Joint In Copper Wire . Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. This paper provides a comprehensive review on copper (cu) wire bonding. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. Reinhard schemmel, simon althoff, +3 authors w. Firstly, it introduces the common. Effects of different working frequencies on the joint formation in copper wire bonding. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit. A solder joint specimen is shown in figure 1.

from slidecourse.blogspot.com

The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. A solder joint specimen is shown in figure 1. Firstly, it introduces the common. This paper provides a comprehensive review on copper (cu) wire bonding. Effects of different working frequencies on the joint formation in copper wire bonding. Reinhard schemmel, simon althoff, +3 authors w. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel.

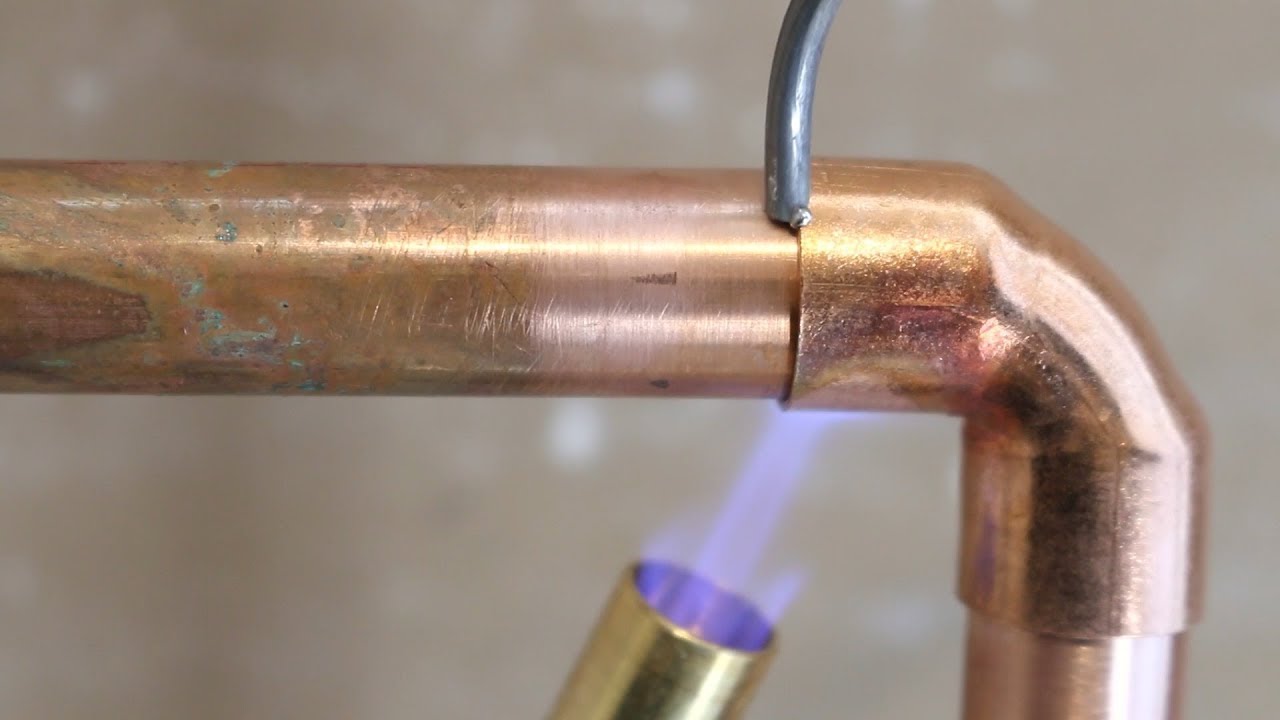

How To Solder Copper Pipes Slide Course

Joint In Copper Wire Firstly, it introduces the common. Effects of different working frequencies on the joint formation in copper wire bonding. Reinhard schemmel, simon althoff, +3 authors w. This paper provides a comprehensive review on copper (cu) wire bonding. A solder joint specimen is shown in figure 1. Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. Firstly, it introduces the common. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit.

From giogomkff.blob.core.windows.net

Copper Wire Joint Machine at Patrick Harper blog Joint In Copper Wire Reinhard schemmel, simon althoff, +3 authors w. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. In this study, the joint holes mainly appear in the copper wire part because the. Joint In Copper Wire.

From www.aliexpress.com

Copper Tube 100 pcs for Carbon Fiber Wire Jointin Cable Clips from Joint In Copper Wire Reinhard schemmel, simon althoff, +3 authors w. This paper provides a comprehensive review on copper (cu) wire bonding. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit. Here. Joint In Copper Wire.

From shopee.com.my

50PCS Copper Connecting Pipe Wire Joint Small Copper Tube Intermediate Joint In Copper Wire A solder joint specimen is shown in figure 1. Firstly, it introduces the common. Effects of different working frequencies on the joint formation in copper wire bonding. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. This paper provides a comprehensive review on copper (cu) wire bonding. In this study,. Joint In Copper Wire.

From www.aliexpress.com

5PCS GT 185MM square copper connecting pipe Cable wire joints Straight Joint In Copper Wire Effects of different working frequencies on the joint formation in copper wire bonding. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. Firstly, it introduces the common. A solder joint specimen is shown in figure 1. It is composed of a pure copper wire of purity 99.9% with a diameter. Joint In Copper Wire.

From en.copper-joint.com

COPPERJOINT Joint In Copper Wire Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. Reinhard schemmel, simon althoff, +3 authors w. Effects of different working frequencies on the joint formation in copper wire bonding. This paper provides a comprehensive review on copper (cu) wire bonding. In this study, the joint holes mainly appear in the. Joint In Copper Wire.

From www.temu.com

Gt Copper Connecting Pipe Wire Joint Small Tube Terminal Temu Joint In Copper Wire Effects of different working frequencies on the joint formation in copper wire bonding. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit. Reinhard schemmel, simon althoff, +3 authors. Joint In Copper Wire.

From www.ebay.co.uk

250Pcs 7 size Copper Connecting Pipe Wire Joint Small Intermediate Cold Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Reinhard schemmel, simon althoff, +3 authors w. This paper provides a comprehensive review on copper (cu) wire bonding. Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. A solder. Joint In Copper Wire.

From giogomkff.blob.core.windows.net

Copper Wire Joint Machine at Patrick Harper blog Joint In Copper Wire A solder joint specimen is shown in figure 1. Firstly, it introduces the common. Reinhard schemmel, simon althoff, +3 authors w. This paper provides a comprehensive review on copper (cu) wire bonding. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit. It is composed of a pure. Joint In Copper Wire.

From www.youtube.com

Awesome Idea! How to Twist Electric Wire Together Properly Joint Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. A solder joint specimen is shown in figure 1. In this study, the joint holes mainly appear in the copper. Joint In Copper Wire.

From qatar.desertcart.com

Buy XFFCSEC Butt Connectors (3Types Gauge Wire Connectors AWG 4/6/8 Joint In Copper Wire A solder joint specimen is shown in figure 1. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. Firstly, it introduces the common. Effects of different working frequencies on. Joint In Copper Wire.

From www.diydoctor.org.uk

Copper Compression Joints DIY Doctor Joint In Copper Wire Effects of different working frequencies on the joint formation in copper wire bonding. A solder joint specimen is shown in figure 1. Firstly, it introduces the common. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit. This paper provides a comprehensive review on copper (cu) wire bonding.. Joint In Copper Wire.

From www.rkens.com

Copper Strap Wire Joint Machine, Wire Connecting Machine, Copper Tape Joint Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. This paper provides a comprehensive review on copper (cu) wire bonding. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. The limits of aluminum wire bonds can be overcome by copper. Joint In Copper Wire.

From www.youtube.com

Wire Joint Proper Joint of Electrical Wire वायर जोड़ने का सही तरीका Joint In Copper Wire Effects of different working frequencies on the joint formation in copper wire bonding. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. A solder joint specimen is shown in figure 1. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly. Joint In Copper Wire.

From www.aliexpress.com

Copper wiring lug Copper terminal Copper joint Wire connector Battery Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Firstly, it introduces the common. Effects of different working frequencies on the joint formation in copper wire bonding. A solder joint specimen is shown in figure 1. Here a generalized model for the numerical simulation of the bond formation with respect. Joint In Copper Wire.

From www.temu.com

Gt Copper Connecting Pipe Wire Joint Small Tube Terminal Temu Australia Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. A solder joint specimen is shown in figure 1. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. Here a generalized model for the numerical simulation of the bond formation with. Joint In Copper Wire.

From hvacseer.com

How To Flare Copper Tubing [A Detailed Guide For Beginners] Joint In Copper Wire The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. This paper provides a comprehensive review on copper (cu) wire bonding. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Firstly, it introduces the common. A solder joint specimen is shown. Joint In Copper Wire.

From www.lazada.co.th

250Pcs GT Copper Connecting Pipe Wire Joint Small Copper Tube Terminal Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Effects of different working frequencies on the joint formation in copper wire bonding. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. Interface indicated that the tin layer remained between the. Joint In Copper Wire.

From www.diynetwork.com

How to Solder Copper Pipe Using a Propane Torch howtos DIY Joint In Copper Wire Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Effects of different working frequencies on the joint formation in copper wire bonding. This paper provides a comprehensive review on copper (cu). Joint In Copper Wire.

From yomgroup.en.made-in-china.com

T/J Electrical Brass Copper Split Bolt CloseEnd Clamp Screw Wire to Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. A solder joint specimen is shown in figure 1. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. Firstly, it introduces the common. In this study, the joint holes mainly appear. Joint In Copper Wire.

From slidecourse.blogspot.com

How To Solder Copper Pipes Slide Course Joint In Copper Wire Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. Reinhard schemmel, simon althoff, +3 authors w. Interface indicated that the tin layer remained between the copper wire and copper. Joint In Copper Wire.

From schematictimbres.z21.web.core.windows.net

How To Connect 3 6 Gauge Wires Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms. Joint In Copper Wire.

From shopee.com.my

[HYH] All Copper Inner Wire Joint 16/20/25/32mm Double Inner Wire Joint In Copper Wire Firstly, it introduces the common. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under. Joint In Copper Wire.

From yomgroup.en.made-in-china.com

T/J Brass Copper Split Electrical Bolt CloseEnd Clamp Screw Wire to Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. A solder joint specimen is shown in figure 1. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. Reinhard schemmel, simon althoff, +3 authors w. Here a generalized model for the. Joint In Copper Wire.

From www.aliexpress.com

Free shipping Wire Terminal Copper Joint Wire Connector Open Copper Joint In Copper Wire The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. Effects of different working frequencies on the joint formation in copper wire bonding. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. This paper provides a comprehensive review on copper (cu). Joint In Copper Wire.

From www.youtube.com

HOW TO TWIST ELECTRIC WIRE TOGETHER. Proper Joint of Electric Wire Joint In Copper Wire A solder joint specimen is shown in figure 1. Reinhard schemmel, simon althoff, +3 authors w. Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. Effects of different working frequencies on the joint formation in copper wire bonding. This paper provides a comprehensive review on copper (cu) wire. Joint In Copper Wire.

From www.tradeindia.com

Copper Parallel Joint Wire at Best Price in Delhi Tavish Overseas Joint In Copper Wire Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. Effects of different working frequencies on the joint formation in copper wire bonding. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. A solder joint specimen is shown in. Joint In Copper Wire.

From www.youtube.com

Copper single wire joint / single core wire joint YouTube Joint In Copper Wire This paper provides a comprehensive review on copper (cu) wire bonding. Firstly, it introduces the common. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit. It is composed. Joint In Copper Wire.

From wiringdbjasminamaba.z21.web.core.windows.net

How To Use Solderless Wire Connectors Joint In Copper Wire This paper provides a comprehensive review on copper (cu) wire bonding. Firstly, it introduces the common. Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. Effects of different working frequencies on the joint formation in copper wire bonding. The limits of aluminum wire bonds can be overcome by. Joint In Copper Wire.

From www.instantssolution.com

Proper Joint of Electric Wire, Types of Joint, Types of Wire Joint Joint In Copper Wire In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. Effects of different working frequencies on the joint formation in copper wire bonding. Reinhard schemmel, simon althoff, +3 authors. Joint In Copper Wire.

From www.pinterest.com

Proper wire joint 3 way YouTube Wire tie, Wire, Diy electrical Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. Firstly, it introduces the common. In this study, the joint holes mainly appear in the copper wire part because the. Joint In Copper Wire.

From www.pinterest.de

Another incarnation of the copper wire joint on a new piece Im working Joint In Copper Wire Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm,. Joint In Copper Wire.

From dailyengineering.com

Types Of Electrical Wire Joints Daily Engineering Joint In Copper Wire A solder joint specimen is shown in figure 1. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. In this study, the joint holes mainly appear in the copper wire part. Joint In Copper Wire.

From www.keep-co.com

Copper Sleeves/Connectors Keep Co. Joint In Copper Wire Here a generalized model for the numerical simulation of the bond formation with respect to the dynamics of the substructure is. Effects of different working frequencies on the joint formation in copper wire bonding. Reinhard schemmel, simon althoff, +3 authors w. It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel.. Joint In Copper Wire.

From www.rkens.com

Automatic copper strap machine wire joint machine RS04A Joint In Copper Wire In this study, the joint holes mainly appear in the copper wire part because the joint forming process slowly forms mechanical fit. Interface indicated that the tin layer remained between the copper wire and copper substrate after bonding under these conditions. This paper provides a comprehensive review on copper (cu) wire bonding. Here a generalized model for the numerical simulation. Joint In Copper Wire.

From lightning-safetech.com

250pcs GT Copper Connecting Pipe Wire Joint Small Copper Tube Terminal Joint In Copper Wire It is composed of a pure copper wire of purity 99.9% with a diameter of 0.3 mm, a nickel. The limits of aluminum wire bonds can be overcome by copper wire bonds because of their significantly higher electrical. A solder joint specimen is shown in figure 1. Effects of different working frequencies on the joint formation in copper wire bonding.. Joint In Copper Wire.