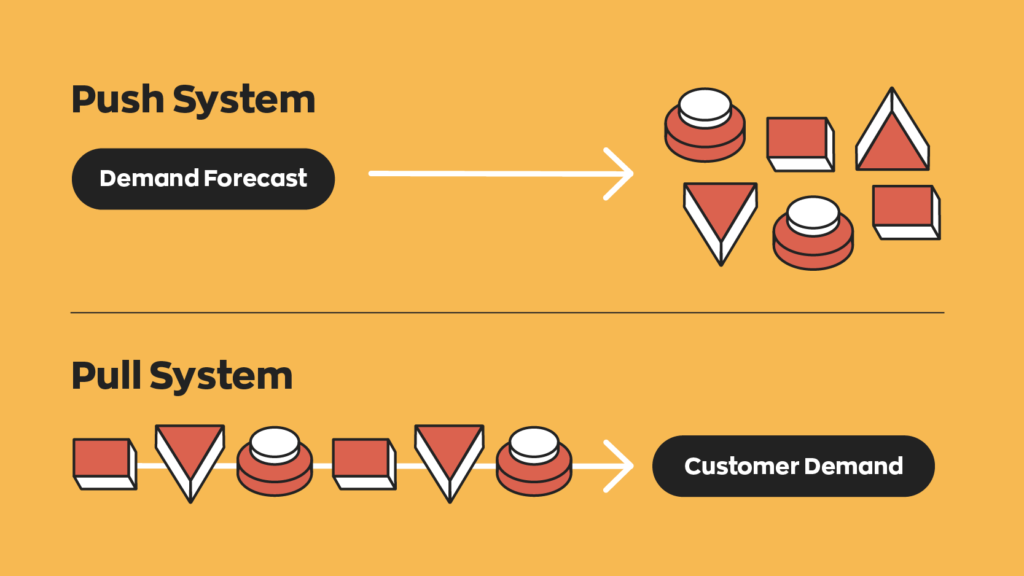

Push And Pull Method Of Manufacturing . By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. a push system is a type of inventory control system in which businesses predict consumer demand. a pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation. Then they push products to distributors and retailers in anticipation of consumer purchases. in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. In contrast, a pull system is an inventory control system in which businesses respond to consumer demand. below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp software solutions. push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”.

from www.inflowinventory.com

below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp software solutions. a pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation. the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. Then they push products to distributors and retailers in anticipation of consumer purchases. in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. In contrast, a pull system is an inventory control system in which businesses respond to consumer demand. a push system is a type of inventory control system in which businesses predict consumer demand.

Push vs Pull System Manufacturing An InDepth Analysis

Push And Pull Method Of Manufacturing a pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation. In contrast, a pull system is an inventory control system in which businesses respond to consumer demand. the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp software solutions. Then they push products to distributors and retailers in anticipation of consumer purchases. in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. a push system is a type of inventory control system in which businesses predict consumer demand. a pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing.

From 101blockchains.com

Push and Pull Strategy in Supply Chain Management A Comprehensive Guide Push And Pull Method Of Manufacturing below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp software solutions. the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. In contrast, a. Push And Pull Method Of Manufacturing.

From www.mudamasters.com

The Pull Principle In Production, the Office & in Life MudaMasters Push And Pull Method Of Manufacturing in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. a push system is a type of inventory control system in which businesses predict consumer demand. below, we’ll. Push And Pull Method Of Manufacturing.

From businessmap.io

What Is a Pull System? A Practical Guide to Increasing Process Efficiency Push And Pull Method Of Manufacturing in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. a pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage.. Push And Pull Method Of Manufacturing.

From www.blockchain-council.org

What is Push and Pull Strategy in Supply Chain Management? Push And Pull Method Of Manufacturing the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. push manufacturing can result in increased inventory and lead times, while pull manufacturing. Push And Pull Method Of Manufacturing.

From slidemodel.com

Strategic Model of Push Pull in PowerPoint SlideModel Push And Pull Method Of Manufacturing the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. a pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in. Push And Pull Method Of Manufacturing.

From dokumen.tips

(PDF) Yield comparison of push and pull control methods on production systems with unreliable Push And Pull Method Of Manufacturing push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. a push system is a type of inventory control system in which businesses predict consumer demand.. Push And Pull Method Of Manufacturing.

From powerslides.com

Push vs Pull Strategy 7,000+ Templates PowerSlides™ Push And Pull Method Of Manufacturing push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp software solutions. a push system is a type of inventory control. Push And Pull Method Of Manufacturing.

From www.allaboutlean.com

Logistic Plan Push Pull? Push And Pull Method Of Manufacturing Then they push products to distributors and retailers in anticipation of consumer purchases. a push system is a type of inventory control system in which businesses predict consumer demand. push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. the concepts of push, pull, and flow are not just strategies. Push And Pull Method Of Manufacturing.

From alexsibaja.blogspot.com

Lean Manufacturing & Six Sigma Pull Production Systems 生産システムを引いて The benefits and a brief Push And Pull Method Of Manufacturing the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. a push system is a type of inventory control system in which businesses predict consumer demand. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes. Push And Pull Method Of Manufacturing.

From smart-storage.lt

Just In Time or nowaste manufacturing SMART STORAGE SYSTEMS Push And Pull Method Of Manufacturing the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. Then they push products to distributors and retailers in anticipation of consumer purchases. a push system is. Push And Pull Method Of Manufacturing.

From slidetodoc.com

CHAPTER 7 Push and Pull Production Control Systems Push And Pull Method Of Manufacturing the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp software solutions. a pull system initiates production as. Push And Pull Method Of Manufacturing.

From leanmanufacturingtools.org

Kanban Systems; Design, Types and Implementation Push And Pull Method Of Manufacturing in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. In contrast, a pull system is an inventory control system in which businesses respond to consumer demand. push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. a push system is a type of. Push And Pull Method Of Manufacturing.

From operationsinsider.com

Push vs Pull — Operations Insider Push And Pull Method Of Manufacturing the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. In contrast, a pull system is an inventory control system in which businesses respond to consumer demand. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce. Push And Pull Method Of Manufacturing.

From blog.infodiagram.com

How to Create a Memorable Supply Chain Process Presentation Push And Pull Method Of Manufacturing Then they push products to distributors and retailers in anticipation of consumer purchases. a push system is a type of inventory control system in which businesses predict consumer demand. a pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation. the main difference between push and pull manufacturing is. Push And Pull Method Of Manufacturing.

From evisualcontrol.com

Push System (ระบบผลัก) และ Pull System (ระบบดึง) ต่างกันยังไง ? Factory Visual Control Push And Pull Method Of Manufacturing By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. a pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation. the concepts of push, pull, and flow are not just strategies but are integral to the. Push And Pull Method Of Manufacturing.

From cmuscm.blogspot.com

Supply Chain Management Boeing Making Lean Manufacturing Fly Push And Pull Method Of Manufacturing in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. a. Push And Pull Method Of Manufacturing.

From www.relexsolutions.com

How a planning solution helps tackle food manufacturing challenges RELEX Solutions Push And Pull Method Of Manufacturing push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. a pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation. the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. . Push And Pull Method Of Manufacturing.

From www.mecalux.com

Push and pull system in logistics Push And Pull Method Of Manufacturing the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. a push system is a type of inventory control system in which businesses. Push And Pull Method Of Manufacturing.

From www.allaboutlean.com

Push Pull Illustration Push And Pull Method Of Manufacturing the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. a pull system initiates production as a reaction to present demand, while a push system initiates production. Push And Pull Method Of Manufacturing.

From slidemodel.com

Manufacturing Pull vs Push PowerPoint Template SlideModel Push And Pull Method Of Manufacturing By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to. Push And Pull Method Of Manufacturing.

From ar.inspiredpencil.com

Push And Pull Strategy Push And Pull Method Of Manufacturing below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp software solutions. in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. a pull system initiates production as a reaction to present. Push And Pull Method Of Manufacturing.

From www.inflowinventory.com

Push vs Pull System Manufacturing An InDepth Analysis Push And Pull Method Of Manufacturing push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. a push system is a type of inventory control system in which businesses predict consumer demand. in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. the main difference between push and pull. Push And Pull Method Of Manufacturing.

From waxemi.com

Push System vs. Pull System in Manufacturing Management (2023) Push And Pull Method Of Manufacturing a push system is a type of inventory control system in which businesses predict consumer demand. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. In contrast, a. Push And Pull Method Of Manufacturing.

From www.leaneast.com

The Difference Between Push and Pull Lean East Push And Pull Method Of Manufacturing below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp software solutions. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. a push system is. Push And Pull Method Of Manufacturing.

From cashflowinventory.com

Pull and Push Strategy in Supply Chain Management Push And Pull Method Of Manufacturing Then they push products to distributors and retailers in anticipation of consumer purchases. the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some. Push And Pull Method Of Manufacturing.

From blog.megaventory.com

Push vs Pull Inventory Management Which One Is Better For You Push And Pull Method Of Manufacturing the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. a pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation. In contrast, a pull system is an inventory control system in which businesses respond to consumer demand. the. Push And Pull Method Of Manufacturing.

From mungfali.com

Push And Pull System Push And Pull Method Of Manufacturing Then they push products to distributors and retailers in anticipation of consumer purchases. In contrast, a pull system is an inventory control system in which businesses respond to consumer demand. below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp. Push And Pull Method Of Manufacturing.

From www.slideserve.com

PPT Operations Management JustinTime and Lean Production Systems Chapter 16 PowerPoint Push And Pull Method Of Manufacturing below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp software solutions. Then they push products to distributors and retailers in anticipation of consumer purchases. the concepts of push, pull, and flow are not just strategies but are integral. Push And Pull Method Of Manufacturing.

From ar.inspiredpencil.com

Push And Pull Strategy Push And Pull Method Of Manufacturing in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. In contrast, a pull system is an inventory control system in which businesses respond to consumer demand. push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. the concepts of push, pull, and flow. Push And Pull Method Of Manufacturing.

From www.slideserve.com

PPT An overview to push & pull systems PowerPoint Presentation ID3766164 Push And Pull Method Of Manufacturing below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid approach supplemented by some powerful erp and mrp software solutions. Then they push products to distributors and retailers in anticipation of consumer purchases. the main difference between push and pull manufacturing is that in a push system,. Push And Pull Method Of Manufacturing.

From www.deskera.com

Push System vs. Pull System in Manufacturing Management Push And Pull Method Of Manufacturing In contrast, a pull system is an inventory control system in which businesses respond to consumer demand. the concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. below, we’ll dig into the specifics of push and pull manufacturing, how they differ, and the benefits of using a hybrid. Push And Pull Method Of Manufacturing.

From www.sketchbubble.com

Push and Pull Strategy PowerPoint Template SketchBubble Push And Pull Method Of Manufacturing the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. a push system is a type of inventory control system in which businesses predict consumer demand. In contrast, a pull system is an inventory control system in which businesses respond to consumer demand. Then. Push And Pull Method Of Manufacturing.

From www.blockchain-council.org

What is Push and Pull Strategy in Supply Chain Management? Push And Pull Method Of Manufacturing push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. a push system is a type of inventory control system in which businesses predict consumer demand. the concepts of push, pull, and flow. Push And Pull Method Of Manufacturing.

From www.lean.org

Pull Production Lean Enterprise Institute Push And Pull Method Of Manufacturing the main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed”. in lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both.. Push And Pull Method Of Manufacturing.

From solatatech.com

What is Push and Pull Strategy in Supply Chain Management? (2023) Push And Pull Method Of Manufacturing Then they push products to distributors and retailers in anticipation of consumer purchases. push manufacturing can result in increased inventory and lead times, while pull manufacturing seeks to minimize both. a push system is a type of inventory control system in which businesses predict consumer demand. the concepts of push, pull, and flow are not just strategies. Push And Pull Method Of Manufacturing.