below to determine what kind of spindle nose you have. All chucks with a2 mount can be installed on either a1 or a2 spindle nose. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. To establish the. A2-6 Taper Dimensions.

From lessonzoneschwartz.z13.web.core.windows.net

Morse Taper Sizes Chart A2-6 Taper Dimensions Select the spindle nose size for your chuck. Make the necessary measurements after analyzing the. *when two chuck sizes are listed, the smaller diameter is standard. The easiest way to determine which type of spindle nose your lathe requires is to remove the chuck and/or adapter plate from the spindle nose and measure it. Tapped holes in fl ange (outer. A2-6 Taper Dimensions.